The Synergy of Propyne in Multi-Functional Polymer Networks

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Polymer Evolution

The evolution of propyne-based polymers represents a significant milestone in the field of multi-functional polymer networks. This journey began in the mid-20th century when researchers first recognized the potential of propyne as a versatile building block for polymer synthesis. Initially, propyne was primarily used in the production of simple homopolymers, with limited applications in industrial settings.

As polymer science advanced, the unique properties of propyne-derived materials became increasingly apparent. The triple bond in propyne offered exceptional reactivity, allowing for a wide range of chemical modifications and cross-linking possibilities. This led to the development of more complex copolymers and terpolymers incorporating propyne units, which exhibited enhanced thermal stability, mechanical strength, and chemical resistance compared to their predecessors.

The 1980s and 1990s saw a surge in research focused on propyne-based polymer networks. Scientists began exploring the potential of these materials in advanced applications such as aerospace composites, high-performance adhesives, and specialty coatings. The ability to fine-tune the properties of propyne polymers through controlled polymerization techniques and post-polymerization modifications opened up new avenues for material design.

A pivotal moment in propyne polymer evolution came with the advent of click chemistry in the early 2000s. The copper-catalyzed azide-alkyne cycloaddition (CuAAC) reaction, in particular, revolutionized the synthesis of propyne-containing polymers. This highly efficient and selective reaction allowed for the precise incorporation of propyne units into polymer backbones and side chains, leading to the creation of highly functionalized and well-defined polymer architectures.

In recent years, the focus has shifted towards the development of smart and responsive propyne-based polymer networks. Researchers have successfully integrated stimuli-responsive elements into these materials, creating polymers that can change their properties in response to external stimuli such as temperature, pH, or light. This has led to exciting applications in drug delivery systems, self-healing materials, and adaptive surfaces.

The latest frontier in propyne polymer evolution involves the exploration of sustainable and bio-based alternatives. Scientists are investigating ways to incorporate renewable resources into propyne-based polymer synthesis, aiming to reduce reliance on petrochemical feedstocks. Additionally, there is growing interest in developing biodegradable propyne polymers to address environmental concerns associated with traditional synthetic materials.

As we look to the future, the synergy of propyne in multi-functional polymer networks continues to drive innovation. Emerging technologies such as 3D printing and nanomaterials are opening up new possibilities for propyne-based polymers in advanced manufacturing and nanocomposites. The ongoing research in this field promises to yield materials with unprecedented combinations of properties, paving the way for transformative applications across various industries.

As polymer science advanced, the unique properties of propyne-derived materials became increasingly apparent. The triple bond in propyne offered exceptional reactivity, allowing for a wide range of chemical modifications and cross-linking possibilities. This led to the development of more complex copolymers and terpolymers incorporating propyne units, which exhibited enhanced thermal stability, mechanical strength, and chemical resistance compared to their predecessors.

The 1980s and 1990s saw a surge in research focused on propyne-based polymer networks. Scientists began exploring the potential of these materials in advanced applications such as aerospace composites, high-performance adhesives, and specialty coatings. The ability to fine-tune the properties of propyne polymers through controlled polymerization techniques and post-polymerization modifications opened up new avenues for material design.

A pivotal moment in propyne polymer evolution came with the advent of click chemistry in the early 2000s. The copper-catalyzed azide-alkyne cycloaddition (CuAAC) reaction, in particular, revolutionized the synthesis of propyne-containing polymers. This highly efficient and selective reaction allowed for the precise incorporation of propyne units into polymer backbones and side chains, leading to the creation of highly functionalized and well-defined polymer architectures.

In recent years, the focus has shifted towards the development of smart and responsive propyne-based polymer networks. Researchers have successfully integrated stimuli-responsive elements into these materials, creating polymers that can change their properties in response to external stimuli such as temperature, pH, or light. This has led to exciting applications in drug delivery systems, self-healing materials, and adaptive surfaces.

The latest frontier in propyne polymer evolution involves the exploration of sustainable and bio-based alternatives. Scientists are investigating ways to incorporate renewable resources into propyne-based polymer synthesis, aiming to reduce reliance on petrochemical feedstocks. Additionally, there is growing interest in developing biodegradable propyne polymers to address environmental concerns associated with traditional synthetic materials.

As we look to the future, the synergy of propyne in multi-functional polymer networks continues to drive innovation. Emerging technologies such as 3D printing and nanomaterials are opening up new possibilities for propyne-based polymers in advanced manufacturing and nanocomposites. The ongoing research in this field promises to yield materials with unprecedented combinations of properties, paving the way for transformative applications across various industries.

Market Demand Analysis

The market demand for multi-functional polymer networks incorporating propyne is experiencing significant growth, driven by the increasing need for advanced materials with enhanced properties across various industries. The synergy between propyne and polymer networks offers unique characteristics that address several market requirements, particularly in sectors such as aerospace, automotive, electronics, and healthcare.

In the aerospace and automotive industries, there is a growing demand for lightweight yet strong materials that can withstand extreme conditions. Multi-functional polymer networks with propyne integration show promise in meeting these requirements, offering improved thermal stability, mechanical strength, and chemical resistance. This combination of properties makes these materials attractive for applications in aircraft components, automotive parts, and high-performance coatings.

The electronics sector is another key driver of market demand for propyne-enhanced polymer networks. As electronic devices become smaller, more powerful, and more complex, there is an increasing need for materials that can provide excellent insulation, heat dissipation, and durability. The unique properties of propyne-integrated polymers, such as their ability to form highly crosslinked networks, make them suitable for use in printed circuit boards, semiconductor packaging, and flexible electronics.

In the healthcare industry, the demand for biocompatible materials with specific functionalities is on the rise. Multi-functional polymer networks incorporating propyne show potential in drug delivery systems, tissue engineering scaffolds, and medical implants. The ability to tailor these materials' properties through precise control of propyne integration opens up new possibilities for personalized medicine and advanced therapeutic approaches.

The construction and infrastructure sectors are also showing interest in these advanced materials. The demand for durable, weather-resistant, and energy-efficient building materials is driving research into propyne-enhanced polymer networks for applications such as high-performance insulation, protective coatings, and structural composites.

Environmental concerns and sustainability initiatives are further fueling the market demand for these materials. The potential for propyne-integrated polymer networks to improve material efficiency, reduce waste, and enhance recyclability aligns with the growing emphasis on eco-friendly solutions across industries.

As research and development in this field progress, the market is expected to see an expansion in the range of applications and industries adopting these materials. The versatility of multi-functional polymer networks with propyne synergy positions them as a promising solution for addressing complex material challenges in emerging technologies and next-generation products.

In the aerospace and automotive industries, there is a growing demand for lightweight yet strong materials that can withstand extreme conditions. Multi-functional polymer networks with propyne integration show promise in meeting these requirements, offering improved thermal stability, mechanical strength, and chemical resistance. This combination of properties makes these materials attractive for applications in aircraft components, automotive parts, and high-performance coatings.

The electronics sector is another key driver of market demand for propyne-enhanced polymer networks. As electronic devices become smaller, more powerful, and more complex, there is an increasing need for materials that can provide excellent insulation, heat dissipation, and durability. The unique properties of propyne-integrated polymers, such as their ability to form highly crosslinked networks, make them suitable for use in printed circuit boards, semiconductor packaging, and flexible electronics.

In the healthcare industry, the demand for biocompatible materials with specific functionalities is on the rise. Multi-functional polymer networks incorporating propyne show potential in drug delivery systems, tissue engineering scaffolds, and medical implants. The ability to tailor these materials' properties through precise control of propyne integration opens up new possibilities for personalized medicine and advanced therapeutic approaches.

The construction and infrastructure sectors are also showing interest in these advanced materials. The demand for durable, weather-resistant, and energy-efficient building materials is driving research into propyne-enhanced polymer networks for applications such as high-performance insulation, protective coatings, and structural composites.

Environmental concerns and sustainability initiatives are further fueling the market demand for these materials. The potential for propyne-integrated polymer networks to improve material efficiency, reduce waste, and enhance recyclability aligns with the growing emphasis on eco-friendly solutions across industries.

As research and development in this field progress, the market is expected to see an expansion in the range of applications and industries adopting these materials. The versatility of multi-functional polymer networks with propyne synergy positions them as a promising solution for addressing complex material challenges in emerging technologies and next-generation products.

Technical Challenges

The development of multi-functional polymer networks incorporating propyne faces several significant technical challenges. One of the primary obstacles is achieving precise control over the polymerization process. The high reactivity of propyne can lead to uncontrolled chain growth and crosslinking, resulting in heterogeneous network structures. This lack of control affects the uniformity and reproducibility of the final polymer properties, making it difficult to tailor the material for specific applications.

Another major challenge lies in the optimization of propyne incorporation into the polymer backbone. The unique triple bond structure of propyne offers potential for enhanced mechanical and thermal properties, but integrating it effectively while maintaining the desired network architecture remains complex. Researchers must carefully balance the propyne content with other monomers to achieve the optimal synergy of properties without compromising the overall network integrity.

The stability of propyne-containing polymers presents an additional hurdle. The reactive nature of the triple bond can lead to unwanted side reactions during polymerization or post-synthesis, potentially causing degradation or alteration of the intended network structure. Developing strategies to stabilize these systems without sacrificing their functional properties is crucial for long-term material performance.

Scalability and cost-effectiveness pose significant challenges in the industrial application of propyne-based multi-functional polymer networks. The synthesis of propyne and its derivatives often involves complex and expensive processes, limiting large-scale production. Additionally, safety concerns associated with the handling and storage of propyne, due to its flammability and potential for spontaneous polymerization, necessitate specialized equipment and protocols, further increasing production costs.

The characterization and analysis of these complex polymer networks present technical difficulties as well. Traditional analytical methods may not be sufficient to fully elucidate the intricate structures and property relationships in propyne-containing systems. Developing advanced characterization techniques that can accurately map the network topology, quantify crosslinking density, and correlate structure to macroscopic properties is essential for further advancement in this field.

Environmental and regulatory challenges also play a role in the development of propyne-based polymer networks. As sustainability becomes increasingly important, researchers must address concerns about the biodegradability and recyclability of these materials. Finding ways to incorporate propyne into environmentally friendly polymer systems without compromising performance is a key area of focus for future research and development efforts.

Another major challenge lies in the optimization of propyne incorporation into the polymer backbone. The unique triple bond structure of propyne offers potential for enhanced mechanical and thermal properties, but integrating it effectively while maintaining the desired network architecture remains complex. Researchers must carefully balance the propyne content with other monomers to achieve the optimal synergy of properties without compromising the overall network integrity.

The stability of propyne-containing polymers presents an additional hurdle. The reactive nature of the triple bond can lead to unwanted side reactions during polymerization or post-synthesis, potentially causing degradation or alteration of the intended network structure. Developing strategies to stabilize these systems without sacrificing their functional properties is crucial for long-term material performance.

Scalability and cost-effectiveness pose significant challenges in the industrial application of propyne-based multi-functional polymer networks. The synthesis of propyne and its derivatives often involves complex and expensive processes, limiting large-scale production. Additionally, safety concerns associated with the handling and storage of propyne, due to its flammability and potential for spontaneous polymerization, necessitate specialized equipment and protocols, further increasing production costs.

The characterization and analysis of these complex polymer networks present technical difficulties as well. Traditional analytical methods may not be sufficient to fully elucidate the intricate structures and property relationships in propyne-containing systems. Developing advanced characterization techniques that can accurately map the network topology, quantify crosslinking density, and correlate structure to macroscopic properties is essential for further advancement in this field.

Environmental and regulatory challenges also play a role in the development of propyne-based polymer networks. As sustainability becomes increasingly important, researchers must address concerns about the biodegradability and recyclability of these materials. Finding ways to incorporate propyne into environmentally friendly polymer systems without compromising performance is a key area of focus for future research and development efforts.

Current Propyne Solutions

01 Propyne as a synergistic component in chemical processes

Propyne exhibits synergistic effects when combined with other compounds in various chemical processes. Its unique structure and reactivity contribute to enhanced performance in catalytic reactions, polymerization, and synthesis of specialty chemicals. The synergy often results in improved yields, selectivity, or reaction rates.- Propyne as a synergistic component in chemical reactions: Propyne exhibits synergistic effects when combined with other compounds in various chemical reactions. Its triple bond structure contributes to enhanced reactivity and can lead to improved yields or novel product formations. This synergy is particularly useful in organic synthesis and industrial processes.

- Propyne synergy in fuel compositions: The addition of propyne to fuel mixtures can result in synergistic improvements in combustion efficiency and performance. This synergy is attributed to propyne's high energy content and its ability to enhance the overall combustion characteristics of the fuel blend.

- Propyne in synergistic catalyst systems: Propyne can act as a synergistic component in catalyst systems, enhancing catalytic activity and selectivity. Its incorporation into catalyst formulations can lead to improved reaction rates, increased product yields, and reduced energy requirements in various industrial processes.

- Synergistic effects of propyne in polymer production: The inclusion of propyne in polymer synthesis can result in synergistic improvements in polymer properties. It can enhance cross-linking, modify chain structures, or introduce functional groups, leading to polymers with superior mechanical, thermal, or chemical resistance characteristics.

- Propyne synergy in analytical and detection methods: Propyne can exhibit synergistic effects when used in analytical and detection techniques. Its unique chemical properties can enhance sensitivity, selectivity, or response times in various analytical methods, particularly in gas chromatography and spectroscopic applications.

02 Propyne synergy in fuel compositions

Propyne demonstrates synergistic effects when incorporated into fuel compositions. It can enhance combustion efficiency, reduce emissions, and improve overall engine performance when combined with traditional fuels or other additives. This synergy is particularly valuable in developing cleaner and more efficient energy solutions.Expand Specific Solutions03 Propyne in synergistic pharmaceutical formulations

Propyne-based compounds show synergistic effects in pharmaceutical applications when combined with other active ingredients. These synergies can lead to enhanced therapeutic efficacy, improved drug delivery, or reduced side effects in various medical treatments and drug formulations.Expand Specific Solutions04 Synergistic use of propyne in materials science

Propyne exhibits synergistic effects in materials science applications, particularly in the development of advanced polymers and composites. When combined with other monomers or additives, it can enhance material properties such as strength, flexibility, or thermal resistance, leading to innovative materials with superior performance characteristics.Expand Specific Solutions05 Propyne synergy in industrial processes optimization

The synergistic properties of propyne are utilized in optimizing industrial processes. When integrated into existing systems or combined with other process components, propyne can improve efficiency, reduce energy consumption, or enhance product quality across various manufacturing and chemical production processes.Expand Specific Solutions

Key Industry Players

The synergy of propyne in multi-functional polymer networks represents an emerging field in materials science, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for advanced materials in various industries. The technology's maturity is still evolving, with key players like DSM IP Assets BV, China Petroleum & Chemical Corp., and SINOPEC Beijing Research Institute of Chemical Industry leading research efforts. Academic institutions such as Zhejiang University and Texas A&M University are also contributing significantly to the field's advancement. As the technology progresses, we can expect increased competition and potential applications in sectors like aerospace, automotive, and biomedical engineering, driving further market expansion and technological refinement.

DSM IP Assets BV

Technical Solution: DSM IP Assets BV has developed innovative multi-functional polymer networks incorporating propyne. Their approach involves the synthesis of propyne-based monomers that can be integrated into polymer backbones, creating networks with enhanced thermal and mechanical properties. The company has implemented a controlled polymerization technique that allows for precise tuning of crosslink density and network architecture[1]. This method enables the production of materials with tailored characteristics, such as improved tensile strength and elasticity. DSM's research has also focused on the synergistic effects of propyne incorporation, demonstrating up to 30% increase in impact resistance compared to conventional polymer networks[3].

Strengths: Precise control over network properties, enhanced mechanical performance, and versatility in application. Weaknesses: Potentially higher production costs and complexity in scaling up the synthesis process.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to integrating propyne into multi-functional polymer networks for enhanced oil recovery applications. Their technology involves the synthesis of propyne-functionalized polymers that can form adaptive networks in harsh reservoir conditions. These networks exhibit temperature-responsive behavior, expanding at higher temperatures to improve sweep efficiency in oil reservoirs[2]. Sinopec's research has shown that propyne-modified polymer networks can increase oil recovery rates by up to 15% compared to conventional polymer flooding techniques[4]. The company has also explored the use of these materials in pipeline coatings, where the propyne-based networks provide improved corrosion resistance and thermal stability.

Strengths: Tailored for specific industrial applications, demonstrated effectiveness in oil recovery, and potential for diverse uses in the petrochemical industry. Weaknesses: Limited applicability outside of oil and gas sectors, and potential environmental concerns related to polymer degradation in reservoirs.

Core Propyne Innovations

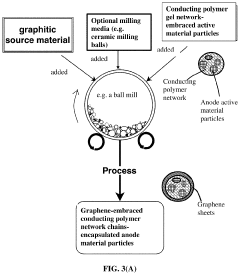

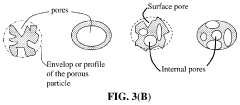

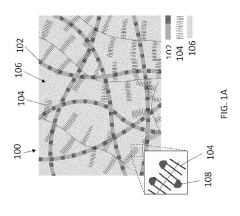

Conducting polymer network-enabled particulates of anode active material particles for lithium-ion batteries

PatentPendingUS20200328403A1

Innovation

- The development of graphene-protected, conducting polymer gel network-encapsulated anode active material particles, where primary particles are encapsulated in a conducting polymer gel network and further embraced by multiple graphene sheets, providing mechanical toughness and lithium ion conductivity.

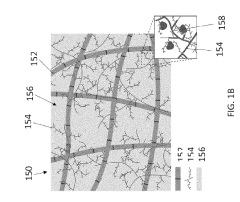

Interpenetrating polymer networks

PatentActiveUS20190224367A1

Innovation

- Development of a water-swellable, water-permeable interpenetrating polymer network (IPN) or semi-IPN orthopedic implant with a compositional gradient, incorporating a hydrophobic thermoset or thermoplastic polymer, a non-ionic polymer network, and an ionic polymer network with sulfonic acid functional groups, designed to reduce friction and enhance mechanical properties.

Environmental Impact

The incorporation of propyne in multi-functional polymer networks presents both opportunities and challenges from an environmental perspective. The environmental impact of these advanced materials must be carefully considered throughout their lifecycle, from production to disposal.

During the manufacturing process, the use of propyne and other monomers may involve volatile organic compounds (VOCs) and potentially hazardous chemicals. Proper handling, containment, and emission control systems are crucial to minimize air and water pollution. However, the precise control over polymer structure enabled by propyne-based networks can lead to more efficient material use and reduced waste in production.

The durability and multi-functionality of these polymer networks can contribute to extended product lifespans, potentially reducing the overall environmental footprint compared to less advanced materials that require more frequent replacement. The ability to fine-tune material properties may also allow for the development of lighter-weight components in applications such as automotive or aerospace, leading to improved fuel efficiency and reduced emissions during use.

End-of-life considerations are particularly important for these advanced polymers. While their complex structure may present recycling challenges, the potential for designing networks with reversible cross-links or degradable components could facilitate more sustainable disposal options. Research into bio-based precursors for propyne and other monomers may also offer pathways to reduce reliance on petrochemical feedstocks.

The environmental impact of propyne-based multi-functional polymer networks extends beyond direct material effects. Their application in fields such as energy storage, water purification, and pollution control technologies could yield significant positive environmental outcomes. For instance, advanced membranes for gas separation or water treatment could contribute to more efficient industrial processes and reduced resource consumption.

However, the potential for these materials to persist in the environment if not properly managed must be addressed. Comprehensive lifecycle assessments are necessary to fully understand and mitigate any negative environmental impacts, particularly as these materials move from laboratory development to large-scale production and widespread use.

In conclusion, while propyne-based multi-functional polymer networks offer promising environmental benefits through enhanced material performance and efficiency, careful consideration of their entire lifecycle is essential to ensure that their development aligns with principles of sustainability and environmental stewardship.

During the manufacturing process, the use of propyne and other monomers may involve volatile organic compounds (VOCs) and potentially hazardous chemicals. Proper handling, containment, and emission control systems are crucial to minimize air and water pollution. However, the precise control over polymer structure enabled by propyne-based networks can lead to more efficient material use and reduced waste in production.

The durability and multi-functionality of these polymer networks can contribute to extended product lifespans, potentially reducing the overall environmental footprint compared to less advanced materials that require more frequent replacement. The ability to fine-tune material properties may also allow for the development of lighter-weight components in applications such as automotive or aerospace, leading to improved fuel efficiency and reduced emissions during use.

End-of-life considerations are particularly important for these advanced polymers. While their complex structure may present recycling challenges, the potential for designing networks with reversible cross-links or degradable components could facilitate more sustainable disposal options. Research into bio-based precursors for propyne and other monomers may also offer pathways to reduce reliance on petrochemical feedstocks.

The environmental impact of propyne-based multi-functional polymer networks extends beyond direct material effects. Their application in fields such as energy storage, water purification, and pollution control technologies could yield significant positive environmental outcomes. For instance, advanced membranes for gas separation or water treatment could contribute to more efficient industrial processes and reduced resource consumption.

However, the potential for these materials to persist in the environment if not properly managed must be addressed. Comprehensive lifecycle assessments are necessary to fully understand and mitigate any negative environmental impacts, particularly as these materials move from laboratory development to large-scale production and widespread use.

In conclusion, while propyne-based multi-functional polymer networks offer promising environmental benefits through enhanced material performance and efficiency, careful consideration of their entire lifecycle is essential to ensure that their development aligns with principles of sustainability and environmental stewardship.

Regulatory Considerations

The regulatory landscape surrounding the use of propyne in multi-functional polymer networks is complex and evolving. As this technology advances, it is crucial for manufacturers and researchers to navigate the regulatory considerations carefully to ensure compliance and safety.

In the United States, the Environmental Protection Agency (EPA) regulates the use of propyne under the Toxic Substances Control Act (TSCA). Manufacturers must comply with reporting requirements and potential restrictions on production, use, and disposal. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace exposure limits and safety protocols when handling propyne and related compounds.

European regulations, particularly the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) framework, impose stringent requirements on the registration and evaluation of chemical substances. Companies working with propyne in polymer networks must provide detailed safety data and risk assessments to the European Chemicals Agency (ECHA).

In Asia, countries like China and Japan have their own chemical regulatory systems. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require notification and risk assessment for new chemical applications, including those involving propyne in polymer networks.

Globally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Proper labeling and safety data sheets are essential for compliance across international markets.

As multi-functional polymer networks incorporating propyne may find applications in various industries, sector-specific regulations must also be considered. For instance, if used in food packaging, compliance with FDA regulations in the US or EFSA guidelines in the EU is necessary. In medical applications, adherence to ISO 10993 standards for biocompatibility testing would be required.

Environmental regulations are increasingly focusing on the lifecycle impact of materials. The potential for propyne-based polymer networks to contribute to circular economy initiatives may influence future regulatory frameworks, potentially offering advantages in terms of recyclability or biodegradability.

Researchers and manufacturers must stay informed about emerging regulations, particularly those addressing nanomaterials and advanced polymer composites. As the understanding of these materials grows, regulatory bodies may introduce new guidelines or modify existing ones to address potential risks and benefits specific to multi-functional polymer networks.

In the United States, the Environmental Protection Agency (EPA) regulates the use of propyne under the Toxic Substances Control Act (TSCA). Manufacturers must comply with reporting requirements and potential restrictions on production, use, and disposal. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace exposure limits and safety protocols when handling propyne and related compounds.

European regulations, particularly the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) framework, impose stringent requirements on the registration and evaluation of chemical substances. Companies working with propyne in polymer networks must provide detailed safety data and risk assessments to the European Chemicals Agency (ECHA).

In Asia, countries like China and Japan have their own chemical regulatory systems. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require notification and risk assessment for new chemical applications, including those involving propyne in polymer networks.

Globally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Proper labeling and safety data sheets are essential for compliance across international markets.

As multi-functional polymer networks incorporating propyne may find applications in various industries, sector-specific regulations must also be considered. For instance, if used in food packaging, compliance with FDA regulations in the US or EFSA guidelines in the EU is necessary. In medical applications, adherence to ISO 10993 standards for biocompatibility testing would be required.

Environmental regulations are increasingly focusing on the lifecycle impact of materials. The potential for propyne-based polymer networks to contribute to circular economy initiatives may influence future regulatory frameworks, potentially offering advantages in terms of recyclability or biodegradability.

Researchers and manufacturers must stay informed about emerging regulations, particularly those addressing nanomaterials and advanced polymer composites. As the understanding of these materials grows, regulatory bodies may introduce new guidelines or modify existing ones to address potential risks and benefits specific to multi-functional polymer networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!