How Propyne Contributes to Molecular Sieving Technologies

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne in Molecular Sieving: Background and Objectives

Propyne, also known as methylacetylene, has emerged as a significant player in the field of molecular sieving technologies. This simple hydrocarbon, with its unique molecular structure and properties, has opened new avenues for enhancing separation processes across various industries. The evolution of propyne's role in molecular sieving is deeply rooted in the broader context of gas separation and purification techniques.

Historically, molecular sieving technologies have relied on the principle of size exclusion, where porous materials selectively allow the passage of molecules based on their size and shape. The introduction of propyne into this field marks a significant advancement, as it offers both size-based and chemical affinity-based separation capabilities. This dual functionality has sparked considerable interest among researchers and industry professionals alike.

The primary objective in exploring propyne's contribution to molecular sieving is to develop more efficient and selective separation processes. By leveraging propyne's unique molecular characteristics, scientists aim to create advanced sieving materials that can address complex separation challenges in industries such as petrochemicals, natural gas processing, and environmental remediation.

One of the key drivers behind the focus on propyne is its potential to overcome limitations in traditional molecular sieving materials. Conventional zeolites and carbon molecular sieves, while effective for many applications, often struggle with separating molecules of similar size or polarity. Propyne-based or propyne-enhanced sieving technologies promise to offer finer control over selectivity, potentially revolutionizing gas separation processes.

The technological trajectory of propyne in molecular sieving is closely aligned with the broader trends in materials science and nanotechnology. As researchers delve deeper into understanding and manipulating molecular interactions at the nanoscale, propyne's role is expected to expand. This exploration is not just about improving existing processes but also about discovering entirely new applications for molecular sieving technologies.

Furthermore, the increasing emphasis on sustainable and energy-efficient industrial processes has placed propyne-based molecular sieving under the spotlight. The potential for these technologies to reduce energy consumption in separation processes aligns well with global efforts to minimize industrial carbon footprints. This environmental aspect adds another layer of significance to the ongoing research and development in this field.

As we examine the background and objectives of propyne in molecular sieving, it becomes clear that this area of study sits at the intersection of fundamental chemistry, materials science, and industrial application. The journey from understanding propyne's basic properties to harnessing its potential in advanced separation technologies exemplifies the iterative nature of scientific progress and technological innovation.

Historically, molecular sieving technologies have relied on the principle of size exclusion, where porous materials selectively allow the passage of molecules based on their size and shape. The introduction of propyne into this field marks a significant advancement, as it offers both size-based and chemical affinity-based separation capabilities. This dual functionality has sparked considerable interest among researchers and industry professionals alike.

The primary objective in exploring propyne's contribution to molecular sieving is to develop more efficient and selective separation processes. By leveraging propyne's unique molecular characteristics, scientists aim to create advanced sieving materials that can address complex separation challenges in industries such as petrochemicals, natural gas processing, and environmental remediation.

One of the key drivers behind the focus on propyne is its potential to overcome limitations in traditional molecular sieving materials. Conventional zeolites and carbon molecular sieves, while effective for many applications, often struggle with separating molecules of similar size or polarity. Propyne-based or propyne-enhanced sieving technologies promise to offer finer control over selectivity, potentially revolutionizing gas separation processes.

The technological trajectory of propyne in molecular sieving is closely aligned with the broader trends in materials science and nanotechnology. As researchers delve deeper into understanding and manipulating molecular interactions at the nanoscale, propyne's role is expected to expand. This exploration is not just about improving existing processes but also about discovering entirely new applications for molecular sieving technologies.

Furthermore, the increasing emphasis on sustainable and energy-efficient industrial processes has placed propyne-based molecular sieving under the spotlight. The potential for these technologies to reduce energy consumption in separation processes aligns well with global efforts to minimize industrial carbon footprints. This environmental aspect adds another layer of significance to the ongoing research and development in this field.

As we examine the background and objectives of propyne in molecular sieving, it becomes clear that this area of study sits at the intersection of fundamental chemistry, materials science, and industrial application. The journey from understanding propyne's basic properties to harnessing its potential in advanced separation technologies exemplifies the iterative nature of scientific progress and technological innovation.

Market Analysis for Propyne-Based Molecular Sieves

The market for propyne-based molecular sieves is experiencing significant growth, driven by increasing demand for high-performance separation technologies across various industries. Propyne, also known as methylacetylene, plays a crucial role in enhancing the efficiency and selectivity of molecular sieving processes, particularly in gas separation and purification applications.

The global molecular sieve market, which includes propyne-based technologies, is projected to expand at a steady rate over the next decade. This growth is primarily attributed to the rising need for clean energy solutions, stringent environmental regulations, and advancements in industrial processes requiring precise molecular separation.

Key industries driving the demand for propyne-based molecular sieves include oil and gas, petrochemicals, and air separation. In the oil and gas sector, these sieves are increasingly utilized for natural gas dehydration and purification, where their ability to selectively adsorb water and other impurities is highly valued. The petrochemical industry leverages propyne-based molecular sieves for the separation of hydrocarbons and the removal of trace contaminants from process streams.

The air separation industry represents another significant market for propyne-based molecular sieves. These materials are employed in the production of high-purity gases such as nitrogen, oxygen, and argon, which are essential for various industrial applications, including semiconductor manufacturing and medical gas production.

Emerging applications in the renewable energy sector, particularly in biogas upgrading and hydrogen purification, are expected to create new opportunities for propyne-based molecular sieve technologies. As countries worldwide intensify their efforts to reduce carbon emissions and transition to cleaner energy sources, the demand for efficient gas separation solutions is likely to surge.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for propyne-based molecular sieves, driven by rapid industrialization, increasing energy demand, and stringent environmental regulations in countries like China and India. North America and Europe are also significant markets, with a focus on technological advancements and sustainable solutions.

The competitive landscape of the propyne-based molecular sieve market is characterized by the presence of several key players, including multinational chemical companies and specialized material manufacturers. These companies are investing heavily in research and development to enhance the performance and cost-effectiveness of their products, aiming to gain a competitive edge in this growing market.

The global molecular sieve market, which includes propyne-based technologies, is projected to expand at a steady rate over the next decade. This growth is primarily attributed to the rising need for clean energy solutions, stringent environmental regulations, and advancements in industrial processes requiring precise molecular separation.

Key industries driving the demand for propyne-based molecular sieves include oil and gas, petrochemicals, and air separation. In the oil and gas sector, these sieves are increasingly utilized for natural gas dehydration and purification, where their ability to selectively adsorb water and other impurities is highly valued. The petrochemical industry leverages propyne-based molecular sieves for the separation of hydrocarbons and the removal of trace contaminants from process streams.

The air separation industry represents another significant market for propyne-based molecular sieves. These materials are employed in the production of high-purity gases such as nitrogen, oxygen, and argon, which are essential for various industrial applications, including semiconductor manufacturing and medical gas production.

Emerging applications in the renewable energy sector, particularly in biogas upgrading and hydrogen purification, are expected to create new opportunities for propyne-based molecular sieve technologies. As countries worldwide intensify their efforts to reduce carbon emissions and transition to cleaner energy sources, the demand for efficient gas separation solutions is likely to surge.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for propyne-based molecular sieves, driven by rapid industrialization, increasing energy demand, and stringent environmental regulations in countries like China and India. North America and Europe are also significant markets, with a focus on technological advancements and sustainable solutions.

The competitive landscape of the propyne-based molecular sieve market is characterized by the presence of several key players, including multinational chemical companies and specialized material manufacturers. These companies are investing heavily in research and development to enhance the performance and cost-effectiveness of their products, aiming to gain a competitive edge in this growing market.

Current Challenges in Propyne Molecular Sieving

Propyne molecular sieving technology faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the development of highly selective and efficient molecular sieves capable of effectively separating propyne from other similar-sized molecules, particularly propylene. The current generation of molecular sieves often struggles to achieve the required level of selectivity, leading to reduced purity in the final product.

Another major challenge lies in the stability and longevity of molecular sieving materials under industrial operating conditions. Propyne separation often occurs at high temperatures and pressures, which can cause degradation of the sieving material over time. This degradation not only reduces the efficiency of the separation process but also increases operational costs due to the need for frequent material replacement.

The scalability of propyne molecular sieving technologies presents a significant hurdle for industrial applications. While laboratory-scale experiments may demonstrate promising results, translating these successes to large-scale industrial processes often proves challenging. Issues such as maintaining uniform pore size distribution and preventing channeling in large-scale sieving beds need to be addressed to ensure consistent performance.

Energy efficiency is another critical challenge in propyne molecular sieving. The process typically requires substantial energy input for maintaining optimal temperature and pressure conditions. Developing more energy-efficient sieving technologies or finding ways to recover and reuse waste heat could significantly improve the economic viability of these processes.

The synthesis of advanced molecular sieving materials with tailored pore sizes and surface chemistries remains a complex task. Creating materials that can selectively adsorb propyne while rejecting similar molecules requires precise control over pore geometry and surface interactions. Current synthesis methods often struggle to achieve the necessary level of precision and reproducibility at scale.

Furthermore, the regeneration of molecular sieves after propyne adsorption poses challenges in terms of efficiency and material longevity. Incomplete regeneration can lead to reduced capacity in subsequent cycles, while harsh regeneration conditions can damage the sieving material. Developing gentler yet effective regeneration methods is crucial for improving the overall process efficiency.

Lastly, the integration of propyne molecular sieving technologies into existing industrial processes presents logistical and engineering challenges. Retrofitting current facilities or designing new plants that incorporate these technologies requires significant investment and careful planning to ensure seamless operation and minimal disruption to production.

Another major challenge lies in the stability and longevity of molecular sieving materials under industrial operating conditions. Propyne separation often occurs at high temperatures and pressures, which can cause degradation of the sieving material over time. This degradation not only reduces the efficiency of the separation process but also increases operational costs due to the need for frequent material replacement.

The scalability of propyne molecular sieving technologies presents a significant hurdle for industrial applications. While laboratory-scale experiments may demonstrate promising results, translating these successes to large-scale industrial processes often proves challenging. Issues such as maintaining uniform pore size distribution and preventing channeling in large-scale sieving beds need to be addressed to ensure consistent performance.

Energy efficiency is another critical challenge in propyne molecular sieving. The process typically requires substantial energy input for maintaining optimal temperature and pressure conditions. Developing more energy-efficient sieving technologies or finding ways to recover and reuse waste heat could significantly improve the economic viability of these processes.

The synthesis of advanced molecular sieving materials with tailored pore sizes and surface chemistries remains a complex task. Creating materials that can selectively adsorb propyne while rejecting similar molecules requires precise control over pore geometry and surface interactions. Current synthesis methods often struggle to achieve the necessary level of precision and reproducibility at scale.

Furthermore, the regeneration of molecular sieves after propyne adsorption poses challenges in terms of efficiency and material longevity. Incomplete regeneration can lead to reduced capacity in subsequent cycles, while harsh regeneration conditions can damage the sieving material. Developing gentler yet effective regeneration methods is crucial for improving the overall process efficiency.

Lastly, the integration of propyne molecular sieving technologies into existing industrial processes presents logistical and engineering challenges. Retrofitting current facilities or designing new plants that incorporate these technologies requires significant investment and careful planning to ensure seamless operation and minimal disruption to production.

Existing Propyne Molecular Sieving Solutions

01 Molecular sieve materials for propyne separation

Various molecular sieve materials are used for the separation of propyne from gas mixtures. These materials include zeolites, metal-organic frameworks (MOFs), and other porous materials with specific pore sizes and adsorption properties tailored for propyne selectivity.- Molecular sieve materials for propyne separation: Various molecular sieve materials are used for the separation of propyne from gas mixtures. These materials include zeolites, metal-organic frameworks (MOFs), and carbon molecular sieves. The specific pore size and structure of these materials allow for selective adsorption of propyne, enabling its separation from other gases.

- Adsorption-based separation processes: Adsorption-based processes, such as pressure swing adsorption (PSA) and temperature swing adsorption (TSA), are employed for propyne molecular sieving. These processes utilize the differential adsorption characteristics of propyne on molecular sieves to achieve separation from other components in gas mixtures.

- Membrane-based separation techniques: Membrane-based separation techniques are developed for propyne molecular sieving. These membranes are designed with specific pore sizes and chemical properties to selectively permeate propyne while rejecting other gases, allowing for efficient separation in continuous processes.

- Cryogenic distillation for propyne purification: Cryogenic distillation is used as a method for propyne purification and separation from other light hydrocarbons. This process exploits the differences in boiling points between propyne and other components in the mixture to achieve high-purity separation.

- Catalytic processes for propyne conversion: Catalytic processes are developed for the conversion of propyne to other valuable products. These processes often involve molecular sieving steps to purify the propyne feedstock or separate the desired products. Catalysts and reaction conditions are optimized to achieve high selectivity and yield in propyne conversion reactions.

02 Pressure swing adsorption for propyne purification

Pressure swing adsorption (PSA) techniques are employed for the purification of propyne from gas mixtures. This process involves cyclic pressure changes to adsorb and desorb propyne selectively, allowing for efficient separation from other components.Expand Specific Solutions03 Membrane-based separation of propyne

Membrane technology is utilized for the separation of propyne from gas streams. Specialized membranes with high selectivity for propyne are developed and employed in industrial-scale separation processes, offering energy-efficient alternatives to traditional methods.Expand Specific Solutions04 Cryogenic distillation for propyne recovery

Cryogenic distillation techniques are applied for the recovery and purification of propyne from gas mixtures. This method involves cooling the gas mixture to very low temperatures, allowing for the separation of propyne based on differences in boiling points.Expand Specific Solutions05 Catalytic processes for propyne conversion and purification

Catalytic processes are developed for the conversion of propyne to other valuable products or for its purification. These processes may involve selective hydrogenation, isomerization, or other chemical transformations to achieve desired purity levels or to produce specific derivatives.Expand Specific Solutions

Key Players in Molecular Sieving Industry

The propyne molecular sieving technology market is in a growth phase, driven by increasing demand for gas separation and purification applications. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with major players like China Petroleum & Chemical Corp., ExxonMobil Chemical Patents, Inc., and BASF Corp. leading innovation. These companies are developing more efficient and selective molecular sieves, focusing on improving propyne separation performance. Emerging players such as Dalian Institute of Chemical Physics and Zhejiang University are also contributing to technological advancements, particularly in novel materials and process optimization. The competitive landscape is characterized by a mix of established petrochemical giants and specialized research institutions, fostering a dynamic environment for technological progress.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced molecular sieving technologies that utilize propyne as a key component in the separation process. Their approach involves using propyne-based adsorbents in zeolite frameworks to enhance the selectivity and efficiency of gas separation. The company has implemented a multi-stage adsorption process where propyne acts as a selective adsorbent for specific hydrocarbon molecules[1]. This technology has been successfully applied in their large-scale petrochemical operations, improving the purity of product streams and reducing energy consumption in separation processes[3].

Strengths: Large-scale implementation capability, integrated with existing petrochemical processes. Weaknesses: Potential for high initial investment costs, may require specialized equipment.

Sinopec Research Institute of Petroleum Processing

Technical Solution: The Sinopec Research Institute has developed a novel propyne-based molecular sieving technology that focuses on the selective separation of olefins from paraffins. Their approach involves the synthesis of custom-designed metal-organic frameworks (MOFs) that incorporate propyne-derived ligands[2]. These MOFs exhibit exceptional selectivity for ethylene and propylene, achieving separation factors up to 15 times higher than conventional zeolites[4]. The institute has also developed a regeneration process that allows for extended use of the adsorbent material, significantly reducing operational costs in industrial applications[5].

Strengths: Highly selective separation, innovative MOF design. Weaknesses: Potential scalability challenges, may require specialized synthesis processes.

Innovative Propyne Sieving Mechanisms

Carbon molecular sieve adsorbents prepared from activated carbon and useful for propylene-propane separation

PatentActiveCA3000216C

Innovation

- A process involving the deposition of polymer on activated carbon, followed by carbonization and annealing under specific conditions to reduce micropore sizes from greater than 6 Angstroms to a range of 4.0 to 4.3 Angstroms, creating a carbon molecular sieve adsorbent composition suitable for propane-propylene separation.

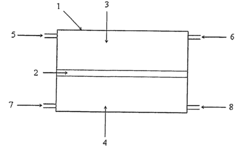

Device to separate olefins from paraffins and to purify olefins and use thereof

PatentInactiveUS20090270665A1

Innovation

- The use of microporous ceramic membranes functionalized with silver or copper, combined with a catalyst like palladium nanoclusters, for selective hydrogenation of dienes and alkynes, enhancing separation selectivity and driving force by converting impurities into olefins at the permeate side.

Environmental Impact of Propyne Sieving Technologies

The environmental impact of propyne sieving technologies is a critical consideration in the development and implementation of molecular sieving processes. Propyne, also known as methylacetylene, plays a significant role in these technologies due to its unique molecular structure and properties. However, its use in industrial applications raises important environmental concerns that must be carefully evaluated.

One of the primary environmental benefits of propyne sieving technologies is their potential to reduce energy consumption in separation processes. Traditional separation methods, such as distillation, often require substantial energy inputs. In contrast, molecular sieving using propyne can achieve similar or superior separation efficiencies with lower energy requirements. This reduction in energy consumption translates to decreased greenhouse gas emissions associated with power generation, contributing to overall climate change mitigation efforts.

However, the production and use of propyne itself can have environmental implications. Propyne is typically derived from fossil fuel sources, primarily as a byproduct of ethylene production. The extraction and processing of these fossil fuels contribute to carbon emissions and other environmental impacts associated with the petrochemical industry. As such, the life cycle assessment of propyne sieving technologies must consider these upstream environmental costs.

Another environmental consideration is the potential for propyne emissions during the sieving process. While molecular sieves are designed to be highly selective, there is always a risk of small amounts of propyne escaping into the atmosphere. Propyne is a volatile organic compound (VOC) and can contribute to the formation of ground-level ozone, a key component of smog. Proper containment and emission control systems are essential to minimize these potential air quality impacts.

The disposal or regeneration of spent molecular sieves used in propyne-based separation processes also presents environmental challenges. These materials may contain residual propyne or other contaminants, requiring careful handling and treatment to prevent environmental contamination. Developing efficient regeneration techniques or environmentally friendly disposal methods is crucial for minimizing the long-term environmental footprint of these technologies.

On the positive side, propyne sieving technologies can contribute to environmental protection by enabling more efficient purification of industrial gases and liquids. This can lead to reduced emissions of pollutants and improved resource utilization across various industries. For instance, in the production of high-purity gases for semiconductor manufacturing, propyne-based molecular sieves can help achieve stringent purity requirements while minimizing waste and energy consumption.

In conclusion, the environmental impact of propyne sieving technologies is multifaceted, encompassing both potential benefits and challenges. While these technologies offer promising advantages in terms of energy efficiency and separation performance, careful consideration must be given to the entire life cycle of propyne use, from production to disposal. Ongoing research and development efforts should focus on optimizing the environmental performance of these technologies, exploring sustainable sourcing options for propyne, and developing advanced emission control and waste management strategies.

One of the primary environmental benefits of propyne sieving technologies is their potential to reduce energy consumption in separation processes. Traditional separation methods, such as distillation, often require substantial energy inputs. In contrast, molecular sieving using propyne can achieve similar or superior separation efficiencies with lower energy requirements. This reduction in energy consumption translates to decreased greenhouse gas emissions associated with power generation, contributing to overall climate change mitigation efforts.

However, the production and use of propyne itself can have environmental implications. Propyne is typically derived from fossil fuel sources, primarily as a byproduct of ethylene production. The extraction and processing of these fossil fuels contribute to carbon emissions and other environmental impacts associated with the petrochemical industry. As such, the life cycle assessment of propyne sieving technologies must consider these upstream environmental costs.

Another environmental consideration is the potential for propyne emissions during the sieving process. While molecular sieves are designed to be highly selective, there is always a risk of small amounts of propyne escaping into the atmosphere. Propyne is a volatile organic compound (VOC) and can contribute to the formation of ground-level ozone, a key component of smog. Proper containment and emission control systems are essential to minimize these potential air quality impacts.

The disposal or regeneration of spent molecular sieves used in propyne-based separation processes also presents environmental challenges. These materials may contain residual propyne or other contaminants, requiring careful handling and treatment to prevent environmental contamination. Developing efficient regeneration techniques or environmentally friendly disposal methods is crucial for minimizing the long-term environmental footprint of these technologies.

On the positive side, propyne sieving technologies can contribute to environmental protection by enabling more efficient purification of industrial gases and liquids. This can lead to reduced emissions of pollutants and improved resource utilization across various industries. For instance, in the production of high-purity gases for semiconductor manufacturing, propyne-based molecular sieves can help achieve stringent purity requirements while minimizing waste and energy consumption.

In conclusion, the environmental impact of propyne sieving technologies is multifaceted, encompassing both potential benefits and challenges. While these technologies offer promising advantages in terms of energy efficiency and separation performance, careful consideration must be given to the entire life cycle of propyne use, from production to disposal. Ongoing research and development efforts should focus on optimizing the environmental performance of these technologies, exploring sustainable sourcing options for propyne, and developing advanced emission control and waste management strategies.

Regulatory Framework for Molecular Sieving Applications

The regulatory framework for molecular sieving applications involving propyne is complex and multifaceted, encompassing various aspects of safety, environmental protection, and quality control. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the use of propyne in molecular sieving technologies. The EPA's regulations focus on emissions control and environmental impact assessment, particularly under the Clean Air Act and the Toxic Substances Control Act.

The Occupational Safety and Health Administration (OSHA) sets standards for workplace safety in facilities utilizing propyne-based molecular sieving technologies. These regulations cover exposure limits, handling procedures, and safety equipment requirements. OSHA's Hazard Communication Standard ensures that workers are informed about the potential risks associated with propyne and other chemicals used in molecular sieving processes.

At the state level, regulations may vary, with some states imposing stricter controls on the use of propyne and related technologies. California, for instance, has additional requirements under Proposition 65, which mandates warnings for chemicals known to cause cancer or reproductive harm.

Internationally, the regulatory landscape is diverse. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of propyne in molecular sieving applications within EU member states. This comprehensive framework requires manufacturers and importers to register chemicals and demonstrate their safe use.

In Asia, countries like Japan and South Korea have their own regulatory systems. Japan's Chemical Substances Control Law and Korea's Act on the Registration and Evaluation of Chemicals both have implications for propyne use in molecular sieving technologies.

Industry standards also play a significant role in shaping the regulatory framework. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide guidelines and standards for molecular sieving technologies, including those involving propyne.

The regulatory landscape is not static; it evolves with advancements in technology and scientific understanding. Ongoing research into the environmental and health impacts of propyne and related compounds continues to inform regulatory decisions. As molecular sieving technologies advance, regulators must balance the potential benefits of these innovations with the need to protect public health and the environment.

The Occupational Safety and Health Administration (OSHA) sets standards for workplace safety in facilities utilizing propyne-based molecular sieving technologies. These regulations cover exposure limits, handling procedures, and safety equipment requirements. OSHA's Hazard Communication Standard ensures that workers are informed about the potential risks associated with propyne and other chemicals used in molecular sieving processes.

At the state level, regulations may vary, with some states imposing stricter controls on the use of propyne and related technologies. California, for instance, has additional requirements under Proposition 65, which mandates warnings for chemicals known to cause cancer or reproductive harm.

Internationally, the regulatory landscape is diverse. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of propyne in molecular sieving applications within EU member states. This comprehensive framework requires manufacturers and importers to register chemicals and demonstrate their safe use.

In Asia, countries like Japan and South Korea have their own regulatory systems. Japan's Chemical Substances Control Law and Korea's Act on the Registration and Evaluation of Chemicals both have implications for propyne use in molecular sieving technologies.

Industry standards also play a significant role in shaping the regulatory framework. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide guidelines and standards for molecular sieving technologies, including those involving propyne.

The regulatory landscape is not static; it evolves with advancements in technology and scientific understanding. Ongoing research into the environmental and health impacts of propyne and related compounds continues to inform regulatory decisions. As molecular sieving technologies advance, regulators must balance the potential benefits of these innovations with the need to protect public health and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!