Degradation Mechanisms of Propyne-based Materials

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Materials Background and Objectives

Propyne-based materials have gained significant attention in recent years due to their unique properties and potential applications across various industries. These materials, derived from propyne (also known as methylacetylene), offer a promising avenue for developing advanced materials with enhanced performance characteristics. The evolution of propyne-based materials can be traced back to the mid-20th century when researchers first began exploring the potential of acetylenic compounds in polymer science.

The development of propyne-based materials has been driven by the increasing demand for high-performance materials in sectors such as aerospace, automotive, and electronics. As traditional materials reach their performance limits, the need for innovative solutions has become more pressing. Propyne-based materials have emerged as a potential answer to these challenges, offering improved thermal stability, mechanical strength, and chemical resistance compared to conventional alternatives.

The technological trajectory of propyne-based materials has been marked by several key milestones. Initial research focused on understanding the fundamental chemistry of propyne and its derivatives. This was followed by the development of novel synthesis methods and the exploration of various polymerization techniques. In recent years, there has been a shift towards the creation of composite materials and the investigation of nanoscale structures to further enhance material properties.

One of the primary objectives in the field of propyne-based materials research is to address the issue of degradation. While these materials offer superior performance in many aspects, their long-term stability and resistance to environmental factors remain areas of concern. Understanding the degradation mechanisms of propyne-based materials is crucial for developing strategies to mitigate these issues and extend the lifespan of products incorporating these materials.

The research goals in this area are multifaceted. Scientists aim to elucidate the chemical and physical processes that lead to the breakdown of propyne-based materials under various conditions. This includes investigating the effects of temperature, humidity, UV radiation, and mechanical stress on material integrity. Additionally, researchers are working to develop novel additives and processing techniques that can enhance the resistance of these materials to degradation.

Another important objective is to establish standardized testing methods for assessing the long-term performance of propyne-based materials. This is essential for predicting the service life of products and ensuring their reliability in real-world applications. Furthermore, there is a growing focus on developing environmentally friendly and sustainable approaches to the synthesis and disposal of propyne-based materials, aligning with global efforts towards greener technologies.

As the field progresses, researchers are also exploring the potential of propyne-based materials in emerging technologies such as flexible electronics, advanced composites for space applications, and high-performance coatings. The ultimate goal is to unlock the full potential of these materials, pushing the boundaries of what is possible in material science and engineering.

The development of propyne-based materials has been driven by the increasing demand for high-performance materials in sectors such as aerospace, automotive, and electronics. As traditional materials reach their performance limits, the need for innovative solutions has become more pressing. Propyne-based materials have emerged as a potential answer to these challenges, offering improved thermal stability, mechanical strength, and chemical resistance compared to conventional alternatives.

The technological trajectory of propyne-based materials has been marked by several key milestones. Initial research focused on understanding the fundamental chemistry of propyne and its derivatives. This was followed by the development of novel synthesis methods and the exploration of various polymerization techniques. In recent years, there has been a shift towards the creation of composite materials and the investigation of nanoscale structures to further enhance material properties.

One of the primary objectives in the field of propyne-based materials research is to address the issue of degradation. While these materials offer superior performance in many aspects, their long-term stability and resistance to environmental factors remain areas of concern. Understanding the degradation mechanisms of propyne-based materials is crucial for developing strategies to mitigate these issues and extend the lifespan of products incorporating these materials.

The research goals in this area are multifaceted. Scientists aim to elucidate the chemical and physical processes that lead to the breakdown of propyne-based materials under various conditions. This includes investigating the effects of temperature, humidity, UV radiation, and mechanical stress on material integrity. Additionally, researchers are working to develop novel additives and processing techniques that can enhance the resistance of these materials to degradation.

Another important objective is to establish standardized testing methods for assessing the long-term performance of propyne-based materials. This is essential for predicting the service life of products and ensuring their reliability in real-world applications. Furthermore, there is a growing focus on developing environmentally friendly and sustainable approaches to the synthesis and disposal of propyne-based materials, aligning with global efforts towards greener technologies.

As the field progresses, researchers are also exploring the potential of propyne-based materials in emerging technologies such as flexible electronics, advanced composites for space applications, and high-performance coatings. The ultimate goal is to unlock the full potential of these materials, pushing the boundaries of what is possible in material science and engineering.

Market Analysis for Propyne-based Products

The market for propyne-based products has shown significant growth potential in recent years, driven by increasing demand across various industries. Propyne, also known as methylacetylene, serves as a versatile building block for numerous chemical compounds and materials. Its unique triple bond structure makes it particularly valuable in the production of specialty chemicals, polymers, and advanced materials.

In the petrochemical industry, propyne-based products find extensive applications as intermediates for the synthesis of high-value chemicals. The automotive sector utilizes propyne derivatives in the manufacturing of lightweight materials and advanced composites, contributing to improved fuel efficiency and reduced emissions. Additionally, the electronics industry employs propyne-based materials in the production of semiconductors and display technologies, capitalizing on their unique properties.

The global market for propyne-based products is expected to experience steady growth over the coming years. This growth is primarily attributed to the expanding applications in emerging technologies and the increasing focus on sustainable and eco-friendly materials. The Asia-Pacific region, particularly China and India, is anticipated to be a major driver of market growth due to rapid industrialization and increasing investments in research and development.

One of the key factors influencing market demand is the growing emphasis on environmental sustainability. Propyne-based materials offer potential advantages in terms of recyclability and reduced carbon footprint compared to traditional petrochemical products. This aligns well with the global trend towards circular economy principles and stricter environmental regulations.

However, the market for propyne-based products also faces certain challenges. The availability and cost of raw materials, particularly propyne itself, can be a limiting factor. Fluctuations in oil and gas prices directly impact the production costs of propyne and its derivatives, potentially affecting market growth. Additionally, the development of alternative materials and competing technologies poses a potential threat to the market expansion of propyne-based products.

Despite these challenges, the market outlook remains positive. Ongoing research and development efforts are focused on improving the performance and cost-effectiveness of propyne-based materials. Innovations in catalysis and process technologies are expected to enhance the efficiency of propyne production and its conversion into value-added products. This continuous innovation is likely to open up new application areas and market opportunities for propyne-based materials in the future.

In the petrochemical industry, propyne-based products find extensive applications as intermediates for the synthesis of high-value chemicals. The automotive sector utilizes propyne derivatives in the manufacturing of lightweight materials and advanced composites, contributing to improved fuel efficiency and reduced emissions. Additionally, the electronics industry employs propyne-based materials in the production of semiconductors and display technologies, capitalizing on their unique properties.

The global market for propyne-based products is expected to experience steady growth over the coming years. This growth is primarily attributed to the expanding applications in emerging technologies and the increasing focus on sustainable and eco-friendly materials. The Asia-Pacific region, particularly China and India, is anticipated to be a major driver of market growth due to rapid industrialization and increasing investments in research and development.

One of the key factors influencing market demand is the growing emphasis on environmental sustainability. Propyne-based materials offer potential advantages in terms of recyclability and reduced carbon footprint compared to traditional petrochemical products. This aligns well with the global trend towards circular economy principles and stricter environmental regulations.

However, the market for propyne-based products also faces certain challenges. The availability and cost of raw materials, particularly propyne itself, can be a limiting factor. Fluctuations in oil and gas prices directly impact the production costs of propyne and its derivatives, potentially affecting market growth. Additionally, the development of alternative materials and competing technologies poses a potential threat to the market expansion of propyne-based products.

Despite these challenges, the market outlook remains positive. Ongoing research and development efforts are focused on improving the performance and cost-effectiveness of propyne-based materials. Innovations in catalysis and process technologies are expected to enhance the efficiency of propyne production and its conversion into value-added products. This continuous innovation is likely to open up new application areas and market opportunities for propyne-based materials in the future.

Current Challenges in Propyne Material Stability

Propyne-based materials have gained significant attention in various industrial applications due to their unique properties. However, their widespread adoption faces several challenges, primarily related to material stability and degradation mechanisms. One of the most pressing issues is the susceptibility of propyne-based materials to thermal degradation, which can lead to a significant reduction in their mechanical and chemical properties over time.

The thermal instability of propyne-based materials is largely attributed to the presence of the highly reactive triple bond in the propyne molecule. At elevated temperatures, this bond can undergo various reactions, including polymerization, isomerization, and fragmentation, leading to changes in the material's structure and properties. These thermal degradation processes are often accelerated in the presence of oxygen or other reactive species, further complicating the stability issue.

Another major challenge is the photochemical degradation of propyne-based materials. When exposed to ultraviolet (UV) light, these materials can undergo photolysis, resulting in the formation of free radicals and subsequent chain reactions that alter the material's composition and performance. This photosensitivity limits the use of propyne-based materials in outdoor applications or environments with high UV exposure.

Chemical stability is also a significant concern for propyne-based materials. These materials are prone to oxidation and hydrolysis, particularly in humid or acidic environments. The oxidation process can lead to the formation of various oxygenated compounds, which can significantly impact the material's properties and longevity. Additionally, the presence of impurities or catalytic species can accelerate these degradation processes, making it challenging to maintain the material's integrity over extended periods.

The mechanical stability of propyne-based materials under stress is another area of concern. These materials can exhibit creep behavior, where they slowly deform under constant load, potentially leading to failure over time. This issue is particularly problematic in applications where long-term structural integrity is crucial, such as in aerospace or automotive industries.

Furthermore, the degradation of propyne-based materials can result in the release of volatile organic compounds (VOCs), raising environmental and health concerns. This off-gassing phenomenon not only affects the material's performance but also limits its use in certain applications, particularly in enclosed spaces or sensitive environments.

Addressing these stability challenges requires a multifaceted approach, including the development of novel stabilization techniques, improved processing methods, and the design of more robust propyne-based materials. Research efforts are ongoing to enhance the thermal, photochemical, and chemical stability of these materials through the incorporation of stabilizers, UV absorbers, and antioxidants. Additionally, there is a growing focus on understanding the fundamental degradation mechanisms at the molecular level to develop more targeted and effective solutions for improving the overall stability and longevity of propyne-based materials.

The thermal instability of propyne-based materials is largely attributed to the presence of the highly reactive triple bond in the propyne molecule. At elevated temperatures, this bond can undergo various reactions, including polymerization, isomerization, and fragmentation, leading to changes in the material's structure and properties. These thermal degradation processes are often accelerated in the presence of oxygen or other reactive species, further complicating the stability issue.

Another major challenge is the photochemical degradation of propyne-based materials. When exposed to ultraviolet (UV) light, these materials can undergo photolysis, resulting in the formation of free radicals and subsequent chain reactions that alter the material's composition and performance. This photosensitivity limits the use of propyne-based materials in outdoor applications or environments with high UV exposure.

Chemical stability is also a significant concern for propyne-based materials. These materials are prone to oxidation and hydrolysis, particularly in humid or acidic environments. The oxidation process can lead to the formation of various oxygenated compounds, which can significantly impact the material's properties and longevity. Additionally, the presence of impurities or catalytic species can accelerate these degradation processes, making it challenging to maintain the material's integrity over extended periods.

The mechanical stability of propyne-based materials under stress is another area of concern. These materials can exhibit creep behavior, where they slowly deform under constant load, potentially leading to failure over time. This issue is particularly problematic in applications where long-term structural integrity is crucial, such as in aerospace or automotive industries.

Furthermore, the degradation of propyne-based materials can result in the release of volatile organic compounds (VOCs), raising environmental and health concerns. This off-gassing phenomenon not only affects the material's performance but also limits its use in certain applications, particularly in enclosed spaces or sensitive environments.

Addressing these stability challenges requires a multifaceted approach, including the development of novel stabilization techniques, improved processing methods, and the design of more robust propyne-based materials. Research efforts are ongoing to enhance the thermal, photochemical, and chemical stability of these materials through the incorporation of stabilizers, UV absorbers, and antioxidants. Additionally, there is a growing focus on understanding the fundamental degradation mechanisms at the molecular level to develop more targeted and effective solutions for improving the overall stability and longevity of propyne-based materials.

Existing Approaches to Mitigate Degradation

01 Thermal degradation of propyne-based materials

Propyne-based materials undergo thermal degradation at high temperatures. This process involves the breakdown of molecular structures, leading to changes in material properties. Understanding thermal degradation is crucial for developing heat-resistant propyne-based materials and improving their performance in high-temperature applications.- Thermal degradation of propyne-based materials: Propyne-based materials can undergo thermal degradation when exposed to high temperatures. This process involves the breakdown of the molecular structure, potentially leading to changes in material properties and performance. Understanding the thermal degradation mechanisms is crucial for developing heat-resistant propyne-based materials and optimizing their use in high-temperature applications.

- Chemical degradation of propyne-based polymers: Propyne-based polymers are susceptible to chemical degradation when exposed to certain reactive substances or environmental conditions. This can result in chain scission, cross-linking, or other chemical modifications that affect the polymer's properties. Studying the chemical degradation pathways helps in developing strategies to enhance the chemical resistance of propyne-based materials and extend their lifespan in various applications.

- Biodegradation of propyne-containing compounds: Some propyne-based materials may undergo biodegradation when exposed to specific microorganisms or environmental conditions. This process involves the breakdown of the material by biological agents, potentially leading to the formation of simpler compounds. Understanding the biodegradation mechanisms of propyne-based materials is important for assessing their environmental impact and developing more sustainable alternatives.

- Photodegradation of propyne-based materials: Propyne-based materials can be susceptible to photodegradation when exposed to light, particularly UV radiation. This process can lead to changes in the material's physical and chemical properties, affecting its performance and durability. Investigating the photodegradation mechanisms helps in developing strategies to improve the light stability of propyne-based materials and extend their service life in outdoor applications.

- Degradation inhibitors for propyne-based materials: Various additives and treatments can be employed to inhibit or slow down the degradation of propyne-based materials. These inhibitors may include antioxidants, UV stabilizers, or other specialized compounds that protect the material from different degradation mechanisms. Developing effective degradation inhibitors is crucial for enhancing the longevity and performance of propyne-based materials in diverse applications and environments.

02 Chemical degradation mechanisms of propyne-based compounds

Chemical degradation of propyne-based materials can occur through various mechanisms, including oxidation, hydrolysis, and photolysis. These processes can be influenced by environmental factors such as pH, moisture, and light exposure. Studying these mechanisms helps in developing strategies to enhance the chemical stability of propyne-based materials.Expand Specific Solutions03 Biodegradation of propyne-derived polymers

Propyne-derived polymers can undergo biodegradation through the action of microorganisms. This process involves the breakdown of complex polymer structures into simpler compounds. Understanding biodegradation pathways is essential for developing environmentally friendly propyne-based materials and assessing their long-term environmental impact.Expand Specific Solutions04 Stabilization techniques for propyne-based materials

Various stabilization techniques can be employed to enhance the resistance of propyne-based materials to degradation. These may include the use of antioxidants, UV stabilizers, and thermal stabilizers. Developing effective stabilization methods is crucial for extending the lifespan and improving the performance of propyne-based materials in diverse applications.Expand Specific Solutions05 Analytical methods for studying propyne-based material degradation

Advanced analytical techniques are employed to study the degradation of propyne-based materials. These methods may include spectroscopic analysis, chromatography, and thermal analysis. Developing and refining analytical approaches is essential for accurately characterizing degradation processes and evaluating the effectiveness of stabilization strategies.Expand Specific Solutions

Key Players in Propyne Material Research

The research on degradation mechanisms of propyne-based materials is in an emerging stage, with growing interest from both academia and industry. The market size is relatively small but expanding, driven by potential applications in advanced materials and energy sectors. Technologically, the field is still developing, with varying levels of maturity across different aspects. Key players like Zhejiang University, Total Petrochemicals & Refining USA, and King Fahd University of Petroleum & Minerals are contributing to fundamental research. Companies such as Nitto Denko Corp. and China National Petroleum Corp. are exploring practical applications, while institutions like South China University of Technology and Hefei University of Technology are bridging the gap between academic research and industrial implementation.

Zhejiang University

Technical Solution: Zhejiang University has conducted extensive research on the degradation mechanisms of propyne-based materials. Their approach involves advanced spectroscopic techniques, including in-situ FTIR and Raman spectroscopy, to monitor the structural changes during material degradation[1]. They have developed a comprehensive model that accounts for both thermal and oxidative degradation pathways, considering the influence of catalyst residues and impurities on the degradation process[2]. The university's research team has also explored the use of stabilizers and antioxidants to enhance the thermal and oxidative stability of propyne-based materials, particularly focusing on their application in high-temperature environments[3].

Strengths: Comprehensive understanding of degradation pathways, advanced analytical techniques, and innovative stabilization methods. Weaknesses: Potential limitations in scaling up laboratory findings to industrial applications.

Total Petrochemicals & Refining USA, Inc.

Technical Solution: Total Petrochemicals & Refining USA has developed a multi-faceted approach to studying the degradation mechanisms of propyne-based materials, particularly in the context of petrochemical processes. Their research focuses on the impact of process conditions, such as temperature, pressure, and catalyst composition, on the stability of propyne-derived polymers and intermediates[4]. The company has implemented advanced online monitoring systems to detect early signs of material degradation in their production facilities, allowing for real-time adjustments to process parameters[5]. Additionally, they have invested in the development of novel catalyst systems that minimize unwanted side reactions and improve the selectivity towards desired propyne-based products, thereby reducing degradation issues[6].

Strengths: Industrial-scale research capabilities, real-time monitoring systems, and practical application of findings. Weaknesses: Potential bias towards petrochemical industry-specific applications, possibly overlooking other uses of propyne-based materials.

Critical Studies on Propyne Degradation Pathways

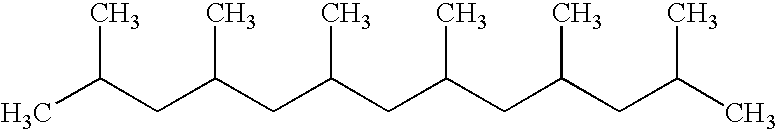

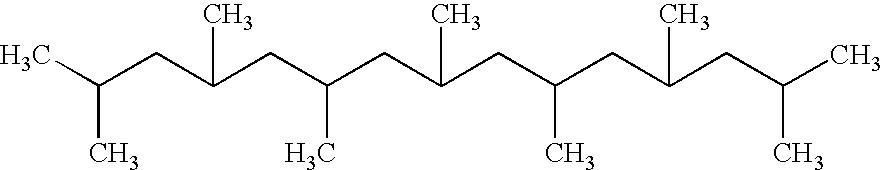

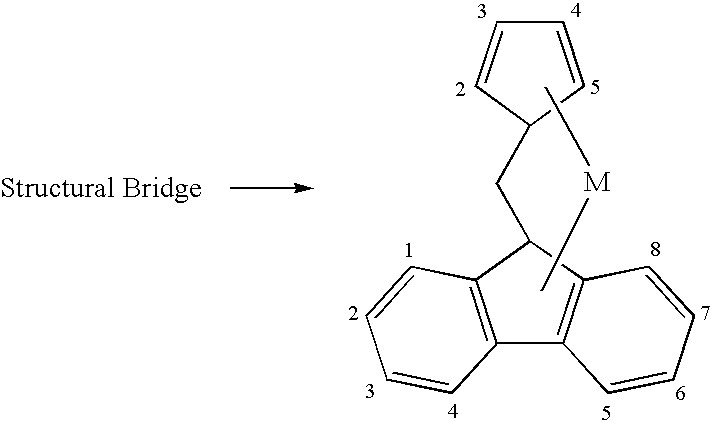

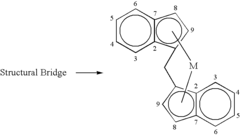

Radiation Resistant Polypropylene Materials

PatentInactiveUS20080275180A1

Innovation

- A blend of isotactic and syndiotactic polypropylene polymers with specific molecular weight distribution and xylene solubles content is used, combined with metallocene catalyst systems, to enhance radiation resistance and maintain machine direction elongation strength, even after exposure to high-energy radiation.

Radiation resistant polypropylene materials

PatentWO2008137449A1

Innovation

- A blend of isotactic and syndiotactic polypropylene polymers with specific molecular weight distribution and xylene solubles content is used, along with metallocene catalyst systems, to enhance radiation resistance and maintain strength properties after exposure to high-energy radiation.

Environmental Impact of Propyne Degradation

The environmental impact of propyne degradation is a critical aspect to consider in the research on degradation mechanisms of propyne-based materials. Propyne, also known as methylacetylene, is a highly reactive alkyne that can undergo various degradation processes, potentially leading to significant environmental consequences.

One of the primary environmental concerns associated with propyne degradation is the formation of atmospheric pollutants. When propyne breaks down in the atmosphere, it can contribute to the production of ground-level ozone, a major component of smog. This process occurs through complex photochemical reactions involving nitrogen oxides and volatile organic compounds. The resulting ozone can have detrimental effects on human health, vegetation, and ecosystems.

Furthermore, the degradation of propyne-based materials may release harmful byproducts into the environment. These byproducts can include various organic compounds, some of which may be toxic or persistent in nature. The accumulation of these substances in soil and water bodies can lead to long-term environmental contamination, affecting both terrestrial and aquatic ecosystems.

The potential for propyne and its degradation products to act as greenhouse gases is another significant environmental concern. While propyne itself has a relatively short atmospheric lifetime, some of its degradation products may have longer lifespans and contribute to global warming. This aspect requires careful consideration in the context of climate change mitigation strategies.

In aquatic environments, the degradation of propyne-based materials can impact water quality and aquatic life. The introduction of propyne and its degradation products into water systems may alter pH levels, dissolved oxygen content, and nutrient balances. These changes can disrupt aquatic ecosystems, potentially leading to algal blooms, fish kills, or other ecological disturbances.

The biodegradability of propyne-based materials is a crucial factor in assessing their overall environmental impact. Materials that degrade rapidly may have less long-term environmental persistence but could potentially release a higher concentration of byproducts in a shorter timeframe. Conversely, more stable materials may have extended environmental lifetimes but could lead to prolonged low-level exposure to degradation products.

Soil contamination is another potential consequence of propyne degradation. As propyne-based materials break down, they may release compounds that can alter soil chemistry, affecting microbial communities and plant growth. This can have cascading effects on terrestrial ecosystems and potentially impact agricultural productivity in affected areas.

Understanding the environmental fate and transport of propyne and its degradation products is essential for accurate risk assessment and management. Factors such as atmospheric dispersion, water solubility, and soil adsorption properties play crucial roles in determining the extent and duration of environmental impacts. Comprehensive studies on these aspects are necessary to develop effective strategies for mitigating the environmental risks associated with propyne-based materials.

One of the primary environmental concerns associated with propyne degradation is the formation of atmospheric pollutants. When propyne breaks down in the atmosphere, it can contribute to the production of ground-level ozone, a major component of smog. This process occurs through complex photochemical reactions involving nitrogen oxides and volatile organic compounds. The resulting ozone can have detrimental effects on human health, vegetation, and ecosystems.

Furthermore, the degradation of propyne-based materials may release harmful byproducts into the environment. These byproducts can include various organic compounds, some of which may be toxic or persistent in nature. The accumulation of these substances in soil and water bodies can lead to long-term environmental contamination, affecting both terrestrial and aquatic ecosystems.

The potential for propyne and its degradation products to act as greenhouse gases is another significant environmental concern. While propyne itself has a relatively short atmospheric lifetime, some of its degradation products may have longer lifespans and contribute to global warming. This aspect requires careful consideration in the context of climate change mitigation strategies.

In aquatic environments, the degradation of propyne-based materials can impact water quality and aquatic life. The introduction of propyne and its degradation products into water systems may alter pH levels, dissolved oxygen content, and nutrient balances. These changes can disrupt aquatic ecosystems, potentially leading to algal blooms, fish kills, or other ecological disturbances.

The biodegradability of propyne-based materials is a crucial factor in assessing their overall environmental impact. Materials that degrade rapidly may have less long-term environmental persistence but could potentially release a higher concentration of byproducts in a shorter timeframe. Conversely, more stable materials may have extended environmental lifetimes but could lead to prolonged low-level exposure to degradation products.

Soil contamination is another potential consequence of propyne degradation. As propyne-based materials break down, they may release compounds that can alter soil chemistry, affecting microbial communities and plant growth. This can have cascading effects on terrestrial ecosystems and potentially impact agricultural productivity in affected areas.

Understanding the environmental fate and transport of propyne and its degradation products is essential for accurate risk assessment and management. Factors such as atmospheric dispersion, water solubility, and soil adsorption properties play crucial roles in determining the extent and duration of environmental impacts. Comprehensive studies on these aspects are necessary to develop effective strategies for mitigating the environmental risks associated with propyne-based materials.

Regulatory Framework for Propyne-based Materials

The regulatory framework for propyne-based materials is a complex and evolving landscape that aims to ensure the safe production, handling, and use of these substances. Propyne, also known as methylacetylene, is a highly flammable gas with various industrial applications. Due to its potential hazards, regulatory bodies worldwide have implemented stringent guidelines and standards to govern its use.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific regulations for propyne under the Hazardous Materials Standards. These regulations outline requirements for workplace safety, including proper storage, handling procedures, and personal protective equipment. The Environmental Protection Agency (EPA) also regulates propyne under the Clean Air Act, focusing on emissions control and environmental impact.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to propyne and its derivatives. REACH requires manufacturers and importers to register substances and provide detailed safety information. Additionally, the Classification, Labeling, and Packaging (CLP) Regulation ensures that the hazards of propyne-based materials are clearly communicated to workers and consumers.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both address the management of propyne and related materials. These regulations focus on risk assessment, data submission, and safety measures.

International standards, such as those set by the International Organization for Standardization (ISO), provide guidelines for the safe handling and transportation of propyne. The United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) has been widely adopted, ensuring consistent hazard communication across borders.

As research on the degradation mechanisms of propyne-based materials progresses, regulatory frameworks are likely to evolve. Emerging concerns about long-term environmental impacts and potential health effects may lead to more stringent regulations. Manufacturers and researchers working with propyne-based materials must stay informed about these regulatory changes and adapt their practices accordingly to ensure compliance and safety.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific regulations for propyne under the Hazardous Materials Standards. These regulations outline requirements for workplace safety, including proper storage, handling procedures, and personal protective equipment. The Environmental Protection Agency (EPA) also regulates propyne under the Clean Air Act, focusing on emissions control and environmental impact.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to propyne and its derivatives. REACH requires manufacturers and importers to register substances and provide detailed safety information. Additionally, the Classification, Labeling, and Packaging (CLP) Regulation ensures that the hazards of propyne-based materials are clearly communicated to workers and consumers.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both address the management of propyne and related materials. These regulations focus on risk assessment, data submission, and safety measures.

International standards, such as those set by the International Organization for Standardization (ISO), provide guidelines for the safe handling and transportation of propyne. The United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) has been widely adopted, ensuring consistent hazard communication across borders.

As research on the degradation mechanisms of propyne-based materials progresses, regulatory frameworks are likely to evolve. Emerging concerns about long-term environmental impacts and potential health effects may lead to more stringent regulations. Manufacturers and researchers working with propyne-based materials must stay informed about these regulatory changes and adapt their practices accordingly to ensure compliance and safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!