How Propyne Enables Low-Temperature Catalytic Reactions

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Catalysis Background and Objectives

Propyne, also known as methylacetylene, has emerged as a promising enabler for low-temperature catalytic reactions in recent years. This aliphatic hydrocarbon, with its unique triple bond structure, offers significant potential for various industrial applications, particularly in the field of catalysis. The evolution of propyne-enabled catalysis can be traced back to the early 2000s when researchers began exploring its reactivity under mild conditions.

The primary objective of propyne-enabled low-temperature catalysis is to develop more energy-efficient and environmentally friendly chemical processes. By lowering reaction temperatures, these catalytic systems aim to reduce energy consumption, minimize unwanted side reactions, and improve overall process economics. This aligns with the growing global emphasis on sustainable chemistry and green technology.

Propyne's ability to facilitate low-temperature catalytic reactions stems from its high reactivity and versatility as a C3 building block. Its triple bond can undergo various transformations, including hydrogenation, hydration, and cycloaddition reactions, often at temperatures significantly lower than those required for traditional catalytic processes. This unique reactivity profile has sparked interest in both academia and industry, leading to a surge in research activities over the past decade.

The technological trajectory of propyne catalysis has been marked by several key milestones. Initial studies focused on understanding the fundamental reaction mechanisms and developing suitable catalysts. Subsequent research has expanded into exploring novel reaction pathways, improving catalyst selectivity, and enhancing process efficiency. Recent advancements have also targeted the integration of propyne-enabled catalysis with other emerging technologies, such as flow chemistry and artificial intelligence-driven catalyst design.

As the field progresses, researchers are increasingly focusing on addressing challenges related to catalyst stability, selectivity, and scalability. The ultimate goal is to develop robust catalytic systems that can be implemented in large-scale industrial processes, potentially revolutionizing the production of various chemicals and materials. This includes applications in pharmaceuticals, fine chemicals, and polymer synthesis, where low-temperature reactions can offer significant advantages in terms of product quality and process control.

The ongoing exploration of propyne-enabled low-temperature catalysis represents a convergence of multiple scientific disciplines, including organic chemistry, materials science, and chemical engineering. This interdisciplinary approach is crucial for overcoming existing limitations and pushing the boundaries of what is possible in catalytic chemistry. As research in this field continues to evolve, it holds the promise of enabling more sustainable and efficient chemical processes across a wide range of industries.

The primary objective of propyne-enabled low-temperature catalysis is to develop more energy-efficient and environmentally friendly chemical processes. By lowering reaction temperatures, these catalytic systems aim to reduce energy consumption, minimize unwanted side reactions, and improve overall process economics. This aligns with the growing global emphasis on sustainable chemistry and green technology.

Propyne's ability to facilitate low-temperature catalytic reactions stems from its high reactivity and versatility as a C3 building block. Its triple bond can undergo various transformations, including hydrogenation, hydration, and cycloaddition reactions, often at temperatures significantly lower than those required for traditional catalytic processes. This unique reactivity profile has sparked interest in both academia and industry, leading to a surge in research activities over the past decade.

The technological trajectory of propyne catalysis has been marked by several key milestones. Initial studies focused on understanding the fundamental reaction mechanisms and developing suitable catalysts. Subsequent research has expanded into exploring novel reaction pathways, improving catalyst selectivity, and enhancing process efficiency. Recent advancements have also targeted the integration of propyne-enabled catalysis with other emerging technologies, such as flow chemistry and artificial intelligence-driven catalyst design.

As the field progresses, researchers are increasingly focusing on addressing challenges related to catalyst stability, selectivity, and scalability. The ultimate goal is to develop robust catalytic systems that can be implemented in large-scale industrial processes, potentially revolutionizing the production of various chemicals and materials. This includes applications in pharmaceuticals, fine chemicals, and polymer synthesis, where low-temperature reactions can offer significant advantages in terms of product quality and process control.

The ongoing exploration of propyne-enabled low-temperature catalysis represents a convergence of multiple scientific disciplines, including organic chemistry, materials science, and chemical engineering. This interdisciplinary approach is crucial for overcoming existing limitations and pushing the boundaries of what is possible in catalytic chemistry. As research in this field continues to evolve, it holds the promise of enabling more sustainable and efficient chemical processes across a wide range of industries.

Market Demand for Low-Temperature Catalytic Processes

The market demand for low-temperature catalytic processes has been steadily growing across various industries due to their potential for energy efficiency, cost reduction, and environmental benefits. These processes are particularly attractive in sectors such as chemical manufacturing, pharmaceuticals, and energy production, where traditional high-temperature reactions often lead to significant energy consumption and unwanted side products.

In the chemical industry, there is a strong push towards greener and more sustainable production methods. Low-temperature catalytic reactions offer a promising solution by reducing energy requirements and improving selectivity. This trend is driven by increasingly stringent environmental regulations and the industry's commitment to reducing its carbon footprint. Companies are actively seeking technologies that can operate at lower temperatures while maintaining or improving product yields.

The pharmaceutical sector has shown considerable interest in low-temperature catalysis for the synthesis of complex molecules and intermediates. These processes can enable the production of temperature-sensitive compounds and improve the overall efficiency of drug manufacturing. As the demand for personalized medicine and novel therapeutics continues to rise, the need for more precise and controllable reaction conditions becomes paramount.

Energy production and refining industries are also exploring low-temperature catalytic processes as a means to optimize fuel production and reduce emissions. With the global focus on cleaner energy sources, there is a growing market for technologies that can efficiently convert raw materials into high-value products under milder conditions.

The potential of propyne in enabling low-temperature catalytic reactions has garnered attention from researchers and industry professionals alike. Its unique properties as a reactive alkyne make it an attractive candidate for various catalytic transformations. The market demand for propyne-based low-temperature catalysis is expected to grow as more applications are discovered and optimized.

However, the adoption of these technologies faces challenges such as catalyst stability, scalability, and integration into existing industrial processes. Overcoming these hurdles presents significant market opportunities for companies that can develop robust and efficient low-temperature catalytic systems.

As sustainability becomes a key driver in industrial decision-making, the market for low-temperature catalytic processes is projected to expand. This growth is further supported by advancements in catalyst design, process engineering, and the increasing availability of renewable feedstocks. The ability of propyne to facilitate these reactions at lower temperatures aligns well with the market's demand for more efficient and environmentally friendly production methods.

In the chemical industry, there is a strong push towards greener and more sustainable production methods. Low-temperature catalytic reactions offer a promising solution by reducing energy requirements and improving selectivity. This trend is driven by increasingly stringent environmental regulations and the industry's commitment to reducing its carbon footprint. Companies are actively seeking technologies that can operate at lower temperatures while maintaining or improving product yields.

The pharmaceutical sector has shown considerable interest in low-temperature catalysis for the synthesis of complex molecules and intermediates. These processes can enable the production of temperature-sensitive compounds and improve the overall efficiency of drug manufacturing. As the demand for personalized medicine and novel therapeutics continues to rise, the need for more precise and controllable reaction conditions becomes paramount.

Energy production and refining industries are also exploring low-temperature catalytic processes as a means to optimize fuel production and reduce emissions. With the global focus on cleaner energy sources, there is a growing market for technologies that can efficiently convert raw materials into high-value products under milder conditions.

The potential of propyne in enabling low-temperature catalytic reactions has garnered attention from researchers and industry professionals alike. Its unique properties as a reactive alkyne make it an attractive candidate for various catalytic transformations. The market demand for propyne-based low-temperature catalysis is expected to grow as more applications are discovered and optimized.

However, the adoption of these technologies faces challenges such as catalyst stability, scalability, and integration into existing industrial processes. Overcoming these hurdles presents significant market opportunities for companies that can develop robust and efficient low-temperature catalytic systems.

As sustainability becomes a key driver in industrial decision-making, the market for low-temperature catalytic processes is projected to expand. This growth is further supported by advancements in catalyst design, process engineering, and the increasing availability of renewable feedstocks. The ability of propyne to facilitate these reactions at lower temperatures aligns well with the market's demand for more efficient and environmentally friendly production methods.

Current State and Challenges in Propyne Catalysis

Propyne catalysis has made significant strides in recent years, enabling a wide range of low-temperature reactions. The current state of propyne catalysis is characterized by a growing understanding of reaction mechanisms and the development of increasingly efficient catalytic systems. Researchers have successfully demonstrated the use of propyne as a versatile C3 building block in various organic transformations, including hydrogenation, hydration, and coupling reactions.

One of the key advancements in propyne catalysis is the design of highly selective catalysts that can operate at lower temperatures. These catalysts often incorporate transition metals such as palladium, platinum, and gold, which have shown remarkable activity in activating the carbon-carbon triple bond of propyne. The use of support materials and ligands has further enhanced catalyst performance, allowing for improved stability and recyclability.

Despite these achievements, several challenges remain in the field of propyne catalysis. One major hurdle is the control of reaction selectivity, particularly in complex reaction networks. Propyne can undergo multiple transformations, and directing the reaction towards the desired product while minimizing side reactions is crucial for industrial applications. This challenge is especially pronounced in the synthesis of fine chemicals and pharmaceuticals, where high purity and yield are essential.

Another significant challenge is the development of more sustainable catalytic systems. Many current catalysts rely on precious metals, which are expensive and have limited availability. There is a growing need for catalysts based on earth-abundant elements that can match or exceed the performance of noble metal catalysts. Additionally, the use of greener solvents and reaction conditions is becoming increasingly important to align with environmental regulations and sustainability goals.

The scalability of propyne catalytic processes also presents challenges. While many reactions have been successfully demonstrated at the laboratory scale, translating these processes to industrial production levels often requires overcoming issues related to heat and mass transfer, catalyst deactivation, and process economics. Researchers are actively working on developing more robust catalysts and reactor designs to address these scaling challenges.

Furthermore, the mechanistic understanding of propyne catalysis at low temperatures is still evolving. Elucidating the precise reaction pathways and intermediate species involved in these transformations is crucial for rational catalyst design and process optimization. Advanced spectroscopic techniques and computational modeling are being employed to gain deeper insights into the molecular-level events occurring during catalysis.

In conclusion, while propyne catalysis has made remarkable progress in enabling low-temperature reactions, there are still significant challenges to overcome. Addressing these issues will require interdisciplinary collaboration and innovative approaches to catalyst design, reaction engineering, and process development.

One of the key advancements in propyne catalysis is the design of highly selective catalysts that can operate at lower temperatures. These catalysts often incorporate transition metals such as palladium, platinum, and gold, which have shown remarkable activity in activating the carbon-carbon triple bond of propyne. The use of support materials and ligands has further enhanced catalyst performance, allowing for improved stability and recyclability.

Despite these achievements, several challenges remain in the field of propyne catalysis. One major hurdle is the control of reaction selectivity, particularly in complex reaction networks. Propyne can undergo multiple transformations, and directing the reaction towards the desired product while minimizing side reactions is crucial for industrial applications. This challenge is especially pronounced in the synthesis of fine chemicals and pharmaceuticals, where high purity and yield are essential.

Another significant challenge is the development of more sustainable catalytic systems. Many current catalysts rely on precious metals, which are expensive and have limited availability. There is a growing need for catalysts based on earth-abundant elements that can match or exceed the performance of noble metal catalysts. Additionally, the use of greener solvents and reaction conditions is becoming increasingly important to align with environmental regulations and sustainability goals.

The scalability of propyne catalytic processes also presents challenges. While many reactions have been successfully demonstrated at the laboratory scale, translating these processes to industrial production levels often requires overcoming issues related to heat and mass transfer, catalyst deactivation, and process economics. Researchers are actively working on developing more robust catalysts and reactor designs to address these scaling challenges.

Furthermore, the mechanistic understanding of propyne catalysis at low temperatures is still evolving. Elucidating the precise reaction pathways and intermediate species involved in these transformations is crucial for rational catalyst design and process optimization. Advanced spectroscopic techniques and computational modeling are being employed to gain deeper insights into the molecular-level events occurring during catalysis.

In conclusion, while propyne catalysis has made remarkable progress in enabling low-temperature reactions, there are still significant challenges to overcome. Addressing these issues will require interdisciplinary collaboration and innovative approaches to catalyst design, reaction engineering, and process development.

Existing Low-Temperature Propyne Catalytic Solutions

01 Temperature control in propyne production

Temperature control is crucial in the production and handling of propyne. Various methods are employed to maintain optimal temperatures during synthesis, purification, and storage processes. This includes cooling systems, heat exchangers, and temperature monitoring devices to ensure safety and efficiency.- Temperature control in propyne production: Temperature control is crucial in the production and handling of propyne. Various methods and systems are employed to maintain optimal temperature conditions during synthesis, purification, and storage processes. This includes cooling systems, heat exchangers, and temperature monitoring devices to ensure product quality and safety.

- Propyne separation and purification techniques: Separation and purification of propyne from other hydrocarbons often involve temperature-dependent processes. These may include cryogenic distillation, membrane separation, or adsorption techniques. Controlling the temperature during these processes is essential for achieving high purity propyne.

- Temperature effects on propyne reactions: The temperature at which propyne reactions occur can significantly impact the yield and selectivity of the products. Research focuses on understanding and optimizing reaction temperatures for various propyne-based syntheses, including polymerization and addition reactions.

- Storage and transportation temperature considerations: Proper temperature management is critical for the safe storage and transportation of propyne. This includes designing storage tanks and transport vessels with appropriate insulation and temperature control systems to prevent unwanted reactions or phase changes.

- Temperature measurement and monitoring in propyne systems: Accurate temperature measurement and monitoring are essential in propyne-related processes. Advanced sensors and control systems are employed to maintain precise temperature conditions throughout production, processing, and handling stages, ensuring process efficiency and safety.

02 Propyne separation and purification techniques

Separation and purification of propyne from other hydrocarbons often involve temperature-dependent processes. These may include cryogenic distillation, membrane separation, or adsorption techniques. The temperature at which these processes occur significantly affects the purity and yield of the final product.Expand Specific Solutions03 Thermal stability and decomposition of propyne

Understanding the thermal stability of propyne is essential for its safe handling and storage. Research focuses on determining the temperature range at which propyne remains stable and the conditions under which it may decompose or polymerize. This knowledge is crucial for designing appropriate storage and transportation systems.Expand Specific Solutions04 Temperature effects on propyne reactions

Temperature plays a significant role in propyne's reactivity and its use as a feedstock in various chemical processes. Studies investigate how different temperatures affect reaction rates, selectivity, and yield in propyne-based syntheses, such as hydrogenation, oxidation, or polymerization reactions.Expand Specific Solutions05 Low-temperature applications of propyne

Propyne's properties at low temperatures are explored for various applications. This includes its use as a refrigerant, in cryogenic systems, or as a component in low-temperature chemical processes. Research in this area focuses on propyne's behavior and effectiveness at temperatures significantly below ambient conditions.Expand Specific Solutions

Key Players in Propyne Catalysis Research and Industry

The competitive landscape for propyne-enabled low-temperature catalytic reactions is in an early development stage, with significant potential for growth. The market size is currently limited but expected to expand as the technology matures. Key players like BASF, ExxonMobil, and Saudi Aramco are investing in research and development to advance this field. Chinese institutions, including the Chinese Academy of Sciences and Tianjin University, are also making notable contributions. The technology's maturity is still evolving, with companies like Idemitsu Kosan and Solvay exploring innovative applications. As environmental regulations tighten, this eco-friendly approach to catalysis is likely to gain traction across various industrial sectors.

BASF Corp.

Technical Solution: BASF has pioneered a low-temperature catalytic process for propyne utilization in the production of high-value chemicals. Their approach involves a multi-step reaction sequence that begins with the partial oxidation of propyne at temperatures below 100°C [4]. This is achieved using a proprietary copper-based catalyst that shows exceptional stability and selectivity. The process then incorporates a novel coupling reaction to form larger molecules, such as C6 and C9 compounds, which are valuable precursors for various industrial applications [5]. BASF's technology also includes an innovative purification system that removes impurities and byproducts, ensuring high-quality final products.

Strengths: Versatile production of high-value chemicals, efficient use of propyne feedstock, and lower energy requirements. Weaknesses: Complex multi-step process may require precise control and specialized equipment.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a groundbreaking low-temperature catalytic process for propyne conversion using advanced nanocatalysts. Their technology employs a bimetallic nanoparticle catalyst composed of platinum and cobalt, supported on a high-surface-area zeolite [6]. This catalyst system enables the selective oligomerization of propyne at temperatures as low as 50°C, producing a range of valuable liquid hydrocarbons. The process incorporates a unique flow reactor design that enhances mass transfer and allows for continuous operation [7]. Additionally, Saudi Aramco's technology includes an in-situ catalyst regeneration system, which significantly extends catalyst lifetime and improves overall process economics.

Strengths: High selectivity towards valuable liquid products, continuous operation capability, and extended catalyst lifetime. Weaknesses: Potential challenges in scaling up the nanocatalyst production and higher initial capital costs.

Core Innovations in Propyne-Enabled Catalysis

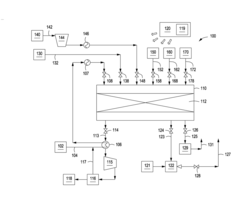

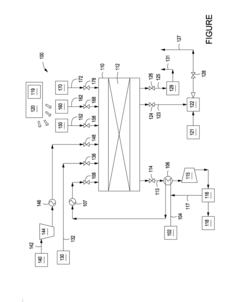

Methods for dehydrogenating one or more alkanes

PatentInactiveUS20170333889A1

Innovation

- A method involving contacting an alkane with a catalyst under reduced pressure, separating the dehydrogenated product, and using a purge fluid to remove residuals before combusting coke with an oxygen-containing fluid to regenerate the catalyst, followed by exposure to a reducing gas to produce a fully regenerated catalyst, which is then reused for further dehydrogenation.

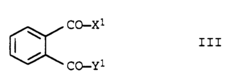

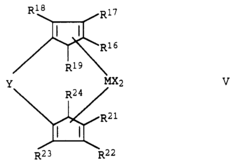

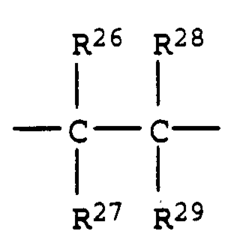

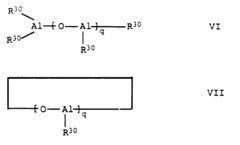

Low temperature impact-resistant composition of semicrystalline propylene homopolymers

PatentInactiveEP0643100A1

Innovation

- Propylene polymers are prepared by mixing components in a single reaction zone using two different catalyst systems, such as Ziegler-Natta catalysts or metallocene complexes, to produce partially crystalline homopolymers with specific melting points and glass transition temperatures, simplifying the process engineering and achieving a balanced property profile.

Environmental Impact of Propyne-Based Catalytic Processes

The environmental impact of propyne-based catalytic processes is a critical consideration in the development and implementation of low-temperature catalytic reactions. Propyne, also known as methylacetylene, offers unique advantages in enabling catalytic reactions at lower temperatures, which can lead to significant environmental benefits.

One of the primary environmental advantages of propyne-based catalytic processes is the reduced energy consumption compared to traditional high-temperature catalytic reactions. By operating at lower temperatures, these processes require less energy input, resulting in decreased greenhouse gas emissions associated with energy production. This aligns with global efforts to mitigate climate change and reduce the carbon footprint of industrial processes.

Furthermore, the use of propyne as a catalyst or reactant in low-temperature reactions can lead to improved selectivity and yield of desired products. This increased efficiency translates to reduced waste generation and fewer byproducts, minimizing the environmental impact of chemical manufacturing processes. The ability to conduct reactions at lower temperatures also reduces the risk of unwanted side reactions, further enhancing the overall sustainability of the process.

Propyne-based catalytic processes often demonstrate enhanced atom economy, meaning a higher percentage of reactant atoms are incorporated into the final product. This efficiency reduces the consumption of raw materials and minimizes the generation of waste streams, contributing to resource conservation and pollution prevention.

The lower operating temperatures of propyne-enabled catalytic reactions also contribute to improved process safety. Reduced thermal stress on equipment and materials can lead to longer equipment lifespans, reducing the environmental impact associated with manufacturing and replacing industrial infrastructure.

However, it is important to consider the potential environmental risks associated with propyne itself. As a flammable gas, proper handling and storage protocols must be implemented to prevent accidental releases or combustion, which could have localized environmental impacts. Additionally, the production of propyne should be evaluated for its environmental footprint to ensure that the benefits of its use in catalytic processes outweigh the impacts of its manufacture.

In terms of life cycle assessment, propyne-based catalytic processes generally show favorable environmental profiles compared to traditional high-temperature alternatives. The reduced energy requirements and improved reaction efficiencies often result in lower overall environmental impacts across various categories, including global warming potential, acidification, and resource depletion.

As research in this field progresses, there is potential for further environmental improvements through the development of more efficient catalysts and reaction systems optimized for propyne-based processes. This ongoing innovation may lead to even greater reductions in energy consumption, waste generation, and overall environmental impact of chemical manufacturing processes.

One of the primary environmental advantages of propyne-based catalytic processes is the reduced energy consumption compared to traditional high-temperature catalytic reactions. By operating at lower temperatures, these processes require less energy input, resulting in decreased greenhouse gas emissions associated with energy production. This aligns with global efforts to mitigate climate change and reduce the carbon footprint of industrial processes.

Furthermore, the use of propyne as a catalyst or reactant in low-temperature reactions can lead to improved selectivity and yield of desired products. This increased efficiency translates to reduced waste generation and fewer byproducts, minimizing the environmental impact of chemical manufacturing processes. The ability to conduct reactions at lower temperatures also reduces the risk of unwanted side reactions, further enhancing the overall sustainability of the process.

Propyne-based catalytic processes often demonstrate enhanced atom economy, meaning a higher percentage of reactant atoms are incorporated into the final product. This efficiency reduces the consumption of raw materials and minimizes the generation of waste streams, contributing to resource conservation and pollution prevention.

The lower operating temperatures of propyne-enabled catalytic reactions also contribute to improved process safety. Reduced thermal stress on equipment and materials can lead to longer equipment lifespans, reducing the environmental impact associated with manufacturing and replacing industrial infrastructure.

However, it is important to consider the potential environmental risks associated with propyne itself. As a flammable gas, proper handling and storage protocols must be implemented to prevent accidental releases or combustion, which could have localized environmental impacts. Additionally, the production of propyne should be evaluated for its environmental footprint to ensure that the benefits of its use in catalytic processes outweigh the impacts of its manufacture.

In terms of life cycle assessment, propyne-based catalytic processes generally show favorable environmental profiles compared to traditional high-temperature alternatives. The reduced energy requirements and improved reaction efficiencies often result in lower overall environmental impacts across various categories, including global warming potential, acidification, and resource depletion.

As research in this field progresses, there is potential for further environmental improvements through the development of more efficient catalysts and reaction systems optimized for propyne-based processes. This ongoing innovation may lead to even greater reductions in energy consumption, waste generation, and overall environmental impact of chemical manufacturing processes.

Economic Viability of Propyne Catalysis Technologies

The economic viability of propyne catalysis technologies hinges on several key factors that impact their potential for commercial adoption and scalability. One of the primary considerations is the cost-effectiveness of propyne as a feedstock compared to traditional catalytic processes. Propyne's ability to enable low-temperature reactions offers significant energy savings, potentially reducing operational costs in industrial applications.

However, the availability and production costs of propyne itself must be carefully evaluated. Currently, propyne is primarily obtained as a byproduct of petroleum refining and ethylene production. The limited supply and fluctuating prices of propyne could pose challenges to its widespread use in catalytic processes. To ensure economic viability, it may be necessary to develop more efficient and cost-effective methods for propyne production or identify alternative sources.

The capital investment required for implementing propyne-based catalytic systems is another crucial factor. While the lower reaction temperatures may reduce energy costs, the initial outlay for specialized equipment and catalysts needs to be considered. The longevity and reusability of these catalysts will significantly impact the overall economic feasibility of the technology.

Market demand for products derived from propyne-enabled catalytic reactions will play a vital role in determining economic viability. Industries such as pharmaceuticals, fine chemicals, and materials science could potentially benefit from the selective and efficient reactions facilitated by propyne catalysis. However, the market size and growth potential for these specific applications must be carefully assessed to justify investment in the technology.

Regulatory factors and environmental considerations also influence the economic landscape for propyne catalysis. The technology's potential to reduce energy consumption and improve reaction selectivity aligns well with sustainability goals, which could provide a competitive advantage in markets with stringent environmental regulations. However, safety concerns related to propyne's flammability and potential toxicity must be addressed, potentially incurring additional costs for safety measures and compliance.

Scalability is a critical aspect of economic viability. The ability to transition propyne catalysis technologies from laboratory-scale demonstrations to industrial-scale production will determine their commercial success. This includes considerations such as process efficiency, yield optimization, and the ability to integrate these technologies into existing manufacturing infrastructure.

In conclusion, while propyne-enabled low-temperature catalytic reactions show promise in terms of energy efficiency and reaction selectivity, their economic viability depends on a complex interplay of factors. Careful analysis of production costs, market demand, regulatory landscape, and scalability potential is essential to determine the long-term economic feasibility of propyne catalysis technologies in various industrial applications.

However, the availability and production costs of propyne itself must be carefully evaluated. Currently, propyne is primarily obtained as a byproduct of petroleum refining and ethylene production. The limited supply and fluctuating prices of propyne could pose challenges to its widespread use in catalytic processes. To ensure economic viability, it may be necessary to develop more efficient and cost-effective methods for propyne production or identify alternative sources.

The capital investment required for implementing propyne-based catalytic systems is another crucial factor. While the lower reaction temperatures may reduce energy costs, the initial outlay for specialized equipment and catalysts needs to be considered. The longevity and reusability of these catalysts will significantly impact the overall economic feasibility of the technology.

Market demand for products derived from propyne-enabled catalytic reactions will play a vital role in determining economic viability. Industries such as pharmaceuticals, fine chemicals, and materials science could potentially benefit from the selective and efficient reactions facilitated by propyne catalysis. However, the market size and growth potential for these specific applications must be carefully assessed to justify investment in the technology.

Regulatory factors and environmental considerations also influence the economic landscape for propyne catalysis. The technology's potential to reduce energy consumption and improve reaction selectivity aligns well with sustainability goals, which could provide a competitive advantage in markets with stringent environmental regulations. However, safety concerns related to propyne's flammability and potential toxicity must be addressed, potentially incurring additional costs for safety measures and compliance.

Scalability is a critical aspect of economic viability. The ability to transition propyne catalysis technologies from laboratory-scale demonstrations to industrial-scale production will determine their commercial success. This includes considerations such as process efficiency, yield optimization, and the ability to integrate these technologies into existing manufacturing infrastructure.

In conclusion, while propyne-enabled low-temperature catalytic reactions show promise in terms of energy efficiency and reaction selectivity, their economic viability depends on a complex interplay of factors. Careful analysis of production costs, market demand, regulatory landscape, and scalability potential is essential to determine the long-term economic feasibility of propyne catalysis technologies in various industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!