How Sodium Alginate Enhances Clay Stabilization Techniques?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Clay Stabilization Background and Objectives

Clay stabilization has been a critical concern in various industries, particularly in construction, oil and gas exploration, and geotechnical engineering. The primary objective of clay stabilization is to prevent the swelling, dispersion, and migration of clay particles, which can lead to numerous structural and operational issues. Over the years, the field has witnessed significant advancements, with researchers and engineers continually seeking more effective and environmentally friendly solutions.

The evolution of clay stabilization techniques can be traced back to the early 20th century when the detrimental effects of clay instability on construction and drilling operations became increasingly apparent. Initial methods relied heavily on mechanical approaches, such as compaction and drainage systems. However, these techniques often proved inadequate in addressing the complex behavior of clay minerals under varying environmental conditions.

As the understanding of clay mineralogy and soil mechanics improved, chemical stabilization methods gained prominence. Traditional chemical stabilizers, including lime, cement, and various salts, have been widely used due to their ability to alter the physicochemical properties of clay. These additives work by modifying the clay structure, reducing its affinity for water, and enhancing its overall strength and stability.

In recent decades, the focus has shifted towards developing more sustainable and efficient stabilization techniques. This shift is driven by increasing environmental concerns, stricter regulations, and the need for cost-effective solutions in large-scale applications. The exploration of bio-based and polymer-based stabilizers has emerged as a promising avenue, offering potential advantages in terms of eco-friendliness and performance.

Sodium alginate, a natural polysaccharide derived from brown algae, has garnered significant attention in the field of clay stabilization. Its unique properties, including high viscosity, gel-forming ability, and biodegradability, make it an attractive candidate for enhancing existing stabilization techniques. The primary objective of incorporating sodium alginate into clay stabilization methods is to leverage its binding and water-retention capabilities to improve the overall effectiveness and durability of stabilized clay structures.

The integration of sodium alginate in clay stabilization aims to address several key challenges faced by traditional methods. These include improving the long-term stability of treated clay, reducing the environmental impact of stabilization processes, and enhancing the performance of stabilized clay under dynamic loading conditions. Additionally, researchers are exploring the potential of sodium alginate to synergistically interact with other stabilizers, potentially leading to more robust and versatile stabilization solutions.

As the field of clay stabilization continues to evolve, the exploration of innovative materials like sodium alginate represents a crucial step towards developing more sustainable and efficient techniques. The ongoing research in this area seeks to optimize the use of sodium alginate, understand its mechanisms of action in clay stabilization, and evaluate its performance across various soil types and environmental conditions.

The evolution of clay stabilization techniques can be traced back to the early 20th century when the detrimental effects of clay instability on construction and drilling operations became increasingly apparent. Initial methods relied heavily on mechanical approaches, such as compaction and drainage systems. However, these techniques often proved inadequate in addressing the complex behavior of clay minerals under varying environmental conditions.

As the understanding of clay mineralogy and soil mechanics improved, chemical stabilization methods gained prominence. Traditional chemical stabilizers, including lime, cement, and various salts, have been widely used due to their ability to alter the physicochemical properties of clay. These additives work by modifying the clay structure, reducing its affinity for water, and enhancing its overall strength and stability.

In recent decades, the focus has shifted towards developing more sustainable and efficient stabilization techniques. This shift is driven by increasing environmental concerns, stricter regulations, and the need for cost-effective solutions in large-scale applications. The exploration of bio-based and polymer-based stabilizers has emerged as a promising avenue, offering potential advantages in terms of eco-friendliness and performance.

Sodium alginate, a natural polysaccharide derived from brown algae, has garnered significant attention in the field of clay stabilization. Its unique properties, including high viscosity, gel-forming ability, and biodegradability, make it an attractive candidate for enhancing existing stabilization techniques. The primary objective of incorporating sodium alginate into clay stabilization methods is to leverage its binding and water-retention capabilities to improve the overall effectiveness and durability of stabilized clay structures.

The integration of sodium alginate in clay stabilization aims to address several key challenges faced by traditional methods. These include improving the long-term stability of treated clay, reducing the environmental impact of stabilization processes, and enhancing the performance of stabilized clay under dynamic loading conditions. Additionally, researchers are exploring the potential of sodium alginate to synergistically interact with other stabilizers, potentially leading to more robust and versatile stabilization solutions.

As the field of clay stabilization continues to evolve, the exploration of innovative materials like sodium alginate represents a crucial step towards developing more sustainable and efficient techniques. The ongoing research in this area seeks to optimize the use of sodium alginate, understand its mechanisms of action in clay stabilization, and evaluate its performance across various soil types and environmental conditions.

Market Analysis for Enhanced Clay Stabilization

The market for enhanced clay stabilization techniques has been experiencing significant growth in recent years, driven by the increasing demand for efficient and environmentally friendly solutions in various industries. The global clay stabilization market is projected to expand at a steady rate, with a particular focus on the oil and gas sector, construction industry, and environmental remediation projects.

In the oil and gas industry, clay stabilization plays a crucial role in maintaining wellbore stability during drilling and production operations. The growing exploration and production activities, especially in unconventional reservoirs, have led to a surge in demand for advanced clay stabilization solutions. This trend is particularly evident in regions with extensive shale gas and tight oil resources, such as North America, China, and Argentina.

The construction industry represents another major market segment for enhanced clay stabilization techniques. As urbanization continues to accelerate worldwide, there is an increasing need for soil improvement methods to support infrastructure development on challenging terrains. Clay stabilization solutions are essential for enhancing soil strength, reducing soil plasticity, and improving overall ground stability for various construction projects, including roads, buildings, and bridges.

Environmental remediation projects have also emerged as a significant driver for the clay stabilization market. With growing concerns about soil and water contamination, there is a rising demand for effective containment and treatment solutions. Clay stabilization techniques, particularly those incorporating sodium alginate, are gaining traction in landfill liner systems, contaminated site remediation, and mine tailings management.

The Asia-Pacific region is expected to witness the highest growth rate in the clay stabilization market, primarily due to rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, driven by ongoing shale gas exploration and stringent environmental regulations.

The introduction of sodium alginate as an enhancer in clay stabilization techniques has opened up new opportunities in the market. This natural, biodegradable polymer offers improved performance characteristics compared to traditional stabilizers, addressing both technical and environmental concerns. The increasing adoption of sodium alginate-based solutions is expected to reshape the competitive landscape of the clay stabilization market, potentially disrupting established product offerings and creating new market segments.

As sustainability becomes a key focus across industries, there is a growing preference for eco-friendly clay stabilization solutions. This trend is likely to drive further innovation in the field, with a particular emphasis on developing bio-based and low-impact stabilizers. The market is also witnessing a shift towards integrated solutions that combine clay stabilization with other soil improvement techniques, offering more comprehensive and cost-effective options for end-users.

In the oil and gas industry, clay stabilization plays a crucial role in maintaining wellbore stability during drilling and production operations. The growing exploration and production activities, especially in unconventional reservoirs, have led to a surge in demand for advanced clay stabilization solutions. This trend is particularly evident in regions with extensive shale gas and tight oil resources, such as North America, China, and Argentina.

The construction industry represents another major market segment for enhanced clay stabilization techniques. As urbanization continues to accelerate worldwide, there is an increasing need for soil improvement methods to support infrastructure development on challenging terrains. Clay stabilization solutions are essential for enhancing soil strength, reducing soil plasticity, and improving overall ground stability for various construction projects, including roads, buildings, and bridges.

Environmental remediation projects have also emerged as a significant driver for the clay stabilization market. With growing concerns about soil and water contamination, there is a rising demand for effective containment and treatment solutions. Clay stabilization techniques, particularly those incorporating sodium alginate, are gaining traction in landfill liner systems, contaminated site remediation, and mine tailings management.

The Asia-Pacific region is expected to witness the highest growth rate in the clay stabilization market, primarily due to rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, driven by ongoing shale gas exploration and stringent environmental regulations.

The introduction of sodium alginate as an enhancer in clay stabilization techniques has opened up new opportunities in the market. This natural, biodegradable polymer offers improved performance characteristics compared to traditional stabilizers, addressing both technical and environmental concerns. The increasing adoption of sodium alginate-based solutions is expected to reshape the competitive landscape of the clay stabilization market, potentially disrupting established product offerings and creating new market segments.

As sustainability becomes a key focus across industries, there is a growing preference for eco-friendly clay stabilization solutions. This trend is likely to drive further innovation in the field, with a particular emphasis on developing bio-based and low-impact stabilizers. The market is also witnessing a shift towards integrated solutions that combine clay stabilization with other soil improvement techniques, offering more comprehensive and cost-effective options for end-users.

Current Challenges in Clay Stabilization Techniques

Clay stabilization techniques face several significant challenges in their current applications, particularly in the oil and gas industry, civil engineering, and environmental remediation. One of the primary issues is the inconsistent performance of traditional stabilizers across different clay types and environmental conditions. Clay minerals exhibit diverse physicochemical properties, making it difficult to develop a one-size-fits-all solution.

The swelling and dispersion of clay particles remain persistent problems, especially in water-sensitive formations. When exposed to water, some clay minerals undergo significant volume changes, leading to wellbore instability, formation damage, and reduced permeability. This not only affects drilling operations but also impacts the long-term productivity of oil and gas wells.

Another challenge is the environmental impact of conventional clay stabilizers. Many traditional chemical additives used for clay stabilization are not biodegradable and can pose risks to ecosystems if released into the environment. This has led to increased regulatory scrutiny and a push for more environmentally friendly alternatives.

The effectiveness of clay stabilizers in high-temperature and high-pressure environments is also a concern. Many oil and gas reservoirs operate under extreme conditions, which can degrade the performance of stabilizing agents or render them ineffective. Developing stabilizers that maintain their efficacy under these harsh conditions remains a significant technical hurdle.

Furthermore, the interaction between clay stabilizers and other additives used in drilling fluids or hydraulic fracturing operations can lead to unexpected chemical reactions. These interactions may reduce the effectiveness of the stabilizer or create new problems, such as formation damage or equipment corrosion.

The long-term stability of treated clay formations is another area of concern. While some stabilizers may provide immediate benefits, their ability to maintain clay stability over extended periods, especially under changing environmental conditions, is often uncertain. This lack of long-term reliability can lead to costly remediation efforts or reduced operational efficiency.

Lastly, the cost-effectiveness of clay stabilization techniques remains a challenge. Many advanced stabilizers or treatment methods come with high implementation costs, making them less attractive for widespread adoption, particularly in lower-margin operations. Balancing performance with economic viability is crucial for the industry-wide acceptance of new clay stabilization technologies.

The swelling and dispersion of clay particles remain persistent problems, especially in water-sensitive formations. When exposed to water, some clay minerals undergo significant volume changes, leading to wellbore instability, formation damage, and reduced permeability. This not only affects drilling operations but also impacts the long-term productivity of oil and gas wells.

Another challenge is the environmental impact of conventional clay stabilizers. Many traditional chemical additives used for clay stabilization are not biodegradable and can pose risks to ecosystems if released into the environment. This has led to increased regulatory scrutiny and a push for more environmentally friendly alternatives.

The effectiveness of clay stabilizers in high-temperature and high-pressure environments is also a concern. Many oil and gas reservoirs operate under extreme conditions, which can degrade the performance of stabilizing agents or render them ineffective. Developing stabilizers that maintain their efficacy under these harsh conditions remains a significant technical hurdle.

Furthermore, the interaction between clay stabilizers and other additives used in drilling fluids or hydraulic fracturing operations can lead to unexpected chemical reactions. These interactions may reduce the effectiveness of the stabilizer or create new problems, such as formation damage or equipment corrosion.

The long-term stability of treated clay formations is another area of concern. While some stabilizers may provide immediate benefits, their ability to maintain clay stability over extended periods, especially under changing environmental conditions, is often uncertain. This lack of long-term reliability can lead to costly remediation efforts or reduced operational efficiency.

Lastly, the cost-effectiveness of clay stabilization techniques remains a challenge. Many advanced stabilizers or treatment methods come with high implementation costs, making them less attractive for widespread adoption, particularly in lower-margin operations. Balancing performance with economic viability is crucial for the industry-wide acceptance of new clay stabilization technologies.

Sodium Alginate-Based Clay Stabilization Solutions

01 Sodium alginate as a clay stabilizer

Sodium alginate is used as an effective clay stabilizer in various applications. It helps to prevent clay swelling and dispersion, improving the stability of clay-based formations. This natural polymer can be used in drilling fluids, cement slurries, and other applications where clay stabilization is crucial.- Sodium alginate as a clay stabilizer: Sodium alginate is used as an effective clay stabilizer in various applications. It helps to prevent clay swelling and dispersion, improving the stability of clay-based formations. This natural polymer can be used in drilling fluids, cement slurries, and other applications where clay stabilization is crucial.

- Composite stabilization systems: Composite stabilization systems combining sodium alginate with other materials are developed to enhance clay stabilization. These systems may include combinations with inorganic salts, polymers, or nanoparticles to provide synergistic effects in stabilizing clay formations and improving overall performance.

- Application in drilling fluids: Sodium alginate is incorporated into drilling fluid formulations to improve clay stabilization during drilling operations. It helps maintain wellbore stability, reduce fluid loss, and prevent formation damage. The addition of sodium alginate can enhance the performance of water-based drilling fluids in challenging drilling environments.

- Use in cement slurries: Sodium alginate is utilized in cement slurry compositions to improve clay stabilization during cementing operations. It helps prevent clay swelling and migration, enhancing the bond between the cement and the formation. This application is particularly useful in oil and gas well cementing to ensure long-term wellbore integrity.

- Environmental and cost-effective solution: Sodium alginate offers an environmentally friendly and cost-effective solution for clay stabilization compared to traditional chemical stabilizers. Its biodegradability and non-toxic nature make it suitable for use in environmentally sensitive areas. The abundance of algae as a source material also contributes to its cost-effectiveness in various industrial applications.

02 Composite stabilization systems

Composite stabilization systems combining sodium alginate with other materials are developed to enhance clay stabilization effects. These systems may include combinations with inorganic salts, polymers, or nanoparticles to provide synergistic stabilization effects and improve overall performance in various environmental conditions.Expand Specific Solutions03 Application in drilling fluids

Sodium alginate is incorporated into drilling fluid formulations to improve clay stabilization during drilling operations. It helps maintain wellbore stability, reduce fluid loss, and prevent formation damage. The addition of sodium alginate can enhance the performance of water-based drilling fluids in challenging drilling environments.Expand Specific Solutions04 Use in cement slurries

Sodium alginate is utilized in cement slurry compositions to improve clay stabilization during cementing operations. It helps prevent clay swelling and migration, enhancing the bond between the cement and the formation. This application is particularly useful in oil and gas well cementing to ensure long-term wellbore integrity.Expand Specific Solutions05 Environmental remediation applications

Sodium alginate is employed in environmental remediation projects for clay stabilization. It can be used to treat contaminated soils, prevent erosion, and improve soil structure. The biodegradable nature of sodium alginate makes it an environmentally friendly option for various remediation applications.Expand Specific Solutions

Key Players in Clay Stabilization Industry

The sodium alginate clay stabilization technique is in a growth phase, with increasing market size due to rising demand in oil and gas drilling operations. The global market for clay stabilizers is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with major players like China Petroleum & Chemical Corp., Baker Hughes Co., and Halliburton Energy Services, Inc. leading innovation. These companies are investing heavily in research and development to enhance the effectiveness of sodium alginate-based stabilizers. Smaller firms like Integrity Bio-Chemicals LLC are also contributing to technological advancements, focusing on eco-friendly solutions. The competitive landscape is characterized by a mix of established oil field service giants and specialized chemical companies, driving continuous improvement in clay stabilization techniques.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced sodium alginate-based clay stabilization technique for enhanced oil recovery. Their method involves creating a cross-linked polymer network using sodium alginate and multivalent cations, which forms a protective film on clay surfaces[1]. This film prevents clay swelling and migration, thereby maintaining formation permeability. The company has optimized the concentration of sodium alginate (typically 0.1-0.5% by weight) and cross-linking agents to achieve maximum stabilization efficiency[2]. Sinopec's approach also incorporates nanoparticles to further enhance the stability of the alginate network, resulting in improved long-term performance in high-temperature reservoirs[3].

Strengths: Effective in high-temperature environments, long-lasting stabilization effect, and environmentally friendly. Weaknesses: May require careful pH control and potential higher cost compared to traditional methods.

Baker Hughes Co.

Technical Solution: Baker Hughes has innovated a sodium alginate-based clay stabilization system that combines the natural polymer with proprietary synthetic additives. Their approach focuses on creating a synergistic effect between sodium alginate and other clay stabilizers, such as potassium chloride or quaternary amines[4]. The company's technology involves a dual-action mechanism: sodium alginate forms a protective layer on clay surfaces, while the synthetic additives provide additional ionic stabilization. Baker Hughes has reported up to 95% reduction in clay swelling using this combined approach[5]. Additionally, they have developed a controlled-release formulation that gradually releases the stabilizing agents, ensuring prolonged effectiveness in challenging downhole conditions[6].

Strengths: High efficiency in clay swelling reduction, prolonged effectiveness due to controlled release. Weaknesses: May be more complex to formulate and potentially more expensive than single-component systems.

Core Innovations in Sodium Alginate Application

Method for stabilising clay soils with natural organic polymers reinforced with animal fibres

PatentWO2012101299A1

Innovation

- A soil stabilization procedure using natural organic polymers derived from seaweed alginate and animal fibers like sheep's wool, which improves mechanical strength, reduces energy consumption, and facilitates sustainable, non-toxic composite material production with reduced environmental impact.

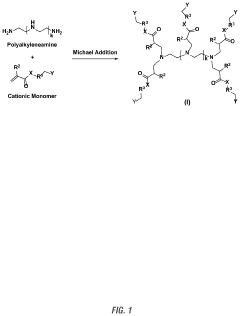

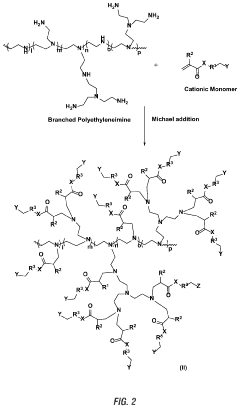

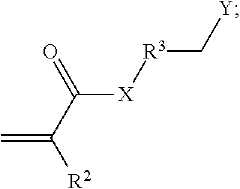

Use of multiple charged cationic compounds derived from polyamines for clay stabilization in oil and gas operations

PatentActiveUS20210332288A1

Innovation

- Development of multiple charged cationic compounds derived from polyamines through an aza-Michael Addition reaction with α, β-unsaturated carbonyl compounds, which are used as clay stabilizers to prevent swelling, migration, and sludge formation, and also serve as coagulants, water clarifiers, corrosion inhibitors, and reverse emulsion breakers.

Environmental Impact Assessment

The use of sodium alginate in clay stabilization techniques has significant environmental implications that warrant careful consideration. This natural polysaccharide, derived from brown algae, offers a more eco-friendly alternative to traditional chemical stabilizers, potentially reducing the environmental footprint of soil stabilization processes.

One of the primary environmental benefits of sodium alginate is its biodegradability. Unlike synthetic polymers commonly used in soil stabilization, sodium alginate can be broken down by microorganisms in the soil, minimizing long-term accumulation of foreign substances in the environment. This characteristic is particularly important in areas where soil health and ecosystem balance are critical concerns.

The production of sodium alginate also tends to have a lower environmental impact compared to many synthetic stabilizers. The harvesting and processing of brown algae for alginate extraction generally requires less energy and produces fewer harmful byproducts than the manufacturing of petroleum-based stabilizers. This can contribute to a reduction in overall carbon emissions associated with clay stabilization projects.

In terms of water quality, sodium alginate presents advantages over conventional chemical stabilizers. Its natural origin and non-toxic nature mean that it is less likely to contaminate groundwater or nearby water bodies. This is especially crucial in regions where soil stabilization activities occur near sensitive aquatic ecosystems or in areas with high water tables.

However, it is important to note that the large-scale harvesting of brown algae for sodium alginate production could potentially impact marine ecosystems if not managed sustainably. Careful consideration must be given to sourcing practices to ensure that algae harvesting does not disrupt coastal habitats or marine food chains.

The application of sodium alginate in clay stabilization may also have positive effects on soil ecology. By improving soil structure and water retention, it can create more favorable conditions for plant growth and microbial activity. This can lead to enhanced soil health and potentially increase carbon sequestration in treated soils, contributing to climate change mitigation efforts.

Furthermore, the use of sodium alginate may reduce the need for frequent re-application of stabilizers, thereby minimizing soil disturbance and the associated environmental impacts of repeated treatment processes. This can be particularly beneficial in erosion-prone areas or construction sites where long-term soil stability is crucial.

In conclusion, while sodium alginate offers numerous environmental advantages in clay stabilization techniques, a comprehensive life cycle assessment would be beneficial to fully quantify its environmental impact compared to traditional methods. Such an assessment should consider factors such as production, transportation, application, and long-term effects on soil and ecosystem health to provide a holistic view of its environmental performance.

One of the primary environmental benefits of sodium alginate is its biodegradability. Unlike synthetic polymers commonly used in soil stabilization, sodium alginate can be broken down by microorganisms in the soil, minimizing long-term accumulation of foreign substances in the environment. This characteristic is particularly important in areas where soil health and ecosystem balance are critical concerns.

The production of sodium alginate also tends to have a lower environmental impact compared to many synthetic stabilizers. The harvesting and processing of brown algae for alginate extraction generally requires less energy and produces fewer harmful byproducts than the manufacturing of petroleum-based stabilizers. This can contribute to a reduction in overall carbon emissions associated with clay stabilization projects.

In terms of water quality, sodium alginate presents advantages over conventional chemical stabilizers. Its natural origin and non-toxic nature mean that it is less likely to contaminate groundwater or nearby water bodies. This is especially crucial in regions where soil stabilization activities occur near sensitive aquatic ecosystems or in areas with high water tables.

However, it is important to note that the large-scale harvesting of brown algae for sodium alginate production could potentially impact marine ecosystems if not managed sustainably. Careful consideration must be given to sourcing practices to ensure that algae harvesting does not disrupt coastal habitats or marine food chains.

The application of sodium alginate in clay stabilization may also have positive effects on soil ecology. By improving soil structure and water retention, it can create more favorable conditions for plant growth and microbial activity. This can lead to enhanced soil health and potentially increase carbon sequestration in treated soils, contributing to climate change mitigation efforts.

Furthermore, the use of sodium alginate may reduce the need for frequent re-application of stabilizers, thereby minimizing soil disturbance and the associated environmental impacts of repeated treatment processes. This can be particularly beneficial in erosion-prone areas or construction sites where long-term soil stability is crucial.

In conclusion, while sodium alginate offers numerous environmental advantages in clay stabilization techniques, a comprehensive life cycle assessment would be beneficial to fully quantify its environmental impact compared to traditional methods. Such an assessment should consider factors such as production, transportation, application, and long-term effects on soil and ecosystem health to provide a holistic view of its environmental performance.

Cost-Benefit Analysis of Sodium Alginate Use

The cost-benefit analysis of sodium alginate use in clay stabilization techniques reveals a complex interplay of economic factors and performance advantages. Initial investment in sodium alginate may be higher compared to traditional stabilizers, but its long-term benefits often outweigh the upfront costs.

Sodium alginate's superior stabilizing properties lead to reduced clay swelling and dispersion, resulting in improved wellbore stability. This translates to fewer drilling complications, reduced downtime, and lower overall operational costs. The enhanced efficiency in drilling operations can lead to significant time savings, which is a crucial factor in the oil and gas industry where rig time is expensive.

The environmental benefits of sodium alginate use also contribute to its cost-effectiveness. As a biodegradable and non-toxic substance, it reduces environmental remediation costs and aligns with increasingly stringent environmental regulations. This can result in avoided fines and improved corporate image, which, while difficult to quantify, can have substantial long-term financial benefits.

In terms of material consumption, sodium alginate's high efficiency means that smaller quantities are required compared to conventional stabilizers. This leads to reduced transportation and storage costs, as well as decreased waste management expenses. The extended shelf life of sodium alginate formulations also contributes to cost savings through reduced product loss and improved inventory management.

However, the cost-benefit ratio can vary depending on specific well conditions and operational requirements. In some cases, the performance improvements may not justify the increased material costs, particularly in less challenging drilling environments. It's essential to conduct site-specific analyses to determine the optimal application of sodium alginate.

The scalability of sodium alginate use is another factor to consider. As adoption increases and production scales up, the cost of sodium alginate is likely to decrease, further improving its cost-benefit ratio. Additionally, ongoing research into more efficient production methods and formulations may lead to further cost reductions and performance enhancements.

When evaluating the long-term economic impact, it's crucial to consider the potential for sodium alginate to enable drilling in previously inaccessible or economically unfeasible formations. By stabilizing challenging clay formations, sodium alginate can unlock new reserves, potentially leading to substantial revenue increases that far outweigh the initial investment costs.

Sodium alginate's superior stabilizing properties lead to reduced clay swelling and dispersion, resulting in improved wellbore stability. This translates to fewer drilling complications, reduced downtime, and lower overall operational costs. The enhanced efficiency in drilling operations can lead to significant time savings, which is a crucial factor in the oil and gas industry where rig time is expensive.

The environmental benefits of sodium alginate use also contribute to its cost-effectiveness. As a biodegradable and non-toxic substance, it reduces environmental remediation costs and aligns with increasingly stringent environmental regulations. This can result in avoided fines and improved corporate image, which, while difficult to quantify, can have substantial long-term financial benefits.

In terms of material consumption, sodium alginate's high efficiency means that smaller quantities are required compared to conventional stabilizers. This leads to reduced transportation and storage costs, as well as decreased waste management expenses. The extended shelf life of sodium alginate formulations also contributes to cost savings through reduced product loss and improved inventory management.

However, the cost-benefit ratio can vary depending on specific well conditions and operational requirements. In some cases, the performance improvements may not justify the increased material costs, particularly in less challenging drilling environments. It's essential to conduct site-specific analyses to determine the optimal application of sodium alginate.

The scalability of sodium alginate use is another factor to consider. As adoption increases and production scales up, the cost of sodium alginate is likely to decrease, further improving its cost-benefit ratio. Additionally, ongoing research into more efficient production methods and formulations may lead to further cost reductions and performance enhancements.

When evaluating the long-term economic impact, it's crucial to consider the potential for sodium alginate to enable drilling in previously inaccessible or economically unfeasible formations. By stabilizing challenging clay formations, sodium alginate can unlock new reserves, potentially leading to substantial revenue increases that far outweigh the initial investment costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!