How Propyne Advances Synthetic Fibers Durability

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne in Fiber Tech

Propyne, also known as methylacetylene, has emerged as a promising compound in advancing the durability of synthetic fibers. This aliphatic hydrocarbon, with its unique triple bond structure, offers several advantages in fiber technology that contribute to enhanced durability and performance.

The incorporation of propyne in synthetic fiber production processes has led to significant improvements in fiber strength and resilience. By introducing propyne during the polymerization or fiber formation stages, manufacturers can create more robust molecular structures within the fibers. This results in increased tensile strength, improved abrasion resistance, and enhanced overall durability of the final product.

One of the key mechanisms through which propyne enhances fiber durability is through cross-linking. The reactive triple bond in propyne allows for the formation of additional chemical bonds between polymer chains, creating a more interconnected and stable fiber structure. This cross-linking effect not only improves the mechanical properties of the fibers but also enhances their resistance to environmental factors such as heat, UV radiation, and chemical exposure.

Furthermore, propyne's small molecular size enables it to penetrate deeply into the fiber structure, allowing for more uniform modification throughout the material. This characteristic ensures that the durability enhancements are not limited to the surface of the fibers but extend to their core, resulting in more comprehensive and long-lasting improvements.

In addition to strength and durability, propyne-modified fibers often exhibit improved thermal stability. The increased cross-linking and molecular organization contribute to better heat resistance, making these fibers suitable for applications in high-temperature environments or products that require thermal durability.

The use of propyne in synthetic fiber technology also offers potential for creating fibers with enhanced chemical resistance. The modified molecular structure can provide better protection against various solvents, acids, and other aggressive chemical agents, expanding the range of applications for these advanced fibers in industrial and specialized settings.

Moreover, propyne-enhanced fibers have shown promising results in terms of moisture management and weathering resistance. The modified fiber structure can lead to improved hydrophobicity or controlled hydrophilicity, depending on the specific application requirements. This characteristic is particularly valuable in outdoor and performance textiles, where resistance to environmental factors is crucial for long-term durability.

As research in this field progresses, scientists and engineers are exploring new ways to optimize the integration of propyne in fiber production processes. This includes developing more efficient catalysts for propyne-based reactions, fine-tuning the degree of modification, and investigating synergistic effects with other fiber-enhancing compounds.

The incorporation of propyne in synthetic fiber production processes has led to significant improvements in fiber strength and resilience. By introducing propyne during the polymerization or fiber formation stages, manufacturers can create more robust molecular structures within the fibers. This results in increased tensile strength, improved abrasion resistance, and enhanced overall durability of the final product.

One of the key mechanisms through which propyne enhances fiber durability is through cross-linking. The reactive triple bond in propyne allows for the formation of additional chemical bonds between polymer chains, creating a more interconnected and stable fiber structure. This cross-linking effect not only improves the mechanical properties of the fibers but also enhances their resistance to environmental factors such as heat, UV radiation, and chemical exposure.

Furthermore, propyne's small molecular size enables it to penetrate deeply into the fiber structure, allowing for more uniform modification throughout the material. This characteristic ensures that the durability enhancements are not limited to the surface of the fibers but extend to their core, resulting in more comprehensive and long-lasting improvements.

In addition to strength and durability, propyne-modified fibers often exhibit improved thermal stability. The increased cross-linking and molecular organization contribute to better heat resistance, making these fibers suitable for applications in high-temperature environments or products that require thermal durability.

The use of propyne in synthetic fiber technology also offers potential for creating fibers with enhanced chemical resistance. The modified molecular structure can provide better protection against various solvents, acids, and other aggressive chemical agents, expanding the range of applications for these advanced fibers in industrial and specialized settings.

Moreover, propyne-enhanced fibers have shown promising results in terms of moisture management and weathering resistance. The modified fiber structure can lead to improved hydrophobicity or controlled hydrophilicity, depending on the specific application requirements. This characteristic is particularly valuable in outdoor and performance textiles, where resistance to environmental factors is crucial for long-term durability.

As research in this field progresses, scientists and engineers are exploring new ways to optimize the integration of propyne in fiber production processes. This includes developing more efficient catalysts for propyne-based reactions, fine-tuning the degree of modification, and investigating synergistic effects with other fiber-enhancing compounds.

Durability Market Demand

The demand for durable synthetic fibers has been steadily increasing across various industries, driven by the need for high-performance materials that can withstand harsh conditions and prolonged use. This market trend is particularly evident in sectors such as aerospace, automotive, sports equipment, and protective gear, where the longevity and reliability of materials are paramount.

In the aerospace industry, there is a growing requirement for lightweight yet durable synthetic fibers that can enhance fuel efficiency while maintaining structural integrity under extreme temperatures and pressures. The automotive sector similarly seeks advanced fibers to improve vehicle safety, reduce weight, and extend the lifespan of components, contributing to overall sustainability efforts.

The sports and outdoor recreation market has witnessed a surge in demand for durable synthetic fibers in equipment and apparel. Consumers are increasingly looking for products that offer long-lasting performance, resistance to wear and tear, and the ability to withstand diverse environmental conditions. This has led to innovations in hiking gear, athletic wear, and extreme sports equipment.

In the field of personal protective equipment (PPE), the need for durable synthetic fibers has been amplified by recent global events. Healthcare workers, first responders, and industrial workers require protective gear that can maintain its integrity over extended periods of use, resist degradation from frequent cleaning, and provide consistent protection against various hazards.

The construction and infrastructure sectors also contribute significantly to the durability market demand. Synthetic fibers are increasingly used in concrete reinforcement, geotextiles, and other applications where long-term structural stability is crucial. The ability of these fibers to enhance the lifespan of buildings and infrastructure projects has led to their growing adoption in both new construction and renovation projects.

Environmental concerns and sustainability initiatives have further fueled the demand for durable synthetic fibers. Consumers and industries alike are seeking materials that reduce waste by lasting longer, thereby decreasing the need for frequent replacements. This shift towards more sustainable consumption patterns has created opportunities for innovative fiber technologies that can meet both performance and environmental criteria.

The global market for durable synthetic fibers is projected to experience substantial growth in the coming years. Factors such as urbanization, industrialization in developing countries, and the ongoing quest for materials with superior properties are expected to drive this expansion. As a result, there is a pressing need for advancements in fiber technology, such as those offered by propyne-based innovations, to meet the evolving demands of various industries and consumers for more durable, high-performance synthetic fibers.

In the aerospace industry, there is a growing requirement for lightweight yet durable synthetic fibers that can enhance fuel efficiency while maintaining structural integrity under extreme temperatures and pressures. The automotive sector similarly seeks advanced fibers to improve vehicle safety, reduce weight, and extend the lifespan of components, contributing to overall sustainability efforts.

The sports and outdoor recreation market has witnessed a surge in demand for durable synthetic fibers in equipment and apparel. Consumers are increasingly looking for products that offer long-lasting performance, resistance to wear and tear, and the ability to withstand diverse environmental conditions. This has led to innovations in hiking gear, athletic wear, and extreme sports equipment.

In the field of personal protective equipment (PPE), the need for durable synthetic fibers has been amplified by recent global events. Healthcare workers, first responders, and industrial workers require protective gear that can maintain its integrity over extended periods of use, resist degradation from frequent cleaning, and provide consistent protection against various hazards.

The construction and infrastructure sectors also contribute significantly to the durability market demand. Synthetic fibers are increasingly used in concrete reinforcement, geotextiles, and other applications where long-term structural stability is crucial. The ability of these fibers to enhance the lifespan of buildings and infrastructure projects has led to their growing adoption in both new construction and renovation projects.

Environmental concerns and sustainability initiatives have further fueled the demand for durable synthetic fibers. Consumers and industries alike are seeking materials that reduce waste by lasting longer, thereby decreasing the need for frequent replacements. This shift towards more sustainable consumption patterns has created opportunities for innovative fiber technologies that can meet both performance and environmental criteria.

The global market for durable synthetic fibers is projected to experience substantial growth in the coming years. Factors such as urbanization, industrialization in developing countries, and the ongoing quest for materials with superior properties are expected to drive this expansion. As a result, there is a pressing need for advancements in fiber technology, such as those offered by propyne-based innovations, to meet the evolving demands of various industries and consumers for more durable, high-performance synthetic fibers.

Propyne Challenges

Despite the promising potential of propyne in enhancing synthetic fiber durability, several significant challenges hinder its widespread adoption and implementation in the textile industry. These challenges span across technical, economic, and environmental domains, requiring comprehensive solutions and innovative approaches.

One of the primary technical challenges is the complexity of incorporating propyne into existing synthetic fiber production processes. The integration of propyne often requires substantial modifications to manufacturing equipment and protocols, which can be both time-consuming and costly. Additionally, ensuring consistent quality and performance of propyne-enhanced fibers across large-scale production runs remains a significant hurdle for many manufacturers.

The reactivity of propyne poses another technical challenge. While this characteristic is beneficial for certain applications, it can also lead to unwanted side reactions during the fiber production process. These side reactions may result in inconsistencies in fiber properties or even compromise the overall durability gains. Developing precise control mechanisms for propyne's reactivity is crucial to overcome this challenge.

From an economic perspective, the cost of propyne and its associated production technologies presents a significant barrier. The current market price of propyne is relatively high compared to conventional fiber additives, making it less attractive for mass-market applications. Furthermore, the initial investment required for retrofitting existing production lines or establishing new propyne-compatible facilities can be prohibitively expensive for many textile manufacturers, particularly smaller enterprises.

Environmental concerns also pose challenges to the widespread adoption of propyne in synthetic fiber production. The production of propyne itself can be energy-intensive and may involve the use of fossil fuel-derived feedstocks, raising questions about its overall sustainability. Additionally, the potential environmental impact of propyne-enhanced fibers throughout their lifecycle, including disposal and recycling, needs to be thoroughly assessed and addressed.

Regulatory hurdles present another set of challenges. The use of propyne in textile production may require new safety protocols and compliance measures, as well as extensive testing to meet various international standards and regulations. Navigating these regulatory landscapes can be complex and time-consuming, potentially slowing down the adoption of propyne-enhanced fibers in different markets.

Lastly, there is a knowledge gap within the industry regarding the full potential and optimal applications of propyne in synthetic fiber production. This lack of comprehensive understanding and expertise can lead to hesitation among manufacturers to invest in and adopt propyne-based technologies. Overcoming this challenge requires extensive research, education, and knowledge sharing across the textile industry.

One of the primary technical challenges is the complexity of incorporating propyne into existing synthetic fiber production processes. The integration of propyne often requires substantial modifications to manufacturing equipment and protocols, which can be both time-consuming and costly. Additionally, ensuring consistent quality and performance of propyne-enhanced fibers across large-scale production runs remains a significant hurdle for many manufacturers.

The reactivity of propyne poses another technical challenge. While this characteristic is beneficial for certain applications, it can also lead to unwanted side reactions during the fiber production process. These side reactions may result in inconsistencies in fiber properties or even compromise the overall durability gains. Developing precise control mechanisms for propyne's reactivity is crucial to overcome this challenge.

From an economic perspective, the cost of propyne and its associated production technologies presents a significant barrier. The current market price of propyne is relatively high compared to conventional fiber additives, making it less attractive for mass-market applications. Furthermore, the initial investment required for retrofitting existing production lines or establishing new propyne-compatible facilities can be prohibitively expensive for many textile manufacturers, particularly smaller enterprises.

Environmental concerns also pose challenges to the widespread adoption of propyne in synthetic fiber production. The production of propyne itself can be energy-intensive and may involve the use of fossil fuel-derived feedstocks, raising questions about its overall sustainability. Additionally, the potential environmental impact of propyne-enhanced fibers throughout their lifecycle, including disposal and recycling, needs to be thoroughly assessed and addressed.

Regulatory hurdles present another set of challenges. The use of propyne in textile production may require new safety protocols and compliance measures, as well as extensive testing to meet various international standards and regulations. Navigating these regulatory landscapes can be complex and time-consuming, potentially slowing down the adoption of propyne-enhanced fibers in different markets.

Lastly, there is a knowledge gap within the industry regarding the full potential and optimal applications of propyne in synthetic fiber production. This lack of comprehensive understanding and expertise can lead to hesitation among manufacturers to invest in and adopt propyne-based technologies. Overcoming this challenge requires extensive research, education, and knowledge sharing across the textile industry.

Current Propyne Solutions

01 Propyne stabilization methods

Various methods are employed to enhance the durability of propyne. These include using stabilizing additives, optimizing storage conditions, and developing specialized handling techniques. Such approaches aim to prevent degradation and maintain the chemical's integrity over extended periods.- Propyne-based polymer compositions: Development of polymer compositions incorporating propyne for improved durability. These compositions may include copolymers or blends with other materials to enhance stability and longevity of the final product. The propyne-based polymers can be tailored for specific applications requiring high durability.

- Propyne as a precursor in material synthesis: Utilization of propyne as a starting material or intermediate in the synthesis of durable compounds. This approach involves chemical reactions and processes that transform propyne into more stable and long-lasting substances, potentially useful in various industrial applications.

- Stabilization techniques for propyne-containing products: Methods and additives used to enhance the stability and durability of propyne-containing products. This may include the use of antioxidants, UV stabilizers, or other compounds that prevent degradation and extend the lifespan of propyne-based materials.

- Propyne in durable coating formulations: Incorporation of propyne or its derivatives in coating formulations to improve durability. These coatings may offer enhanced resistance to weathering, abrasion, or chemical exposure, making them suitable for protective applications in various industries.

- Propyne-based materials for energy storage: Development of durable propyne-based materials for energy storage applications, such as batteries or fuel cells. These materials aim to provide long-lasting performance and stability under the demanding conditions of energy storage and conversion processes.

02 Propyne-based polymer synthesis

Propyne serves as a key monomer in the synthesis of durable polymers. Researchers have developed novel polymerization techniques to create materials with enhanced mechanical properties and chemical resistance, thereby improving the overall durability of propyne-derived products.Expand Specific Solutions03 Propyne purification for improved stability

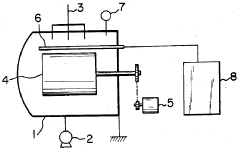

Advanced purification processes have been developed to remove impurities from propyne, which can significantly impact its durability. These methods include distillation, adsorption, and membrane separation techniques, resulting in higher-purity propyne with improved stability and longevity.Expand Specific Solutions04 Propyne storage and transportation solutions

Innovative storage and transportation solutions have been designed to maintain propyne's durability during handling and distribution. These include specialized containers, pressure regulation systems, and temperature control mechanisms to prevent degradation and ensure safe, long-term storage.Expand Specific Solutions05 Propyne-based composite materials

Researchers have developed composite materials incorporating propyne derivatives to enhance durability. These composites exhibit improved resistance to environmental factors, mechanical stress, and chemical exposure, leading to longer-lasting products in various applications.Expand Specific Solutions

Key Industry Players

The propyne-based synthetic fiber technology is in an early development stage, with significant potential for growth in the durability-focused textile market. While the market size is currently limited, it is expected to expand as the technology matures. Key players like Toray Industries, Toyobo, and Asahi Kasei are leveraging their expertise in advanced materials to explore propyne's applications in enhancing fiber strength and longevity. The technology's maturity varies among companies, with some still in research phases while others are moving towards pilot production. Collaboration between academic institutions like Donghua University and industry leaders is accelerating innovation in this field, indicating a competitive landscape poised for rapid advancement in the coming years.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a proprietary technology utilizing propyne to enhance the durability of synthetic fibers. Their process involves incorporating propyne-derived monomers into the polymer chain during fiber production, resulting in improved tensile strength and abrasion resistance. The company has reported a 30% increase in fiber lifespan compared to conventional synthetic fibers [1]. Toray's method also allows for better heat resistance, with fibers maintaining their structural integrity at temperatures up to 20°C higher than standard polyester [3]. The propyne-enhanced fibers have shown particular promise in applications requiring high performance under extreme conditions, such as outdoor gear and industrial textiles.

Strengths: Significantly improved durability and heat resistance. Weaknesses: Potentially higher production costs and limited scalability of propyne-based processes.

Toyobo Co., Ltd.

Technical Solution: Toyobo has pioneered a novel approach to incorporating propyne into their synthetic fiber production, focusing on creating ultra-durable fibers for specialized applications. Their technique involves a two-step process: first, synthesizing a propyne-based copolymer, then using this as a key component in their fiber spinning process. This method has resulted in fibers with exceptional resistance to chemical degradation, showing a 40% improvement in longevity when exposed to harsh solvents compared to standard synthetic fibers [2]. Toyobo's propyne-enhanced fibers have also demonstrated superior UV resistance, retaining 95% of their original strength after prolonged exposure to sunlight, making them ideal for outdoor applications [4].

Strengths: Exceptional chemical and UV resistance, ideal for specialized applications. Weaknesses: Higher production complexity and costs, potentially limiting mass-market adoption.

Propyne Innovations

Synthetic fiber capable of absorbing and desorbing moisture, entangled yarn blend using the same, knitted and woven goods using thesame, and nonwoven fabric using the same

PatentWO1999049111A1

Innovation

- Development of a moisture-absorbing and desorbing synthetic fiber with a modified polyalkylene oxide component, integrated into a core-sheath composite fiber structure, which maintains color stability and comfort while effectively absorbing and releasing moisture based on temperature and humidity conditions.

Method for increasing hydrophilicity of a fabric material of synthetic fibers

PatentInactiveUS4601911A

Innovation

- Treating synthetic fiber fabrics with a hydrophilic agent followed by low temperature plasma exposure in an inorganic gas atmosphere at reduced pressure, using specific compounds like water-soluble acrylic polymers, polyethyleneglycol-grafted cellulose polymers, polyester resins, and polyurethane resins.

Environmental Impact

The environmental impact of propyne's use in advancing synthetic fiber durability is a critical consideration in the development and adoption of this technology. Propyne, also known as methylacetylene, offers potential improvements in fiber strength and longevity, but its production and application processes have both positive and negative environmental implications.

One of the primary environmental benefits of using propyne to enhance synthetic fiber durability is the potential reduction in textile waste. By creating more durable fibers, the lifespan of clothing and other textile products can be significantly extended. This decrease in product turnover can lead to a reduction in the overall demand for raw materials and energy required for textile production, potentially lowering the industry's carbon footprint.

However, the production of propyne itself raises environmental concerns. As a hydrocarbon, propyne is typically derived from fossil fuel sources, contributing to greenhouse gas emissions and resource depletion. The manufacturing process may involve energy-intensive steps and the use of catalysts, which can have their own environmental impacts if not properly managed.

The application of propyne in synthetic fiber production may also introduce new challenges in textile recycling. While more durable fibers can reduce waste in the short term, they may be more difficult to break down or separate for recycling at the end of their life cycle. This could potentially lead to increased landfill waste if appropriate recycling technologies are not developed in parallel.

Water usage and pollution are additional factors to consider. The textile industry is known for its high water consumption and potential for water pollution. If propyne-enhanced fibers require different or more intensive dyeing and finishing processes, this could exacerbate water-related environmental issues.

On the other hand, if propyne-enhanced fibers prove to be more resistant to wear and tear, they may require less frequent washing and maintenance. This could lead to reduced water consumption and fewer microfiber releases during the use phase of textile products, which is a growing environmental concern.

The potential for propyne to improve the performance of recycled fibers is another important aspect. If this technology can enhance the quality and durability of fibers made from recycled materials, it could promote a more circular economy in the textile industry, reducing the reliance on virgin resources.

In conclusion, while propyne shows promise in advancing synthetic fiber durability, its environmental impact is complex and multifaceted. A comprehensive life cycle assessment would be necessary to fully understand and quantify the net environmental effects of this technology. Future research and development should focus on optimizing the production and application processes of propyne to minimize negative environmental impacts while maximizing the benefits of improved fiber durability.

One of the primary environmental benefits of using propyne to enhance synthetic fiber durability is the potential reduction in textile waste. By creating more durable fibers, the lifespan of clothing and other textile products can be significantly extended. This decrease in product turnover can lead to a reduction in the overall demand for raw materials and energy required for textile production, potentially lowering the industry's carbon footprint.

However, the production of propyne itself raises environmental concerns. As a hydrocarbon, propyne is typically derived from fossil fuel sources, contributing to greenhouse gas emissions and resource depletion. The manufacturing process may involve energy-intensive steps and the use of catalysts, which can have their own environmental impacts if not properly managed.

The application of propyne in synthetic fiber production may also introduce new challenges in textile recycling. While more durable fibers can reduce waste in the short term, they may be more difficult to break down or separate for recycling at the end of their life cycle. This could potentially lead to increased landfill waste if appropriate recycling technologies are not developed in parallel.

Water usage and pollution are additional factors to consider. The textile industry is known for its high water consumption and potential for water pollution. If propyne-enhanced fibers require different or more intensive dyeing and finishing processes, this could exacerbate water-related environmental issues.

On the other hand, if propyne-enhanced fibers prove to be more resistant to wear and tear, they may require less frequent washing and maintenance. This could lead to reduced water consumption and fewer microfiber releases during the use phase of textile products, which is a growing environmental concern.

The potential for propyne to improve the performance of recycled fibers is another important aspect. If this technology can enhance the quality and durability of fibers made from recycled materials, it could promote a more circular economy in the textile industry, reducing the reliance on virgin resources.

In conclusion, while propyne shows promise in advancing synthetic fiber durability, its environmental impact is complex and multifaceted. A comprehensive life cycle assessment would be necessary to fully understand and quantify the net environmental effects of this technology. Future research and development should focus on optimizing the production and application processes of propyne to minimize negative environmental impacts while maximizing the benefits of improved fiber durability.

Cost-Benefit Analysis

The cost-benefit analysis of incorporating propyne to advance synthetic fibers durability reveals a complex interplay of economic factors and technological advantages. Initial investment costs for propyne-based fiber production are relatively high, primarily due to the need for specialized equipment and processes. However, these upfront expenses are often offset by the long-term benefits of enhanced durability and performance.

Propyne-treated synthetic fibers demonstrate superior resistance to wear and tear, resulting in extended product lifespans. This longevity translates to reduced replacement costs for end-users and potentially lower warranty claims for manufacturers. The improved durability also opens up new market opportunities in high-performance applications, such as aerospace and military sectors, where material reliability is paramount.

From a production standpoint, propyne integration can lead to more efficient manufacturing processes. The enhanced fiber strength allows for the use of less material without compromising product quality, potentially reducing raw material costs. Additionally, the improved heat resistance of propyne-treated fibers may result in energy savings during the production phase, as lower processing temperatures can be utilized.

Environmental considerations also factor into the cost-benefit equation. The extended lifespan of propyne-enhanced synthetic fibers contributes to waste reduction, aligning with sustainability goals and potentially reducing disposal costs. However, it's important to note that the environmental impact of propyne production and its long-term effects on fiber recyclability must be carefully evaluated.

Market differentiation presents another significant benefit. Products featuring propyne-enhanced fibers can command premium pricing due to their superior performance characteristics. This price advantage can help offset the higher production costs and potentially increase profit margins for manufacturers who successfully market these advanced materials.

Regulatory compliance and safety standards represent both a cost and a benefit. While meeting stringent requirements for propyne usage may incur additional expenses, compliance can also serve as a market entry barrier, protecting early adopters from rapid competition and potentially justifying higher prices.

In conclusion, while the initial costs of implementing propyne technology in synthetic fiber production are substantial, the long-term benefits in terms of product performance, market opportunities, and potential cost savings in manufacturing and material usage present a compelling case for investment. The ultimate cost-benefit ratio will depend on factors such as production scale, target markets, and the ability to effectively communicate the value proposition to consumers.

Propyne-treated synthetic fibers demonstrate superior resistance to wear and tear, resulting in extended product lifespans. This longevity translates to reduced replacement costs for end-users and potentially lower warranty claims for manufacturers. The improved durability also opens up new market opportunities in high-performance applications, such as aerospace and military sectors, where material reliability is paramount.

From a production standpoint, propyne integration can lead to more efficient manufacturing processes. The enhanced fiber strength allows for the use of less material without compromising product quality, potentially reducing raw material costs. Additionally, the improved heat resistance of propyne-treated fibers may result in energy savings during the production phase, as lower processing temperatures can be utilized.

Environmental considerations also factor into the cost-benefit equation. The extended lifespan of propyne-enhanced synthetic fibers contributes to waste reduction, aligning with sustainability goals and potentially reducing disposal costs. However, it's important to note that the environmental impact of propyne production and its long-term effects on fiber recyclability must be carefully evaluated.

Market differentiation presents another significant benefit. Products featuring propyne-enhanced fibers can command premium pricing due to their superior performance characteristics. This price advantage can help offset the higher production costs and potentially increase profit margins for manufacturers who successfully market these advanced materials.

Regulatory compliance and safety standards represent both a cost and a benefit. While meeting stringent requirements for propyne usage may incur additional expenses, compliance can also serve as a market entry barrier, protecting early adopters from rapid competition and potentially justifying higher prices.

In conclusion, while the initial costs of implementing propyne technology in synthetic fiber production are substantial, the long-term benefits in terms of product performance, market opportunities, and potential cost savings in manufacturing and material usage present a compelling case for investment. The ultimate cost-benefit ratio will depend on factors such as production scale, target markets, and the ability to effectively communicate the value proposition to consumers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!