How Sodium Alginate Benefits Non-Aqueous Solvent Formulation?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate in Non-Aqueous Solvents: Background and Objectives

Sodium alginate, a versatile polysaccharide derived from brown algae, has long been recognized for its unique properties in aqueous environments. However, its potential applications in non-aqueous solvent formulations have recently garnered significant attention from researchers and industry professionals alike. This emerging field of study aims to explore and exploit the benefits of sodium alginate in systems where water is not the primary solvent.

The evolution of sodium alginate's use in non-aqueous solvents can be traced back to the early 2000s when scientists began investigating its behavior in organic media. Initially, these studies were primarily focused on understanding the fundamental interactions between sodium alginate and various organic solvents. As research progressed, the potential for sodium alginate to enhance the properties of non-aqueous formulations became increasingly apparent.

The primary objective of incorporating sodium alginate into non-aqueous solvent formulations is to leverage its unique structural and functional characteristics to improve the performance of various products and processes. These improvements may include enhanced stability, controlled release properties, improved rheological behavior, and increased biocompatibility in certain applications.

One of the key drivers behind this research is the growing demand for sustainable and bio-based materials in industries such as pharmaceuticals, cosmetics, and advanced materials. Sodium alginate, being a naturally derived polymer, aligns well with this trend towards eco-friendly solutions. Its biodegradability and non-toxicity make it an attractive option for formulators seeking to develop more environmentally responsible products.

The technical challenges associated with integrating sodium alginate into non-aqueous systems are numerous and complex. These include issues related to solubility, dispersion, and maintaining the polymer's functional properties in the absence of water. Overcoming these challenges requires a deep understanding of polymer chemistry, surface science, and formulation technology.

As research in this field progresses, several key technological trends are emerging. These include the development of novel modification techniques to enhance sodium alginate's compatibility with non-aqueous solvents, the exploration of synergistic effects between sodium alginate and other additives, and the investigation of new application areas where the unique properties of sodium alginate in non-aqueous media can be exploited.

The potential impact of this technology on various industries is significant. In the pharmaceutical sector, for instance, sodium alginate in non-aqueous formulations could lead to improved drug delivery systems with enhanced stability and controlled release profiles. In the field of materials science, it may enable the development of new composite materials with unique properties.

The evolution of sodium alginate's use in non-aqueous solvents can be traced back to the early 2000s when scientists began investigating its behavior in organic media. Initially, these studies were primarily focused on understanding the fundamental interactions between sodium alginate and various organic solvents. As research progressed, the potential for sodium alginate to enhance the properties of non-aqueous formulations became increasingly apparent.

The primary objective of incorporating sodium alginate into non-aqueous solvent formulations is to leverage its unique structural and functional characteristics to improve the performance of various products and processes. These improvements may include enhanced stability, controlled release properties, improved rheological behavior, and increased biocompatibility in certain applications.

One of the key drivers behind this research is the growing demand for sustainable and bio-based materials in industries such as pharmaceuticals, cosmetics, and advanced materials. Sodium alginate, being a naturally derived polymer, aligns well with this trend towards eco-friendly solutions. Its biodegradability and non-toxicity make it an attractive option for formulators seeking to develop more environmentally responsible products.

The technical challenges associated with integrating sodium alginate into non-aqueous systems are numerous and complex. These include issues related to solubility, dispersion, and maintaining the polymer's functional properties in the absence of water. Overcoming these challenges requires a deep understanding of polymer chemistry, surface science, and formulation technology.

As research in this field progresses, several key technological trends are emerging. These include the development of novel modification techniques to enhance sodium alginate's compatibility with non-aqueous solvents, the exploration of synergistic effects between sodium alginate and other additives, and the investigation of new application areas where the unique properties of sodium alginate in non-aqueous media can be exploited.

The potential impact of this technology on various industries is significant. In the pharmaceutical sector, for instance, sodium alginate in non-aqueous formulations could lead to improved drug delivery systems with enhanced stability and controlled release profiles. In the field of materials science, it may enable the development of new composite materials with unique properties.

Market Analysis for Non-Aqueous Formulations

The non-aqueous formulation market has been experiencing significant growth in recent years, driven by the increasing demand for innovative drug delivery systems and the need for improved stability and bioavailability of active pharmaceutical ingredients (APIs). This market segment encompasses a wide range of products, including oral suspensions, topical creams, and injectable formulations that utilize non-aqueous solvents as the primary vehicle for drug delivery.

The global non-aqueous formulation market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of chronic diseases, the growing geriatric population, and the increasing adoption of advanced drug delivery technologies. Additionally, the pharmaceutical industry's focus on developing complex molecules and biologics has further fueled the demand for non-aqueous formulations.

Key market drivers include the ability of non-aqueous formulations to enhance drug stability, improve solubility of poorly water-soluble drugs, and provide controlled release profiles. These advantages have led to increased research and development activities in this field, with pharmaceutical companies investing heavily in novel formulation techniques and excipients.

The market for non-aqueous formulations is segmented based on dosage form, application, and geography. Oral suspensions and topical formulations currently dominate the market, accounting for a significant share of the overall revenue. However, injectable non-aqueous formulations are expected to witness the highest growth rate during the forecast period, driven by the increasing demand for long-acting injectables and depot formulations.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, is a major contributor to market growth, owing to its well-established pharmaceutical industry and favorable regulatory environment. However, emerging economies in Asia-Pacific, such as China and India, are expected to exhibit the fastest growth rates due to increasing healthcare expenditure and growing pharmaceutical manufacturing capabilities.

The competitive landscape of the non-aqueous formulation market is characterized by the presence of both large pharmaceutical companies and specialized formulation development firms. Key players are focusing on strategic collaborations, mergers and acquisitions, and product innovations to maintain their market position and expand their product portfolios.

In the context of sodium alginate's potential benefits in non-aqueous solvent formulations, there is growing interest in exploring its applications beyond traditional aqueous systems. While sodium alginate is primarily known for its use in aqueous formulations, its unique properties, such as thickening, stabilizing, and gel-forming abilities, are being investigated for potential advantages in non-aqueous environments. This presents an opportunity for market expansion and differentiation in the highly competitive non-aqueous formulation landscape.

The global non-aqueous formulation market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of chronic diseases, the growing geriatric population, and the increasing adoption of advanced drug delivery technologies. Additionally, the pharmaceutical industry's focus on developing complex molecules and biologics has further fueled the demand for non-aqueous formulations.

Key market drivers include the ability of non-aqueous formulations to enhance drug stability, improve solubility of poorly water-soluble drugs, and provide controlled release profiles. These advantages have led to increased research and development activities in this field, with pharmaceutical companies investing heavily in novel formulation techniques and excipients.

The market for non-aqueous formulations is segmented based on dosage form, application, and geography. Oral suspensions and topical formulations currently dominate the market, accounting for a significant share of the overall revenue. However, injectable non-aqueous formulations are expected to witness the highest growth rate during the forecast period, driven by the increasing demand for long-acting injectables and depot formulations.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, is a major contributor to market growth, owing to its well-established pharmaceutical industry and favorable regulatory environment. However, emerging economies in Asia-Pacific, such as China and India, are expected to exhibit the fastest growth rates due to increasing healthcare expenditure and growing pharmaceutical manufacturing capabilities.

The competitive landscape of the non-aqueous formulation market is characterized by the presence of both large pharmaceutical companies and specialized formulation development firms. Key players are focusing on strategic collaborations, mergers and acquisitions, and product innovations to maintain their market position and expand their product portfolios.

In the context of sodium alginate's potential benefits in non-aqueous solvent formulations, there is growing interest in exploring its applications beyond traditional aqueous systems. While sodium alginate is primarily known for its use in aqueous formulations, its unique properties, such as thickening, stabilizing, and gel-forming abilities, are being investigated for potential advantages in non-aqueous environments. This presents an opportunity for market expansion and differentiation in the highly competitive non-aqueous formulation landscape.

Current Challenges in Non-Aqueous Solvent Formulations

Non-aqueous solvent formulations face several significant challenges that hinder their widespread adoption and optimal performance across various industries. One of the primary issues is the limited solubility of many compounds in non-aqueous solvents, which can restrict the range of applications and reduce overall efficacy. This solubility constraint often leads to difficulties in achieving desired concentrations of active ingredients, potentially compromising the formulation's effectiveness.

Another critical challenge is the stability of formulations in non-aqueous environments. Many compounds that are stable in aqueous solutions may undergo degradation or chemical changes when exposed to non-aqueous solvents, leading to reduced shelf life and altered product performance. This instability can result in the formation of precipitates, phase separation, or changes in viscosity over time, all of which can negatively impact the quality and consistency of the final product.

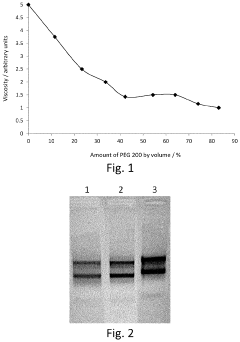

The viscosity control of non-aqueous formulations presents another significant hurdle. Unlike water-based systems, where viscosity modifiers are well-established, achieving the desired flow properties in non-aqueous solvents can be complex. This challenge is particularly evident in applications requiring specific rheological characteristics, such as in lubricants, coatings, or personal care products.

Compatibility issues between different components in non-aqueous formulations also pose a substantial challenge. The interaction between active ingredients, additives, and the solvent itself can lead to unexpected reactions or changes in the formulation's properties. This complexity often necessitates extensive testing and reformulation efforts to achieve a stable and effective product.

Environmental and safety concerns associated with many non-aqueous solvents add another layer of complexity to formulation development. Volatile organic compounds (VOCs) and other potentially harmful substances commonly used in non-aqueous systems face increasing regulatory scrutiny, driving the need for more environmentally friendly alternatives that maintain performance standards.

The scalability of non-aqueous formulations from laboratory to industrial production presents additional challenges. Processes that work well at small scales may encounter issues when scaled up, such as heat transfer problems, mixing inefficiencies, or changes in reaction kinetics. These scaling challenges can significantly impact product consistency and manufacturing costs.

Lastly, the lack of standardized testing methods for non-aqueous formulations complicates quality control and product comparison across different manufacturers. This absence of universal standards can lead to inconsistencies in product evaluation and make it difficult for consumers and industries to make informed decisions about product selection and performance expectations.

Another critical challenge is the stability of formulations in non-aqueous environments. Many compounds that are stable in aqueous solutions may undergo degradation or chemical changes when exposed to non-aqueous solvents, leading to reduced shelf life and altered product performance. This instability can result in the formation of precipitates, phase separation, or changes in viscosity over time, all of which can negatively impact the quality and consistency of the final product.

The viscosity control of non-aqueous formulations presents another significant hurdle. Unlike water-based systems, where viscosity modifiers are well-established, achieving the desired flow properties in non-aqueous solvents can be complex. This challenge is particularly evident in applications requiring specific rheological characteristics, such as in lubricants, coatings, or personal care products.

Compatibility issues between different components in non-aqueous formulations also pose a substantial challenge. The interaction between active ingredients, additives, and the solvent itself can lead to unexpected reactions or changes in the formulation's properties. This complexity often necessitates extensive testing and reformulation efforts to achieve a stable and effective product.

Environmental and safety concerns associated with many non-aqueous solvents add another layer of complexity to formulation development. Volatile organic compounds (VOCs) and other potentially harmful substances commonly used in non-aqueous systems face increasing regulatory scrutiny, driving the need for more environmentally friendly alternatives that maintain performance standards.

The scalability of non-aqueous formulations from laboratory to industrial production presents additional challenges. Processes that work well at small scales may encounter issues when scaled up, such as heat transfer problems, mixing inefficiencies, or changes in reaction kinetics. These scaling challenges can significantly impact product consistency and manufacturing costs.

Lastly, the lack of standardized testing methods for non-aqueous formulations complicates quality control and product comparison across different manufacturers. This absence of universal standards can lead to inconsistencies in product evaluation and make it difficult for consumers and industries to make informed decisions about product selection and performance expectations.

Existing Solutions Using Sodium Alginate

01 Wound healing and tissue regeneration

Sodium alginate has been found to promote wound healing and tissue regeneration. It can be used in various medical applications such as wound dressings, scaffolds for tissue engineering, and drug delivery systems. The biocompatible nature of sodium alginate allows it to create a moist environment conducive to healing while also providing a barrier against external contaminants.- Wound healing and tissue regeneration: Sodium alginate has been found to promote wound healing and tissue regeneration. It can be used in various medical applications such as wound dressings, scaffolds for tissue engineering, and drug delivery systems. The biocompatible nature of sodium alginate allows it to create a moist environment conducive to healing while also providing a barrier against external contaminants.

- Gastrointestinal health and digestion: Sodium alginate has beneficial effects on gastrointestinal health and digestion. It can act as a prebiotic, promoting the growth of beneficial gut bacteria. Additionally, it may help in managing acid reflux and heartburn by forming a protective barrier in the stomach. Its gel-forming properties also contribute to a feeling of fullness, potentially aiding in weight management.

- Dental and oral care applications: In dental and oral care, sodium alginate is utilized for its unique properties. It is commonly used in dental impressions due to its ability to form stable gels quickly. Moreover, it can be incorporated into oral care products to help reduce tooth sensitivity, promote remineralization, and provide a protective coating on teeth and gums.

- Cosmetic and skincare benefits: Sodium alginate offers various benefits in cosmetic and skincare formulations. It acts as a natural thickener and emulsifier, improving the texture and stability of products. Its moisturizing properties help to hydrate the skin, while its film-forming ability can provide a protective barrier. It may also have anti-aging effects by promoting collagen production and protecting against free radicals.

- Food industry applications: In the food industry, sodium alginate serves multiple purposes. It is used as a thickening agent, stabilizer, and emulsifier in various food products. Its gel-forming properties make it useful in restructured foods and as a replacement for fats in low-calorie products. Additionally, it can be used to create edible films and coatings, extending the shelf life of fruits and vegetables.

02 Gastrointestinal health and digestion

Sodium alginate has benefits for gastrointestinal health and digestion. It can form a protective barrier in the stomach, helping to alleviate symptoms of acid reflux and heartburn. Additionally, it may act as a prebiotic, supporting the growth of beneficial gut bacteria and promoting overall digestive health.Expand Specific Solutions03 Food and beverage applications

In the food and beverage industry, sodium alginate serves as a versatile additive. It functions as a thickening agent, stabilizer, and emulsifier in various products. Its ability to form gels and improve texture makes it valuable in creating innovative food formulations and enhancing the overall quality of processed foods.Expand Specific Solutions04 Dental and oral care

Sodium alginate has applications in dental and oral care products. It can be used in dental impressions, as a component in toothpaste formulations, and in oral drug delivery systems. Its biocompatibility and ability to form hydrogels make it suitable for various dental and oral health applications.Expand Specific Solutions05 Environmental and industrial applications

Sodium alginate has benefits in environmental and industrial applications. It can be used in water treatment processes for removing heavy metals and other pollutants. In industrial settings, it finds use in textile printing, paper coating, and as a binder in various manufacturing processes. Its biodegradability makes it an environmentally friendly option for many applications.Expand Specific Solutions

Key Players in Sodium Alginate Industry

The sodium alginate market for non-aqueous solvent formulations is in a growth phase, driven by increasing demand in pharmaceutical and cosmetic industries. The global market size is projected to expand significantly in the coming years, with key players like L'Oréal SA, Colgate-Palmolive Co., and BASF Corp. leading innovation. Technological advancements are improving the performance and versatility of sodium alginate in non-aqueous applications, with companies such as Qingdao Mingyue Alginate and Qingdao Bright Moon Seaweed Group focusing on developing specialized formulations. Research institutions like Shandong University and the National University of Singapore are contributing to the advancement of sodium alginate technology, indicating a moderate to high level of technological maturity in this field.

L'Oréal SA

Technical Solution: L'Oréal SA has leveraged sodium alginate in non-aqueous solvent formulations for cosmetic applications. Their research focuses on creating stable emulsions and gels using sodium alginate in combination with oil-soluble polymers and emulsifiers[4]. This approach allows for the development of anhydrous or low-water content cosmetic products with improved texture and stability. L'Oréal has patented methods for incorporating sodium alginate into lipstick formulations, where it acts as a structuring agent and enhances wear resistance[5]. Additionally, they have explored the use of sodium alginate in powder-to-cream formulations, where it facilitates the transformation from a powder to a creamy texture upon application[6].

Strengths: Enhances texture and stability of cosmetic products, particularly in anhydrous formulations. Enables innovative product forms like powder-to-cream. Weaknesses: May be limited to specific cosmetic applications, potentially less versatile in other industries.

Colgate-Palmolive Co.

Technical Solution: Colgate-Palmolive Co. has incorporated sodium alginate into non-aqueous solvent formulations for oral care and personal care products. Their research has focused on developing stable suspensions of sodium alginate in glycerin and other polyols, which serve as the base for various anhydrous products[10]. This approach allows for the creation of alcohol-free mouthwashes and toothpastes with enhanced moisturizing and film-forming properties. Colgate-Palmolive has also explored the use of sodium alginate in combination with silicone oils for leave-on skin care products, where it acts as a thickener and provides a smooth, non-greasy feel[11]. The company has patented methods for incorporating sodium alginate into non-aqueous antiperspirant formulations, improving their stability and application properties[12].

Strengths: Enables the development of anhydrous oral care and personal care products with improved sensory properties. Expands the use of sodium alginate in antiperspirant formulations. Weaknesses: May be primarily focused on personal care applications, limiting broader industrial use.

Innovative Sodium Alginate Modifications

Process for tartaric stabilization of wines and products derived from wine or derived from grapes

PatentInactiveEP4123009A1

Innovation

- The use of alginic acid or alginate, derived from algae or bacteria, as a protective colloid to slow the growth of potassium hydrogen tartrate and calcium tartrate crystals in wines, with concentrations between 5 g/hL and 100 g/hL, effectively stabilizing wines and grape derivatives by inhibiting crystal formation without affecting wine quality or causing allergenic concerns.

Composition and method for inactivating a virus

PatentPendingUS20230220313A1

Innovation

- A composition comprising a quaternary ammonium compound and a halogenated organic compound, such as betaine and trifluoroacetamide, is used to inactivate viruses, stabilize biomolecules, and enable direct analysis without prior purification, utilizing deep eutectic solvents or classical solutions to maintain viral particle integrity and facilitate safer handling and transport.

Environmental Impact of Sodium Alginate Use

The use of sodium alginate in non-aqueous solvent formulations has significant environmental implications that warrant careful consideration. As a biodegradable and renewable resource derived from brown seaweed, sodium alginate offers several environmental benefits compared to synthetic alternatives.

One of the primary environmental advantages of sodium alginate is its biodegradability. When released into the environment, it naturally decomposes without leaving harmful residues or persistent pollutants. This characteristic reduces the long-term environmental impact associated with its use in various applications, including non-aqueous solvent formulations.

Furthermore, the production of sodium alginate from seaweed contributes to the sustainable use of marine resources. Seaweed cultivation requires minimal inputs and does not compete with land-based agriculture for resources. This aspect aligns with global efforts to promote sustainable resource management and reduce the environmental footprint of industrial processes.

In non-aqueous solvent formulations, sodium alginate can potentially replace or reduce the use of synthetic polymers and additives. This substitution can lead to a decrease in the overall environmental impact of the formulation, as synthetic materials often have higher carbon footprints and may pose greater risks to ecosystems upon disposal.

The use of sodium alginate may also contribute to improved end-of-life scenarios for products containing non-aqueous solvent formulations. As a natural polymer, it can be more easily integrated into existing waste management and recycling streams, potentially reducing the burden on landfills and incineration facilities.

However, it is important to note that the environmental impact of sodium alginate use is not entirely benign. The harvesting of seaweed, if not managed sustainably, could potentially disrupt marine ecosystems. Additionally, the processing of seaweed into sodium alginate requires energy and resources, which must be factored into overall environmental assessments.

In terms of water pollution, sodium alginate generally poses a lower risk compared to many synthetic alternatives. Its natural origin and biodegradability mean that accidental releases into aquatic environments are less likely to cause long-term harm to marine life or water quality.

When considering the broader lifecycle of products containing sodium alginate in non-aqueous solvent formulations, there may be opportunities for reduced environmental impact during manufacturing, use, and disposal phases. This could include lower energy requirements for processing, reduced emissions during product use, and easier biodegradation at the end of the product's life.

One of the primary environmental advantages of sodium alginate is its biodegradability. When released into the environment, it naturally decomposes without leaving harmful residues or persistent pollutants. This characteristic reduces the long-term environmental impact associated with its use in various applications, including non-aqueous solvent formulations.

Furthermore, the production of sodium alginate from seaweed contributes to the sustainable use of marine resources. Seaweed cultivation requires minimal inputs and does not compete with land-based agriculture for resources. This aspect aligns with global efforts to promote sustainable resource management and reduce the environmental footprint of industrial processes.

In non-aqueous solvent formulations, sodium alginate can potentially replace or reduce the use of synthetic polymers and additives. This substitution can lead to a decrease in the overall environmental impact of the formulation, as synthetic materials often have higher carbon footprints and may pose greater risks to ecosystems upon disposal.

The use of sodium alginate may also contribute to improved end-of-life scenarios for products containing non-aqueous solvent formulations. As a natural polymer, it can be more easily integrated into existing waste management and recycling streams, potentially reducing the burden on landfills and incineration facilities.

However, it is important to note that the environmental impact of sodium alginate use is not entirely benign. The harvesting of seaweed, if not managed sustainably, could potentially disrupt marine ecosystems. Additionally, the processing of seaweed into sodium alginate requires energy and resources, which must be factored into overall environmental assessments.

In terms of water pollution, sodium alginate generally poses a lower risk compared to many synthetic alternatives. Its natural origin and biodegradability mean that accidental releases into aquatic environments are less likely to cause long-term harm to marine life or water quality.

When considering the broader lifecycle of products containing sodium alginate in non-aqueous solvent formulations, there may be opportunities for reduced environmental impact during manufacturing, use, and disposal phases. This could include lower energy requirements for processing, reduced emissions during product use, and easier biodegradation at the end of the product's life.

Regulatory Considerations for Non-Aqueous Formulations

The regulatory landscape for non-aqueous formulations incorporating sodium alginate presents unique challenges and considerations. Regulatory bodies, such as the FDA in the United States and the EMA in Europe, have established specific guidelines for the use of excipients in non-aqueous formulations. These guidelines often focus on safety, stability, and efficacy aspects of the formulation.

One key regulatory consideration is the classification of sodium alginate within non-aqueous systems. While sodium alginate is generally recognized as safe (GRAS) for use in food and pharmaceutical applications, its use in non-aqueous solvents may require additional safety assessments. Regulatory agencies may require manufacturers to provide data demonstrating the stability and compatibility of sodium alginate in these novel formulations.

The impact of sodium alginate on the bioavailability and pharmacokinetics of active pharmaceutical ingredients (APIs) in non-aqueous formulations is another critical regulatory concern. Manufacturers must conduct thorough studies to evaluate how sodium alginate affects drug release profiles and absorption rates in these systems. This data is essential for obtaining regulatory approval and ensuring patient safety.

Environmental considerations also play a role in the regulatory landscape for non-aqueous formulations containing sodium alginate. As sustainability becomes increasingly important, regulatory bodies may scrutinize the environmental impact of these formulations, including their biodegradability and potential effects on aquatic ecosystems.

Quality control and consistency in manufacturing processes are paramount from a regulatory standpoint. Manufacturers must demonstrate robust quality management systems and consistent production methods to ensure the uniformity and reliability of non-aqueous formulations containing sodium alginate. This includes establishing appropriate specifications for raw materials, in-process controls, and finished product testing.

Labeling and packaging requirements for non-aqueous formulations with sodium alginate may differ from traditional aqueous formulations. Regulatory agencies may require specific information on labels regarding the presence of sodium alginate and any potential allergen concerns. Additionally, stability studies under various environmental conditions may be necessary to determine appropriate storage conditions and shelf life.

International harmonization of regulations for non-aqueous formulations remains an ongoing challenge. Manufacturers seeking global market access must navigate varying regulatory requirements across different regions. This may necessitate additional studies or documentation to meet specific regional standards for the use of sodium alginate in non-aqueous systems.

One key regulatory consideration is the classification of sodium alginate within non-aqueous systems. While sodium alginate is generally recognized as safe (GRAS) for use in food and pharmaceutical applications, its use in non-aqueous solvents may require additional safety assessments. Regulatory agencies may require manufacturers to provide data demonstrating the stability and compatibility of sodium alginate in these novel formulations.

The impact of sodium alginate on the bioavailability and pharmacokinetics of active pharmaceutical ingredients (APIs) in non-aqueous formulations is another critical regulatory concern. Manufacturers must conduct thorough studies to evaluate how sodium alginate affects drug release profiles and absorption rates in these systems. This data is essential for obtaining regulatory approval and ensuring patient safety.

Environmental considerations also play a role in the regulatory landscape for non-aqueous formulations containing sodium alginate. As sustainability becomes increasingly important, regulatory bodies may scrutinize the environmental impact of these formulations, including their biodegradability and potential effects on aquatic ecosystems.

Quality control and consistency in manufacturing processes are paramount from a regulatory standpoint. Manufacturers must demonstrate robust quality management systems and consistent production methods to ensure the uniformity and reliability of non-aqueous formulations containing sodium alginate. This includes establishing appropriate specifications for raw materials, in-process controls, and finished product testing.

Labeling and packaging requirements for non-aqueous formulations with sodium alginate may differ from traditional aqueous formulations. Regulatory agencies may require specific information on labels regarding the presence of sodium alginate and any potential allergen concerns. Additionally, stability studies under various environmental conditions may be necessary to determine appropriate storage conditions and shelf life.

International harmonization of regulations for non-aqueous formulations remains an ongoing challenge. Manufacturers seeking global market access must navigate varying regulatory requirements across different regions. This may necessitate additional studies or documentation to meet specific regional standards for the use of sodium alginate in non-aqueous systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!