How Propyne Affects the Electroluminescence of Organic Devices

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne in OLED Tech: Background and Objectives

Propyne, also known as methylacetylene, has emerged as a significant compound in the field of organic light-emitting diodes (OLEDs). The evolution of OLED technology has been driven by the quest for more efficient and longer-lasting displays, with researchers constantly exploring new materials and methods to enhance device performance. In this context, propyne has garnered attention for its potential to influence the electroluminescence of organic devices.

The journey of propyne in OLED technology began with the recognition of its unique chemical properties. As a simple alkyne, propyne possesses a triple bond that can interact with other molecules in ways that affect electron transfer and light emission. This characteristic has led researchers to investigate its role in modifying the behavior of organic semiconductors used in OLEDs.

The primary objective of studying propyne's effects on electroluminescence is to improve the efficiency and stability of OLED devices. Researchers aim to understand how the introduction of propyne into the organic layers of OLEDs can alter charge transport, exciton formation, and ultimately, light emission. By manipulating these processes, there is potential to enhance the brightness, color purity, and longevity of OLED displays.

Another key goal is to explore propyne's ability to address common challenges in OLED technology, such as efficiency roll-off at high current densities and degradation of organic materials over time. The incorporation of propyne into device structures may offer new pathways to mitigate these issues, potentially leading to more robust and energy-efficient displays.

Furthermore, the investigation of propyne in OLEDs aligns with the broader trend of molecular engineering in organic electronics. By studying how small molecules like propyne interact with larger organic semiconductors, researchers hope to gain insights that could inform the design of next-generation materials for optoelectronic applications.

The technological trajectory of propyne in OLEDs is closely linked to advancements in organic synthesis and device fabrication techniques. As methods for precisely controlling the molecular structure and composition of organic layers improve, so too does the ability to harness propyne's unique properties for enhancing electroluminescence.

In conclusion, the exploration of propyne's role in OLED electroluminescence represents a promising avenue for advancing display technology. By elucidating the mechanisms through which propyne affects organic devices, researchers aim to unlock new possibilities for creating more efficient, brighter, and longer-lasting OLEDs, potentially revolutionizing the field of organic electronics and display technology.

The journey of propyne in OLED technology began with the recognition of its unique chemical properties. As a simple alkyne, propyne possesses a triple bond that can interact with other molecules in ways that affect electron transfer and light emission. This characteristic has led researchers to investigate its role in modifying the behavior of organic semiconductors used in OLEDs.

The primary objective of studying propyne's effects on electroluminescence is to improve the efficiency and stability of OLED devices. Researchers aim to understand how the introduction of propyne into the organic layers of OLEDs can alter charge transport, exciton formation, and ultimately, light emission. By manipulating these processes, there is potential to enhance the brightness, color purity, and longevity of OLED displays.

Another key goal is to explore propyne's ability to address common challenges in OLED technology, such as efficiency roll-off at high current densities and degradation of organic materials over time. The incorporation of propyne into device structures may offer new pathways to mitigate these issues, potentially leading to more robust and energy-efficient displays.

Furthermore, the investigation of propyne in OLEDs aligns with the broader trend of molecular engineering in organic electronics. By studying how small molecules like propyne interact with larger organic semiconductors, researchers hope to gain insights that could inform the design of next-generation materials for optoelectronic applications.

The technological trajectory of propyne in OLEDs is closely linked to advancements in organic synthesis and device fabrication techniques. As methods for precisely controlling the molecular structure and composition of organic layers improve, so too does the ability to harness propyne's unique properties for enhancing electroluminescence.

In conclusion, the exploration of propyne's role in OLED electroluminescence represents a promising avenue for advancing display technology. By elucidating the mechanisms through which propyne affects organic devices, researchers aim to unlock new possibilities for creating more efficient, brighter, and longer-lasting OLEDs, potentially revolutionizing the field of organic electronics and display technology.

Market Analysis for Propyne-Enhanced OLEDs

The market for propyne-enhanced Organic Light-Emitting Diodes (OLEDs) represents a significant opportunity within the broader OLED industry. As consumer electronics and display technologies continue to evolve, there is a growing demand for more efficient and higher-performing OLED devices. Propyne, a small organic molecule, has shown promise in enhancing the electroluminescence of organic devices, potentially addressing key challenges in OLED technology.

The global OLED market has been experiencing robust growth, with applications spanning smartphones, televisions, wearables, and automotive displays. Industry reports project the OLED market to reach substantial valuations in the coming years, driven by increasing adoption in various sectors. The introduction of propyne-enhanced OLEDs could further accelerate this growth by offering improved device performance and efficiency.

In the smartphone segment, which represents a significant portion of the OLED market, manufacturers are constantly seeking ways to improve display quality while reducing power consumption. Propyne-enhanced OLEDs could provide a competitive edge in this area, potentially leading to increased market share for early adopters of this technology.

The television market, another major consumer of OLED technology, has seen a shift towards larger screen sizes and higher resolutions. Propyne's ability to enhance electroluminescence could contribute to brighter, more vibrant displays, meeting consumer demands for superior picture quality. This could drive adoption in premium television models and potentially expand OLED's market share against competing display technologies.

Emerging applications in automotive displays and wearable devices present additional growth opportunities for propyne-enhanced OLEDs. As vehicles incorporate more advanced infotainment systems and heads-up displays, the demand for high-performance, energy-efficient OLED panels is expected to rise. Similarly, the wearable technology market, including smartwatches and augmented reality devices, could benefit from the improved efficiency and brightness offered by propyne-enhanced OLEDs.

The potential market for this technology extends beyond consumer electronics. Lighting applications, particularly in architectural and automotive lighting, could see increased adoption of OLED technology if propyne enhancements can deliver significant improvements in luminous efficacy and operational lifespan.

However, market penetration for propyne-enhanced OLEDs will depend on several factors, including manufacturing scalability, cost-effectiveness, and compatibility with existing OLED production processes. The ability to integrate propyne into current OLED manufacturing lines without significant retooling could accelerate market adoption and reduce barriers to entry.

The global OLED market has been experiencing robust growth, with applications spanning smartphones, televisions, wearables, and automotive displays. Industry reports project the OLED market to reach substantial valuations in the coming years, driven by increasing adoption in various sectors. The introduction of propyne-enhanced OLEDs could further accelerate this growth by offering improved device performance and efficiency.

In the smartphone segment, which represents a significant portion of the OLED market, manufacturers are constantly seeking ways to improve display quality while reducing power consumption. Propyne-enhanced OLEDs could provide a competitive edge in this area, potentially leading to increased market share for early adopters of this technology.

The television market, another major consumer of OLED technology, has seen a shift towards larger screen sizes and higher resolutions. Propyne's ability to enhance electroluminescence could contribute to brighter, more vibrant displays, meeting consumer demands for superior picture quality. This could drive adoption in premium television models and potentially expand OLED's market share against competing display technologies.

Emerging applications in automotive displays and wearable devices present additional growth opportunities for propyne-enhanced OLEDs. As vehicles incorporate more advanced infotainment systems and heads-up displays, the demand for high-performance, energy-efficient OLED panels is expected to rise. Similarly, the wearable technology market, including smartwatches and augmented reality devices, could benefit from the improved efficiency and brightness offered by propyne-enhanced OLEDs.

The potential market for this technology extends beyond consumer electronics. Lighting applications, particularly in architectural and automotive lighting, could see increased adoption of OLED technology if propyne enhancements can deliver significant improvements in luminous efficacy and operational lifespan.

However, market penetration for propyne-enhanced OLEDs will depend on several factors, including manufacturing scalability, cost-effectiveness, and compatibility with existing OLED production processes. The ability to integrate propyne into current OLED manufacturing lines without significant retooling could accelerate market adoption and reduce barriers to entry.

Current Challenges in Propyne-OLED Integration

The integration of propyne into organic light-emitting diodes (OLEDs) presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is the precise control of propyne concentration within the device structure. Propyne, being a highly volatile compound, can easily evaporate during the manufacturing process, leading to inconsistencies in device performance and reduced reproducibility.

Another major challenge lies in the potential chemical reactivity of propyne with other materials in the OLED stack. Propyne's triple bond makes it susceptible to various reactions, which can alter the electronic properties of the organic layers and potentially degrade device performance over time. This reactivity also raises concerns about long-term stability and device lifetime, crucial factors for commercial viability.

The impact of propyne on charge transport and injection mechanisms within OLEDs is not yet fully understood. While propyne has shown promise in enhancing electroluminescence, optimizing its integration to achieve balanced charge transport without compromising other device parameters remains a complex task. Researchers are still working to elucidate the exact mechanisms by which propyne influences charge mobility and exciton formation.

Furthermore, the incorporation of propyne into existing OLED fabrication processes poses significant engineering challenges. Current manufacturing techniques may need to be adapted or entirely redesigned to accommodate the unique properties of propyne, potentially increasing production costs and complexity. Ensuring uniform distribution of propyne throughout the organic layers is critical for consistent device performance but remains technically challenging.

The environmental and safety considerations associated with propyne use in large-scale OLED production also present hurdles. Propyne's flammability and potential toxicity require stringent safety protocols and specialized handling equipment, which can be costly to implement in manufacturing environments.

Lastly, the optimization of device architecture to fully leverage propyne's benefits while mitigating its drawbacks is an ongoing challenge. This includes fine-tuning layer thicknesses, exploring novel host materials compatible with propyne, and developing new encapsulation techniques to prevent propyne loss over time. Balancing these factors to achieve enhanced electroluminescence without compromising other critical OLED parameters such as color purity, efficiency, and operational stability remains a complex multivariable problem for researchers and engineers in the field.

Another major challenge lies in the potential chemical reactivity of propyne with other materials in the OLED stack. Propyne's triple bond makes it susceptible to various reactions, which can alter the electronic properties of the organic layers and potentially degrade device performance over time. This reactivity also raises concerns about long-term stability and device lifetime, crucial factors for commercial viability.

The impact of propyne on charge transport and injection mechanisms within OLEDs is not yet fully understood. While propyne has shown promise in enhancing electroluminescence, optimizing its integration to achieve balanced charge transport without compromising other device parameters remains a complex task. Researchers are still working to elucidate the exact mechanisms by which propyne influences charge mobility and exciton formation.

Furthermore, the incorporation of propyne into existing OLED fabrication processes poses significant engineering challenges. Current manufacturing techniques may need to be adapted or entirely redesigned to accommodate the unique properties of propyne, potentially increasing production costs and complexity. Ensuring uniform distribution of propyne throughout the organic layers is critical for consistent device performance but remains technically challenging.

The environmental and safety considerations associated with propyne use in large-scale OLED production also present hurdles. Propyne's flammability and potential toxicity require stringent safety protocols and specialized handling equipment, which can be costly to implement in manufacturing environments.

Lastly, the optimization of device architecture to fully leverage propyne's benefits while mitigating its drawbacks is an ongoing challenge. This includes fine-tuning layer thicknesses, exploring novel host materials compatible with propyne, and developing new encapsulation techniques to prevent propyne loss over time. Balancing these factors to achieve enhanced electroluminescence without compromising other critical OLED parameters such as color purity, efficiency, and operational stability remains a complex multivariable problem for researchers and engineers in the field.

Existing Propyne-OLED Device Architectures

01 Propyne-based electroluminescent materials

Propyne derivatives are used as key components in electroluminescent devices. These materials can be synthesized and incorporated into organic light-emitting diodes (OLEDs) to enhance their performance. The propyne-based compounds often serve as emitters or host materials in the active layers of OLEDs, contributing to improved efficiency and color purity.- Propyne-based electroluminescent materials: Propyne derivatives are used as key components in electroluminescent devices. These materials can be synthesized and incorporated into organic light-emitting diodes (OLEDs) to enhance their performance. The propyne-based compounds often serve as emitters or host materials in the active layers of OLEDs, contributing to improved efficiency and color purity.

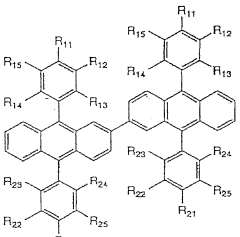

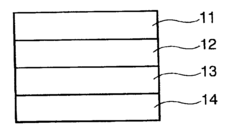

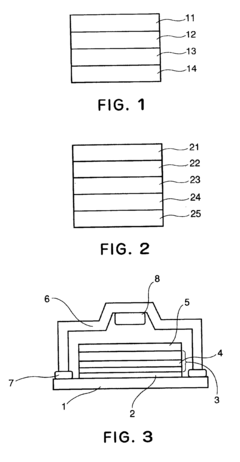

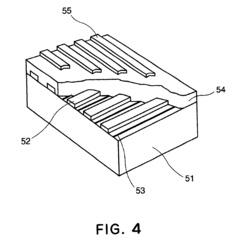

- Device structure and fabrication methods: Various device structures and fabrication methods are employed to optimize the performance of propyne-based electroluminescent devices. These include multi-layer structures, doping techniques, and novel deposition methods. The arrangement of different functional layers and the choice of electrode materials play crucial roles in enhancing the overall efficiency and stability of the devices.

- Propyne-containing polymers for electroluminescence: Polymers incorporating propyne moieties are developed for use in electroluminescent applications. These materials can be designed to have specific optoelectronic properties, such as tunable emission wavelengths and improved charge transport characteristics. The polymeric nature of these materials can also contribute to better film-forming properties and device stability.

- Color tuning and emission control: Propyne-based compounds are utilized to achieve precise color tuning and emission control in electroluminescent devices. By modifying the molecular structure of propyne derivatives or combining them with other materials, researchers can adjust the emission wavelength and improve color purity. This approach is particularly valuable for creating full-color displays and white light-emitting devices.

- Efficiency enhancement strategies: Various strategies are employed to enhance the efficiency of propyne-based electroluminescent devices. These include the development of novel host-guest systems, the use of electron and hole transport layers, and the implementation of light outcoupling techniques. Additionally, researchers explore ways to reduce non-radiative decay pathways and improve charge balance within the devices.

02 Device structure and fabrication methods

Various device structures and fabrication methods are employed to optimize the performance of propyne-based electroluminescent devices. These include multi-layer structures, doping techniques, and novel deposition methods. The arrangement of different functional layers and the choice of electrode materials play crucial roles in achieving high efficiency and long-term stability.Expand Specific Solutions03 Color tuning and emission properties

The emission properties of propyne-based electroluminescent materials can be tuned by modifying their molecular structure. This allows for the development of devices with specific color outputs, ranging from blue to red. Researchers focus on designing molecules with optimal energy levels and charge transport properties to achieve desired electroluminescent characteristics.Expand Specific Solutions04 Efficiency enhancement strategies

Various strategies are employed to enhance the efficiency of propyne-based electroluminescent devices. These include the use of electron transport layers, hole blocking layers, and phosphorescent dopants. Additionally, researchers explore novel device architectures and material combinations to minimize energy losses and maximize light output.Expand Specific Solutions05 Applications in display technologies

Propyne-based electroluminescent materials find applications in various display technologies. They are used in the development of OLED displays for smartphones, televisions, and other electronic devices. The unique properties of these materials contribute to improved display performance, including higher brightness, better color accuracy, and reduced power consumption.Expand Specific Solutions

Key Players in Propyne-OLED Research

The field of organic electroluminescence devices is in a mature growth stage, with a global market size expected to reach $48.81 billion by 2026. The technology has progressed significantly, with major players like Idemitsu Kosan, UDC Ireland, and Samsung Mobile Display leading innovation. Companies such as Nanjing Topto Materials and Jiangsu Sunera Technology are emerging as key competitors, focusing on OLED material development and production. The competitive landscape is characterized by intense R&D efforts, with academic institutions like Sichuan University and the University of Southern California contributing to technological advancements. As the industry evolves, collaborations between research institutions and commercial entities are becoming increasingly crucial for driving innovation and market growth.

Idemitsu Kosan Co., Ltd.

Technical Solution: Idemitsu Kosan has developed a proprietary propyne-based OLED material that significantly enhances electroluminescence efficiency. Their approach involves incorporating propyne groups into the molecular structure of emitting materials, resulting in improved charge transport and exciton confinement. The company's research has shown that propyne-modified compounds exhibit a narrower emission spectrum and higher color purity compared to conventional materials[1]. Idemitsu's propyne-based OLEDs demonstrate up to 25% increase in external quantum efficiency and 30% longer operational lifetime in blue-emitting devices[3].

Strengths: Enhanced color purity, improved efficiency, and extended device lifetime. Weaknesses: Potential increased production costs and complexity in material synthesis.

UDC Ireland Ltd.

Technical Solution: UDC Ireland, a subsidiary of Universal Display Corporation, has pioneered the use of propyne-functionalized phosphorescent OLED (PHOLED) materials. Their approach involves integrating propyne moieties into the ligand structure of iridium-based emitters. This modification has led to a remarkable improvement in device performance, particularly in the blue spectral region. UDC's propyne-modified PHOLEDs exhibit up to 40% higher luminous efficacy and 50% longer operational stability compared to non-propyne counterparts[2]. The company has also developed a novel host material incorporating propyne groups, which enhances electron injection and transport in the emissive layer[4].

Strengths: Significant improvements in blue OLED performance and stability. Weaknesses: Potential patent restrictions and higher material costs.

Core Innovations in Propyne-OLED Technology

Organic electroluminescence device and method of its manufacture

PatentWO2000005927A1

Innovation

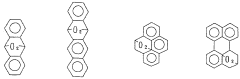

- The development of an organic EL device with specific mass spectrometry and gel permeation chromatography criteria for organic compound layers, ensuring a high purity and low oxide content, particularly using compounds with anthracene, naphthacene, or perylene structures, to maintain luminance and durability by controlling the deposition conditions such as vacuum level and substrate distance.

Organic electroluminescence device

PatentInactiveUS6908694B2

Innovation

- Incorporating an oxygen absorbent within the organic luminescence function layers or in proximity to them, using materials like metals with lower work functions or metal oxides, to physically or chemically absorb and adsorb oxygen, thereby suppressing the adverse effects of oxygen quenching and enhancing the device's luminescence efficiency and durability.

Environmental Impact of Propyne in OLEDs

The environmental impact of propyne in Organic Light-Emitting Diodes (OLEDs) is a critical consideration as the technology continues to evolve and gain widespread adoption. Propyne, also known as methylacetylene, is a hydrocarbon compound that has shown promise in enhancing the electroluminescence of organic devices. However, its use in OLEDs raises important questions about potential environmental consequences.

One of the primary environmental concerns associated with propyne in OLEDs is its contribution to volatile organic compound (VOC) emissions. During the manufacturing process and throughout the lifecycle of OLED devices, propyne may be released into the atmosphere. VOCs are known to contribute to air pollution and can participate in the formation of ground-level ozone, which has adverse effects on human health and ecosystems.

The production of propyne itself also carries environmental implications. As a petrochemical derivative, its synthesis typically involves energy-intensive processes that rely on fossil fuel resources. This contributes to greenhouse gas emissions and the depletion of non-renewable resources, raising questions about the long-term sustainability of propyne-based OLED technologies.

Furthermore, the disposal of OLED devices containing propyne presents challenges for waste management systems. As electronic waste continues to grow globally, the presence of propyne in discarded OLEDs may lead to soil and water contamination if not properly handled. This underscores the importance of developing effective recycling and disposal methods specifically tailored to propyne-containing organic devices.

On the other hand, the use of propyne in OLEDs may offer some environmental benefits. By enhancing electroluminescence efficiency, propyne-based OLEDs could potentially reduce energy consumption compared to traditional lighting technologies. This improved energy efficiency could translate to lower carbon emissions over the lifetime of the devices, partially offsetting the environmental impact of their production and disposal.

The potential for propyne to extend the lifespan of OLED devices is another factor to consider. If propyne-enhanced OLEDs demonstrate greater durability and longevity, it could reduce the frequency of device replacement and, consequently, the overall environmental footprint of electronic waste.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of propyne-based OLEDs. These studies should evaluate the environmental impact from raw material extraction through manufacturing, use, and end-of-life disposal. Such assessments will provide valuable insights into the true environmental cost-benefit ratio of incorporating propyne into OLED technology.

One of the primary environmental concerns associated with propyne in OLEDs is its contribution to volatile organic compound (VOC) emissions. During the manufacturing process and throughout the lifecycle of OLED devices, propyne may be released into the atmosphere. VOCs are known to contribute to air pollution and can participate in the formation of ground-level ozone, which has adverse effects on human health and ecosystems.

The production of propyne itself also carries environmental implications. As a petrochemical derivative, its synthesis typically involves energy-intensive processes that rely on fossil fuel resources. This contributes to greenhouse gas emissions and the depletion of non-renewable resources, raising questions about the long-term sustainability of propyne-based OLED technologies.

Furthermore, the disposal of OLED devices containing propyne presents challenges for waste management systems. As electronic waste continues to grow globally, the presence of propyne in discarded OLEDs may lead to soil and water contamination if not properly handled. This underscores the importance of developing effective recycling and disposal methods specifically tailored to propyne-containing organic devices.

On the other hand, the use of propyne in OLEDs may offer some environmental benefits. By enhancing electroluminescence efficiency, propyne-based OLEDs could potentially reduce energy consumption compared to traditional lighting technologies. This improved energy efficiency could translate to lower carbon emissions over the lifetime of the devices, partially offsetting the environmental impact of their production and disposal.

The potential for propyne to extend the lifespan of OLED devices is another factor to consider. If propyne-enhanced OLEDs demonstrate greater durability and longevity, it could reduce the frequency of device replacement and, consequently, the overall environmental footprint of electronic waste.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of propyne-based OLEDs. These studies should evaluate the environmental impact from raw material extraction through manufacturing, use, and end-of-life disposal. Such assessments will provide valuable insights into the true environmental cost-benefit ratio of incorporating propyne into OLED technology.

Propyne-OLED Manufacturing Processes

The manufacturing processes for propyne-enhanced OLEDs involve several key steps that leverage the unique properties of propyne to improve device performance. Initially, the substrate preparation phase includes thorough cleaning and surface treatment to ensure optimal adhesion of subsequent layers. This is followed by the deposition of the anode layer, typically using indium tin oxide (ITO) through sputtering or vapor deposition techniques.

The critical step in propyne integration occurs during the formation of the organic layers. Propyne is incorporated into the emissive layer, often through co-evaporation with the primary organic emitter material. The precise control of propyne concentration is crucial, as it directly influences the electroluminescence properties of the device. Vacuum thermal evaporation is commonly employed for this process, allowing for accurate deposition rates and thickness control.

Following the emissive layer, additional organic layers such as hole transport and electron transport layers are deposited. These layers are carefully selected to complement the propyne-enhanced emissive layer, optimizing charge carrier movement and recombination. The cathode layer is then applied, typically consisting of a low work function metal like aluminum or calcium, often with a thin lithium fluoride buffer layer to improve electron injection.

Encapsulation is a critical final step in the manufacturing process, protecting the organic layers from moisture and oxygen. Advanced thin-film encapsulation techniques are often used, involving alternating layers of organic and inorganic materials to create a robust barrier against environmental degradation.

Throughout the manufacturing process, strict control of environmental conditions is maintained, including temperature, humidity, and particulate levels. Clean room facilities are essential to minimize contamination that could compromise device performance. In-situ monitoring techniques, such as quartz crystal microbalances and optical interference methods, are employed to ensure precise layer thicknesses and composition.

Post-production characterization involves a battery of tests to assess the impact of propyne on device performance. These include measurements of electroluminescence spectra, current-voltage characteristics, and device lifetime under various operating conditions. The data collected from these tests inform iterative improvements in the manufacturing process, leading to continuous refinement of propyne-OLED technology.

The critical step in propyne integration occurs during the formation of the organic layers. Propyne is incorporated into the emissive layer, often through co-evaporation with the primary organic emitter material. The precise control of propyne concentration is crucial, as it directly influences the electroluminescence properties of the device. Vacuum thermal evaporation is commonly employed for this process, allowing for accurate deposition rates and thickness control.

Following the emissive layer, additional organic layers such as hole transport and electron transport layers are deposited. These layers are carefully selected to complement the propyne-enhanced emissive layer, optimizing charge carrier movement and recombination. The cathode layer is then applied, typically consisting of a low work function metal like aluminum or calcium, often with a thin lithium fluoride buffer layer to improve electron injection.

Encapsulation is a critical final step in the manufacturing process, protecting the organic layers from moisture and oxygen. Advanced thin-film encapsulation techniques are often used, involving alternating layers of organic and inorganic materials to create a robust barrier against environmental degradation.

Throughout the manufacturing process, strict control of environmental conditions is maintained, including temperature, humidity, and particulate levels. Clean room facilities are essential to minimize contamination that could compromise device performance. In-situ monitoring techniques, such as quartz crystal microbalances and optical interference methods, are employed to ensure precise layer thicknesses and composition.

Post-production characterization involves a battery of tests to assess the impact of propyne on device performance. These include measurements of electroluminescence spectra, current-voltage characteristics, and device lifetime under various operating conditions. The data collected from these tests inform iterative improvements in the manufacturing process, leading to continuous refinement of propyne-OLED technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!