How Sodium Alginate Drives Innovation in Omega-3 Delivery Systems?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Omega-3 Delivery Evolution

The evolution of Omega-3 delivery systems has been marked by significant advancements in recent years, driven by the growing awareness of the health benefits associated with Omega-3 fatty acids. Initially, Omega-3 supplementation was primarily achieved through the consumption of fish oil capsules, which often presented challenges in terms of taste, odor, and digestibility.

As consumer demand for more palatable and efficient delivery methods increased, the industry began exploring alternative approaches. One of the early innovations was the development of emulsion-based systems, which allowed for better dispersion of Omega-3 oils in water-based products. This breakthrough enabled the incorporation of Omega-3s into a wider range of food and beverage applications.

The next significant milestone in Omega-3 delivery evolution was the introduction of microencapsulation techniques. This technology involved encasing tiny droplets of Omega-3 oils within a protective shell, typically made from materials such as proteins or carbohydrates. Microencapsulation not only improved the stability and shelf life of Omega-3 products but also helped mask the unpleasant fishy taste and odor associated with traditional fish oil supplements.

As research in nanotechnology progressed, nanoencapsulation emerged as a promising approach for Omega-3 delivery. This method allowed for even smaller particle sizes, potentially enhancing bioavailability and enabling the incorporation of Omega-3s into a broader range of products, including clear beverages and functional foods.

The quest for improved bioavailability led to the development of various chemical modifications of Omega-3 fatty acids. Ethyl ester forms and re-esterified triglycerides were introduced as alternatives to natural triglycerides, each offering unique advantages in terms of concentration and absorption.

More recently, the focus has shifted towards plant-based sources of Omega-3s, such as algal oils, in response to growing environmental concerns and the increasing popularity of vegetarian and vegan diets. This has spurred innovation in extraction and purification techniques to obtain high-quality Omega-3s from algal sources.

The latest frontier in Omega-3 delivery systems involves the use of advanced biomaterials and smart delivery technologies. This includes the exploration of biopolymers like sodium alginate, which offers unique properties for controlled release and enhanced stability of Omega-3 fatty acids. The integration of sodium alginate in Omega-3 delivery systems represents a significant step forward in addressing the challenges of oxidation, bioavailability, and sensory attributes associated with Omega-3 supplementation.

As consumer demand for more palatable and efficient delivery methods increased, the industry began exploring alternative approaches. One of the early innovations was the development of emulsion-based systems, which allowed for better dispersion of Omega-3 oils in water-based products. This breakthrough enabled the incorporation of Omega-3s into a wider range of food and beverage applications.

The next significant milestone in Omega-3 delivery evolution was the introduction of microencapsulation techniques. This technology involved encasing tiny droplets of Omega-3 oils within a protective shell, typically made from materials such as proteins or carbohydrates. Microencapsulation not only improved the stability and shelf life of Omega-3 products but also helped mask the unpleasant fishy taste and odor associated with traditional fish oil supplements.

As research in nanotechnology progressed, nanoencapsulation emerged as a promising approach for Omega-3 delivery. This method allowed for even smaller particle sizes, potentially enhancing bioavailability and enabling the incorporation of Omega-3s into a broader range of products, including clear beverages and functional foods.

The quest for improved bioavailability led to the development of various chemical modifications of Omega-3 fatty acids. Ethyl ester forms and re-esterified triglycerides were introduced as alternatives to natural triglycerides, each offering unique advantages in terms of concentration and absorption.

More recently, the focus has shifted towards plant-based sources of Omega-3s, such as algal oils, in response to growing environmental concerns and the increasing popularity of vegetarian and vegan diets. This has spurred innovation in extraction and purification techniques to obtain high-quality Omega-3s from algal sources.

The latest frontier in Omega-3 delivery systems involves the use of advanced biomaterials and smart delivery technologies. This includes the exploration of biopolymers like sodium alginate, which offers unique properties for controlled release and enhanced stability of Omega-3 fatty acids. The integration of sodium alginate in Omega-3 delivery systems represents a significant step forward in addressing the challenges of oxidation, bioavailability, and sensory attributes associated with Omega-3 supplementation.

Market Demand Analysis

The market demand for innovative omega-3 delivery systems utilizing sodium alginate has been steadily increasing in recent years. This growth is primarily driven by the rising consumer awareness of the health benefits associated with omega-3 fatty acids, coupled with the challenges in traditional delivery methods. The global omega-3 market is experiencing robust expansion, with a particular focus on enhanced bioavailability and improved palatability of omega-3 supplements.

Sodium alginate, a natural polysaccharide derived from brown seaweed, has emerged as a key player in addressing the limitations of conventional omega-3 delivery systems. Its unique properties, including gel-forming capabilities and stability in acidic environments, make it an ideal candidate for encapsulation and controlled release of omega-3 fatty acids. This has led to a surge in research and development activities aimed at leveraging sodium alginate in novel omega-3 formulations.

The pharmaceutical and nutraceutical industries have shown significant interest in sodium alginate-based omega-3 delivery systems. These industries are actively seeking solutions to overcome issues such as oxidation, poor absorption, and unpleasant taste associated with traditional fish oil supplements. The demand for sodium alginate in this context is expected to grow as companies strive to differentiate their products in a competitive market.

Consumer preferences are shifting towards more convenient and palatable omega-3 supplements. Sodium alginate-based delivery systems offer the potential for creating tasteless, odorless, and easy-to-swallow formulations, addressing a major pain point in the omega-3 supplement market. This trend is particularly evident in the growing demand for vegetarian and vegan omega-3 sources, where sodium alginate can play a crucial role in improving the delivery of plant-based omega-3s.

The functional food and beverage sector is another area where sodium alginate-driven omega-3 delivery systems are gaining traction. Manufacturers are exploring ways to incorporate omega-3s into a wider range of food products without compromising taste or shelf-life. Sodium alginate's versatility in food applications makes it an attractive option for developing fortified products that meet consumer demand for healthier food choices.

In the aquaculture industry, there is a growing interest in using sodium alginate to enhance the delivery of omega-3s in fish feed. This application aims to improve the nutritional profile of farmed fish, addressing concerns about declining omega-3 levels in farm-raised seafood. The potential for sodium alginate to increase the efficiency of omega-3 uptake in fish could have significant implications for the sustainability and nutritional value of aquaculture products.

As the global population ages and the prevalence of chronic diseases increases, the demand for effective omega-3 supplementation is expected to rise. Sodium alginate-based delivery systems are well-positioned to meet this demand by offering improved bioavailability and targeted delivery of omega-3s. This trend is likely to drive further innovation and market growth in the coming years.

Sodium alginate, a natural polysaccharide derived from brown seaweed, has emerged as a key player in addressing the limitations of conventional omega-3 delivery systems. Its unique properties, including gel-forming capabilities and stability in acidic environments, make it an ideal candidate for encapsulation and controlled release of omega-3 fatty acids. This has led to a surge in research and development activities aimed at leveraging sodium alginate in novel omega-3 formulations.

The pharmaceutical and nutraceutical industries have shown significant interest in sodium alginate-based omega-3 delivery systems. These industries are actively seeking solutions to overcome issues such as oxidation, poor absorption, and unpleasant taste associated with traditional fish oil supplements. The demand for sodium alginate in this context is expected to grow as companies strive to differentiate their products in a competitive market.

Consumer preferences are shifting towards more convenient and palatable omega-3 supplements. Sodium alginate-based delivery systems offer the potential for creating tasteless, odorless, and easy-to-swallow formulations, addressing a major pain point in the omega-3 supplement market. This trend is particularly evident in the growing demand for vegetarian and vegan omega-3 sources, where sodium alginate can play a crucial role in improving the delivery of plant-based omega-3s.

The functional food and beverage sector is another area where sodium alginate-driven omega-3 delivery systems are gaining traction. Manufacturers are exploring ways to incorporate omega-3s into a wider range of food products without compromising taste or shelf-life. Sodium alginate's versatility in food applications makes it an attractive option for developing fortified products that meet consumer demand for healthier food choices.

In the aquaculture industry, there is a growing interest in using sodium alginate to enhance the delivery of omega-3s in fish feed. This application aims to improve the nutritional profile of farmed fish, addressing concerns about declining omega-3 levels in farm-raised seafood. The potential for sodium alginate to increase the efficiency of omega-3 uptake in fish could have significant implications for the sustainability and nutritional value of aquaculture products.

As the global population ages and the prevalence of chronic diseases increases, the demand for effective omega-3 supplementation is expected to rise. Sodium alginate-based delivery systems are well-positioned to meet this demand by offering improved bioavailability and targeted delivery of omega-3s. This trend is likely to drive further innovation and market growth in the coming years.

Sodium Alginate Challenges

Despite the numerous advantages of sodium alginate in omega-3 delivery systems, several challenges persist in its application and development. One of the primary obstacles is the variability in alginate composition and quality. Sodium alginate, derived from brown seaweed, can exhibit significant variations in its molecular weight, viscosity, and gelation properties depending on the source and extraction method. This inconsistency poses difficulties in maintaining product uniformity and predictable performance across different batches.

Another challenge lies in the stability of sodium alginate-based delivery systems under various environmental conditions. While alginate gels can effectively encapsulate omega-3 fatty acids, they may be susceptible to degradation in acidic environments, such as the stomach. This can lead to premature release of the encapsulated nutrients, reducing the overall efficacy of the delivery system. Additionally, the stability of alginate gels can be compromised by the presence of certain ions, particularly monovalent cations, which can interfere with the cross-linking process.

The bioavailability of omega-3 fatty acids encapsulated in sodium alginate matrices presents another hurdle. Although alginate-based systems can protect omega-3s from oxidation and degradation, the release kinetics and absorption of these nutrients in the gastrointestinal tract may not always be optimal. Ensuring controlled and targeted release of omega-3s at the desired site of absorption remains a significant challenge in the development of effective delivery systems.

Scale-up and manufacturing processes also pose challenges in the commercial production of sodium alginate-based omega-3 delivery systems. Maintaining consistent gel formation, particle size distribution, and encapsulation efficiency during large-scale production can be difficult. Furthermore, the choice of appropriate cross-linking agents and the optimization of cross-linking conditions to achieve desired gel properties while ensuring product safety and regulatory compliance add complexity to the manufacturing process.

Lastly, the sensory attributes of alginate-based delivery systems can be a challenge in certain applications, particularly in food and beverage products. The texture and mouthfeel imparted by alginate gels may not always align with consumer preferences, necessitating careful formulation and optimization to achieve acceptable sensory properties without compromising the functional benefits of the delivery system.

Addressing these challenges requires ongoing research and development efforts, including the exploration of novel alginate modifications, innovative cross-linking techniques, and advanced processing technologies. Overcoming these obstacles will be crucial in fully realizing the potential of sodium alginate as a versatile and effective carrier for omega-3 fatty acids across various applications in the nutraceutical and functional food industries.

Another challenge lies in the stability of sodium alginate-based delivery systems under various environmental conditions. While alginate gels can effectively encapsulate omega-3 fatty acids, they may be susceptible to degradation in acidic environments, such as the stomach. This can lead to premature release of the encapsulated nutrients, reducing the overall efficacy of the delivery system. Additionally, the stability of alginate gels can be compromised by the presence of certain ions, particularly monovalent cations, which can interfere with the cross-linking process.

The bioavailability of omega-3 fatty acids encapsulated in sodium alginate matrices presents another hurdle. Although alginate-based systems can protect omega-3s from oxidation and degradation, the release kinetics and absorption of these nutrients in the gastrointestinal tract may not always be optimal. Ensuring controlled and targeted release of omega-3s at the desired site of absorption remains a significant challenge in the development of effective delivery systems.

Scale-up and manufacturing processes also pose challenges in the commercial production of sodium alginate-based omega-3 delivery systems. Maintaining consistent gel formation, particle size distribution, and encapsulation efficiency during large-scale production can be difficult. Furthermore, the choice of appropriate cross-linking agents and the optimization of cross-linking conditions to achieve desired gel properties while ensuring product safety and regulatory compliance add complexity to the manufacturing process.

Lastly, the sensory attributes of alginate-based delivery systems can be a challenge in certain applications, particularly in food and beverage products. The texture and mouthfeel imparted by alginate gels may not always align with consumer preferences, necessitating careful formulation and optimization to achieve acceptable sensory properties without compromising the functional benefits of the delivery system.

Addressing these challenges requires ongoing research and development efforts, including the exploration of novel alginate modifications, innovative cross-linking techniques, and advanced processing technologies. Overcoming these obstacles will be crucial in fully realizing the potential of sodium alginate as a versatile and effective carrier for omega-3 fatty acids across various applications in the nutraceutical and functional food industries.

Current Delivery Solutions

01 Sodium alginate-based drug delivery systems

Sodium alginate is used to create drug delivery systems that can control the release of active ingredients. These systems can be formulated as hydrogels, microspheres, or nanoparticles, offering versatile options for various pharmaceutical applications. The unique properties of sodium alginate allow for targeted and sustained release of drugs, improving therapeutic efficacy and patient compliance.- Sodium alginate-based drug delivery systems: Sodium alginate is used to create various drug delivery systems, including microspheres, nanoparticles, and hydrogels. These systems can encapsulate and control the release of various drugs, improving their bioavailability and therapeutic efficacy. The versatility of sodium alginate allows for tailored drug release profiles and targeted delivery to specific sites in the body.

- Sodium alginate in wound healing applications: Sodium alginate is utilized in wound dressings and healing applications due to its biocompatibility and ability to maintain a moist environment. It can be formulated into films, foams, or gels that promote wound healing, absorb exudates, and facilitate the delivery of therapeutic agents to the wound site. These formulations may also incorporate antimicrobial agents for enhanced wound protection.

- Oral delivery systems using sodium alginate: Sodium alginate is employed in oral drug delivery systems to improve the stability and bioavailability of various compounds. It can form protective matrices or coatings that shield drugs from harsh gastric conditions and control their release in the intestinal tract. This approach is particularly useful for delivering sensitive molecules such as proteins, peptides, and probiotics.

- Sodium alginate in tissue engineering and regenerative medicine: Sodium alginate serves as a scaffold material in tissue engineering applications. It can be used to create biocompatible structures that support cell growth, differentiation, and tissue regeneration. These scaffolds may be designed to deliver growth factors or other bioactive molecules to enhance tissue repair and regeneration in various medical applications.

- Sodium alginate-based nanocarriers for targeted drug delivery: Nanocarriers based on sodium alginate are developed for targeted drug delivery applications. These nanocarriers can be functionalized with specific ligands or modified to respond to environmental stimuli, allowing for precise drug delivery to target tissues or cells. This approach enhances therapeutic efficacy while minimizing side effects in treatments such as cancer therapy.

02 Sodium alginate in wound healing applications

Sodium alginate is utilized in wound dressings and healing applications due to its biocompatibility and ability to maintain a moist environment. These dressings can be formulated to incorporate antimicrobial agents or growth factors, promoting faster healing and reducing the risk of infection. The gel-forming properties of sodium alginate also allow for easy application and removal of dressings.Expand Specific Solutions03 Sodium alginate in oral drug delivery

Sodium alginate is employed in oral drug delivery systems to improve the bioavailability and controlled release of drugs. It can be used to create floating drug delivery systems, mucoadhesive formulations, or enteric-coated tablets. These formulations can protect drugs from gastric acid, target specific areas of the gastrointestinal tract, or prolong drug release, enhancing therapeutic outcomes.Expand Specific Solutions04 Sodium alginate in tissue engineering and regenerative medicine

Sodium alginate is used to create scaffolds and hydrogels for tissue engineering and regenerative medicine applications. These biomaterials can support cell growth, differentiation, and tissue formation. The ability to modify alginate properties allows for the development of tailored scaffolds for various tissue types, including bone, cartilage, and soft tissues.Expand Specific Solutions05 Sodium alginate in nasal and pulmonary drug delivery

Sodium alginate is utilized in nasal and pulmonary drug delivery systems to improve drug absorption and residence time in the respiratory tract. It can be formulated into nanoparticles, microparticles, or gels for intranasal or inhaled drug delivery. These formulations can enhance the bioavailability of drugs and provide sustained release, making them suitable for treating respiratory conditions or systemic diseases.Expand Specific Solutions

Key Industry Players

The market for innovative omega-3 delivery systems using sodium alginate is in a growth phase, driven by increasing consumer demand for functional foods and nutraceuticals. The global market size is estimated to reach several billion dollars by 2025, with a compound annual growth rate of over 7%. Technologically, the field is advancing rapidly, with companies like PepsiCo, Aker Biomarine, and Novaliq leading research and development efforts. These firms are exploring novel encapsulation techniques and bioavailability enhancement methods. While established players dominate, emerging companies like Viva Life Science and Pharmunion are also making strides in developing proprietary formulations, indicating a competitive and innovation-driven landscape.

PepsiCo, Inc.

Technical Solution: PepsiCo has explored sodium alginate-based delivery systems for omega-3 fatty acids as part of their efforts to develop functional beverages and snacks. Their research has focused on creating stable omega-3 emulsions using a combination of sodium alginate and other natural stabilizers. The company has developed a patented process that encapsulates omega-3 oils in alginate-based microbeads, which can be easily dispersed in liquid formulations or incorporated into dry snack products[8]. This technology allows for the addition of omega-3s to a wide range of products without compromising taste or texture. PepsiCo's studies have demonstrated that their alginate-based delivery system can protect omega-3 fatty acids from oxidation for up to 9 months in beverage applications, maintaining nutritional value and sensory quality[10]. The company has also investigated the use of this technology in plant-based omega-3 sources, such as algal oils, to cater to the growing demand for vegetarian and vegan options.

Strengths: Versatile application in both liquid and dry products, compatibility with plant-based omega-3 sources. Weaknesses: May require reformulation of existing products, potential regulatory challenges in some markets.

Aker Biomarine Antarctic AS

Technical Solution: Aker Biomarine has developed a proprietary sodium alginate-based delivery system for their krill oil omega-3 products. Their technology utilizes a unique combination of sodium alginate and other marine polysaccharides to create a protective matrix around the omega-3 fatty acids. This system, known as Flexitech, enhances the stability of the omega-3s and allows for flexible dosage forms, including gummies and soft gels[2]. The company's research has demonstrated that their alginate-based delivery system can increase the bioavailability of EPA and DHA by up to 25% compared to standard fish oil capsules[4]. Additionally, Aker Biomarine has developed a patented process for incorporating their alginate-omega-3 complex into various food and beverage applications, expanding the potential for fortified products[6].

Strengths: Increased bioavailability, versatile dosage forms, and potential for food and beverage applications. Weaknesses: Limited to krill oil-based omega-3s, which may have a higher cost compared to fish oil sources.

Sodium Alginate Innovations

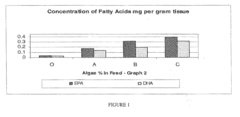

Selecting, producing, and feeding whole algae as a feed supplement for cattle and bison to produce meat high in omega 3's for human health

PatentActiveUS20150174180A1

Innovation

- A method and system utilizing heterotrophic algae grown with sugar as a carbon source, which are rich in Omega-3 fatty acids, specifically DHA and EPA, and have a resilient cell wall to protect these nutrients during digestion, allowing for their absorption in the small intestine, thereby enhancing the nutritional value of beef without suppressing feed intake or increasing costs.

Regulatory Considerations

The regulatory landscape surrounding sodium alginate and omega-3 delivery systems is complex and multifaceted, requiring careful consideration by manufacturers and researchers. In the United States, the Food and Drug Administration (FDA) classifies sodium alginate as Generally Recognized as Safe (GRAS) for use in food products. However, its application in novel omega-3 delivery systems may necessitate additional regulatory scrutiny, particularly if claims are made regarding enhanced bioavailability or health benefits.

The European Food Safety Authority (EFSA) has also evaluated sodium alginate and deemed it safe for use in food applications. Nevertheless, the use of sodium alginate in innovative omega-3 delivery systems may require specific approval under the Novel Food Regulation if it significantly alters the nutritional value, metabolism, or level of undesirable substances in the final product.

Globally, regulatory bodies are increasingly focusing on the safety and efficacy of functional foods and nutraceuticals. This trend has implications for sodium alginate-based omega-3 delivery systems, as manufacturers may need to provide substantial scientific evidence to support any health claims associated with their products. Clinical trials demonstrating improved bioavailability or enhanced health outcomes may be necessary to satisfy regulatory requirements in various jurisdictions.

Labeling regulations present another critical consideration. In many countries, the presence of sodium alginate must be clearly indicated on product labels, and any claims related to omega-3 content or absorption must be substantiated and comply with local regulations. For instance, the FDA has specific requirements for omega-3 content claims, while the EFSA has established conditions for the use of health claims related to EPA and DHA.

Environmental regulations may also impact the development and production of sodium alginate-based omega-3 delivery systems. As sodium alginate is derived from seaweed, sustainable harvesting practices and potential environmental impacts may come under regulatory scrutiny. Manufacturers may need to demonstrate compliance with environmental standards and sourcing regulations to ensure market access.

As the field of functional foods and nutraceuticals continues to evolve, regulatory frameworks are likely to adapt. Companies investing in sodium alginate-driven innovations for omega-3 delivery must stay abreast of these changes and engage proactively with regulatory bodies to ensure compliance and facilitate market entry. This may involve ongoing dialogue with authorities, participation in public consultations, and contribution to the development of new regulatory guidelines specific to advanced delivery systems for nutritional compounds.

The European Food Safety Authority (EFSA) has also evaluated sodium alginate and deemed it safe for use in food applications. Nevertheless, the use of sodium alginate in innovative omega-3 delivery systems may require specific approval under the Novel Food Regulation if it significantly alters the nutritional value, metabolism, or level of undesirable substances in the final product.

Globally, regulatory bodies are increasingly focusing on the safety and efficacy of functional foods and nutraceuticals. This trend has implications for sodium alginate-based omega-3 delivery systems, as manufacturers may need to provide substantial scientific evidence to support any health claims associated with their products. Clinical trials demonstrating improved bioavailability or enhanced health outcomes may be necessary to satisfy regulatory requirements in various jurisdictions.

Labeling regulations present another critical consideration. In many countries, the presence of sodium alginate must be clearly indicated on product labels, and any claims related to omega-3 content or absorption must be substantiated and comply with local regulations. For instance, the FDA has specific requirements for omega-3 content claims, while the EFSA has established conditions for the use of health claims related to EPA and DHA.

Environmental regulations may also impact the development and production of sodium alginate-based omega-3 delivery systems. As sodium alginate is derived from seaweed, sustainable harvesting practices and potential environmental impacts may come under regulatory scrutiny. Manufacturers may need to demonstrate compliance with environmental standards and sourcing regulations to ensure market access.

As the field of functional foods and nutraceuticals continues to evolve, regulatory frameworks are likely to adapt. Companies investing in sodium alginate-driven innovations for omega-3 delivery must stay abreast of these changes and engage proactively with regulatory bodies to ensure compliance and facilitate market entry. This may involve ongoing dialogue with authorities, participation in public consultations, and contribution to the development of new regulatory guidelines specific to advanced delivery systems for nutritional compounds.

Bioavailability Assessment

Bioavailability assessment is a critical component in evaluating the effectiveness of sodium alginate-based omega-3 delivery systems. This process involves measuring the extent and rate at which omega-3 fatty acids are absorbed and become available at the site of physiological activity when delivered using sodium alginate as a carrier.

One of the primary methods for assessing bioavailability is through in vitro digestion models. These models simulate the human digestive system, allowing researchers to study the release and absorption of omega-3 fatty acids under controlled conditions. By mimicking the pH changes, enzymatic activities, and mechanical forces of the gastrointestinal tract, these models provide valuable insights into how sodium alginate influences the digestion and absorption of omega-3s.

In vivo studies using animal models and human clinical trials are essential for a comprehensive bioavailability assessment. These studies typically involve administering the sodium alginate-omega-3 formulation and measuring the concentration of omega-3 fatty acids in blood plasma over time. The resulting pharmacokinetic profiles provide crucial information about the rate and extent of absorption, as well as the bioavailability of the omega-3s delivered using sodium alginate systems.

Advanced analytical techniques play a vital role in bioavailability assessment. High-performance liquid chromatography (HPLC) coupled with mass spectrometry (MS) is commonly used to quantify omega-3 fatty acids in biological samples. These methods offer high sensitivity and specificity, allowing for accurate measurement of omega-3 levels in plasma, tissues, and other biological matrices.

Researchers also employ imaging techniques to visualize the behavior of sodium alginate-omega-3 formulations in the gastrointestinal tract. Techniques such as magnetic resonance imaging (MRI) and fluorescence microscopy can provide real-time insights into the disintegration of alginate matrices and the release of omega-3 fatty acids under physiological conditions.

Comparative studies are crucial in bioavailability assessment, as they allow researchers to evaluate the performance of sodium alginate-based delivery systems against traditional omega-3 formulations. These studies typically compare the bioavailability of omega-3s from alginate-based systems to that of standard fish oil capsules or other commercial omega-3 supplements.

The impact of sodium alginate on the stability of omega-3 fatty acids during storage and digestion is another important aspect of bioavailability assessment. Researchers evaluate the protective effects of alginate matrices against oxidation and degradation of omega-3s, which can significantly influence their bioavailability and therapeutic efficacy.

By integrating these various assessment methods, researchers can gain a comprehensive understanding of how sodium alginate influences the bioavailability of omega-3 fatty acids. This knowledge is crucial for optimizing delivery systems and ultimately enhancing the health benefits of omega-3 supplementation.

One of the primary methods for assessing bioavailability is through in vitro digestion models. These models simulate the human digestive system, allowing researchers to study the release and absorption of omega-3 fatty acids under controlled conditions. By mimicking the pH changes, enzymatic activities, and mechanical forces of the gastrointestinal tract, these models provide valuable insights into how sodium alginate influences the digestion and absorption of omega-3s.

In vivo studies using animal models and human clinical trials are essential for a comprehensive bioavailability assessment. These studies typically involve administering the sodium alginate-omega-3 formulation and measuring the concentration of omega-3 fatty acids in blood plasma over time. The resulting pharmacokinetic profiles provide crucial information about the rate and extent of absorption, as well as the bioavailability of the omega-3s delivered using sodium alginate systems.

Advanced analytical techniques play a vital role in bioavailability assessment. High-performance liquid chromatography (HPLC) coupled with mass spectrometry (MS) is commonly used to quantify omega-3 fatty acids in biological samples. These methods offer high sensitivity and specificity, allowing for accurate measurement of omega-3 levels in plasma, tissues, and other biological matrices.

Researchers also employ imaging techniques to visualize the behavior of sodium alginate-omega-3 formulations in the gastrointestinal tract. Techniques such as magnetic resonance imaging (MRI) and fluorescence microscopy can provide real-time insights into the disintegration of alginate matrices and the release of omega-3 fatty acids under physiological conditions.

Comparative studies are crucial in bioavailability assessment, as they allow researchers to evaluate the performance of sodium alginate-based delivery systems against traditional omega-3 formulations. These studies typically compare the bioavailability of omega-3s from alginate-based systems to that of standard fish oil capsules or other commercial omega-3 supplements.

The impact of sodium alginate on the stability of omega-3 fatty acids during storage and digestion is another important aspect of bioavailability assessment. Researchers evaluate the protective effects of alginate matrices against oxidation and degradation of omega-3s, which can significantly influence their bioavailability and therapeutic efficacy.

By integrating these various assessment methods, researchers can gain a comprehensive understanding of how sodium alginate influences the bioavailability of omega-3 fatty acids. This knowledge is crucial for optimizing delivery systems and ultimately enhancing the health benefits of omega-3 supplementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!