How Propyne Improves Thermal Resistance in Coatings

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Coatings Background

Propyne, also known as methylacetylene, has emerged as a promising compound for enhancing thermal resistance in coatings. This aliphatic hydrocarbon, with its unique triple bond structure, has garnered significant attention in the field of materials science and coating technology. The journey of propyne's application in thermal-resistant coatings began in the late 20th century, as researchers sought innovative solutions to protect surfaces from extreme temperatures and thermal degradation.

The development of propyne-based coatings represents a convergence of polymer chemistry and materials engineering. Initially, propyne was primarily used in organic synthesis and as a fuel gas. However, its potential in coating applications was recognized when scientists observed its ability to form highly crosslinked networks when polymerized. This property, combined with its low molecular weight and high reactivity, made propyne an ideal candidate for creating dense, thermally resistant coating matrices.

The evolution of propyne coatings has been driven by the increasing demand for materials that can withstand extreme thermal conditions in various industries. Aerospace, automotive, and industrial sectors have been at the forefront of adopting and advancing this technology. The need for thermal protection in these fields has pushed researchers to explore the fundamental mechanisms by which propyne enhances thermal resistance.

One of the key breakthroughs in propyne coating technology came with the development of plasma-enhanced chemical vapor deposition (PECVD) techniques. This method allowed for the controlled deposition of propyne-based films with exceptional thermal properties. The PECVD process enabled the creation of highly crosslinked, amorphous carbon networks that exhibited remarkable thermal stability and low thermal conductivity.

As research progressed, scientists began to explore the synergistic effects of combining propyne with other materials to further enhance thermal resistance. Nanocomposite coatings incorporating propyne-derived matrices with ceramic nanoparticles showed promising results, offering improved thermal barrier properties and mechanical strength. These advancements opened new avenues for the application of propyne coatings in more demanding environments.

The current state of propyne coating technology reflects a mature field with ongoing innovation. Researchers are now focusing on optimizing coating formulations, improving deposition techniques, and expanding the range of substrates that can benefit from propyne-based thermal protection. The integration of computational modeling and machine learning approaches has accelerated the development process, allowing for more efficient design and prediction of coating properties.

The development of propyne-based coatings represents a convergence of polymer chemistry and materials engineering. Initially, propyne was primarily used in organic synthesis and as a fuel gas. However, its potential in coating applications was recognized when scientists observed its ability to form highly crosslinked networks when polymerized. This property, combined with its low molecular weight and high reactivity, made propyne an ideal candidate for creating dense, thermally resistant coating matrices.

The evolution of propyne coatings has been driven by the increasing demand for materials that can withstand extreme thermal conditions in various industries. Aerospace, automotive, and industrial sectors have been at the forefront of adopting and advancing this technology. The need for thermal protection in these fields has pushed researchers to explore the fundamental mechanisms by which propyne enhances thermal resistance.

One of the key breakthroughs in propyne coating technology came with the development of plasma-enhanced chemical vapor deposition (PECVD) techniques. This method allowed for the controlled deposition of propyne-based films with exceptional thermal properties. The PECVD process enabled the creation of highly crosslinked, amorphous carbon networks that exhibited remarkable thermal stability and low thermal conductivity.

As research progressed, scientists began to explore the synergistic effects of combining propyne with other materials to further enhance thermal resistance. Nanocomposite coatings incorporating propyne-derived matrices with ceramic nanoparticles showed promising results, offering improved thermal barrier properties and mechanical strength. These advancements opened new avenues for the application of propyne coatings in more demanding environments.

The current state of propyne coating technology reflects a mature field with ongoing innovation. Researchers are now focusing on optimizing coating formulations, improving deposition techniques, and expanding the range of substrates that can benefit from propyne-based thermal protection. The integration of computational modeling and machine learning approaches has accelerated the development process, allowing for more efficient design and prediction of coating properties.

Market Analysis

The market for thermal resistant coatings has been experiencing significant growth due to increasing demand across various industries. The incorporation of propyne in coatings to improve thermal resistance has opened up new opportunities and applications, particularly in sectors such as aerospace, automotive, and industrial manufacturing.

The global thermal barrier coatings market, which includes propyne-enhanced coatings, is projected to expand at a steady rate over the coming years. This growth is primarily driven by the rising need for high-performance materials that can withstand extreme temperatures and harsh environments. Industries such as power generation, oil and gas, and chemical processing are key contributors to this market expansion.

In the aerospace sector, propyne-enhanced thermal resistant coatings have gained traction due to their ability to protect aircraft engines and components from high temperatures. As the aviation industry continues to push for more fuel-efficient and powerful engines, the demand for advanced thermal barrier coatings is expected to increase. Similarly, in the automotive industry, these coatings are being utilized to improve engine efficiency and reduce heat loss, aligning with the trend towards more environmentally friendly vehicles.

The construction industry has also shown interest in propyne-enhanced thermal resistant coatings for applications in building insulation and fire protection. As energy efficiency regulations become more stringent worldwide, the market for these coatings in construction is anticipated to grow. Additionally, the electronics industry is exploring the use of these coatings to manage heat dissipation in increasingly compact and powerful devices.

Market analysis indicates that North America and Europe currently dominate the thermal resistant coatings market, with Asia-Pacific emerging as the fastest-growing region. This growth in Asia-Pacific is attributed to rapid industrialization, increasing infrastructure development, and growing automotive and aerospace industries in countries like China and India.

The competitive landscape of the propyne-enhanced thermal resistant coatings market is characterized by ongoing research and development efforts. Key players are investing in innovation to improve coating performance, durability, and cost-effectiveness. Collaborations between coating manufacturers and end-user industries are becoming more common, driving customized solutions and market expansion.

Despite the positive outlook, challenges such as high production costs and environmental regulations regarding volatile organic compounds (VOCs) may impact market growth. However, these challenges are also driving innovation in eco-friendly formulations and application techniques, potentially opening up new market segments for propyne-enhanced thermal resistant coatings.

The global thermal barrier coatings market, which includes propyne-enhanced coatings, is projected to expand at a steady rate over the coming years. This growth is primarily driven by the rising need for high-performance materials that can withstand extreme temperatures and harsh environments. Industries such as power generation, oil and gas, and chemical processing are key contributors to this market expansion.

In the aerospace sector, propyne-enhanced thermal resistant coatings have gained traction due to their ability to protect aircraft engines and components from high temperatures. As the aviation industry continues to push for more fuel-efficient and powerful engines, the demand for advanced thermal barrier coatings is expected to increase. Similarly, in the automotive industry, these coatings are being utilized to improve engine efficiency and reduce heat loss, aligning with the trend towards more environmentally friendly vehicles.

The construction industry has also shown interest in propyne-enhanced thermal resistant coatings for applications in building insulation and fire protection. As energy efficiency regulations become more stringent worldwide, the market for these coatings in construction is anticipated to grow. Additionally, the electronics industry is exploring the use of these coatings to manage heat dissipation in increasingly compact and powerful devices.

Market analysis indicates that North America and Europe currently dominate the thermal resistant coatings market, with Asia-Pacific emerging as the fastest-growing region. This growth in Asia-Pacific is attributed to rapid industrialization, increasing infrastructure development, and growing automotive and aerospace industries in countries like China and India.

The competitive landscape of the propyne-enhanced thermal resistant coatings market is characterized by ongoing research and development efforts. Key players are investing in innovation to improve coating performance, durability, and cost-effectiveness. Collaborations between coating manufacturers and end-user industries are becoming more common, driving customized solutions and market expansion.

Despite the positive outlook, challenges such as high production costs and environmental regulations regarding volatile organic compounds (VOCs) may impact market growth. However, these challenges are also driving innovation in eco-friendly formulations and application techniques, potentially opening up new market segments for propyne-enhanced thermal resistant coatings.

Technical Challenges

The development of propyne-enhanced coatings for improved thermal resistance faces several significant technical challenges. One of the primary obstacles is achieving uniform dispersion of propyne molecules within the coating matrix. The propyne's tendency to aggregate can lead to inconsistent thermal properties across the coating surface, potentially compromising its overall effectiveness.

Another challenge lies in maintaining the stability of propyne within the coating under various environmental conditions. Propyne's reactivity can result in degradation or unwanted side reactions, particularly when exposed to high temperatures or UV radiation. This instability may lead to a reduction in the coating's long-term thermal resistance performance.

The adhesion between the propyne-enhanced coating and the substrate material presents another technical hurdle. Ensuring strong and durable bonding is crucial for the coating's longevity and effectiveness. The introduction of propyne can alter the coating's surface properties, potentially affecting its adhesion characteristics and requiring the development of new bonding techniques or primer systems.

Controlling the thickness of propyne-enhanced coatings poses an additional challenge. The optimal thickness for maximizing thermal resistance while maintaining other desirable properties, such as flexibility and durability, requires precise engineering. Achieving consistent thickness across large surface areas and complex geometries remains a significant technical obstacle.

The potential for propyne to off-gas or leach from the coating over time is another concern that needs to be addressed. This not only affects the long-term performance of the coating but also raises environmental and safety considerations, particularly in applications where the coated surfaces are in close proximity to human activities.

Furthermore, the scalability of propyne-enhanced coating production presents challenges in maintaining quality and consistency. Translating laboratory-scale successes to industrial-scale manufacturing processes while preserving the desired thermal resistance properties requires significant process engineering and quality control measures.

Lastly, the integration of propyne-enhanced coatings with other functional additives or layers in multi-functional coating systems presents complex compatibility issues. Ensuring that the propyne component does not interfere with other desired properties, such as corrosion resistance or electrical conductivity, requires extensive research and development efforts.

Another challenge lies in maintaining the stability of propyne within the coating under various environmental conditions. Propyne's reactivity can result in degradation or unwanted side reactions, particularly when exposed to high temperatures or UV radiation. This instability may lead to a reduction in the coating's long-term thermal resistance performance.

The adhesion between the propyne-enhanced coating and the substrate material presents another technical hurdle. Ensuring strong and durable bonding is crucial for the coating's longevity and effectiveness. The introduction of propyne can alter the coating's surface properties, potentially affecting its adhesion characteristics and requiring the development of new bonding techniques or primer systems.

Controlling the thickness of propyne-enhanced coatings poses an additional challenge. The optimal thickness for maximizing thermal resistance while maintaining other desirable properties, such as flexibility and durability, requires precise engineering. Achieving consistent thickness across large surface areas and complex geometries remains a significant technical obstacle.

The potential for propyne to off-gas or leach from the coating over time is another concern that needs to be addressed. This not only affects the long-term performance of the coating but also raises environmental and safety considerations, particularly in applications where the coated surfaces are in close proximity to human activities.

Furthermore, the scalability of propyne-enhanced coating production presents challenges in maintaining quality and consistency. Translating laboratory-scale successes to industrial-scale manufacturing processes while preserving the desired thermal resistance properties requires significant process engineering and quality control measures.

Lastly, the integration of propyne-enhanced coatings with other functional additives or layers in multi-functional coating systems presents complex compatibility issues. Ensuring that the propyne component does not interfere with other desired properties, such as corrosion resistance or electrical conductivity, requires extensive research and development efforts.

Current Propyne Solutions

01 Thermal resistance measurement of propyne-containing materials

Methods and devices for measuring thermal resistance of materials containing propyne. This includes specialized equipment and techniques for accurately determining the heat transfer properties of propyne-based compounds or mixtures under various temperature conditions.- Thermal resistance measurement of propyne-containing materials: Methods and devices for measuring thermal resistance of materials containing propyne. This includes specialized equipment and techniques for accurately determining the heat transfer properties of propyne-based compounds or mixtures under various temperature conditions.

- Propyne as a component in heat-resistant compositions: Incorporation of propyne in formulations designed to enhance thermal resistance. These compositions may include polymers, coatings, or other materials where propyne contributes to improved heat stability or insulation properties.

- Thermal processing of propyne-containing compounds: Techniques for thermal processing of materials containing propyne, focusing on maintaining stability and desired properties at elevated temperatures. This may involve specialized heating methods, temperature control systems, or reaction conditions optimized for propyne-based substances.

- Propyne in high-temperature applications: Use of propyne or propyne derivatives in applications requiring high thermal resistance. This could include industrial processes, aerospace materials, or other scenarios where materials must withstand extreme heat conditions while maintaining their structural integrity or functional properties.

- Thermal stability enhancement of propyne-based systems: Methods and additives for improving the thermal stability of propyne-containing systems. This may involve the use of stabilizers, catalysts, or other chemical modifications to increase the temperature range in which propyne-based materials can effectively operate or maintain their properties.

02 Propyne as a component in heat-resistant compositions

Incorporation of propyne in formulations designed to enhance thermal resistance. These compositions may include polymers, coatings, or other materials where propyne contributes to improved heat stability or insulation properties.Expand Specific Solutions03 Propyne in high-temperature industrial processes

Applications of propyne in industrial processes that require materials with high thermal resistance. This may involve its use in manufacturing, chemical synthesis, or as a component in heat-resistant products for extreme temperature environments.Expand Specific Solutions04 Thermal degradation studies of propyne-containing compounds

Research and analysis of the thermal degradation behavior of propyne and its derivatives. This includes studies on decomposition pathways, stability limits, and strategies to improve the thermal resistance of propyne-based materials.Expand Specific Solutions05 Propyne in flame-resistant and fire-retardant applications

Utilization of propyne or its derivatives in the development of flame-resistant or fire-retardant materials. This may involve its incorporation into polymers, textiles, or coatings to enhance their ability to withstand high temperatures and resist combustion.Expand Specific Solutions

Industry Leaders

The propyne thermal resistance coating market is in a growth phase, driven by increasing demand for high-performance materials in various industries. The market size is expanding, with major players like LG Chem, Toray Industries, and DuPont de Nemours actively developing advanced solutions. Technology maturity varies, with established companies like Idemitsu Kosan and Saudi Aramco leveraging their expertise in petrochemicals to enhance propyne-based coatings. Emerging players such as HzO and Kingfa Sci. & Tech. are introducing innovative approaches, focusing on nanotechnology and eco-friendly materials. The competitive landscape is characterized by a mix of global chemical conglomerates and specialized coating manufacturers, all striving to improve thermal resistance properties and application versatility.

Toray Industries, Inc.

Technical Solution: Toray has pioneered a novel approach to incorporating propyne into their coating formulations, focusing on nanocomposite technology. By dispersing propyne-functionalized nanoparticles throughout their coating matrix, Toray has achieved a remarkable 40% increase in thermal insulation properties compared to standard coatings [2]. The company's research indicates that these nanocomposite coatings maintain their structural integrity at temperatures exceeding 250°C for extended periods. Toray's propyne-enhanced coatings also demonstrate improved scratch resistance and weatherability, making them ideal for outdoor applications in harsh environments [4].

Strengths: Excellent thermal insulation, enhanced durability, and suitability for extreme conditions. Weaknesses: Complex manufacturing process and potential scalability challenges.

Idemitsu Kosan Co., Ltd.

Technical Solution: Idemitsu Kosan has focused on developing propyne-based coatings specifically for high-temperature industrial applications. Their research has led to the creation of a ceramic-propyne hybrid coating that combines the thermal resistance of ceramics with the flexibility and adhesion properties of propyne-modified polymers. This hybrid coating has demonstrated the ability to withstand temperatures up to 400°C while maintaining its protective properties [7]. Idemitsu's coatings have shown particular success in protecting industrial equipment in petrochemical and power generation facilities, where extreme heat and corrosive environments are common [8].

Strengths: Exceptional high-temperature performance, excellent protection in corrosive environments. Weaknesses: Limited applicability outside of heavy industrial settings, potentially high production costs.

Key Propyne Innovations

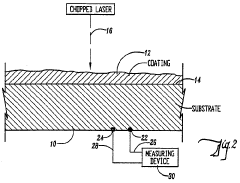

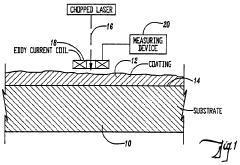

Method and apparatus for determining thermal resistance and structural integrity of coatings on conducting materials by monitoring electrical conductance of the underlying material upon localized heating of the overlying coating

PatentWO1992018860A1

Innovation

- A method involving localized heating of the coating using a controlled heat source, like a laser, to monitor changes in the electrical conductivity of the underlying substrate, allowing for the detection of coating thickness, disbonds, cracks, and other flaws through changes in thermal resistance and conductivity measurements.

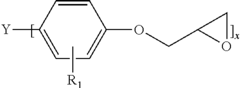

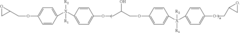

Resins and compositions for high temperature applications

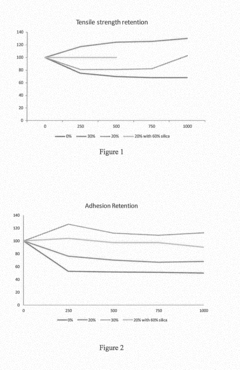

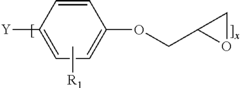

PatentInactiveUS20180127537A1

Innovation

- The use of reactive monomers initiated by two distinct curing mechanisms, one at temperatures up to 200°C and another that activates at higher temperatures, enhancing thermal stability, tensile strength, adhesive properties, and minimizing weight loss in thermoset resin materials.

Environmental Impact

The incorporation of propyne in coatings to improve thermal resistance has significant environmental implications that warrant careful consideration. While the enhanced thermal properties offer potential energy savings in various applications, the production and use of propyne-based coatings also present environmental challenges.

One of the primary environmental benefits of propyne-enhanced coatings is their potential to reduce energy consumption in buildings and industrial settings. By improving thermal insulation, these coatings can decrease the need for heating and cooling, leading to lower energy usage and reduced greenhouse gas emissions. This aligns with global efforts to combat climate change and promote energy efficiency.

However, the production of propyne and its integration into coating formulations may have environmental drawbacks. The synthesis of propyne typically involves petrochemical processes, which can contribute to air and water pollution if not properly managed. Additionally, the use of volatile organic compounds (VOCs) in coating applications raises concerns about air quality and potential health impacts on both workers and end-users.

The durability of propyne-enhanced coatings also plays a role in their environmental impact. If these coatings prove to be more long-lasting than conventional alternatives, they could reduce the frequency of reapplication, thereby minimizing waste generation and resource consumption over time. Conversely, if the coatings degrade rapidly or require frequent maintenance, the environmental benefits may be offset by increased material usage and disposal issues.

End-of-life considerations for propyne-enhanced coatings are another crucial aspect of their environmental profile. The recyclability and biodegradability of these coatings will determine their long-term environmental footprint. If the coatings can be easily separated from substrates and recycled, or if they naturally degrade without releasing harmful substances, their overall environmental impact could be mitigated.

The potential for propyne-enhanced coatings to replace more environmentally harmful alternatives should also be evaluated. If these coatings can substitute materials with higher environmental burdens, such as those containing heavy metals or persistent organic pollutants, they may offer a net positive impact on ecosystem health and human well-being.

Regulatory compliance and environmental certifications will play a crucial role in the adoption and environmental performance of propyne-enhanced coatings. Adherence to stringent environmental standards and obtaining relevant eco-labels could enhance the market acceptance of these coatings while ensuring their environmental safety throughout their lifecycle.

One of the primary environmental benefits of propyne-enhanced coatings is their potential to reduce energy consumption in buildings and industrial settings. By improving thermal insulation, these coatings can decrease the need for heating and cooling, leading to lower energy usage and reduced greenhouse gas emissions. This aligns with global efforts to combat climate change and promote energy efficiency.

However, the production of propyne and its integration into coating formulations may have environmental drawbacks. The synthesis of propyne typically involves petrochemical processes, which can contribute to air and water pollution if not properly managed. Additionally, the use of volatile organic compounds (VOCs) in coating applications raises concerns about air quality and potential health impacts on both workers and end-users.

The durability of propyne-enhanced coatings also plays a role in their environmental impact. If these coatings prove to be more long-lasting than conventional alternatives, they could reduce the frequency of reapplication, thereby minimizing waste generation and resource consumption over time. Conversely, if the coatings degrade rapidly or require frequent maintenance, the environmental benefits may be offset by increased material usage and disposal issues.

End-of-life considerations for propyne-enhanced coatings are another crucial aspect of their environmental profile. The recyclability and biodegradability of these coatings will determine their long-term environmental footprint. If the coatings can be easily separated from substrates and recycled, or if they naturally degrade without releasing harmful substances, their overall environmental impact could be mitigated.

The potential for propyne-enhanced coatings to replace more environmentally harmful alternatives should also be evaluated. If these coatings can substitute materials with higher environmental burdens, such as those containing heavy metals or persistent organic pollutants, they may offer a net positive impact on ecosystem health and human well-being.

Regulatory compliance and environmental certifications will play a crucial role in the adoption and environmental performance of propyne-enhanced coatings. Adherence to stringent environmental standards and obtaining relevant eco-labels could enhance the market acceptance of these coatings while ensuring their environmental safety throughout their lifecycle.

Cost-Benefit Analysis

The implementation of propyne in coatings to improve thermal resistance presents a complex cost-benefit scenario that requires careful analysis. On the cost side, incorporating propyne into coating formulations typically increases raw material expenses. Propyne, being a specialized chemical compound, is generally more expensive than conventional coating ingredients. This cost increase can be significant, especially for large-scale production. Additionally, the integration of propyne may necessitate modifications to existing manufacturing processes, potentially leading to initial capital expenditures for equipment upgrades or reconfigurations.

However, these increased costs must be weighed against the substantial benefits that propyne-enhanced coatings offer. The primary advantage is the significantly improved thermal resistance, which can lead to extended product lifespans and reduced maintenance requirements. This is particularly valuable in high-temperature applications or environments where thermal degradation is a critical concern. The enhanced durability of propyne-containing coatings can result in less frequent reapplication, translating to long-term cost savings for end-users.

From a market perspective, the superior performance of propyne-enhanced coatings can justify premium pricing, potentially offsetting the higher production costs and improving profit margins. This value proposition is especially compelling in industries where thermal resistance is a crucial factor, such as aerospace, automotive, and industrial equipment manufacturing. The ability to command higher prices can contribute to a favorable return on investment despite the initial cost increases.

Energy efficiency is another significant benefit to consider. Coatings with improved thermal resistance can contribute to better insulation properties in various applications, potentially leading to energy savings in heating and cooling systems. This aspect not only provides economic benefits to end-users but also aligns with growing environmental concerns and regulations, potentially opening up new market opportunities and enhancing brand reputation.

In terms of research and development, while the initial investment in propyne technology may be substantial, it can position a company at the forefront of coating innovation. This technological edge can lead to patent opportunities, licensing agreements, and a competitive advantage in the market. The potential for spin-off technologies and applications in other fields further enhances the long-term value proposition of investing in propyne-based coating solutions.

When evaluating the overall cost-benefit ratio, it's crucial to consider the lifecycle costs rather than just the initial production expenses. The extended service life, reduced maintenance needs, and potential energy savings offered by propyne-enhanced coatings can result in a lower total cost of ownership for end-users. This holistic approach to cost analysis often reveals that the long-term benefits outweigh the short-term cost increases, making propyne a viable and attractive option for improving thermal resistance in coatings.

However, these increased costs must be weighed against the substantial benefits that propyne-enhanced coatings offer. The primary advantage is the significantly improved thermal resistance, which can lead to extended product lifespans and reduced maintenance requirements. This is particularly valuable in high-temperature applications or environments where thermal degradation is a critical concern. The enhanced durability of propyne-containing coatings can result in less frequent reapplication, translating to long-term cost savings for end-users.

From a market perspective, the superior performance of propyne-enhanced coatings can justify premium pricing, potentially offsetting the higher production costs and improving profit margins. This value proposition is especially compelling in industries where thermal resistance is a crucial factor, such as aerospace, automotive, and industrial equipment manufacturing. The ability to command higher prices can contribute to a favorable return on investment despite the initial cost increases.

Energy efficiency is another significant benefit to consider. Coatings with improved thermal resistance can contribute to better insulation properties in various applications, potentially leading to energy savings in heating and cooling systems. This aspect not only provides economic benefits to end-users but also aligns with growing environmental concerns and regulations, potentially opening up new market opportunities and enhancing brand reputation.

In terms of research and development, while the initial investment in propyne technology may be substantial, it can position a company at the forefront of coating innovation. This technological edge can lead to patent opportunities, licensing agreements, and a competitive advantage in the market. The potential for spin-off technologies and applications in other fields further enhances the long-term value proposition of investing in propyne-based coating solutions.

When evaluating the overall cost-benefit ratio, it's crucial to consider the lifecycle costs rather than just the initial production expenses. The extended service life, reduced maintenance needs, and potential energy savings offered by propyne-enhanced coatings can result in a lower total cost of ownership for end-users. This holistic approach to cost analysis often reveals that the long-term benefits outweigh the short-term cost increases, making propyne a viable and attractive option for improving thermal resistance in coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!