Utilizing Propyne for Innovative Food Preservation Techniques

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Preservation Background and Objectives

Propyne, also known as methylacetylene, has emerged as a promising compound in the field of food preservation. This innovative approach to extending the shelf life of perishable goods has its roots in the broader context of food science and preservation techniques. The evolution of food preservation methods has been driven by the need to combat food spoilage, reduce waste, and ensure food safety for consumers worldwide.

Historically, food preservation techniques have ranged from traditional methods such as salting, drying, and fermentation to more modern approaches like refrigeration, canning, and chemical preservatives. However, as consumer preferences shift towards minimally processed foods with fewer artificial additives, there is a growing demand for novel preservation techniques that can maintain food quality without compromising nutritional value or taste.

The exploration of propyne as a food preservation agent represents a significant step forward in this field. Propyne, a colorless gas with a slightly sweet odor, belongs to the alkyne family of hydrocarbons. Its potential in food preservation stems from its unique chemical properties and interactions with biological systems. The primary objective of utilizing propyne in food preservation is to develop a method that effectively inhibits microbial growth and enzymatic reactions responsible for food spoilage, while maintaining the organoleptic properties of the food.

Research into propyne-based preservation techniques aims to address several key challenges in the food industry. These include extending the shelf life of fresh produce, reducing the reliance on synthetic preservatives, and developing preservation methods that are compatible with a wide range of food products. Additionally, there is a focus on creating preservation solutions that are environmentally friendly and cost-effective for large-scale implementation.

The development of propyne preservation technology is driven by the need to meet stringent food safety regulations while addressing consumer demands for "clean label" products. As such, the objectives of this research extend beyond mere preservation to encompass aspects of food quality, safety, and consumer acceptance. Researchers are exploring the optimal conditions for propyne application, including concentration levels, exposure times, and delivery methods that maximize efficacy while ensuring food safety.

Furthermore, the investigation into propyne preservation techniques aligns with broader trends in sustainable food production and distribution. By potentially reducing food waste and extending the geographical reach of perishable goods, propyne-based methods could contribute to more efficient food supply chains and improved food security on a global scale.

As the field progresses, researchers are also examining the potential synergies between propyne and other preservation methods, aiming to develop integrated approaches that leverage the strengths of multiple techniques. This holistic approach to food preservation reflects the complex nature of food spoilage and the multifaceted requirements of modern food preservation strategies.

Historically, food preservation techniques have ranged from traditional methods such as salting, drying, and fermentation to more modern approaches like refrigeration, canning, and chemical preservatives. However, as consumer preferences shift towards minimally processed foods with fewer artificial additives, there is a growing demand for novel preservation techniques that can maintain food quality without compromising nutritional value or taste.

The exploration of propyne as a food preservation agent represents a significant step forward in this field. Propyne, a colorless gas with a slightly sweet odor, belongs to the alkyne family of hydrocarbons. Its potential in food preservation stems from its unique chemical properties and interactions with biological systems. The primary objective of utilizing propyne in food preservation is to develop a method that effectively inhibits microbial growth and enzymatic reactions responsible for food spoilage, while maintaining the organoleptic properties of the food.

Research into propyne-based preservation techniques aims to address several key challenges in the food industry. These include extending the shelf life of fresh produce, reducing the reliance on synthetic preservatives, and developing preservation methods that are compatible with a wide range of food products. Additionally, there is a focus on creating preservation solutions that are environmentally friendly and cost-effective for large-scale implementation.

The development of propyne preservation technology is driven by the need to meet stringent food safety regulations while addressing consumer demands for "clean label" products. As such, the objectives of this research extend beyond mere preservation to encompass aspects of food quality, safety, and consumer acceptance. Researchers are exploring the optimal conditions for propyne application, including concentration levels, exposure times, and delivery methods that maximize efficacy while ensuring food safety.

Furthermore, the investigation into propyne preservation techniques aligns with broader trends in sustainable food production and distribution. By potentially reducing food waste and extending the geographical reach of perishable goods, propyne-based methods could contribute to more efficient food supply chains and improved food security on a global scale.

As the field progresses, researchers are also examining the potential synergies between propyne and other preservation methods, aiming to develop integrated approaches that leverage the strengths of multiple techniques. This holistic approach to food preservation reflects the complex nature of food spoilage and the multifaceted requirements of modern food preservation strategies.

Market Analysis for Novel Food Preservation Methods

The global food preservation market is experiencing significant growth, driven by increasing consumer demand for extended shelf life, food safety, and convenience. As of 2023, the market size for food preservation technologies is estimated to be around $300 billion, with a projected compound annual growth rate (CAGR) of 4.5% over the next five years. This growth is fueled by factors such as urbanization, changing dietary habits, and the need for sustainable food storage solutions.

Traditional food preservation methods, including canning, freezing, and dehydration, continue to dominate the market. However, there is a growing interest in novel preservation techniques that can maintain food quality while minimizing the use of artificial additives. This shift is primarily driven by consumer preferences for clean label products and natural preservation methods.

The propyne-based food preservation technique represents an innovative approach in this evolving market landscape. Its potential lies in its ability to inhibit microbial growth and extend shelf life without compromising food quality or nutritional value. This aligns well with the current market trends towards minimally processed foods and natural preservation methods.

Market segmentation for novel food preservation methods reveals several key sectors. The packaged food industry, valued at approximately $2.5 trillion globally, stands to benefit significantly from advanced preservation techniques. The fresh produce sector, with a market size of around $200 billion, is another prime target for innovative preservation solutions. Additionally, the meat and seafood industry, valued at $1.3 trillion, is actively seeking new methods to extend product shelf life and maintain quality.

Geographically, North America and Europe are currently the largest markets for advanced food preservation technologies, accounting for about 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, increasing disposable incomes, and changing food consumption patterns.

Consumer acceptance is a critical factor in the adoption of new preservation techniques. Recent surveys indicate that 72% of consumers are willing to pay a premium for food products with extended shelf life, provided they are perceived as natural and safe. This presents a significant opportunity for propyne-based preservation methods, as they offer a potential solution that aligns with consumer preferences for clean label products.

The regulatory landscape plays a crucial role in the market adoption of novel preservation techniques. While regulations vary by region, there is a general trend towards stricter food safety standards and increased scrutiny of preservation methods. The success of propyne-based preservation will largely depend on its ability to meet these regulatory requirements and demonstrate its safety and efficacy.

Traditional food preservation methods, including canning, freezing, and dehydration, continue to dominate the market. However, there is a growing interest in novel preservation techniques that can maintain food quality while minimizing the use of artificial additives. This shift is primarily driven by consumer preferences for clean label products and natural preservation methods.

The propyne-based food preservation technique represents an innovative approach in this evolving market landscape. Its potential lies in its ability to inhibit microbial growth and extend shelf life without compromising food quality or nutritional value. This aligns well with the current market trends towards minimally processed foods and natural preservation methods.

Market segmentation for novel food preservation methods reveals several key sectors. The packaged food industry, valued at approximately $2.5 trillion globally, stands to benefit significantly from advanced preservation techniques. The fresh produce sector, with a market size of around $200 billion, is another prime target for innovative preservation solutions. Additionally, the meat and seafood industry, valued at $1.3 trillion, is actively seeking new methods to extend product shelf life and maintain quality.

Geographically, North America and Europe are currently the largest markets for advanced food preservation technologies, accounting for about 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, increasing disposable incomes, and changing food consumption patterns.

Consumer acceptance is a critical factor in the adoption of new preservation techniques. Recent surveys indicate that 72% of consumers are willing to pay a premium for food products with extended shelf life, provided they are perceived as natural and safe. This presents a significant opportunity for propyne-based preservation methods, as they offer a potential solution that aligns with consumer preferences for clean label products.

The regulatory landscape plays a crucial role in the market adoption of novel preservation techniques. While regulations vary by region, there is a general trend towards stricter food safety standards and increased scrutiny of preservation methods. The success of propyne-based preservation will largely depend on its ability to meet these regulatory requirements and demonstrate its safety and efficacy.

Current Challenges in Propyne-Based Food Preservation

Despite the promising potential of propyne in food preservation, several significant challenges currently hinder its widespread adoption and implementation. These challenges span technical, regulatory, and practical domains, requiring comprehensive solutions before propyne-based techniques can be fully realized in the food industry.

One of the primary technical challenges is the development of safe and efficient delivery systems for propyne. As a highly flammable gas, propyne requires careful handling and specialized equipment for storage and application. Researchers are grappling with the design of controlled-release mechanisms that can maintain effective concentrations of propyne within food packaging without compromising safety or product quality.

Another significant hurdle is the lack of standardized protocols for propyne application in various food types. Different foods have unique compositions and preservation requirements, necessitating tailored approaches. The food industry currently lacks comprehensive guidelines on optimal propyne concentrations, exposure times, and application methods for diverse food categories, limiting its practical implementation.

Regulatory challenges pose a substantial barrier to the adoption of propyne-based preservation techniques. Many countries have not yet established clear regulatory frameworks for the use of propyne in food preservation. This regulatory uncertainty creates hesitation among food manufacturers and retailers, who are wary of investing in new technologies without assurance of compliance with food safety standards.

The potential impact of propyne on food organoleptic properties presents another challenge. While propyne has shown promise in extending shelf life, its effects on taste, texture, and aroma across various food types are not fully understood. Ensuring that propyne-based preservation does not negatively alter the sensory qualities of food products is crucial for consumer acceptance and commercial viability.

Environmental concerns also factor into the challenges facing propyne-based preservation. As a hydrocarbon, propyne's production and use may contribute to carbon emissions. The food industry is under increasing pressure to adopt sustainable practices, and any new preservation technology must demonstrate a favorable environmental profile to gain widespread acceptance.

Lastly, the economic feasibility of implementing propyne-based preservation systems poses a significant challenge. The initial investment required for specialized equipment, safety measures, and staff training can be substantial. Food manufacturers must weigh these costs against the potential benefits of extended shelf life and reduced food waste. Developing cost-effective solutions that make propyne-based preservation accessible to a wide range of food producers, from small-scale operations to large industrial facilities, remains a critical challenge.

One of the primary technical challenges is the development of safe and efficient delivery systems for propyne. As a highly flammable gas, propyne requires careful handling and specialized equipment for storage and application. Researchers are grappling with the design of controlled-release mechanisms that can maintain effective concentrations of propyne within food packaging without compromising safety or product quality.

Another significant hurdle is the lack of standardized protocols for propyne application in various food types. Different foods have unique compositions and preservation requirements, necessitating tailored approaches. The food industry currently lacks comprehensive guidelines on optimal propyne concentrations, exposure times, and application methods for diverse food categories, limiting its practical implementation.

Regulatory challenges pose a substantial barrier to the adoption of propyne-based preservation techniques. Many countries have not yet established clear regulatory frameworks for the use of propyne in food preservation. This regulatory uncertainty creates hesitation among food manufacturers and retailers, who are wary of investing in new technologies without assurance of compliance with food safety standards.

The potential impact of propyne on food organoleptic properties presents another challenge. While propyne has shown promise in extending shelf life, its effects on taste, texture, and aroma across various food types are not fully understood. Ensuring that propyne-based preservation does not negatively alter the sensory qualities of food products is crucial for consumer acceptance and commercial viability.

Environmental concerns also factor into the challenges facing propyne-based preservation. As a hydrocarbon, propyne's production and use may contribute to carbon emissions. The food industry is under increasing pressure to adopt sustainable practices, and any new preservation technology must demonstrate a favorable environmental profile to gain widespread acceptance.

Lastly, the economic feasibility of implementing propyne-based preservation systems poses a significant challenge. The initial investment required for specialized equipment, safety measures, and staff training can be substantial. Food manufacturers must weigh these costs against the potential benefits of extended shelf life and reduced food waste. Developing cost-effective solutions that make propyne-based preservation accessible to a wide range of food producers, from small-scale operations to large industrial facilities, remains a critical challenge.

Existing Propyne Preservation Techniques

01 Synthesis and production of propyne

Various methods and processes for synthesizing and producing propyne are described. These include catalytic reactions, thermal decomposition, and other chemical processes to obtain propyne efficiently and with high purity.- Synthesis and production of propyne: Various methods and processes for synthesizing and producing propyne, including catalytic reactions, thermal decomposition, and chemical transformations. These techniques aim to improve yield, efficiency, and purity of propyne production for industrial applications.

- Propyne as a raw material in chemical processes: Utilization of propyne as a key raw material or intermediate in the production of various chemicals, polymers, and other valuable compounds. This includes its role in organic synthesis, polymerization reactions, and the creation of specialized materials.

- Purification and separation of propyne: Techniques and methods for purifying and separating propyne from mixtures or by-products. This involves various separation processes, distillation techniques, and purification steps to obtain high-purity propyne for specific applications.

- Propyne in fuel and energy applications: Exploration of propyne's potential in fuel and energy-related applications. This includes its use in fuel blends, combustion processes, and as a potential alternative or additive in energy systems.

- Safety and handling of propyne: Considerations and methods for the safe handling, storage, and transportation of propyne. This includes safety protocols, equipment design, and risk management strategies to mitigate hazards associated with this flammable gas.

02 Propyne as a raw material in chemical processes

Propyne serves as an important raw material in various chemical processes. It is used in the production of other chemicals, polymers, and materials, showcasing its versatility in industrial applications.Expand Specific Solutions03 Purification and separation of propyne

Techniques for purifying and separating propyne from mixtures or by-products are discussed. These methods aim to improve the quality and purity of propyne for various applications.Expand Specific Solutions04 Propyne in fuel compositions

The use of propyne in fuel compositions is explored. It can be incorporated into various fuel blends to enhance combustion properties or as an additive to improve fuel performance.Expand Specific Solutions05 Propyne in polymer production

Propyne is utilized in the production of polymers and copolymers. It serves as a monomer or co-monomer in polymerization reactions, contributing to the development of new materials with specific properties.Expand Specific Solutions

Key Players in Food Preservation Industry

The market for innovative food preservation techniques utilizing propyne is in its early stages, with significant potential for growth as food safety and shelf-life extension remain critical industry concerns. The competitive landscape is diverse, featuring established food and chemical companies alongside research institutions. Key players like Unilever, BASF, and Chr. Hansen are leveraging their R&D capabilities to explore propyne-based solutions. While the technology is still emerging, collaborations between academic institutions like Tufts University and industry leaders are driving advancements. The market size is expected to expand as the technology matures and regulatory approvals are obtained, with early adopters gaining a competitive edge in this promising field.

Purac Biochem BV

Technical Solution: Purac Biochem BV has pioneered a propyne-based food preservation system that focuses on natural fermentation processes. Their technology utilizes propyne as a precursor in the production of specialized lactic acid bacteria strains. These modified bacteria produce propyne-derived metabolites during fermentation, which act as powerful preservatives[2]. The company has developed a range of starter cultures that can be used in various fermented food products, such as yogurt, cheese, and pickles. These cultures not only extend shelf life but also enhance flavor profiles. Purac's approach also includes the development of a proprietary encapsulation technology that protects the propyne-derived compounds during food processing and ensures their gradual release during storage[4]. This method allows for the preservation of both fresh and processed foods without altering their organoleptic properties.

Strengths: Natural preservation method, dual benefit of preservation and flavor enhancement, applicable to a wide range of products. Weaknesses: Limited to fermented foods, potential flavor alterations in some applications, requires careful control of fermentation conditions.

Chr. Hansen A/S

Technical Solution: Chr. Hansen A/S has developed a novel food preservation technique that combines propyne-derived compounds with their expertise in microbial solutions. Their approach involves the creation of a bioprotective culture system that incorporates propyne as a key component. The company has engineered specific probiotic strains that can metabolize propyne into potent antimicrobial compounds in situ[6]. This dynamic preservation system adapts to the food matrix, providing tailored protection against spoilage organisms. Chr. Hansen has also developed a synergistic blend of propyne-based preservatives and natural antimicrobial peptides produced by their proprietary bacterial strains, creating a robust preservation system[8]. Additionally, they have implemented advanced genomic techniques to optimize the production and efficacy of these propyne-derived biopreservatives, ensuring consistent performance across various food applications[9].

Strengths: Adaptive preservation system, synergy with probiotic benefits, potential for clean label products. Weaknesses: Complexity in application, potential interactions with existing food cultures, higher cost compared to traditional preservatives.

Core Innovations in Propyne-Based Preservation

Food preservation process

PatentInactiveUS20110123693A1

Innovation

- A process involving food packing, heating the food/package system in contact with atmospheric air, changing the gaseous composition inside the package, closing the package, and subjecting it to a thermal treatment, which allows for the preservation of various food types for up to five years without altering their essential characteristics.

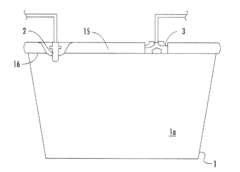

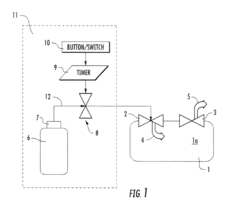

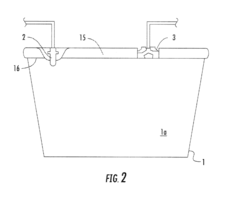

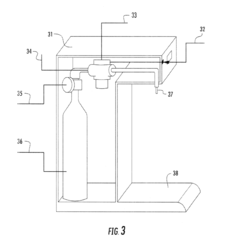

Food preservation system

PatentInactiveUS20150307217A1

Innovation

- A modified MAP system using two one-way valves to introduce preservation gas and flush out air, eliminating the need for a vacuum step and separate gas regulation, with a timer controlling the gas introduction to optimize the flushing process, allowing for cost-effective and efficient food preservation.

Regulatory Framework for Novel Food Preservatives

The regulatory framework for novel food preservatives, such as propyne-based techniques, is a complex and evolving landscape that requires careful navigation. In the United States, the Food and Drug Administration (FDA) plays a pivotal role in overseeing the safety and approval of new food preservation methods. The FDA's regulatory process for novel preservatives typically involves extensive safety assessments, including toxicological studies and evaluations of potential long-term health effects.

For propyne-based food preservation techniques to gain regulatory approval, developers must demonstrate that the method is safe for consumption and does not adversely affect the nutritional quality of the food. This process often involves submitting a food additive petition or a Generally Recognized as Safe (GRAS) notification to the FDA. The petition must include comprehensive data on the chemical composition of propyne, its intended use in food preservation, and any potential byproducts or residues that may result from its application.

Internationally, regulatory bodies such as the European Food Safety Authority (EFSA) and the Joint FAO/WHO Expert Committee on Food Additives (JECFA) also play crucial roles in evaluating novel food preservatives. These organizations often require additional safety data and may have more stringent criteria for approval compared to the FDA. Harmonization of regulations across different countries can be challenging, potentially impacting the global adoption of propyne-based preservation techniques.

Environmental considerations are increasingly important in the regulatory framework for food preservatives. Regulatory bodies may require assessments of propyne's environmental impact, including its potential effects on air quality and ozone depletion. This aspect is particularly relevant given propyne's chemical properties and potential for atmospheric reactions.

Labeling requirements for foods preserved using novel techniques like propyne-based methods are another critical regulatory consideration. Transparency in food labeling is essential for consumer trust and regulatory compliance. Regulators may mandate specific labeling to inform consumers about the use of new preservation technologies.

As the food industry continues to innovate, regulatory frameworks must evolve to keep pace with technological advancements. This may involve developing new testing methodologies, updating risk assessment protocols, and establishing specific guidelines for emerging preservation techniques. Collaboration between industry stakeholders, regulatory agencies, and scientific experts is crucial in shaping an effective and adaptive regulatory environment for novel food preservatives like propyne-based systems.

For propyne-based food preservation techniques to gain regulatory approval, developers must demonstrate that the method is safe for consumption and does not adversely affect the nutritional quality of the food. This process often involves submitting a food additive petition or a Generally Recognized as Safe (GRAS) notification to the FDA. The petition must include comprehensive data on the chemical composition of propyne, its intended use in food preservation, and any potential byproducts or residues that may result from its application.

Internationally, regulatory bodies such as the European Food Safety Authority (EFSA) and the Joint FAO/WHO Expert Committee on Food Additives (JECFA) also play crucial roles in evaluating novel food preservatives. These organizations often require additional safety data and may have more stringent criteria for approval compared to the FDA. Harmonization of regulations across different countries can be challenging, potentially impacting the global adoption of propyne-based preservation techniques.

Environmental considerations are increasingly important in the regulatory framework for food preservatives. Regulatory bodies may require assessments of propyne's environmental impact, including its potential effects on air quality and ozone depletion. This aspect is particularly relevant given propyne's chemical properties and potential for atmospheric reactions.

Labeling requirements for foods preserved using novel techniques like propyne-based methods are another critical regulatory consideration. Transparency in food labeling is essential for consumer trust and regulatory compliance. Regulators may mandate specific labeling to inform consumers about the use of new preservation technologies.

As the food industry continues to innovate, regulatory frameworks must evolve to keep pace with technological advancements. This may involve developing new testing methodologies, updating risk assessment protocols, and establishing specific guidelines for emerging preservation techniques. Collaboration between industry stakeholders, regulatory agencies, and scientific experts is crucial in shaping an effective and adaptive regulatory environment for novel food preservatives like propyne-based systems.

Environmental Impact of Propyne Preservation Methods

The environmental impact of propyne preservation methods is a crucial aspect to consider when evaluating the viability of this innovative food preservation technique. Propyne, also known as methylacetylene, is a colorless gas that has shown promise in extending the shelf life of various food products. However, its widespread adoption must be carefully assessed in terms of its ecological footprint.

One of the primary environmental concerns associated with propyne preservation is its potential contribution to greenhouse gas emissions. While propyne itself is not a direct greenhouse gas, its production and use may involve processes that release carbon dioxide and other harmful emissions. The energy-intensive nature of propyne synthesis and the need for specialized equipment in its application could lead to increased carbon footprints in the food industry.

Water usage and contamination are additional environmental factors to consider. The application of propyne in food preservation may require water-intensive cleaning processes to ensure food safety. Furthermore, there is a risk of propyne or its byproducts entering water systems, potentially affecting aquatic ecosystems. Proper waste management and water treatment protocols must be established to mitigate these risks.

The impact on air quality is another significant concern. While propyne is generally considered non-toxic, its release into the atmosphere during preservation processes could contribute to the formation of ground-level ozone and other air pollutants. This may have implications for local air quality, particularly in areas with high concentrations of food processing facilities utilizing propyne-based preservation methods.

On the positive side, propyne preservation techniques have the potential to reduce food waste significantly. By extending the shelf life of perishable goods, these methods could decrease the amount of food that ends up in landfills, thereby reducing methane emissions from decomposing organic matter. This indirect environmental benefit may partially offset the direct impacts of propyne use.

The lifecycle analysis of propyne preservation methods must also consider the environmental costs of transportation and storage. If propyne-preserved foods can be transported and stored at ambient temperatures for longer periods, it could lead to reduced energy consumption in refrigeration and faster transportation methods, potentially lowering overall carbon emissions in the food supply chain.

Biodegradability and long-term environmental persistence of propyne and its byproducts are areas that require further research. Understanding how these compounds break down in the environment and their potential accumulation in soil or water bodies is crucial for assessing the long-term ecological impact of widespread propyne use in food preservation.

One of the primary environmental concerns associated with propyne preservation is its potential contribution to greenhouse gas emissions. While propyne itself is not a direct greenhouse gas, its production and use may involve processes that release carbon dioxide and other harmful emissions. The energy-intensive nature of propyne synthesis and the need for specialized equipment in its application could lead to increased carbon footprints in the food industry.

Water usage and contamination are additional environmental factors to consider. The application of propyne in food preservation may require water-intensive cleaning processes to ensure food safety. Furthermore, there is a risk of propyne or its byproducts entering water systems, potentially affecting aquatic ecosystems. Proper waste management and water treatment protocols must be established to mitigate these risks.

The impact on air quality is another significant concern. While propyne is generally considered non-toxic, its release into the atmosphere during preservation processes could contribute to the formation of ground-level ozone and other air pollutants. This may have implications for local air quality, particularly in areas with high concentrations of food processing facilities utilizing propyne-based preservation methods.

On the positive side, propyne preservation techniques have the potential to reduce food waste significantly. By extending the shelf life of perishable goods, these methods could decrease the amount of food that ends up in landfills, thereby reducing methane emissions from decomposing organic matter. This indirect environmental benefit may partially offset the direct impacts of propyne use.

The lifecycle analysis of propyne preservation methods must also consider the environmental costs of transportation and storage. If propyne-preserved foods can be transported and stored at ambient temperatures for longer periods, it could lead to reduced energy consumption in refrigeration and faster transportation methods, potentially lowering overall carbon emissions in the food supply chain.

Biodegradability and long-term environmental persistence of propyne and its byproducts are areas that require further research. Understanding how these compounds break down in the environment and their potential accumulation in soil or water bodies is crucial for assessing the long-term ecological impact of widespread propyne use in food preservation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!