How Sulfamic Acid Facilitates Lignin Breakdown in Biomass

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfamic Acid in Lignin Breakdown: Background and Objectives

Sulfamic acid has emerged as a promising catalyst in the field of biomass processing, particularly in facilitating lignin breakdown. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternative methods for lignin depolymerization. As the demand for sustainable and eco-friendly processes in the biorefinery industry grew, sulfamic acid gained attention due to its unique properties and potential applications.

The primary objective of utilizing sulfamic acid in lignin breakdown is to develop an efficient and environmentally benign method for converting lignocellulosic biomass into valuable chemicals and fuels. This approach aims to address the challenges associated with traditional lignin degradation techniques, which often involve harsh conditions, high energy consumption, and the use of toxic chemicals.

Sulfamic acid's role in lignin breakdown is rooted in its ability to act as both a Brønsted acid and a nucleophile. This dual functionality allows it to catalyze the cleavage of various lignin bonds, including β-O-4 linkages, which are predominant in lignin structures. The mild reaction conditions required for sulfamic acid-catalyzed processes make it an attractive option for industrial applications, potentially reducing energy costs and minimizing equipment corrosion.

The development of sulfamic acid-based lignin breakdown techniques aligns with the broader trend of green chemistry and sustainable biorefinery processes. As global efforts to reduce dependence on fossil fuels intensify, the conversion of biomass into high-value products has become a key focus area. Sulfamic acid's potential in this field extends beyond lignin depolymerization, encompassing applications in cellulose hydrolysis and hemicellulose conversion.

Recent technological advancements have further expanded the scope of sulfamic acid in biomass processing. Researchers have explored various modifications and combinations, such as the use of sulfamic acid in conjunction with ionic liquids or metal catalysts, to enhance its effectiveness and selectivity in lignin breakdown. These innovations aim to improve product yields, reduce reaction times, and increase the range of obtainable bio-based chemicals.

The ultimate goal of this technology is to establish a robust and scalable process for lignin valorization, transforming what was once considered a waste product into a valuable resource. By enabling more efficient lignin breakdown, sulfamic acid-based methods could potentially unlock new revenue streams for biorefineries and contribute to the development of a circular bioeconomy.

The primary objective of utilizing sulfamic acid in lignin breakdown is to develop an efficient and environmentally benign method for converting lignocellulosic biomass into valuable chemicals and fuels. This approach aims to address the challenges associated with traditional lignin degradation techniques, which often involve harsh conditions, high energy consumption, and the use of toxic chemicals.

Sulfamic acid's role in lignin breakdown is rooted in its ability to act as both a Brønsted acid and a nucleophile. This dual functionality allows it to catalyze the cleavage of various lignin bonds, including β-O-4 linkages, which are predominant in lignin structures. The mild reaction conditions required for sulfamic acid-catalyzed processes make it an attractive option for industrial applications, potentially reducing energy costs and minimizing equipment corrosion.

The development of sulfamic acid-based lignin breakdown techniques aligns with the broader trend of green chemistry and sustainable biorefinery processes. As global efforts to reduce dependence on fossil fuels intensify, the conversion of biomass into high-value products has become a key focus area. Sulfamic acid's potential in this field extends beyond lignin depolymerization, encompassing applications in cellulose hydrolysis and hemicellulose conversion.

Recent technological advancements have further expanded the scope of sulfamic acid in biomass processing. Researchers have explored various modifications and combinations, such as the use of sulfamic acid in conjunction with ionic liquids or metal catalysts, to enhance its effectiveness and selectivity in lignin breakdown. These innovations aim to improve product yields, reduce reaction times, and increase the range of obtainable bio-based chemicals.

The ultimate goal of this technology is to establish a robust and scalable process for lignin valorization, transforming what was once considered a waste product into a valuable resource. By enabling more efficient lignin breakdown, sulfamic acid-based methods could potentially unlock new revenue streams for biorefineries and contribute to the development of a circular bioeconomy.

Market Demand for Efficient Biomass Processing

The market demand for efficient biomass processing has been steadily increasing in recent years, driven by the global push towards sustainable energy sources and the need to reduce dependence on fossil fuels. Biomass, as a renewable resource, offers significant potential for energy production, biofuel manufacturing, and the creation of value-added chemicals. However, the efficient breakdown of lignin, a complex polymer found in plant cell walls, remains a critical challenge in biomass processing.

The growing interest in lignin valorization has created a substantial market opportunity for technologies that can effectively break down this recalcitrant component of biomass. Industries such as biofuels, paper and pulp, and biochemicals are actively seeking innovative solutions to improve lignin degradation efficiency. This demand is further fueled by stringent environmental regulations and the increasing focus on circular economy principles.

In the biofuels sector, efficient lignin breakdown is crucial for enhancing the overall yield of fermentable sugars from lignocellulosic biomass. This directly impacts the production costs and competitiveness of second-generation biofuels. The paper and pulp industry, traditionally a major consumer of biomass, is also exploring new methods to valorize lignin-rich waste streams, creating additional revenue streams and improving resource utilization.

The biochemical industry represents another significant market for efficient biomass processing technologies. As the demand for bio-based materials and chemicals continues to rise, there is a growing need for cost-effective methods to extract and convert lignin into high-value products. This includes applications in adhesives, resins, and carbon fibers, among others.

Geographically, North America and Europe currently lead in biomass processing technology adoption, driven by supportive policies and a strong focus on renewable energy. However, emerging economies in Asia and South America are rapidly catching up, presenting substantial growth opportunities for biomass processing technologies.

The market size for biomass processing technologies is projected to expand significantly in the coming years. This growth is underpinned by increasing investments in biorefinery projects, government incentives for renewable energy adoption, and the rising demand for sustainable products across various industries.

In conclusion, the market demand for efficient biomass processing, particularly in lignin breakdown, is robust and diverse. The potential applications span multiple industries, from energy to materials science, indicating a strong and sustained market pull for innovative solutions in this field. The development of technologies like sulfamic acid-facilitated lignin breakdown could potentially address this growing market need, offering significant economic and environmental benefits.

The growing interest in lignin valorization has created a substantial market opportunity for technologies that can effectively break down this recalcitrant component of biomass. Industries such as biofuels, paper and pulp, and biochemicals are actively seeking innovative solutions to improve lignin degradation efficiency. This demand is further fueled by stringent environmental regulations and the increasing focus on circular economy principles.

In the biofuels sector, efficient lignin breakdown is crucial for enhancing the overall yield of fermentable sugars from lignocellulosic biomass. This directly impacts the production costs and competitiveness of second-generation biofuels. The paper and pulp industry, traditionally a major consumer of biomass, is also exploring new methods to valorize lignin-rich waste streams, creating additional revenue streams and improving resource utilization.

The biochemical industry represents another significant market for efficient biomass processing technologies. As the demand for bio-based materials and chemicals continues to rise, there is a growing need for cost-effective methods to extract and convert lignin into high-value products. This includes applications in adhesives, resins, and carbon fibers, among others.

Geographically, North America and Europe currently lead in biomass processing technology adoption, driven by supportive policies and a strong focus on renewable energy. However, emerging economies in Asia and South America are rapidly catching up, presenting substantial growth opportunities for biomass processing technologies.

The market size for biomass processing technologies is projected to expand significantly in the coming years. This growth is underpinned by increasing investments in biorefinery projects, government incentives for renewable energy adoption, and the rising demand for sustainable products across various industries.

In conclusion, the market demand for efficient biomass processing, particularly in lignin breakdown, is robust and diverse. The potential applications span multiple industries, from energy to materials science, indicating a strong and sustained market pull for innovative solutions in this field. The development of technologies like sulfamic acid-facilitated lignin breakdown could potentially address this growing market need, offering significant economic and environmental benefits.

Current Challenges in Lignin Degradation

Lignin degradation remains a significant challenge in biomass processing, particularly in the context of biofuel production and biorefinery applications. The recalcitrant nature of lignin, a complex aromatic polymer, poses several obstacles to efficient breakdown and utilization. One of the primary challenges is the heterogeneous structure of lignin, which varies significantly across different plant species and even within the same plant. This structural diversity makes it difficult to develop a universal degradation method.

The strong covalent bonds within lignin, especially the carbon-carbon and ether linkages, are highly resistant to chemical and enzymatic attacks. Traditional methods often require harsh conditions, such as high temperatures and pressures, or the use of strong acids and bases, which can lead to unwanted side reactions and degradation of valuable components. These aggressive approaches also raise environmental concerns and increase processing costs.

Another significant challenge is the limited selectivity of current degradation techniques. Many methods result in a complex mixture of aromatic compounds, making it challenging to isolate and purify specific high-value products. This lack of selectivity hinders the economic viability of lignin valorization processes and limits the potential applications of lignin-derived materials.

The presence of inhibitory compounds formed during lignin degradation further complicates the process. These compounds can interfere with downstream fermentation steps in biofuel production or hinder subsequent chemical transformations. Developing effective strategies to remove or neutralize these inhibitors without compromising the desired products remains an ongoing challenge.

Scale-up and process integration present additional hurdles. Many promising lignin degradation techniques demonstrated at the laboratory scale face significant challenges when scaled up to industrial levels. Issues such as mass transfer limitations, reactor design, and process control become more pronounced at larger scales, affecting the efficiency and economic feasibility of the degradation process.

The development of efficient catalysts for lignin degradation is another area of active research. While several catalytic systems have shown promise, many suffer from issues such as low turnover numbers, catalyst deactivation, and poor selectivity. Finding catalysts that can operate under mild conditions while maintaining high activity and selectivity remains a key challenge in the field.

Lastly, the integration of lignin degradation processes with existing biorefinery operations poses logistical and technical challenges. Optimizing the overall process to maximize the utilization of all biomass components while minimizing waste and energy consumption requires careful consideration of process design and integration strategies.

The strong covalent bonds within lignin, especially the carbon-carbon and ether linkages, are highly resistant to chemical and enzymatic attacks. Traditional methods often require harsh conditions, such as high temperatures and pressures, or the use of strong acids and bases, which can lead to unwanted side reactions and degradation of valuable components. These aggressive approaches also raise environmental concerns and increase processing costs.

Another significant challenge is the limited selectivity of current degradation techniques. Many methods result in a complex mixture of aromatic compounds, making it challenging to isolate and purify specific high-value products. This lack of selectivity hinders the economic viability of lignin valorization processes and limits the potential applications of lignin-derived materials.

The presence of inhibitory compounds formed during lignin degradation further complicates the process. These compounds can interfere with downstream fermentation steps in biofuel production or hinder subsequent chemical transformations. Developing effective strategies to remove or neutralize these inhibitors without compromising the desired products remains an ongoing challenge.

Scale-up and process integration present additional hurdles. Many promising lignin degradation techniques demonstrated at the laboratory scale face significant challenges when scaled up to industrial levels. Issues such as mass transfer limitations, reactor design, and process control become more pronounced at larger scales, affecting the efficiency and economic feasibility of the degradation process.

The development of efficient catalysts for lignin degradation is another area of active research. While several catalytic systems have shown promise, many suffer from issues such as low turnover numbers, catalyst deactivation, and poor selectivity. Finding catalysts that can operate under mild conditions while maintaining high activity and selectivity remains a key challenge in the field.

Lastly, the integration of lignin degradation processes with existing biorefinery operations poses logistical and technical challenges. Optimizing the overall process to maximize the utilization of all biomass components while minimizing waste and energy consumption requires careful consideration of process design and integration strategies.

Existing Sulfamic Acid-Based Lignin Breakdown Solutions

01 Sulfamic acid for lignin depolymerization

Sulfamic acid is used as a catalyst or reagent in the process of breaking down lignin into smaller molecules. This method can be effective for lignin depolymerization, potentially leading to the production of valuable chemicals from biomass.- Sulfamic acid for lignin depolymerization: Sulfamic acid is used as a catalyst or reagent in the process of breaking down lignin into smaller molecules. This method can be effective for lignin depolymerization, potentially leading to the production of valuable chemicals or materials from lignin.

- Lignin breakdown in pulp and paper industry: Sulfamic acid is employed in the pulp and paper industry to break down lignin in wood fibers. This process helps in the production of high-quality paper by removing lignin, which can interfere with paper properties.

- Sulfamic acid in biomass pretreatment: Sulfamic acid is used in the pretreatment of lignocellulosic biomass to enhance the breakdown of lignin. This pretreatment step is crucial for improving the efficiency of subsequent processes such as enzymatic hydrolysis or fermentation for biofuel production.

- Lignin valorization using sulfamic acid: Sulfamic acid is utilized in processes aimed at converting lignin into value-added products. This approach focuses on breaking down lignin into smaller, more useful molecules that can serve as precursors for various chemicals and materials.

- Sulfamic acid in combination with other reagents: Sulfamic acid is used in combination with other reagents or catalysts to enhance the efficiency of lignin breakdown. These synergistic approaches can lead to more effective depolymerization of lignin under milder conditions.

02 Lignin breakdown in pulp and paper industry

Sulfamic acid is employed in the pulp and paper industry to break down lignin in wood fibers. This process helps in the production of high-quality paper by removing lignin, which can interfere with paper properties.Expand Specific Solutions03 Sulfamic acid in biomass pretreatment

Sulfamic acid is used in the pretreatment of lignocellulosic biomass to enhance the accessibility of cellulose and hemicellulose for further processing. This pretreatment step is crucial for efficient conversion of biomass into biofuels and biochemicals.Expand Specific Solutions04 Sulfamic acid-based lignin valorization

Sulfamic acid is utilized in processes aimed at valorizing lignin by breaking it down into valuable aromatic compounds. This approach can lead to the production of renewable chemicals and materials from lignin, a major component of plant biomass.Expand Specific Solutions05 Sulfamic acid in combination with other reagents

Sulfamic acid is often used in combination with other reagents or catalysts to enhance the efficiency of lignin breakdown. These synergistic approaches can improve the yield and selectivity of desired products from lignin depolymerization.Expand Specific Solutions

Key Players in Biomass Processing Industry

The competitive landscape for sulfamic acid-facilitated lignin breakdown in biomass is characterized by a diverse mix of academic institutions, government research bodies, and private companies at various stages of development. The market is still in its early growth phase, with significant potential for expansion as the demand for sustainable biomass processing increases. Key players include South China University of Technology, DuPont, and Virent, each bringing unique expertise in green chemistry and biomass conversion. The technology's maturity varies, with some entities like CSIR and University of California conducting fundamental research, while companies such as Vertichem and Midori Renewables are advancing towards commercialization. Overall, the field is rapidly evolving, driven by the global push for renewable resources and bio-based materials.

South China University of Technology

Technical Solution: South China University of Technology has developed an innovative approach to lignin breakdown using sulfamic acid. Their method involves a two-step process: first, pretreatment of biomass with sulfamic acid at moderate temperatures (100-140°C) to partially depolymerize lignin and increase its solubility[1]. This is followed by a catalytic oxidation step using a copper-based catalyst in the presence of oxygen, which further breaks down the lignin into valuable aromatic compounds[2]. The use of sulfamic acid as a pretreatment agent has shown to significantly enhance the efficiency of lignin depolymerization compared to traditional acid treatments[3]. The researchers have also optimized the reaction conditions to achieve up to 80% lignin conversion with high selectivity towards specific aromatic monomers[4].

Strengths: High lignin conversion rate, selective production of valuable aromatics, relatively mild reaction conditions. Weaknesses: Potential corrosion issues with sulfamic acid, need for specialized catalysts in the second step.

National Technology & Engineering Solutions of Sandia LLC

Technical Solution: Sandia National Laboratories has developed a novel approach to lignin breakdown using sulfamic acid in conjunction with ionic liquids. Their process involves dissolving biomass in an ionic liquid, followed by the addition of sulfamic acid as a catalyst[1]. The sulfamic acid acts as both a proton donor and a nucleophile, facilitating the cleavage of ether bonds in lignin[2]. This method has shown to be effective at lower temperatures (80-120°C) compared to traditional acid hydrolysis, reducing energy requirements[3]. The use of ionic liquids allows for better penetration of the acid into the lignin structure, leading to more efficient depolymerization[4]. Sandia's researchers have also developed a recovery system for the ionic liquid, making the process more economically viable for large-scale applications[5].

Strengths: Lower temperature requirements, efficient lignin depolymerization, potential for solvent recycling. Weaknesses: High cost of ionic liquids, potential challenges in scaling up the process.

Core Innovations in Sulfamic Acid Catalysis

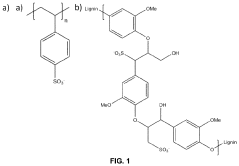

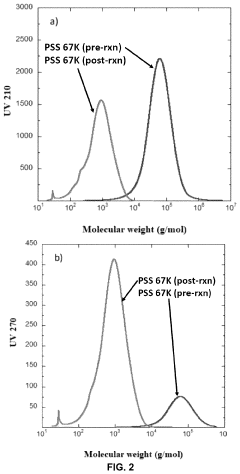

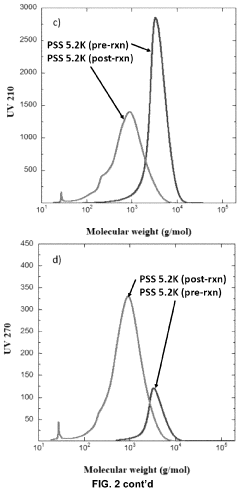

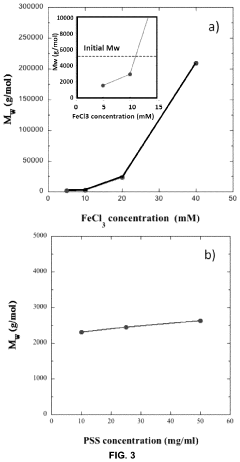

Chelator-mediated fenton (CMF) process to break a c-c bond in lignosulfonate

PatentPendingUS20240059723A1

Innovation

- A method involving sulfonation of lignin followed by a chelator-mediated Fenton reaction, which breaks C—C bonds in lignosulfonate, reducing molecular weight and minimizing repolymerization, allowing for efficient depolymerization suitable for biological conversion into useful chemicals and intermediates.

A process for the isolation and acclimatization of bacteria for lignin degradation

PatentInactiveUS20060121592A1

Innovation

- A novel consortium of ligninolytic bacteria, comprising strains CBTCC/52-03, CBTCC/53-03, and CBTCC/54-03, isolated from a specific site with enhanced lignin degradation capabilities, is formulated and used in a biological process to degrade lignin, overcoming the limitations of fungal-based methods.

Environmental Impact of Sulfamic Acid Use

The use of sulfamic acid in lignin breakdown processes raises important environmental considerations. While this chemical compound offers significant benefits in biomass processing, its potential ecological impacts must be carefully evaluated and managed.

Sulfamic acid, when released into the environment, can affect soil and water pH levels. In aquatic ecosystems, even small changes in acidity can disrupt the delicate balance of flora and fauna. Fish populations are particularly sensitive to pH fluctuations, which can affect their reproductive cycles and overall health. Additionally, increased acidity in water bodies can lead to the leaching of metals from sediments, potentially introducing toxic elements into the food chain.

In terrestrial environments, sulfamic acid can alter soil chemistry. This may impact plant growth and microbial communities essential for nutrient cycling. Changes in soil pH can affect the availability of nutrients to plants, potentially leading to reduced agricultural productivity in affected areas. Furthermore, soil acidification can increase the mobility of certain heavy metals, posing risks to groundwater quality.

The production and transportation of sulfamic acid also contribute to its environmental footprint. Manufacturing processes may result in air and water emissions, while transportation accidents could lead to localized contamination. Proper handling and storage protocols are crucial to minimize these risks.

However, it's important to note that when used responsibly in controlled industrial settings, the environmental impact of sulfamic acid can be significantly mitigated. Proper waste management and neutralization techniques can minimize its release into the environment. Moreover, the efficiency gains in biomass processing achieved through sulfamic acid use may indirectly benefit the environment by reducing overall energy consumption and waste production in biofuel and biomaterial industries.

Research into more environmentally friendly alternatives or modifications to sulfamic acid is ongoing. Green chemistry approaches aim to develop lignin breakdown methods that maintain efficiency while reducing potential ecological harm. These efforts include exploring bio-based catalysts and developing closed-loop systems that minimize chemical release.

In conclusion, while sulfamic acid presents environmental challenges, its judicious use in lignin breakdown can be managed to minimize negative impacts. Balancing the benefits of improved biomass processing against potential ecological risks requires ongoing research, stringent regulations, and responsible industrial practices.

Sulfamic acid, when released into the environment, can affect soil and water pH levels. In aquatic ecosystems, even small changes in acidity can disrupt the delicate balance of flora and fauna. Fish populations are particularly sensitive to pH fluctuations, which can affect their reproductive cycles and overall health. Additionally, increased acidity in water bodies can lead to the leaching of metals from sediments, potentially introducing toxic elements into the food chain.

In terrestrial environments, sulfamic acid can alter soil chemistry. This may impact plant growth and microbial communities essential for nutrient cycling. Changes in soil pH can affect the availability of nutrients to plants, potentially leading to reduced agricultural productivity in affected areas. Furthermore, soil acidification can increase the mobility of certain heavy metals, posing risks to groundwater quality.

The production and transportation of sulfamic acid also contribute to its environmental footprint. Manufacturing processes may result in air and water emissions, while transportation accidents could lead to localized contamination. Proper handling and storage protocols are crucial to minimize these risks.

However, it's important to note that when used responsibly in controlled industrial settings, the environmental impact of sulfamic acid can be significantly mitigated. Proper waste management and neutralization techniques can minimize its release into the environment. Moreover, the efficiency gains in biomass processing achieved through sulfamic acid use may indirectly benefit the environment by reducing overall energy consumption and waste production in biofuel and biomaterial industries.

Research into more environmentally friendly alternatives or modifications to sulfamic acid is ongoing. Green chemistry approaches aim to develop lignin breakdown methods that maintain efficiency while reducing potential ecological harm. These efforts include exploring bio-based catalysts and developing closed-loop systems that minimize chemical release.

In conclusion, while sulfamic acid presents environmental challenges, its judicious use in lignin breakdown can be managed to minimize negative impacts. Balancing the benefits of improved biomass processing against potential ecological risks requires ongoing research, stringent regulations, and responsible industrial practices.

Techno-economic Analysis of Sulfamic Acid Pretreatment

The techno-economic analysis of sulfamic acid pretreatment for lignin breakdown in biomass reveals promising potential for industrial applications. This pretreatment method offers several advantages over conventional approaches, including lower energy requirements, reduced chemical consumption, and improved lignin removal efficiency.

From an economic perspective, sulfamic acid pretreatment demonstrates cost-effectiveness due to its relatively low price and high recyclability. The acid's ability to be recovered and reused multiple times significantly reduces operational expenses, making it an attractive option for large-scale biomass processing facilities.

The process requires minimal capital investment compared to other pretreatment technologies, as it can be implemented using existing equipment with minor modifications. This factor contributes to a lower overall cost of implementation and faster return on investment for biomass processing plants.

Energy consumption during sulfamic acid pretreatment is notably lower than traditional methods, such as dilute acid or steam explosion pretreatments. This reduction in energy input translates to decreased operational costs and improved environmental sustainability, aligning with growing industry trends towards greener processes.

The enhanced lignin removal efficiency achieved through sulfamic acid pretreatment leads to increased yields of fermentable sugars in subsequent enzymatic hydrolysis steps. This improvement in sugar yields directly impacts the economic viability of biofuel and biochemical production processes, potentially increasing revenue streams for biorefineries.

However, the techno-economic analysis also highlights certain challenges that need to be addressed. The cost of sulfamic acid, while competitive, still represents a significant portion of the overall process expenses. Further research into optimizing acid concentrations and recycling methods could potentially reduce this cost factor.

Additionally, the analysis indicates that the pretreatment time required for optimal lignin removal may be longer compared to some alternative methods. This extended processing time could impact overall plant throughput and productivity, necessitating careful scheduling and process optimization to maximize economic benefits.

In conclusion, the techno-economic analysis suggests that sulfamic acid pretreatment offers a promising balance between cost-effectiveness and performance in lignin breakdown for biomass processing. With further optimization and scale-up studies, this method has the potential to become a preferred choice for industrial-scale biomass pretreatment operations, contributing to the economic viability of the biorefinery industry.

From an economic perspective, sulfamic acid pretreatment demonstrates cost-effectiveness due to its relatively low price and high recyclability. The acid's ability to be recovered and reused multiple times significantly reduces operational expenses, making it an attractive option for large-scale biomass processing facilities.

The process requires minimal capital investment compared to other pretreatment technologies, as it can be implemented using existing equipment with minor modifications. This factor contributes to a lower overall cost of implementation and faster return on investment for biomass processing plants.

Energy consumption during sulfamic acid pretreatment is notably lower than traditional methods, such as dilute acid or steam explosion pretreatments. This reduction in energy input translates to decreased operational costs and improved environmental sustainability, aligning with growing industry trends towards greener processes.

The enhanced lignin removal efficiency achieved through sulfamic acid pretreatment leads to increased yields of fermentable sugars in subsequent enzymatic hydrolysis steps. This improvement in sugar yields directly impacts the economic viability of biofuel and biochemical production processes, potentially increasing revenue streams for biorefineries.

However, the techno-economic analysis also highlights certain challenges that need to be addressed. The cost of sulfamic acid, while competitive, still represents a significant portion of the overall process expenses. Further research into optimizing acid concentrations and recycling methods could potentially reduce this cost factor.

Additionally, the analysis indicates that the pretreatment time required for optimal lignin removal may be longer compared to some alternative methods. This extended processing time could impact overall plant throughput and productivity, necessitating careful scheduling and process optimization to maximize economic benefits.

In conclusion, the techno-economic analysis suggests that sulfamic acid pretreatment offers a promising balance between cost-effectiveness and performance in lignin breakdown for biomass processing. With further optimization and scale-up studies, this method has the potential to become a preferred choice for industrial-scale biomass pretreatment operations, contributing to the economic viability of the biorefinery industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!