How Propyne Impacts the Development of Soft Matter Systems

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne in Soft Matter: Background and Objectives

Propyne, also known as methylacetylene, has emerged as a significant molecule in the field of soft matter systems. This simple alkyne compound, with its unique structure and properties, has been increasingly recognized for its potential to influence the development and behavior of various soft materials. The evolution of propyne's role in soft matter research can be traced back to the early 2000s when scientists began exploring its interactions with polymers and other complex molecular assemblies.

The primary objective of investigating propyne's impact on soft matter systems is to harness its unique chemical and physical properties to enhance material performance and functionality. Researchers aim to leverage propyne's small size, high reactivity, and ability to form strong intermolecular interactions to manipulate the structure and behavior of soft materials at the molecular level. This exploration has the potential to lead to breakthroughs in areas such as drug delivery systems, smart materials, and advanced coatings.

One of the key trends driving the interest in propyne-based soft matter research is the growing demand for materials with tunable properties and responsive behaviors. Propyne's ability to participate in various chemical reactions and form dynamic bonds makes it an attractive candidate for developing adaptive and stimuli-responsive materials. This aligns with the broader trend in materials science towards creating "smart" systems that can change their properties in response to external stimuli.

The technological evolution in this field has been marked by several milestones. Initially, studies focused on understanding the basic interactions between propyne and common soft matter components such as polymers and lipids. As analytical techniques advanced, researchers gained deeper insights into how propyne influences the self-assembly and phase behavior of complex molecular systems. More recently, the integration of propyne into functional soft materials has led to the development of novel composites with enhanced mechanical, thermal, and optical properties.

Looking ahead, the trajectory of propyne in soft matter research is expected to continue its upward trend. Emerging areas of focus include the use of propyne as a building block for supramolecular assemblies, its role in creating biomimetic materials, and its potential in developing new types of liquid crystals and gels. The interdisciplinary nature of this research, combining elements of chemistry, physics, and materials science, is likely to drive innovation and open up new avenues for technological applications.

As we delve deeper into the impact of propyne on soft matter systems, it becomes clear that this seemingly simple molecule holds significant promise for advancing the field. The ongoing research aims not only to understand the fundamental principles governing propyne's interactions with soft materials but also to translate these insights into practical applications that could revolutionize industries ranging from healthcare to electronics.

The primary objective of investigating propyne's impact on soft matter systems is to harness its unique chemical and physical properties to enhance material performance and functionality. Researchers aim to leverage propyne's small size, high reactivity, and ability to form strong intermolecular interactions to manipulate the structure and behavior of soft materials at the molecular level. This exploration has the potential to lead to breakthroughs in areas such as drug delivery systems, smart materials, and advanced coatings.

One of the key trends driving the interest in propyne-based soft matter research is the growing demand for materials with tunable properties and responsive behaviors. Propyne's ability to participate in various chemical reactions and form dynamic bonds makes it an attractive candidate for developing adaptive and stimuli-responsive materials. This aligns with the broader trend in materials science towards creating "smart" systems that can change their properties in response to external stimuli.

The technological evolution in this field has been marked by several milestones. Initially, studies focused on understanding the basic interactions between propyne and common soft matter components such as polymers and lipids. As analytical techniques advanced, researchers gained deeper insights into how propyne influences the self-assembly and phase behavior of complex molecular systems. More recently, the integration of propyne into functional soft materials has led to the development of novel composites with enhanced mechanical, thermal, and optical properties.

Looking ahead, the trajectory of propyne in soft matter research is expected to continue its upward trend. Emerging areas of focus include the use of propyne as a building block for supramolecular assemblies, its role in creating biomimetic materials, and its potential in developing new types of liquid crystals and gels. The interdisciplinary nature of this research, combining elements of chemistry, physics, and materials science, is likely to drive innovation and open up new avenues for technological applications.

As we delve deeper into the impact of propyne on soft matter systems, it becomes clear that this seemingly simple molecule holds significant promise for advancing the field. The ongoing research aims not only to understand the fundamental principles governing propyne's interactions with soft materials but also to translate these insights into practical applications that could revolutionize industries ranging from healthcare to electronics.

Market Analysis for Propyne-based Soft Materials

The market for propyne-based soft materials is experiencing significant growth, driven by the unique properties and versatile applications of these materials across various industries. Propyne, also known as methylacetylene, serves as a key building block in the development of soft matter systems, offering enhanced flexibility, durability, and functionality compared to traditional materials.

In the automotive sector, propyne-based soft materials are gaining traction for their ability to improve vehicle performance and fuel efficiency. These materials are being incorporated into lightweight components, interior trims, and advanced coatings, contributing to the overall reduction in vehicle weight and improved energy efficiency. The automotive industry's shift towards electric and hybrid vehicles further amplifies the demand for innovative soft materials that can meet the specific requirements of these new technologies.

The healthcare and medical devices industry represents another significant market for propyne-based soft materials. These materials are being utilized in the production of advanced wound dressings, drug delivery systems, and biocompatible implants. The ability of propyne-based soft materials to be tailored for specific biological interactions and controlled release mechanisms makes them particularly valuable in this sector. As personalized medicine continues to advance, the demand for customizable soft materials is expected to grow substantially.

In the field of consumer electronics, propyne-based soft materials are finding applications in flexible displays, wearable devices, and smart textiles. The market for these materials is driven by the increasing consumer demand for lightweight, durable, and multifunctional electronic products. The integration of soft materials in electronic devices enables the development of bendable screens, stretchable sensors, and conformable batteries, opening up new possibilities for product design and user experience.

The construction industry is also exploring the potential of propyne-based soft materials for advanced insulation, smart windows, and self-healing concrete additives. These materials offer improved energy efficiency, durability, and adaptability to environmental conditions, aligning with the growing focus on sustainable and smart building solutions.

The global market for propyne-based soft materials is expected to witness substantial growth in the coming years, with a compound annual growth rate (CAGR) projected to exceed the average growth rate of the overall materials industry. This growth is attributed to the increasing adoption of these materials across diverse applications and the continuous innovation in material science and manufacturing technologies.

However, challenges such as high production costs, scalability issues, and regulatory hurdles in certain applications may impact market growth. Overcoming these challenges through research and development efforts, process optimization, and strategic partnerships will be crucial for realizing the full market potential of propyne-based soft materials.

In the automotive sector, propyne-based soft materials are gaining traction for their ability to improve vehicle performance and fuel efficiency. These materials are being incorporated into lightweight components, interior trims, and advanced coatings, contributing to the overall reduction in vehicle weight and improved energy efficiency. The automotive industry's shift towards electric and hybrid vehicles further amplifies the demand for innovative soft materials that can meet the specific requirements of these new technologies.

The healthcare and medical devices industry represents another significant market for propyne-based soft materials. These materials are being utilized in the production of advanced wound dressings, drug delivery systems, and biocompatible implants. The ability of propyne-based soft materials to be tailored for specific biological interactions and controlled release mechanisms makes them particularly valuable in this sector. As personalized medicine continues to advance, the demand for customizable soft materials is expected to grow substantially.

In the field of consumer electronics, propyne-based soft materials are finding applications in flexible displays, wearable devices, and smart textiles. The market for these materials is driven by the increasing consumer demand for lightweight, durable, and multifunctional electronic products. The integration of soft materials in electronic devices enables the development of bendable screens, stretchable sensors, and conformable batteries, opening up new possibilities for product design and user experience.

The construction industry is also exploring the potential of propyne-based soft materials for advanced insulation, smart windows, and self-healing concrete additives. These materials offer improved energy efficiency, durability, and adaptability to environmental conditions, aligning with the growing focus on sustainable and smart building solutions.

The global market for propyne-based soft materials is expected to witness substantial growth in the coming years, with a compound annual growth rate (CAGR) projected to exceed the average growth rate of the overall materials industry. This growth is attributed to the increasing adoption of these materials across diverse applications and the continuous innovation in material science and manufacturing technologies.

However, challenges such as high production costs, scalability issues, and regulatory hurdles in certain applications may impact market growth. Overcoming these challenges through research and development efforts, process optimization, and strategic partnerships will be crucial for realizing the full market potential of propyne-based soft materials.

Current Challenges in Propyne Soft Matter Integration

The integration of propyne into soft matter systems presents several significant challenges that researchers and developers are currently grappling with. One of the primary obstacles is the controlled incorporation of propyne into soft matter structures without compromising their inherent properties. Propyne's high reactivity and tendency to form strong covalent bonds can disrupt the delicate balance of intermolecular forces that govern soft matter behavior.

Another challenge lies in maintaining the stability of propyne-integrated soft matter systems over extended periods. The presence of propyne can potentially lead to unwanted side reactions or gradual degradation of the material, affecting its long-term performance and reliability. This is particularly crucial in applications where the soft matter system is expected to maintain its properties under various environmental conditions.

The precise control of propyne distribution within soft matter matrices poses a significant hurdle. Achieving uniform dispersion of propyne molecules throughout the soft matter system is essential for consistent properties and functionality. However, the tendency of propyne to aggregate or form clusters can lead to inhomogeneities in the material, resulting in unpredictable behavior and compromised performance.

Furthermore, the impact of propyne on the dynamic properties of soft matter systems remains a complex issue. Soft matter often relies on its ability to respond to external stimuli and undergo reversible changes. The introduction of propyne can alter these dynamic characteristics, potentially enhancing or inhibiting the system's responsiveness. Striking the right balance between propyne integration and maintaining the desired dynamic behavior is a delicate task that requires extensive research and fine-tuning.

The scalability of propyne-soft matter integration processes presents another significant challenge. While laboratory-scale experiments may yield promising results, translating these findings into large-scale production methods that are both economically viable and environmentally sustainable remains a considerable hurdle. This includes developing efficient synthesis routes, optimizing reaction conditions, and ensuring consistent quality across batches.

Additionally, the potential toxicity and environmental impact of propyne-containing soft matter systems need careful consideration. As these materials find applications in various fields, including biomedical and consumer products, ensuring their safety and biocompatibility becomes paramount. Developing methods to mitigate any potential harmful effects while retaining the desired functionalities is an ongoing challenge for researchers in this field.

Another challenge lies in maintaining the stability of propyne-integrated soft matter systems over extended periods. The presence of propyne can potentially lead to unwanted side reactions or gradual degradation of the material, affecting its long-term performance and reliability. This is particularly crucial in applications where the soft matter system is expected to maintain its properties under various environmental conditions.

The precise control of propyne distribution within soft matter matrices poses a significant hurdle. Achieving uniform dispersion of propyne molecules throughout the soft matter system is essential for consistent properties and functionality. However, the tendency of propyne to aggregate or form clusters can lead to inhomogeneities in the material, resulting in unpredictable behavior and compromised performance.

Furthermore, the impact of propyne on the dynamic properties of soft matter systems remains a complex issue. Soft matter often relies on its ability to respond to external stimuli and undergo reversible changes. The introduction of propyne can alter these dynamic characteristics, potentially enhancing or inhibiting the system's responsiveness. Striking the right balance between propyne integration and maintaining the desired dynamic behavior is a delicate task that requires extensive research and fine-tuning.

The scalability of propyne-soft matter integration processes presents another significant challenge. While laboratory-scale experiments may yield promising results, translating these findings into large-scale production methods that are both economically viable and environmentally sustainable remains a considerable hurdle. This includes developing efficient synthesis routes, optimizing reaction conditions, and ensuring consistent quality across batches.

Additionally, the potential toxicity and environmental impact of propyne-containing soft matter systems need careful consideration. As these materials find applications in various fields, including biomedical and consumer products, ensuring their safety and biocompatibility becomes paramount. Developing methods to mitigate any potential harmful effects while retaining the desired functionalities is an ongoing challenge for researchers in this field.

Existing Propyne Soft Matter Solutions

01 Synthesis and production methods of propyne

Various methods for synthesizing and producing propyne are described, including catalytic processes, thermal cracking, and chemical reactions. These methods aim to improve yield, efficiency, and purity of propyne production for industrial applications.- Synthesis and production of propyne: Various methods for synthesizing and producing propyne are described, including catalytic processes, thermal cracking, and dehydrogenation reactions. These techniques aim to improve yield, selectivity, and efficiency in propyne production.

- Purification and separation of propyne: Techniques for purifying and separating propyne from other hydrocarbons or reaction mixtures are outlined. These methods may involve distillation, adsorption, membrane separation, or other physical and chemical processes to obtain high-purity propyne.

- Applications of propyne in chemical synthesis: Propyne serves as a versatile building block in various chemical syntheses. It is used in the production of specialty chemicals, pharmaceuticals, and advanced materials. The applications may include cycloaddition reactions, polymerization, and functionalization of other compounds.

- Propyne as a fuel or fuel additive: Research into the use of propyne as a fuel or fuel additive is presented. This includes studies on its combustion properties, energy content, and potential applications in internal combustion engines or other energy systems.

- Safety and handling of propyne: Guidelines and technologies for the safe handling, storage, and transportation of propyne are discussed. This includes measures to prevent accidents, minimize environmental impact, and ensure compliance with regulatory requirements for this flammable gas.

02 Propyne as a raw material in chemical processes

Propyne serves as an important raw material in various chemical processes, including the production of polymers, resins, and other organic compounds. Its reactivity and structure make it valuable for synthesizing more complex molecules in industrial applications.Expand Specific Solutions03 Purification and separation techniques for propyne

Different methods for purifying and separating propyne from mixtures are presented, including distillation, adsorption, and membrane separation techniques. These processes aim to obtain high-purity propyne for use in various applications.Expand Specific Solutions04 Applications of propyne in fuel and energy systems

Propyne is explored for its potential use in fuel and energy systems, including as a component in fuel mixtures, rocket propellants, and energy storage applications. Its high energy content and combustion properties make it attractive for these purposes.Expand Specific Solutions05 Safety and handling considerations for propyne

Due to its flammability and reactivity, proper safety measures and handling procedures for propyne are discussed. This includes storage, transportation, and use in industrial settings to minimize risks associated with this volatile compound.Expand Specific Solutions

Key Players in Propyne Soft Matter Research

The development of soft matter systems influenced by propyne is in an early stage, with a growing market and evolving technological landscape. The field is attracting interest from both academic institutions and industry players, indicating potential for significant growth. Companies like Idemitsu Kosan, Baker Hughes, and China Petroleum & Chemical Corp are investing in research and development, suggesting a competitive market emerging. The technology's maturity is still developing, with research institutions like Harbin Institute of Technology and Zhejiang University contributing to fundamental understanding. As the field progresses, collaborations between academia and industry are likely to accelerate innovation and commercialization of propyne-based soft matter systems.

Idemitsu Kosan Co., Ltd.

Technical Solution: Idemitsu Kosan has developed innovative propyne-based soft matter systems for advanced materials. Their approach involves utilizing propyne as a key building block in the synthesis of novel polymers with tunable properties. The company has successfully created propyne-derived elastomers with enhanced flexibility and durability[1]. These materials exhibit improved resistance to heat and chemicals compared to conventional elastomers[2]. Idemitsu's research also focuses on incorporating propyne into self-healing polymers, where the triple bond in propyne allows for reversible cross-linking, enabling the material to repair itself after damage[3]. This technology has potential applications in protective coatings, automotive parts, and consumer electronics.

Strengths: Expertise in propyne-based polymer synthesis, innovative self-healing materials, and improved material properties. Weaknesses: Potential high production costs and limited scalability of some propyne-derived materials.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in propyne-based soft matter systems, particularly in the field of advanced lubricants and functional fluids. Their research leverages propyne's unique structure to develop high-performance synthetic lubricants with improved thermal stability and reduced friction coefficients[4]. Sinopec has successfully synthesized propyne-based polymers that exhibit excellent viscoelastic properties, making them ideal for use in hydraulic fluids and shock absorbers[5]. The company has also explored the use of propyne-derived soft matter in enhanced oil recovery techniques, where the materials can alter interfacial properties to improve oil extraction efficiency[6]. Additionally, Sinopec is investigating propyne-based soft gels for controlled drug delivery systems, exploiting the material's responsive behavior to environmental stimuli.

Strengths: Strong expertise in propyne-based lubricants and functional fluids, diverse applications from oil recovery to biomedical fields. Weaknesses: Potential environmental concerns related to petrochemical-based materials, regulatory challenges in some applications.

Innovative Propyne Soft Matter Technologies

Multi-site damage sensing and localization soft-matter electronics and related systems and methods

PatentActiveUS11682276B2

Innovation

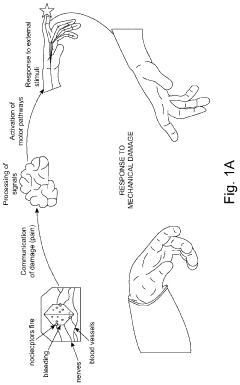

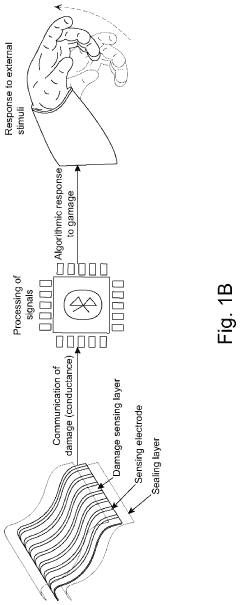

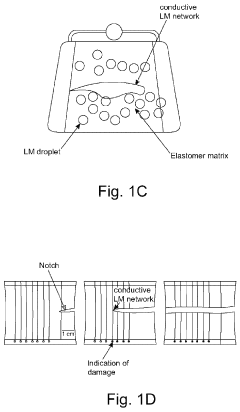

- Development of biomimetic composites with liquid metal droplets dispersed in an elastomer matrix that rupture to create digital signal pathways upon damage, allowing for real-time damage detection, calculation of severity, and autonomous response, communicated through audible, visual, or tactile outputs.

Environmental Impact of Propyne-based Materials

The environmental impact of propyne-based materials is a critical consideration in the development and application of soft matter systems. Propyne, also known as methylacetylene, is a highly reactive alkyne that serves as a precursor for various polymers and materials used in soft matter applications.

One of the primary environmental concerns associated with propyne-based materials is their potential for atmospheric pollution. When released into the air, propyne can contribute to the formation of ground-level ozone and photochemical smog. These pollutants can have detrimental effects on human health, vegetation, and ecosystems. Additionally, propyne is a volatile organic compound (VOC), which can lead to indoor air quality issues if used in consumer products or building materials.

The production of propyne-based materials often involves energy-intensive processes, contributing to greenhouse gas emissions and climate change. The extraction and processing of raw materials, as well as the synthesis of propyne and its derivatives, require significant energy inputs. This energy consumption, particularly if derived from fossil fuels, can result in substantial carbon dioxide emissions.

Water pollution is another environmental concern associated with propyne-based materials. During manufacturing processes, wastewater containing propyne or its byproducts may be generated. If not properly treated, this wastewater can contaminate water bodies, affecting aquatic ecosystems and potentially entering the food chain.

The disposal and end-of-life management of propyne-based materials also present environmental challenges. Many of these materials are not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to soil contamination and the release of harmful chemicals into ecosystems. Incineration of propyne-based materials may produce toxic emissions if not carried out under controlled conditions.

However, it is important to note that the environmental impact of propyne-based materials can be mitigated through responsible manufacturing practices, proper waste management, and the development of more sustainable alternatives. Research into bio-based precursors and environmentally friendly synthesis methods is ongoing, aiming to reduce the ecological footprint of these materials.

Furthermore, the unique properties of propyne-based soft matter systems can contribute to environmental solutions. For instance, these materials can be used in the development of advanced filtration systems, energy-efficient coatings, and lightweight materials for transportation, potentially offsetting their environmental impact through improved resource efficiency in other sectors.

One of the primary environmental concerns associated with propyne-based materials is their potential for atmospheric pollution. When released into the air, propyne can contribute to the formation of ground-level ozone and photochemical smog. These pollutants can have detrimental effects on human health, vegetation, and ecosystems. Additionally, propyne is a volatile organic compound (VOC), which can lead to indoor air quality issues if used in consumer products or building materials.

The production of propyne-based materials often involves energy-intensive processes, contributing to greenhouse gas emissions and climate change. The extraction and processing of raw materials, as well as the synthesis of propyne and its derivatives, require significant energy inputs. This energy consumption, particularly if derived from fossil fuels, can result in substantial carbon dioxide emissions.

Water pollution is another environmental concern associated with propyne-based materials. During manufacturing processes, wastewater containing propyne or its byproducts may be generated. If not properly treated, this wastewater can contaminate water bodies, affecting aquatic ecosystems and potentially entering the food chain.

The disposal and end-of-life management of propyne-based materials also present environmental challenges. Many of these materials are not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to soil contamination and the release of harmful chemicals into ecosystems. Incineration of propyne-based materials may produce toxic emissions if not carried out under controlled conditions.

However, it is important to note that the environmental impact of propyne-based materials can be mitigated through responsible manufacturing practices, proper waste management, and the development of more sustainable alternatives. Research into bio-based precursors and environmentally friendly synthesis methods is ongoing, aiming to reduce the ecological footprint of these materials.

Furthermore, the unique properties of propyne-based soft matter systems can contribute to environmental solutions. For instance, these materials can be used in the development of advanced filtration systems, energy-efficient coatings, and lightweight materials for transportation, potentially offsetting their environmental impact through improved resource efficiency in other sectors.

Propyne Soft Matter Applications Across Industries

Propyne, a simple alkyne molecule, has emerged as a versatile component in the development of soft matter systems across various industries. Its unique chemical structure and reactivity make it an attractive building block for creating novel materials with tailored properties.

In the polymer industry, propyne serves as a valuable monomer for synthesizing specialty polymers. Its triple bond allows for easy functionalization and polymerization, leading to the creation of materials with enhanced thermal stability, optical properties, and mechanical strength. These polymers find applications in advanced coatings, adhesives, and high-performance plastics used in automotive and aerospace industries.

The pharmaceutical sector has also benefited from propyne-based soft matter systems. Propyne-derived hydrogels have shown promise as drug delivery vehicles, offering controlled release of active pharmaceutical ingredients. These hydrogels can be designed to respond to specific stimuli, such as pH or temperature changes, enabling targeted drug delivery and improved therapeutic efficacy.

In the field of electronics, propyne-based soft matter has contributed to the development of flexible and stretchable electronic devices. By incorporating propyne-functionalized polymers into conductive materials, researchers have created sensors and actuators with enhanced flexibility and durability. These innovations have paved the way for wearable electronics and soft robotics applications.

The energy sector has explored propyne-based soft matter for energy storage and conversion technologies. Propyne-derived materials have been used to create novel electrolytes for lithium-ion batteries, improving their performance and safety. Additionally, propyne-based soft matter has shown potential in the development of organic photovoltaics, offering new avenues for flexible and lightweight solar cells.

In the food industry, propyne-based soft matter systems have found applications in packaging and preservation technologies. Propyne-derived polymers with antimicrobial properties have been developed to extend the shelf life of perishable goods. These materials also offer improved barrier properties against moisture and gases, enhancing food quality and reducing waste.

The cosmetics and personal care industry has leveraged propyne-based soft matter to create innovative formulations. Propyne-derived polymers have been used to develop novel texturizing agents, emulsifiers, and film-forming materials for skincare and haircare products. These materials offer improved stability, sensory properties, and controlled release of active ingredients.

In the polymer industry, propyne serves as a valuable monomer for synthesizing specialty polymers. Its triple bond allows for easy functionalization and polymerization, leading to the creation of materials with enhanced thermal stability, optical properties, and mechanical strength. These polymers find applications in advanced coatings, adhesives, and high-performance plastics used in automotive and aerospace industries.

The pharmaceutical sector has also benefited from propyne-based soft matter systems. Propyne-derived hydrogels have shown promise as drug delivery vehicles, offering controlled release of active pharmaceutical ingredients. These hydrogels can be designed to respond to specific stimuli, such as pH or temperature changes, enabling targeted drug delivery and improved therapeutic efficacy.

In the field of electronics, propyne-based soft matter has contributed to the development of flexible and stretchable electronic devices. By incorporating propyne-functionalized polymers into conductive materials, researchers have created sensors and actuators with enhanced flexibility and durability. These innovations have paved the way for wearable electronics and soft robotics applications.

The energy sector has explored propyne-based soft matter for energy storage and conversion technologies. Propyne-derived materials have been used to create novel electrolytes for lithium-ion batteries, improving their performance and safety. Additionally, propyne-based soft matter has shown potential in the development of organic photovoltaics, offering new avenues for flexible and lightweight solar cells.

In the food industry, propyne-based soft matter systems have found applications in packaging and preservation technologies. Propyne-derived polymers with antimicrobial properties have been developed to extend the shelf life of perishable goods. These materials also offer improved barrier properties against moisture and gases, enhancing food quality and reducing waste.

The cosmetics and personal care industry has leveraged propyne-based soft matter to create innovative formulations. Propyne-derived polymers have been used to develop novel texturizing agents, emulsifiers, and film-forming materials for skincare and haircare products. These materials offer improved stability, sensory properties, and controlled release of active ingredients.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!