Propyne in Advances of Biodegradable Packaging Solutions

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Packaging Evolution

The evolution of propyne in biodegradable packaging solutions represents a significant shift in the packaging industry's approach to sustainability. This timeline traces the key developments and milestones in the integration of propyne-based materials into eco-friendly packaging alternatives.

In the early 2000s, researchers began exploring the potential of propyne as a building block for biodegradable polymers. Initial studies focused on understanding the chemical properties of propyne and its potential for polymerization. By 2005, the first laboratory-scale synthesis of propyne-based biodegradable plastics was achieved, marking a crucial breakthrough in the field.

The period between 2006 and 2010 saw increased efforts to optimize the production processes for propyne-derived biodegradable materials. Scientists worked on improving the mechanical properties and durability of these materials to make them suitable for packaging applications. By 2010, the first prototypes of propyne-based biodegradable packaging were developed, primarily for non-food applications.

From 2011 to 2015, the focus shifted towards scaling up production and addressing regulatory challenges. Companies began investing in pilot plants to test the commercial viability of propyne-based biodegradable packaging. During this period, significant advancements were made in enhancing the barrier properties of these materials, making them suitable for a wider range of packaging applications, including food packaging.

The years 2016 to 2020 marked a turning point in the adoption of propyne-based biodegradable packaging. Major consumer goods companies started incorporating these materials into their packaging solutions, driven by increasing consumer demand for sustainable products. This period also saw the development of more sophisticated blends and composites, combining propyne-derived materials with other biodegradable polymers to achieve optimal performance characteristics.

In recent years (2021 onwards), the focus has been on further innovation and refinement of propyne-based biodegradable packaging solutions. Research efforts have concentrated on improving the end-of-life management of these materials, ensuring they decompose efficiently in various environments. Additionally, there has been a push towards developing propyne-based materials from renewable sources, further enhancing their sustainability credentials.

Looking ahead, the evolution of propyne in biodegradable packaging is expected to continue, with emphasis on enhancing recyclability, reducing production costs, and expanding applications across various industries. The ongoing research in this field promises to deliver even more advanced and environmentally friendly packaging solutions in the coming years.

In the early 2000s, researchers began exploring the potential of propyne as a building block for biodegradable polymers. Initial studies focused on understanding the chemical properties of propyne and its potential for polymerization. By 2005, the first laboratory-scale synthesis of propyne-based biodegradable plastics was achieved, marking a crucial breakthrough in the field.

The period between 2006 and 2010 saw increased efforts to optimize the production processes for propyne-derived biodegradable materials. Scientists worked on improving the mechanical properties and durability of these materials to make them suitable for packaging applications. By 2010, the first prototypes of propyne-based biodegradable packaging were developed, primarily for non-food applications.

From 2011 to 2015, the focus shifted towards scaling up production and addressing regulatory challenges. Companies began investing in pilot plants to test the commercial viability of propyne-based biodegradable packaging. During this period, significant advancements were made in enhancing the barrier properties of these materials, making them suitable for a wider range of packaging applications, including food packaging.

The years 2016 to 2020 marked a turning point in the adoption of propyne-based biodegradable packaging. Major consumer goods companies started incorporating these materials into their packaging solutions, driven by increasing consumer demand for sustainable products. This period also saw the development of more sophisticated blends and composites, combining propyne-derived materials with other biodegradable polymers to achieve optimal performance characteristics.

In recent years (2021 onwards), the focus has been on further innovation and refinement of propyne-based biodegradable packaging solutions. Research efforts have concentrated on improving the end-of-life management of these materials, ensuring they decompose efficiently in various environments. Additionally, there has been a push towards developing propyne-based materials from renewable sources, further enhancing their sustainability credentials.

Looking ahead, the evolution of propyne in biodegradable packaging is expected to continue, with emphasis on enhancing recyclability, reducing production costs, and expanding applications across various industries. The ongoing research in this field promises to deliver even more advanced and environmentally friendly packaging solutions in the coming years.

Biodegradable Market Trends

The biodegradable packaging market has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. This trend is expected to continue, with the global biodegradable packaging market projected to reach $21.6 billion by 2025, growing at a CAGR of 17.4% from 2020 to 2025.

Consumer awareness and demand for sustainable packaging solutions have been key drivers of this market growth. As more consumers become environmentally conscious, they are actively seeking products with minimal ecological impact, including biodegradable packaging options. This shift in consumer behavior has prompted many companies to adopt biodegradable packaging as part of their sustainability initiatives.

The food and beverage industry has been at the forefront of adopting biodegradable packaging solutions, accounting for the largest market share. This is primarily due to the high volume of single-use packaging in this sector and the increasing regulations on plastic waste. Other industries, such as personal care and healthcare, are also showing increased interest in biodegradable packaging alternatives.

Regionally, Europe has been leading the biodegradable packaging market, followed by North America. This is largely due to stringent environmental regulations and higher consumer awareness in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental concerns.

The market is seeing a surge in innovation, with companies investing heavily in research and development to create new biodegradable materials and improve existing ones. Propyne-based biodegradable packaging solutions are emerging as a promising area of development, offering potential advantages in terms of durability, barrier properties, and biodegradability.

Despite the positive growth trends, the biodegradable packaging market faces challenges such as higher production costs compared to traditional packaging materials and limitations in performance characteristics. However, ongoing technological advancements and economies of scale are expected to address these issues over time.

In conclusion, the biodegradable packaging market is poised for substantial growth, driven by environmental concerns, regulatory pressures, and changing consumer preferences. The integration of innovative materials like propyne-based solutions is likely to further accelerate market expansion and technological advancements in the coming years.

Consumer awareness and demand for sustainable packaging solutions have been key drivers of this market growth. As more consumers become environmentally conscious, they are actively seeking products with minimal ecological impact, including biodegradable packaging options. This shift in consumer behavior has prompted many companies to adopt biodegradable packaging as part of their sustainability initiatives.

The food and beverage industry has been at the forefront of adopting biodegradable packaging solutions, accounting for the largest market share. This is primarily due to the high volume of single-use packaging in this sector and the increasing regulations on plastic waste. Other industries, such as personal care and healthcare, are also showing increased interest in biodegradable packaging alternatives.

Regionally, Europe has been leading the biodegradable packaging market, followed by North America. This is largely due to stringent environmental regulations and higher consumer awareness in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental concerns.

The market is seeing a surge in innovation, with companies investing heavily in research and development to create new biodegradable materials and improve existing ones. Propyne-based biodegradable packaging solutions are emerging as a promising area of development, offering potential advantages in terms of durability, barrier properties, and biodegradability.

Despite the positive growth trends, the biodegradable packaging market faces challenges such as higher production costs compared to traditional packaging materials and limitations in performance characteristics. However, ongoing technological advancements and economies of scale are expected to address these issues over time.

In conclusion, the biodegradable packaging market is poised for substantial growth, driven by environmental concerns, regulatory pressures, and changing consumer preferences. The integration of innovative materials like propyne-based solutions is likely to further accelerate market expansion and technological advancements in the coming years.

Propyne Tech Challenges

The development of propyne-based biodegradable packaging solutions faces several significant technical challenges that need to be addressed for successful implementation. One of the primary obstacles is the optimization of propyne polymerization processes to achieve desired material properties. Current methods often result in polymers with inconsistent molecular weights and structures, leading to variability in mechanical strength and biodegradability rates.

Another major challenge lies in enhancing the barrier properties of propyne-based materials. While propyne polymers show promise in terms of biodegradability, they often fall short in providing adequate protection against moisture and oxygen permeation. This limitation restricts their use in packaging applications that require extended shelf life for sensitive products.

The scalability of propyne production and polymer synthesis presents a significant hurdle. Current production methods are primarily laboratory-scale, and scaling up to industrial levels while maintaining cost-effectiveness and quality consistency remains a complex task. This challenge is further compounded by the need for specialized equipment and controlled environments to handle the highly reactive nature of propyne.

Ensuring the complete biodegradability of propyne-based packaging materials under various environmental conditions is another critical challenge. While propyne polymers show potential for biodegradation, optimizing this process to occur within acceptable timeframes across different disposal scenarios (e.g., composting, landfill, marine environments) requires extensive research and development.

The compatibility of propyne-based materials with existing packaging manufacturing processes and equipment poses another technical hurdle. Adapting current production lines to work with these new materials without significant modifications or investments is crucial for widespread adoption in the packaging industry.

Addressing the potential toxicity and environmental impact of propyne and its derivatives throughout the lifecycle of the packaging material is also a key challenge. Ensuring that no harmful byproducts are released during production, use, or degradation is essential for regulatory approval and consumer acceptance.

Lastly, the development of effective additives and compatibilizers to enhance the properties of propyne-based materials without compromising their biodegradability presents a significant technical challenge. Finding the right balance between improved performance and maintained environmental benefits requires innovative approaches in material science and chemistry.

Another major challenge lies in enhancing the barrier properties of propyne-based materials. While propyne polymers show promise in terms of biodegradability, they often fall short in providing adequate protection against moisture and oxygen permeation. This limitation restricts their use in packaging applications that require extended shelf life for sensitive products.

The scalability of propyne production and polymer synthesis presents a significant hurdle. Current production methods are primarily laboratory-scale, and scaling up to industrial levels while maintaining cost-effectiveness and quality consistency remains a complex task. This challenge is further compounded by the need for specialized equipment and controlled environments to handle the highly reactive nature of propyne.

Ensuring the complete biodegradability of propyne-based packaging materials under various environmental conditions is another critical challenge. While propyne polymers show potential for biodegradation, optimizing this process to occur within acceptable timeframes across different disposal scenarios (e.g., composting, landfill, marine environments) requires extensive research and development.

The compatibility of propyne-based materials with existing packaging manufacturing processes and equipment poses another technical hurdle. Adapting current production lines to work with these new materials without significant modifications or investments is crucial for widespread adoption in the packaging industry.

Addressing the potential toxicity and environmental impact of propyne and its derivatives throughout the lifecycle of the packaging material is also a key challenge. Ensuring that no harmful byproducts are released during production, use, or degradation is essential for regulatory approval and consumer acceptance.

Lastly, the development of effective additives and compatibilizers to enhance the properties of propyne-based materials without compromising their biodegradability presents a significant technical challenge. Finding the right balance between improved performance and maintained environmental benefits requires innovative approaches in material science and chemistry.

Current Propyne Solutions

01 Synthesis and production methods of propyne

Various methods for synthesizing and producing propyne are described, including catalytic processes, thermal cracking, and chemical reactions. These methods aim to improve yield, efficiency, and purity of propyne production for industrial applications.- Synthesis and production methods of propyne: Various methods for synthesizing and producing propyne are described, including catalytic processes, thermal cracking, and chemical reactions. These methods aim to improve yield, efficiency, and purity of propyne production for industrial applications.

- Purification and separation techniques for propyne: Different techniques for purifying and separating propyne from other gases or mixtures are presented. These include distillation, adsorption, membrane separation, and cryogenic processes, which are crucial for obtaining high-purity propyne for further use.

- Applications of propyne in chemical synthesis: Propyne serves as a valuable starting material or intermediate in various chemical syntheses. It is used in the production of polymers, fine chemicals, pharmaceuticals, and other organic compounds, showcasing its versatility in the chemical industry.

- Storage and handling of propyne: Specialized equipment and methods for storing, handling, and transporting propyne are described. These include pressure vessels, safety systems, and monitoring devices to ensure safe and efficient management of this flammable gas.

- Propyne as a fuel or fuel additive: Research and development efforts exploring the use of propyne as a fuel or fuel additive are presented. This includes studies on combustion properties, engine performance, and emissions reduction when propyne is used in various energy applications.

02 Propyne as a raw material in chemical processes

Propyne serves as an important raw material in various chemical processes, including the production of polymers, resins, and other organic compounds. Its reactivity and structure make it valuable for synthesizing more complex molecules in industrial applications.Expand Specific Solutions03 Purification and separation techniques for propyne

Different methods for purifying and separating propyne from mixtures are presented, including distillation, adsorption, and membrane separation techniques. These processes aim to obtain high-purity propyne for use in various industrial and research applications.Expand Specific Solutions04 Propyne in fuel and energy applications

The use of propyne in fuel and energy-related applications is explored, including its potential as a fuel additive, rocket propellant, and in energy storage systems. Research focuses on harnessing propyne's high energy content and combustion properties.Expand Specific Solutions05 Safety and handling of propyne

Safety measures and handling procedures for propyne are discussed, addressing its flammability and potential hazards. This includes storage methods, transportation guidelines, and risk mitigation strategies for industrial and laboratory use of propyne.Expand Specific Solutions

Key Propyne Packaging Players

The propyne-based biodegradable packaging solutions market is in its early growth stage, with increasing demand driven by environmental concerns and sustainability initiatives. The global market size for biodegradable packaging is projected to reach $21.6 billion by 2025, growing at a CAGR of 17.4%. While the technology is still evolving, companies like Tipa Corp. and Novamont are leading innovation in compostable flexible packaging. Established players such as L'Oréal and PTT Global Chemical are also investing in bio-based materials research. The technology's maturity varies, with some commercial products available but ongoing R&D to improve performance and cost-effectiveness.

Tipa Corp. Ltd.

Technical Solution: Tipa Corp. Ltd. has developed innovative biodegradable packaging solutions using propyne-based materials. Their technology involves creating multi-layer films that incorporate propyne derivatives to enhance biodegradability while maintaining barrier properties. The company's approach includes a proprietary blend of propyne-modified biopolymers that break down into non-toxic components in industrial composting conditions within 180 days[1]. Tipa's packaging solutions are designed to mimic conventional plastic in terms of transparency, durability, and printability, making them suitable for various food and non-food applications[2]. The company has also developed a patented process for incorporating propyne-based additives into their films, which accelerates the biodegradation process without compromising shelf life[3].

Strengths: Highly biodegradable, maintains barrier properties, versatile applications. Weaknesses: May require specific composting conditions, potentially higher production costs compared to conventional plastics.

World Centric

Technical Solution: World Centric has developed a range of biodegradable packaging solutions incorporating propyne-based additives to enhance compostability. Their technology focuses on creating plant-based packaging materials that integrate propyne derivatives to accelerate the biodegradation process in both industrial and home composting environments. World Centric's approach includes a proprietary blend of propyne-modified starches and cellulose that can break down into non-toxic components within 90-180 days in various composting conditions[7]. The company has also developed a unique coating process using propyne-based compounds to improve the water resistance and grease barrier properties of their packaging materials, making them suitable for a wide range of food service applications[8]. Additionally, World Centric has implemented a life cycle assessment methodology to quantify the environmental benefits of their propyne-enhanced biodegradable packaging compared to conventional plastics[9].

Strengths: Rapid biodegradation, suitable for both industrial and home composting, improved barrier properties. Weaknesses: May have limitations in long-term storage applications, potentially higher costs compared to conventional packaging.

Propyne Packaging Innovations

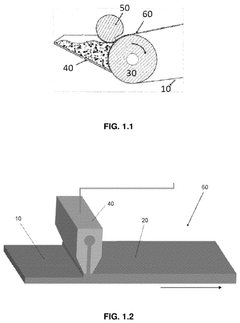

Biodegradable packaging and method for manufacturing same

PatentPendingUS20250058551A1

Innovation

- A biodegradable packaging solution composed of layers, with a paper substrate coated with a vegetable polyurethane resin, which is compostable, recyclable, and can withstand high temperatures, making it suitable for use in cooking ovens and microwave ovens.

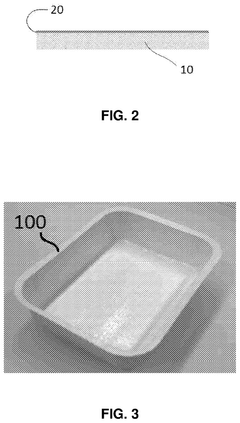

Eco-friendly Food Packaging

PatentActiveKR1020210112527A

Innovation

- A packaging material composed of a foamed propylene polymer base layer with a biodegradable agent and a coating layer made from cellulose, starch, or protein, which is biodegradable without inorganic materials, ensuring heat retention and versatility.

Environmental Impact Assessment

The environmental impact assessment of propyne in biodegradable packaging solutions reveals both potential benefits and challenges. Propyne, as a key component in the development of advanced biodegradable materials, offers promising opportunities for reducing plastic waste and mitigating environmental pollution. However, its production and application also raise concerns that require careful consideration.

One of the primary advantages of propyne-based biodegradable packaging is its potential to significantly reduce the accumulation of plastic waste in landfills and oceans. Unlike conventional plastics that persist in the environment for hundreds of years, propyne-derived materials can decompose within months to a few years under appropriate conditions. This rapid biodegradation process can help alleviate the growing problem of plastic pollution and its detrimental effects on ecosystems and wildlife.

Furthermore, the use of propyne in biodegradable packaging solutions can contribute to the reduction of greenhouse gas emissions associated with the production and disposal of traditional plastics. As propyne-based materials break down, they release fewer harmful substances into the environment compared to conventional plastics, potentially leading to a lower overall carbon footprint.

However, the environmental impact of propyne production must be carefully evaluated. The current methods of propyne synthesis often rely on fossil fuel-based feedstocks, which can offset some of the environmental benefits gained from its biodegradability. Efforts to develop more sustainable production methods, such as using renewable resources or implementing carbon capture technologies, are crucial to maximizing the environmental advantages of propyne-based packaging.

Water consumption and potential contamination during the manufacturing process of propyne-derived materials also require attention. Proper water management strategies and treatment systems must be implemented to minimize the impact on local water resources and ecosystems. Additionally, the potential release of microplastics during the biodegradation process of propyne-based packaging needs further investigation to ensure that it does not contribute to the existing microplastic pollution problem.

The end-of-life management of propyne-based biodegradable packaging is another critical aspect to consider. While these materials can decompose more readily than conventional plastics, they still require specific conditions to biodegrade effectively. Proper waste management infrastructure and consumer education are essential to ensure that these materials are disposed of correctly and can fulfill their environmental potential.

In conclusion, the environmental impact assessment of propyne in biodegradable packaging solutions reveals a complex interplay of benefits and challenges. While the technology offers significant potential for reducing plastic pollution and environmental degradation, careful consideration must be given to the entire lifecycle of propyne-based materials, from production to disposal, to maximize their positive environmental impact and address potential drawbacks.

One of the primary advantages of propyne-based biodegradable packaging is its potential to significantly reduce the accumulation of plastic waste in landfills and oceans. Unlike conventional plastics that persist in the environment for hundreds of years, propyne-derived materials can decompose within months to a few years under appropriate conditions. This rapid biodegradation process can help alleviate the growing problem of plastic pollution and its detrimental effects on ecosystems and wildlife.

Furthermore, the use of propyne in biodegradable packaging solutions can contribute to the reduction of greenhouse gas emissions associated with the production and disposal of traditional plastics. As propyne-based materials break down, they release fewer harmful substances into the environment compared to conventional plastics, potentially leading to a lower overall carbon footprint.

However, the environmental impact of propyne production must be carefully evaluated. The current methods of propyne synthesis often rely on fossil fuel-based feedstocks, which can offset some of the environmental benefits gained from its biodegradability. Efforts to develop more sustainable production methods, such as using renewable resources or implementing carbon capture technologies, are crucial to maximizing the environmental advantages of propyne-based packaging.

Water consumption and potential contamination during the manufacturing process of propyne-derived materials also require attention. Proper water management strategies and treatment systems must be implemented to minimize the impact on local water resources and ecosystems. Additionally, the potential release of microplastics during the biodegradation process of propyne-based packaging needs further investigation to ensure that it does not contribute to the existing microplastic pollution problem.

The end-of-life management of propyne-based biodegradable packaging is another critical aspect to consider. While these materials can decompose more readily than conventional plastics, they still require specific conditions to biodegrade effectively. Proper waste management infrastructure and consumer education are essential to ensure that these materials are disposed of correctly and can fulfill their environmental potential.

In conclusion, the environmental impact assessment of propyne in biodegradable packaging solutions reveals a complex interplay of benefits and challenges. While the technology offers significant potential for reducing plastic pollution and environmental degradation, careful consideration must be given to the entire lifecycle of propyne-based materials, from production to disposal, to maximize their positive environmental impact and address potential drawbacks.

Regulatory Framework

The regulatory framework surrounding propyne in biodegradable packaging solutions is complex and evolving, reflecting the growing emphasis on sustainable practices and environmental protection. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Trade Organization (WTO) have established guidelines and agreements that influence the development and use of biodegradable materials, including propyne-based solutions.

In the European Union, the Packaging and Packaging Waste Directive (94/62/EC) sets standards for packaging materials, including those incorporating propyne. This directive aims to harmonize national measures and promote recycling and recovery of packaging waste. The EU has also introduced the Single-Use Plastics Directive (EU) 2019/904, which further encourages the adoption of biodegradable alternatives, potentially creating opportunities for propyne-based packaging solutions.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials, including biodegradable packaging. The FDA's Food Contact Notification (FCN) program provides a pathway for manufacturers to obtain approval for new food contact substances, which would apply to propyne-based packaging materials. Additionally, the Environmental Protection Agency (EPA) oversees regulations related to environmental impact and waste management, which are relevant to the lifecycle assessment of biodegradable packaging.

Many countries have implemented or are in the process of implementing regulations that promote the use of biodegradable materials. For instance, Japan's Containers and Packaging Recycling Law encourages the use of environmentally friendly packaging materials. Similarly, China has introduced restrictions on non-biodegradable plastics, creating a favorable regulatory environment for alternatives like propyne-based solutions.

Certification systems play a crucial role in the regulatory landscape. Standards such as ASTM D6400 and EN 13432 provide specifications for compostable plastics, which propyne-based biodegradable packaging would need to meet to be labeled as such. These standards ensure that materials break down within specified timeframes under controlled composting conditions.

As the field of biodegradable packaging continues to advance, regulatory bodies are likely to refine and expand their frameworks. This may include more stringent requirements for biodegradability claims, lifecycle assessments, and end-of-life management. Companies developing propyne-based packaging solutions must stay abreast of these evolving regulations to ensure compliance and market acceptance.

The regulatory landscape also presents challenges, such as the lack of global harmonization in standards and definitions for biodegradability. This can create barriers to international trade and complicate the development of universally accepted propyne-based packaging solutions. However, it also presents opportunities for industry leaders to engage with policymakers and shape future regulations.

In the European Union, the Packaging and Packaging Waste Directive (94/62/EC) sets standards for packaging materials, including those incorporating propyne. This directive aims to harmonize national measures and promote recycling and recovery of packaging waste. The EU has also introduced the Single-Use Plastics Directive (EU) 2019/904, which further encourages the adoption of biodegradable alternatives, potentially creating opportunities for propyne-based packaging solutions.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials, including biodegradable packaging. The FDA's Food Contact Notification (FCN) program provides a pathway for manufacturers to obtain approval for new food contact substances, which would apply to propyne-based packaging materials. Additionally, the Environmental Protection Agency (EPA) oversees regulations related to environmental impact and waste management, which are relevant to the lifecycle assessment of biodegradable packaging.

Many countries have implemented or are in the process of implementing regulations that promote the use of biodegradable materials. For instance, Japan's Containers and Packaging Recycling Law encourages the use of environmentally friendly packaging materials. Similarly, China has introduced restrictions on non-biodegradable plastics, creating a favorable regulatory environment for alternatives like propyne-based solutions.

Certification systems play a crucial role in the regulatory landscape. Standards such as ASTM D6400 and EN 13432 provide specifications for compostable plastics, which propyne-based biodegradable packaging would need to meet to be labeled as such. These standards ensure that materials break down within specified timeframes under controlled composting conditions.

As the field of biodegradable packaging continues to advance, regulatory bodies are likely to refine and expand their frameworks. This may include more stringent requirements for biodegradability claims, lifecycle assessments, and end-of-life management. Companies developing propyne-based packaging solutions must stay abreast of these evolving regulations to ensure compliance and market acceptance.

The regulatory landscape also presents challenges, such as the lack of global harmonization in standards and definitions for biodegradability. This can create barriers to international trade and complicate the development of universally accepted propyne-based packaging solutions. However, it also presents opportunities for industry leaders to engage with policymakers and shape future regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!