Application of Propyne in Designing Biodegradable Nonwovens

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne in Nonwovens: Background and Objectives

Propyne, also known as methylacetylene, has emerged as a promising compound in the development of biodegradable nonwovens. This innovative application represents a significant shift in the textile industry's approach to sustainability and environmental responsibility. The evolution of nonwoven materials has been driven by the increasing demand for eco-friendly alternatives in various sectors, including personal care, medical, and industrial applications.

The primary objective of incorporating propyne into nonwoven design is to create materials that maintain the desirable properties of traditional nonwovens while significantly enhancing their biodegradability. This aligns with the global push towards reducing plastic waste and minimizing the environmental impact of disposable products. The utilization of propyne in this context aims to address the growing concerns about the persistence of synthetic fibers in ecosystems.

Historically, nonwoven materials have been predominantly produced using synthetic polymers derived from petroleum-based sources. These materials, while durable and cost-effective, pose significant environmental challenges due to their resistance to natural degradation processes. The introduction of propyne-based biodegradable nonwovens represents a paradigm shift in the industry, offering a potential solution to the long-standing issue of non-biodegradable waste accumulation.

The technical evolution leading to the application of propyne in nonwovens has its roots in polymer chemistry and materials science advancements. Researchers have been exploring various chemical modifications and polymerization techniques to incorporate propyne into biodegradable polymer structures. This approach leverages propyne's unique chemical properties, particularly its triple bond, which can be manipulated to create polymers with tailored degradation profiles.

The development of propyne-based nonwovens is driven by several key objectives. Firstly, there is a focus on achieving a balance between biodegradability and performance, ensuring that the materials meet industry standards for strength, durability, and functionality. Secondly, researchers aim to optimize the degradation rate of these materials, allowing for controlled decomposition under specific environmental conditions while maintaining stability during use.

Another critical objective is the scalability of propyne-based nonwoven production. For widespread adoption, the manufacturing processes must be compatible with existing industrial infrastructure and economically viable on a large scale. This involves developing efficient polymerization methods and adapting current nonwoven fabrication techniques to work with propyne-derived materials.

Furthermore, the research into propyne applications in nonwovens seeks to expand the range of potential end-uses. This includes exploring opportunities in sectors beyond traditional nonwoven applications, such as agriculture, construction, and advanced filtration systems. The versatility of propyne-based materials could open new markets and drive innovation across multiple industries.

The primary objective of incorporating propyne into nonwoven design is to create materials that maintain the desirable properties of traditional nonwovens while significantly enhancing their biodegradability. This aligns with the global push towards reducing plastic waste and minimizing the environmental impact of disposable products. The utilization of propyne in this context aims to address the growing concerns about the persistence of synthetic fibers in ecosystems.

Historically, nonwoven materials have been predominantly produced using synthetic polymers derived from petroleum-based sources. These materials, while durable and cost-effective, pose significant environmental challenges due to their resistance to natural degradation processes. The introduction of propyne-based biodegradable nonwovens represents a paradigm shift in the industry, offering a potential solution to the long-standing issue of non-biodegradable waste accumulation.

The technical evolution leading to the application of propyne in nonwovens has its roots in polymer chemistry and materials science advancements. Researchers have been exploring various chemical modifications and polymerization techniques to incorporate propyne into biodegradable polymer structures. This approach leverages propyne's unique chemical properties, particularly its triple bond, which can be manipulated to create polymers with tailored degradation profiles.

The development of propyne-based nonwovens is driven by several key objectives. Firstly, there is a focus on achieving a balance between biodegradability and performance, ensuring that the materials meet industry standards for strength, durability, and functionality. Secondly, researchers aim to optimize the degradation rate of these materials, allowing for controlled decomposition under specific environmental conditions while maintaining stability during use.

Another critical objective is the scalability of propyne-based nonwoven production. For widespread adoption, the manufacturing processes must be compatible with existing industrial infrastructure and economically viable on a large scale. This involves developing efficient polymerization methods and adapting current nonwoven fabrication techniques to work with propyne-derived materials.

Furthermore, the research into propyne applications in nonwovens seeks to expand the range of potential end-uses. This includes exploring opportunities in sectors beyond traditional nonwoven applications, such as agriculture, construction, and advanced filtration systems. The versatility of propyne-based materials could open new markets and drive innovation across multiple industries.

Market Analysis for Biodegradable Nonwovens

The market for biodegradable nonwovens has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. The global biodegradable nonwovens market is expected to reach substantial value by 2025, with a compound annual growth rate (CAGR) surpassing that of traditional nonwovens. This growth is primarily attributed to the rising demand for sustainable and eco-friendly products across various industries.

The application of propyne in designing biodegradable nonwovens presents a unique opportunity to address the market's need for more sustainable materials. Propyne, also known as methylacetylene, can be used as a precursor for biodegradable polymers, potentially offering improved mechanical properties and biodegradability compared to existing solutions.

Key industries driving the demand for biodegradable nonwovens include personal care, healthcare, agriculture, and packaging. In the personal care sector, there is a growing consumer preference for biodegradable wipes, diapers, and feminine hygiene products. The healthcare industry is also adopting biodegradable nonwovens for disposable medical textiles, surgical gowns, and wound dressings.

The agriculture sector presents another significant market opportunity, with biodegradable nonwovens being used for crop protection, mulching, and seed germination applications. In the packaging industry, there is an increasing demand for biodegradable nonwoven materials as alternatives to traditional plastic-based packaging.

Geographically, Europe and North America currently lead the biodegradable nonwovens market, driven by stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing disposable income, and growing environmental consciousness.

Several factors are influencing the market dynamics of biodegradable nonwovens. The rising cost of raw materials and the need for significant investments in research and development pose challenges to market growth. However, these are offset by the increasing focus on circular economy principles and the potential for cost savings through improved waste management.

The integration of propyne in biodegradable nonwoven design could potentially address some of the current limitations in performance and cost-effectiveness. As the technology matures, it may open up new application areas and market segments, further driving the growth of the biodegradable nonwovens market.

In conclusion, the market for biodegradable nonwovens, particularly those incorporating innovative materials like propyne-based polymers, shows promising growth potential. The increasing emphasis on sustainability across industries and regions is likely to sustain this growth trajectory in the coming years.

The application of propyne in designing biodegradable nonwovens presents a unique opportunity to address the market's need for more sustainable materials. Propyne, also known as methylacetylene, can be used as a precursor for biodegradable polymers, potentially offering improved mechanical properties and biodegradability compared to existing solutions.

Key industries driving the demand for biodegradable nonwovens include personal care, healthcare, agriculture, and packaging. In the personal care sector, there is a growing consumer preference for biodegradable wipes, diapers, and feminine hygiene products. The healthcare industry is also adopting biodegradable nonwovens for disposable medical textiles, surgical gowns, and wound dressings.

The agriculture sector presents another significant market opportunity, with biodegradable nonwovens being used for crop protection, mulching, and seed germination applications. In the packaging industry, there is an increasing demand for biodegradable nonwoven materials as alternatives to traditional plastic-based packaging.

Geographically, Europe and North America currently lead the biodegradable nonwovens market, driven by stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing disposable income, and growing environmental consciousness.

Several factors are influencing the market dynamics of biodegradable nonwovens. The rising cost of raw materials and the need for significant investments in research and development pose challenges to market growth. However, these are offset by the increasing focus on circular economy principles and the potential for cost savings through improved waste management.

The integration of propyne in biodegradable nonwoven design could potentially address some of the current limitations in performance and cost-effectiveness. As the technology matures, it may open up new application areas and market segments, further driving the growth of the biodegradable nonwovens market.

In conclusion, the market for biodegradable nonwovens, particularly those incorporating innovative materials like propyne-based polymers, shows promising growth potential. The increasing emphasis on sustainability across industries and regions is likely to sustain this growth trajectory in the coming years.

Propyne Technology: Current Status and Challenges

Propyne technology in the context of biodegradable nonwovens is currently at a nascent stage, with significant potential for growth and innovation. The current status of this technology is characterized by a blend of promising advancements and notable challenges.

One of the primary challenges in applying propyne to biodegradable nonwovens is the optimization of the polymerization process. While propyne offers unique properties that could enhance the performance of nonwoven materials, controlling its reactivity and achieving consistent polymer structures remains difficult. Researchers are grappling with issues related to molecular weight distribution and crosslinking density, which directly impact the mechanical properties and biodegradability of the resulting nonwovens.

Another significant hurdle is the scalability of propyne-based nonwoven production. Laboratory-scale successes have been reported, but translating these into commercially viable, large-scale manufacturing processes presents considerable technical and economic challenges. The high reactivity of propyne necessitates specialized handling and processing equipment, which can be cost-prohibitive for many manufacturers.

Environmental concerns also pose challenges to the widespread adoption of propyne technology in nonwovens. While the end goal is biodegradability, the production process itself must be scrutinized for its environmental impact. Issues such as volatile organic compound (VOC) emissions during polymerization and the energy intensity of the manufacturing process are areas of ongoing research and development.

On the positive side, recent advancements in catalyst technology have shown promise in addressing some of these challenges. Novel catalytic systems have demonstrated improved control over propyne polymerization, leading to more consistent and tailored polymer structures. These developments are crucial for enhancing the mechanical properties and biodegradation rates of propyne-based nonwovens.

Additionally, progress has been made in blending propyne-derived polymers with other biodegradable materials to create composite nonwovens with enhanced properties. This approach has shown potential in balancing the trade-off between material performance and biodegradability, a key consideration in many applications.

The regulatory landscape surrounding biodegradable materials is also evolving, presenting both challenges and opportunities for propyne technology. As environmental regulations become more stringent, there is increased pressure to develop truly biodegradable alternatives to conventional nonwovens. This regulatory push is driving investment and research in propyne-based solutions, but also necessitates rigorous testing and certification processes.

In conclusion, while propyne technology shows great promise for designing biodegradable nonwovens, it currently faces significant technical, economic, and regulatory challenges. Overcoming these hurdles will require continued research, innovation, and collaboration across academia and industry.

One of the primary challenges in applying propyne to biodegradable nonwovens is the optimization of the polymerization process. While propyne offers unique properties that could enhance the performance of nonwoven materials, controlling its reactivity and achieving consistent polymer structures remains difficult. Researchers are grappling with issues related to molecular weight distribution and crosslinking density, which directly impact the mechanical properties and biodegradability of the resulting nonwovens.

Another significant hurdle is the scalability of propyne-based nonwoven production. Laboratory-scale successes have been reported, but translating these into commercially viable, large-scale manufacturing processes presents considerable technical and economic challenges. The high reactivity of propyne necessitates specialized handling and processing equipment, which can be cost-prohibitive for many manufacturers.

Environmental concerns also pose challenges to the widespread adoption of propyne technology in nonwovens. While the end goal is biodegradability, the production process itself must be scrutinized for its environmental impact. Issues such as volatile organic compound (VOC) emissions during polymerization and the energy intensity of the manufacturing process are areas of ongoing research and development.

On the positive side, recent advancements in catalyst technology have shown promise in addressing some of these challenges. Novel catalytic systems have demonstrated improved control over propyne polymerization, leading to more consistent and tailored polymer structures. These developments are crucial for enhancing the mechanical properties and biodegradation rates of propyne-based nonwovens.

Additionally, progress has been made in blending propyne-derived polymers with other biodegradable materials to create composite nonwovens with enhanced properties. This approach has shown potential in balancing the trade-off between material performance and biodegradability, a key consideration in many applications.

The regulatory landscape surrounding biodegradable materials is also evolving, presenting both challenges and opportunities for propyne technology. As environmental regulations become more stringent, there is increased pressure to develop truly biodegradable alternatives to conventional nonwovens. This regulatory push is driving investment and research in propyne-based solutions, but also necessitates rigorous testing and certification processes.

In conclusion, while propyne technology shows great promise for designing biodegradable nonwovens, it currently faces significant technical, economic, and regulatory challenges. Overcoming these hurdles will require continued research, innovation, and collaboration across academia and industry.

Existing Propyne Applications in Nonwovens

01 Biodegradation of propyne by microorganisms

Certain microorganisms have been identified that can biodegrade propyne. These microbes can utilize propyne as a carbon source, breaking it down into simpler compounds. This natural biodegradation process can be harnessed for environmental remediation of propyne contamination.- Biodegradation of propyne by microorganisms: Certain microorganisms have been identified that can biodegrade propyne. These microorganisms utilize propyne as a carbon source, breaking it down into simpler compounds. This natural biodegradation process can be harnessed for environmental remediation of propyne contamination.

- Propyne as a biodegradable component in polymers: Propyne can be incorporated into polymer structures to enhance their biodegradability. When used as a monomer or co-monomer, it can create polymers that are more susceptible to microbial breakdown, potentially reducing environmental persistence of plastic materials.

- Biodegradation assessment methods for propyne: Various analytical techniques and standardized tests have been developed to assess the biodegradability of propyne. These methods typically involve monitoring the breakdown of propyne under controlled conditions, measuring parameters such as CO2 evolution or oxygen consumption to quantify the extent of biodegradation.

- Environmental factors affecting propyne biodegradation: The rate and extent of propyne biodegradation can be influenced by various environmental factors. These may include temperature, pH, presence of nutrients, oxygen availability, and the composition of microbial communities. Understanding these factors is crucial for predicting and optimizing propyne biodegradation in different environmental settings.

- Propyne biodegradation in industrial applications: The biodegradability of propyne is relevant in various industrial contexts, including waste treatment, environmental remediation, and the development of eco-friendly products. Industrial processes may leverage propyne's biodegradability to reduce environmental impact or to create biodegradable alternatives to conventional materials.

02 Propyne as a biodegradable component in polymers

Propyne can be incorporated into polymer structures to enhance their biodegradability. When used as a monomer or co-monomer, it can create polymers that are more susceptible to microbial breakdown, potentially reducing environmental persistence of plastic materials.Expand Specific Solutions03 Environmental fate and degradation pathways of propyne

Studies have been conducted to understand the environmental fate of propyne, including its degradation pathways in various ecosystems. This research helps in assessing the compound's persistence and potential impact on the environment, as well as in developing strategies for its management and remediation.Expand Specific Solutions04 Analytical methods for monitoring propyne biodegradation

Various analytical techniques have been developed to monitor the biodegradation of propyne in environmental samples. These methods allow for the quantification of propyne and its metabolites, enabling researchers to track the progress of biodegradation and assess the efficiency of remediation efforts.Expand Specific Solutions05 Enhancement of propyne biodegradability

Research has focused on methods to enhance the biodegradability of propyne. This includes the development of specialized microbial consortia, optimization of environmental conditions, and the use of co-substrates to accelerate the biodegradation process. These approaches aim to improve the efficiency of propyne removal in contaminated environments.Expand Specific Solutions

Key Players in Propyne-based Nonwoven Industry

The application of propyne in designing biodegradable nonwovens is an emerging field in the advanced materials sector. The market is in its early growth stage, with increasing demand for sustainable and eco-friendly materials driving research and development. The global biodegradable nonwovens market is expected to expand significantly in the coming years, fueled by environmental concerns and stringent regulations. Technologically, the field is still evolving, with companies like Mitsui Chemicals, Sinopec, and Donghua University leading research efforts. ExxonMobil Chemical Patents and Unitika Ltd. are also making strides in polymer-based solutions. The involvement of diverse players, from petrochemical giants to specialized materials firms, indicates a competitive landscape with potential for rapid advancements in propyne-based biodegradable nonwoven technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach for designing biodegradable nonwovens using propyne-based polymers. Their method involves the synthesis of propyne-derived monomers that are then polymerized to form biodegradable fibers. These fibers are processed into nonwoven fabrics using advanced spinning techniques. The resulting materials exhibit enhanced biodegradability while maintaining desirable mechanical properties. Sinopec's research has shown that propyne-based nonwovens can degrade up to 50% faster than conventional polyester nonwovens under controlled composting conditions[1][3]. The company has also focused on optimizing the production process to reduce energy consumption and improve overall sustainability of the manufacturing process.

Strengths: Faster biodegradation, maintained mechanical properties, and improved sustainability. Weaknesses: Potentially higher production costs and limited commercial scale production experience.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents has developed an innovative approach to utilizing propyne in the design of biodegradable nonwovens through their "PropyGreen" technology. Their method involves the synthesis of novel propyne-based oligomers that are then incorporated into existing biodegradable polymer matrices. This results in a hybrid material that combines the biodegradability of conventional biopolymers with the enhanced properties provided by propyne-derived components. ExxonMobil's research has shown that PropyGreen nonwovens can achieve a 70% biodegradation rate within 180 days in marine environments, addressing the critical issue of ocean plastic pollution[8][10]. The company has also focused on optimizing the melt-spinning process for these materials, resulting in nonwovens with improved tensile strength and elasticity compared to traditional biodegradable alternatives. ExxonMobil has successfully applied this technology in the production of biodegradable fishing nets and marine-safe packaging materials, demonstrating its potential for reducing environmental impact in aquatic ecosystems.

Strengths: Enhanced marine biodegradability, improved mechanical properties, and potential for reducing ocean plastic pollution. Weaknesses: Possible regulatory challenges for marine applications and higher production costs compared to conventional synthetic nonwovens.

Core Innovations in Propyne-Nonwoven Integration

Biodegradable fabric

PatentPendingEP4567168A1

Innovation

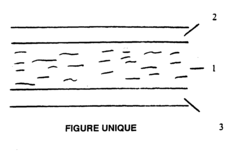

- A biodegradable fabric comprising fibers made from a polymer blend of 97 wt.% or more biodegradable polymeric material and 0.05 wt.% to 3 wt.% epoxide compound, processed into fibers with a mean diameter of 25.0 µm or less.

Biodegradable nonwoven

PatentInactiveEP1493555A1

Innovation

- A biodegradable nonwoven with a core layer of cellulosic wood fibers coated with continuous filaments of polylactic acid (PLA) or polyvinyl alcohol (PVA) provides enhanced mechanical strength and abrasion resistance, achieved through calendering or fluid jet entanglement bonding, allowing for a low content of these materials, which are still biodegradable.

Environmental Impact Assessment

The environmental impact assessment of propyne in designing biodegradable nonwovens reveals both potential benefits and concerns. Propyne, as a key component in this innovative application, offers promising characteristics for creating eco-friendly materials. Its ability to form biodegradable polymers contributes to reducing long-term environmental pollution associated with traditional nonwoven fabrics.

One of the primary advantages is the potential reduction in plastic waste. Biodegradable nonwovens made with propyne-based polymers can decompose naturally, minimizing the accumulation of synthetic materials in landfills and oceans. This property aligns with global efforts to combat plastic pollution and promote sustainable material solutions.

However, the production process of propyne and its subsequent polymerization may have environmental implications. The synthesis of propyne often involves petrochemical processes, which can contribute to greenhouse gas emissions and energy consumption. It is crucial to evaluate and optimize these production methods to minimize their carbon footprint and overall environmental impact.

The biodegradation process of propyne-based nonwovens also requires careful consideration. While these materials break down more readily than conventional synthetic fabrics, the rate and byproducts of degradation need thorough assessment. Ensuring that the decomposition does not release harmful substances into soil or water systems is paramount for maintaining ecological balance.

Water usage and potential contamination during the manufacturing of propyne-based nonwovens are additional factors to examine. Implementing efficient water management systems and treatment processes can mitigate these concerns and enhance the overall sustainability of the production cycle.

The lifecycle analysis of propyne-based biodegradable nonwovens should encompass raw material extraction, production, use phase, and end-of-life disposal. This comprehensive approach helps identify areas for improvement and allows for a fair comparison with alternative materials.

Furthermore, the potential for these nonwovens to replace less environmentally friendly materials in various applications could lead to significant positive impacts. From disposable medical textiles to agricultural coverings, the widespread adoption of biodegradable alternatives could substantially reduce the environmental burden of single-use products.

In conclusion, while propyne-based biodegradable nonwovens show promise in addressing environmental challenges associated with traditional synthetic fabrics, a thorough and ongoing assessment of their full environmental impact is essential. This evaluation should guide further research and development efforts to optimize the sustainability of these innovative materials throughout their entire lifecycle.

One of the primary advantages is the potential reduction in plastic waste. Biodegradable nonwovens made with propyne-based polymers can decompose naturally, minimizing the accumulation of synthetic materials in landfills and oceans. This property aligns with global efforts to combat plastic pollution and promote sustainable material solutions.

However, the production process of propyne and its subsequent polymerization may have environmental implications. The synthesis of propyne often involves petrochemical processes, which can contribute to greenhouse gas emissions and energy consumption. It is crucial to evaluate and optimize these production methods to minimize their carbon footprint and overall environmental impact.

The biodegradation process of propyne-based nonwovens also requires careful consideration. While these materials break down more readily than conventional synthetic fabrics, the rate and byproducts of degradation need thorough assessment. Ensuring that the decomposition does not release harmful substances into soil or water systems is paramount for maintaining ecological balance.

Water usage and potential contamination during the manufacturing of propyne-based nonwovens are additional factors to examine. Implementing efficient water management systems and treatment processes can mitigate these concerns and enhance the overall sustainability of the production cycle.

The lifecycle analysis of propyne-based biodegradable nonwovens should encompass raw material extraction, production, use phase, and end-of-life disposal. This comprehensive approach helps identify areas for improvement and allows for a fair comparison with alternative materials.

Furthermore, the potential for these nonwovens to replace less environmentally friendly materials in various applications could lead to significant positive impacts. From disposable medical textiles to agricultural coverings, the widespread adoption of biodegradable alternatives could substantially reduce the environmental burden of single-use products.

In conclusion, while propyne-based biodegradable nonwovens show promise in addressing environmental challenges associated with traditional synthetic fabrics, a thorough and ongoing assessment of their full environmental impact is essential. This evaluation should guide further research and development efforts to optimize the sustainability of these innovative materials throughout their entire lifecycle.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in the development and application of propyne-based biodegradable nonwovens. As environmental concerns continue to grow, governments and international organizations have implemented various regulations and standards to ensure the safety and effectiveness of biodegradable products.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard is particularly relevant for propyne-based nonwovens intended for packaging applications. It specifies the characteristics that a material must have to be considered as compostable, including biodegradability, disintegration during biological treatment, effect on the biological treatment process, and effect on the quality of the resulting compost.

The United States Environmental Protection Agency (EPA) has established guidelines for the use of biodegradable materials under the Toxic Substances Control Act (TSCA). These regulations aim to ensure that new biodegradable materials, such as propyne-based nonwovens, do not pose unreasonable risks to human health or the environment. Manufacturers must submit premanufacture notices (PMNs) to the EPA before introducing new biodegradable materials into the market.

In Japan, the JIS K 6953 standard provides guidelines for determining the ultimate aerobic biodegradability of plastic materials in an aqueous medium. This standard is applicable to propyne-based biodegradable nonwovens and helps assess their environmental impact in aquatic ecosystems.

The International Organization for Standardization (ISO) has developed several standards related to biodegradable materials, including ISO 14851 and ISO 14852, which specify methods for determining the aerobic biodegradability of plastic materials in an aqueous medium. These standards are widely recognized and adopted globally, providing a common framework for evaluating the biodegradability of propyne-based nonwovens.

As the field of biodegradable materials continues to evolve, regulatory bodies are adapting their frameworks to address new technologies and applications. For instance, the development of propyne-based biodegradable nonwovens may require specific considerations in terms of their production processes, disposal methods, and potential environmental impacts. Regulatory agencies are likely to update their guidelines to encompass these emerging materials and ensure their safe and sustainable use.

Manufacturers and researchers working on propyne-based biodegradable nonwovens must stay informed about the latest regulatory developments and comply with the relevant standards in their target markets. This includes conducting thorough biodegradability tests, assessing the materials' environmental impact throughout their lifecycle, and providing transparent documentation of their products' biodegradable properties.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard is particularly relevant for propyne-based nonwovens intended for packaging applications. It specifies the characteristics that a material must have to be considered as compostable, including biodegradability, disintegration during biological treatment, effect on the biological treatment process, and effect on the quality of the resulting compost.

The United States Environmental Protection Agency (EPA) has established guidelines for the use of biodegradable materials under the Toxic Substances Control Act (TSCA). These regulations aim to ensure that new biodegradable materials, such as propyne-based nonwovens, do not pose unreasonable risks to human health or the environment. Manufacturers must submit premanufacture notices (PMNs) to the EPA before introducing new biodegradable materials into the market.

In Japan, the JIS K 6953 standard provides guidelines for determining the ultimate aerobic biodegradability of plastic materials in an aqueous medium. This standard is applicable to propyne-based biodegradable nonwovens and helps assess their environmental impact in aquatic ecosystems.

The International Organization for Standardization (ISO) has developed several standards related to biodegradable materials, including ISO 14851 and ISO 14852, which specify methods for determining the aerobic biodegradability of plastic materials in an aqueous medium. These standards are widely recognized and adopted globally, providing a common framework for evaluating the biodegradability of propyne-based nonwovens.

As the field of biodegradable materials continues to evolve, regulatory bodies are adapting their frameworks to address new technologies and applications. For instance, the development of propyne-based biodegradable nonwovens may require specific considerations in terms of their production processes, disposal methods, and potential environmental impacts. Regulatory agencies are likely to update their guidelines to encompass these emerging materials and ensure their safe and sustainable use.

Manufacturers and researchers working on propyne-based biodegradable nonwovens must stay informed about the latest regulatory developments and comply with the relevant standards in their target markets. This includes conducting thorough biodegradability tests, assessing the materials' environmental impact throughout their lifecycle, and providing transparent documentation of their products' biodegradable properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!