How to Achieve Balanced Adhesion and Cohesion with Polyvinyl Acetate?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Adhesion-Cohesion Background and Objectives

Polyvinyl acetate (PVAc) has been a cornerstone in adhesive technology since its development in the early 20th century. This versatile polymer has found widespread applications across various industries due to its unique properties, particularly its ability to form strong bonds with a wide range of substrates. The challenge of achieving balanced adhesion and cohesion with PVAc has been a focal point of research and development in the adhesive industry for decades.

The adhesion-cohesion balance is crucial for the performance of PVAc adhesives. Adhesion refers to the bond strength between the adhesive and the substrate, while cohesion represents the internal strength of the adhesive itself. Achieving an optimal balance between these two properties is essential for creating robust and durable bonds that can withstand various environmental conditions and mechanical stresses.

Historically, PVAc adhesives have undergone significant evolution to address this balance. Early formulations often struggled with either weak adhesion to certain substrates or insufficient cohesive strength, leading to bond failures under stress. The development of PVAc technology has been driven by the need to overcome these limitations and create more versatile and reliable adhesive systems.

Recent advancements in polymer science and materials engineering have opened new avenues for enhancing the adhesion-cohesion balance of PVAc. Researchers have explored various strategies, including the modification of PVAc molecular structure, incorporation of additives, and development of hybrid systems combining PVAc with other polymers or nanoparticles.

The primary objective in this field is to develop PVAc-based adhesives that exhibit strong initial tack, rapid bond formation, and excellent long-term durability across a diverse range of substrates and environmental conditions. This involves optimizing the polymer's molecular weight distribution, degree of hydrolysis, and crosslinking density to achieve the desired balance of properties.

Another critical goal is to enhance the water resistance of PVAc adhesives without compromising their ease of use and environmental friendliness. This is particularly important for applications in humid environments or those requiring resistance to moisture exposure.

Furthermore, there is a growing emphasis on developing sustainable PVAc formulations that maintain high performance while reducing environmental impact. This includes exploring bio-based alternatives and improving the recyclability and biodegradability of PVAc adhesives.

As we delve deeper into this technical challenge, it is essential to consider the multifaceted nature of adhesion and cohesion in PVAc systems. The interplay between molecular structure, surface interactions, and environmental factors creates a complex landscape that requires innovative approaches and interdisciplinary collaboration to navigate successfully.

The adhesion-cohesion balance is crucial for the performance of PVAc adhesives. Adhesion refers to the bond strength between the adhesive and the substrate, while cohesion represents the internal strength of the adhesive itself. Achieving an optimal balance between these two properties is essential for creating robust and durable bonds that can withstand various environmental conditions and mechanical stresses.

Historically, PVAc adhesives have undergone significant evolution to address this balance. Early formulations often struggled with either weak adhesion to certain substrates or insufficient cohesive strength, leading to bond failures under stress. The development of PVAc technology has been driven by the need to overcome these limitations and create more versatile and reliable adhesive systems.

Recent advancements in polymer science and materials engineering have opened new avenues for enhancing the adhesion-cohesion balance of PVAc. Researchers have explored various strategies, including the modification of PVAc molecular structure, incorporation of additives, and development of hybrid systems combining PVAc with other polymers or nanoparticles.

The primary objective in this field is to develop PVAc-based adhesives that exhibit strong initial tack, rapid bond formation, and excellent long-term durability across a diverse range of substrates and environmental conditions. This involves optimizing the polymer's molecular weight distribution, degree of hydrolysis, and crosslinking density to achieve the desired balance of properties.

Another critical goal is to enhance the water resistance of PVAc adhesives without compromising their ease of use and environmental friendliness. This is particularly important for applications in humid environments or those requiring resistance to moisture exposure.

Furthermore, there is a growing emphasis on developing sustainable PVAc formulations that maintain high performance while reducing environmental impact. This includes exploring bio-based alternatives and improving the recyclability and biodegradability of PVAc adhesives.

As we delve deeper into this technical challenge, it is essential to consider the multifaceted nature of adhesion and cohesion in PVAc systems. The interplay between molecular structure, surface interactions, and environmental factors creates a complex landscape that requires innovative approaches and interdisciplinary collaboration to navigate successfully.

Market Analysis for Balanced PVAc Adhesives

The market for balanced polyvinyl acetate (PVAc) adhesives has shown significant growth in recent years, driven by increasing demand across various industries. The global PVAc adhesives market is experiencing steady expansion, with a particular focus on formulations that offer improved balance between adhesion and cohesion properties.

Key industries driving the demand for balanced PVAc adhesives include construction, woodworking, packaging, and automotive. In the construction sector, these adhesives are widely used for bonding wood, laminates, and other building materials. The woodworking industry relies heavily on PVAc adhesives for furniture manufacturing and joinery applications. The packaging industry utilizes these adhesives for carton sealing and label applications, while the automotive sector employs them in interior trim assembly.

Market trends indicate a growing preference for environmentally friendly and low-VOC (volatile organic compound) adhesive solutions. This has led to increased research and development efforts to create water-based PVAc formulations that maintain high performance while meeting stringent environmental regulations. The shift towards sustainable adhesives is particularly pronounced in developed markets such as North America and Europe.

Geographically, Asia-Pacific represents the largest and fastest-growing market for balanced PVAc adhesives. This growth is attributed to rapid industrialization, increasing construction activities, and the expansion of manufacturing sectors in countries like China and India. North America and Europe follow as mature markets with steady demand, driven by renovation and remodeling activities in the construction sector.

The market is characterized by intense competition among key players, including Henkel, H.B. Fuller, 3M, and Arkema. These companies are investing heavily in research and development to improve the performance characteristics of their PVAc adhesives, with a focus on enhancing the balance between adhesion and cohesion properties.

Challenges in the market include fluctuating raw material prices, which can impact profit margins for manufacturers. Additionally, the development of alternative adhesive technologies, such as hot melt adhesives and reactive adhesives, poses a potential threat to the PVAc adhesives market share in certain applications.

Looking ahead, the market for balanced PVAc adhesives is expected to continue its growth trajectory. Factors such as increasing urbanization, growth in the packaging industry, and the ongoing trend towards lightweight materials in automotive manufacturing are likely to sustain demand. The development of novel formulations that offer improved performance, faster curing times, and enhanced environmental profiles will be crucial in driving market expansion and maintaining competitiveness in the adhesives industry.

Key industries driving the demand for balanced PVAc adhesives include construction, woodworking, packaging, and automotive. In the construction sector, these adhesives are widely used for bonding wood, laminates, and other building materials. The woodworking industry relies heavily on PVAc adhesives for furniture manufacturing and joinery applications. The packaging industry utilizes these adhesives for carton sealing and label applications, while the automotive sector employs them in interior trim assembly.

Market trends indicate a growing preference for environmentally friendly and low-VOC (volatile organic compound) adhesive solutions. This has led to increased research and development efforts to create water-based PVAc formulations that maintain high performance while meeting stringent environmental regulations. The shift towards sustainable adhesives is particularly pronounced in developed markets such as North America and Europe.

Geographically, Asia-Pacific represents the largest and fastest-growing market for balanced PVAc adhesives. This growth is attributed to rapid industrialization, increasing construction activities, and the expansion of manufacturing sectors in countries like China and India. North America and Europe follow as mature markets with steady demand, driven by renovation and remodeling activities in the construction sector.

The market is characterized by intense competition among key players, including Henkel, H.B. Fuller, 3M, and Arkema. These companies are investing heavily in research and development to improve the performance characteristics of their PVAc adhesives, with a focus on enhancing the balance between adhesion and cohesion properties.

Challenges in the market include fluctuating raw material prices, which can impact profit margins for manufacturers. Additionally, the development of alternative adhesive technologies, such as hot melt adhesives and reactive adhesives, poses a potential threat to the PVAc adhesives market share in certain applications.

Looking ahead, the market for balanced PVAc adhesives is expected to continue its growth trajectory. Factors such as increasing urbanization, growth in the packaging industry, and the ongoing trend towards lightweight materials in automotive manufacturing are likely to sustain demand. The development of novel formulations that offer improved performance, faster curing times, and enhanced environmental profiles will be crucial in driving market expansion and maintaining competitiveness in the adhesives industry.

Current Challenges in PVAc Adhesion-Cohesion Balance

Polyvinyl acetate (PVAc) adhesives face significant challenges in achieving an optimal balance between adhesion and cohesion. This balance is crucial for the performance and durability of PVAc-based products across various applications. One of the primary challenges lies in the inherent molecular structure of PVAc, which affects its ability to form strong bonds with substrates while maintaining internal strength.

The adhesion properties of PVAc are influenced by its polar nature, which allows for good wetting and interaction with many surfaces. However, this same polarity can lead to moisture sensitivity, potentially compromising long-term bond strength in humid environments. Enhancing adhesion often involves modifying the PVAc formulation with additives or functional groups, but these modifications can inadvertently affect cohesive strength.

Cohesion in PVAc adhesives is primarily determined by the polymer's molecular weight and degree of crosslinking. Higher molecular weight generally improves cohesive strength but can also increase viscosity, making application more difficult. Crosslinking agents can enhance cohesion but may reduce flexibility and impact resistance. Striking the right balance between these factors remains a significant challenge for formulators.

Temperature sensitivity presents another hurdle in PVAc adhesive development. The material's glass transition temperature (Tg) affects both adhesion and cohesion properties. At temperatures above Tg, PVAc becomes more flexible, potentially improving adhesion but reducing cohesive strength. Conversely, below Tg, the adhesive becomes more brittle, which can lead to cohesive failure under stress.

The diverse range of substrates used in PVAc applications further complicates the adhesion-cohesion balance. Different materials require varying levels of surface energy and chemical compatibility for optimal adhesion. Developing a universal PVAc formulation that maintains excellent adhesion across multiple substrates while preserving cohesive strength remains a significant challenge.

Environmental factors, such as humidity and UV exposure, pose additional challenges to maintaining the adhesion-cohesion balance over time. PVAc's susceptibility to hydrolysis in high-moisture environments can lead to weakened bonds and reduced cohesive strength. Similarly, UV degradation can alter the polymer structure, affecting both adhesive and cohesive properties.

Addressing these challenges requires innovative approaches in polymer chemistry and formulation technology. Researchers are exploring various strategies, including copolymerization with other monomers, incorporation of nanoparticles, and development of hybrid adhesive systems. However, each of these approaches introduces new complexities in achieving the desired balance between adhesion and cohesion while maintaining other critical properties such as processability and cost-effectiveness.

The adhesion properties of PVAc are influenced by its polar nature, which allows for good wetting and interaction with many surfaces. However, this same polarity can lead to moisture sensitivity, potentially compromising long-term bond strength in humid environments. Enhancing adhesion often involves modifying the PVAc formulation with additives or functional groups, but these modifications can inadvertently affect cohesive strength.

Cohesion in PVAc adhesives is primarily determined by the polymer's molecular weight and degree of crosslinking. Higher molecular weight generally improves cohesive strength but can also increase viscosity, making application more difficult. Crosslinking agents can enhance cohesion but may reduce flexibility and impact resistance. Striking the right balance between these factors remains a significant challenge for formulators.

Temperature sensitivity presents another hurdle in PVAc adhesive development. The material's glass transition temperature (Tg) affects both adhesion and cohesion properties. At temperatures above Tg, PVAc becomes more flexible, potentially improving adhesion but reducing cohesive strength. Conversely, below Tg, the adhesive becomes more brittle, which can lead to cohesive failure under stress.

The diverse range of substrates used in PVAc applications further complicates the adhesion-cohesion balance. Different materials require varying levels of surface energy and chemical compatibility for optimal adhesion. Developing a universal PVAc formulation that maintains excellent adhesion across multiple substrates while preserving cohesive strength remains a significant challenge.

Environmental factors, such as humidity and UV exposure, pose additional challenges to maintaining the adhesion-cohesion balance over time. PVAc's susceptibility to hydrolysis in high-moisture environments can lead to weakened bonds and reduced cohesive strength. Similarly, UV degradation can alter the polymer structure, affecting both adhesive and cohesive properties.

Addressing these challenges requires innovative approaches in polymer chemistry and formulation technology. Researchers are exploring various strategies, including copolymerization with other monomers, incorporation of nanoparticles, and development of hybrid adhesive systems. However, each of these approaches introduces new complexities in achieving the desired balance between adhesion and cohesion while maintaining other critical properties such as processability and cost-effectiveness.

Existing Solutions for PVAc Balance

01 Improving adhesion properties of polyvinyl acetate

Various methods can be employed to enhance the adhesion properties of polyvinyl acetate. These include modifying the polymer structure, incorporating additives, or using surface treatments. Improved adhesion can lead to stronger bonds and better performance in applications such as adhesives, coatings, and sealants.- Improving adhesion properties of polyvinyl acetate: Various methods can be employed to enhance the adhesion properties of polyvinyl acetate. These include modifying the polymer structure, incorporating additives, or using surface treatments. Improved adhesion can lead to stronger bonds and better performance in applications such as adhesives and coatings.

- Enhancing cohesion of polyvinyl acetate formulations: Techniques to increase the cohesive strength of polyvinyl acetate-based materials involve adjusting the molecular weight, crosslinking, or adding reinforcing agents. Enhanced cohesion results in improved internal strength and durability of the material, making it suitable for a wider range of applications.

- Balancing adhesion and cohesion in polyvinyl acetate systems: Achieving an optimal balance between adhesion and cohesion is crucial for many polyvinyl acetate applications. This can be accomplished through careful formulation, including the selection of appropriate copolymers, plasticizers, or other additives. A well-balanced system ensures good bonding to substrates while maintaining internal strength.

- Modifying polyvinyl acetate for specific adhesion requirements: Polyvinyl acetate can be modified to meet specific adhesion requirements for various substrates or environmental conditions. This may involve grafting, copolymerization, or blending with other polymers. Such modifications can tailor the adhesive properties for applications ranging from packaging to construction materials.

- Improving water resistance of polyvinyl acetate adhesives: Enhancing the water resistance of polyvinyl acetate adhesives is important for many applications. This can be achieved through various methods such as crosslinking, incorporation of hydrophobic components, or post-application treatments. Improved water resistance leads to better durability and expanded use in humid or wet environments.

02 Enhancing cohesion of polyvinyl acetate formulations

Techniques to increase the cohesive strength of polyvinyl acetate-based materials involve adjusting the molecular weight, crosslinking density, or incorporating reinforcing agents. Enhanced cohesion results in improved internal strength and durability of the material, making it more resistant to deformation and failure.Expand Specific Solutions03 Balancing adhesion and cohesion in polyvinyl acetate systems

Achieving an optimal balance between adhesion and cohesion is crucial for many polyvinyl acetate applications. This can be accomplished through careful formulation, including the selection of appropriate copolymers, plasticizers, or other additives. A well-balanced system ensures good bonding to substrates while maintaining internal strength.Expand Specific Solutions04 Modifying polyvinyl acetate for specific adhesion requirements

Tailoring polyvinyl acetate to meet specific adhesion requirements involves adjusting its chemical composition or physical properties. This can include grafting functional groups, creating hybrid materials, or developing specialized copolymers. Such modifications allow for customized adhesion properties suitable for diverse applications and substrates.Expand Specific Solutions05 Environmental factors affecting polyvinyl acetate adhesion and cohesion

The adhesion and cohesion of polyvinyl acetate can be significantly influenced by environmental factors such as temperature, humidity, and exposure to chemicals. Understanding and addressing these factors through formulation adjustments or protective measures is essential for maintaining the performance and longevity of polyvinyl acetate-based products in various conditions.Expand Specific Solutions

Key Players in PVAc Adhesive Industry

The market for polyvinyl acetate adhesives is in a mature stage, with established players and steady growth. The global market size is estimated to be over $3 billion, driven by demand in construction, packaging, and woodworking industries. Technologically, polyvinyl acetate adhesives are well-developed, with ongoing innovations focused on improving performance and sustainability. Key players like Henkel, 3M, and Wacker Chemie are investing in R&D to enhance adhesion strength, water resistance, and eco-friendliness. Emerging companies such as Kingfa Sci. & Tech. and Resonac are also contributing to advancements in formulation and application techniques. The competitive landscape is characterized by a mix of large multinational corporations and specialized regional manufacturers, with differentiation based on product quality, customization, and technical support.

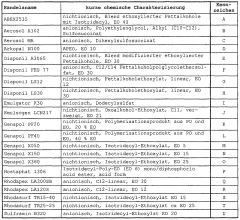

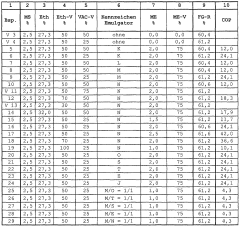

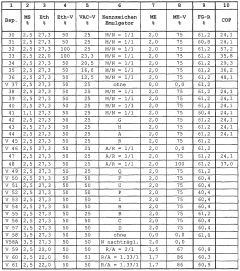

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed a range of polyvinyl acetate (PVAc) dispersions specifically designed to achieve balanced adhesion and cohesion. Their VINNAPAS® product line utilizes a unique copolymerization process that incorporates functional monomers to enhance both adhesive and cohesive properties[1]. The company employs advanced emulsion polymerization techniques to control particle size distribution, which directly impacts the balance between adhesion and cohesion[2]. Additionally, Wacker has implemented post-polymerization modification methods, such as crosslinking agents, to further fine-tune the adhesive performance[3]. Their research has shown that optimizing the glass transition temperature (Tg) of the polymer is crucial for achieving the desired balance, with their products typically ranging from -30°C to +30°C depending on the specific application requirements[4].

Strengths: Extensive experience in PVAc chemistry, wide range of customizable products, and strong R&D capabilities. Weaknesses: Potentially higher cost due to specialized formulations, and may require specific application techniques for optimal performance.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a sophisticated approach to balancing adhesion and cohesion in polyvinyl acetate formulations. Their technology focuses on the molecular weight distribution of PVAc polymers, utilizing a controlled radical polymerization process to achieve precise control over chain length and branching[1]. This allows for the creation of adhesives with tailored viscoelastic properties, crucial for balancing adhesion and cohesion. Henkel's research has shown that incorporating specific functional groups, such as carboxyl or hydroxyl moieties, into the PVAc backbone can significantly enhance interfacial interactions, improving adhesion without compromising cohesive strength[2]. Furthermore, they have developed a proprietary blend of tackifiers and plasticizers that work synergistically with the PVAc base to optimize the balance between surface wetting and internal strength[3]. Recent advancements in their formulation include the use of nanoparticle reinforcements, which have been demonstrated to increase cohesive strength by up to 40% while maintaining excellent adhesion properties[4].

Strengths: Advanced polymer engineering capabilities, broad application expertise across various industries, and strong focus on sustainable adhesive solutions. Weaknesses: Complex formulations may lead to higher production costs, and some specialized products may have limited shelf life.

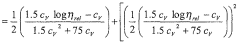

Core Innovations in PVAc Formulation

Method for producing adhesives having improved adhesion

PatentInactiveEP1212383A1

Innovation

- A process for producing adhesives through emulsion polymerization using specific monomers in the presence of polyvinyl alcohol, followed by the addition of 0.3 to 3.0% by weight of anionic, cationic, or nonionic emulsifiers after polymerization, which improves adhesion without significantly reducing cohesion.

Process for producing vinyl acetate/ethylene copolymers by means of emulsion polymerization

PatentWO2010097340A1

Innovation

- A process for emulsion polymerization of vinyl acetate-ethylene copolymers that includes specific ranges of ethylene and vinyl acetate monomers, along with nonionic ethoxylated emulsifiers, to achieve improved adhesion-cohesion balance without the use of emulsifiers like alkylphenol ethoxylates, ensuring high adhesion to difficult-to-bond substrates and fast setting speeds.

Environmental Impact of PVAc Adhesives

Polyvinyl acetate (PVAc) adhesives have gained widespread use in various industries due to their versatility and effectiveness. However, their environmental impact has become a growing concern in recent years. The production, use, and disposal of PVAc adhesives can have significant implications for ecosystems and human health.

During the manufacturing process of PVAc adhesives, volatile organic compounds (VOCs) are released into the atmosphere. These emissions contribute to air pollution and can lead to the formation of ground-level ozone, a major component of smog. Additionally, the production of PVAc requires petroleum-based raw materials, which are non-renewable resources and contribute to carbon emissions.

When PVAc adhesives are applied, they continue to emit VOCs as they cure and dry. This off-gassing can persist for extended periods, potentially affecting indoor air quality in residential and commercial spaces. Prolonged exposure to these emissions may cause respiratory irritation and other health issues, particularly in sensitive individuals.

The disposal of PVAc adhesives and products bonded with them presents another environmental challenge. While PVAc is not considered highly toxic, it is not biodegradable. When discarded in landfills, PVAc-based products can persist for many years, contributing to long-term waste accumulation. Furthermore, the presence of PVAc in recycling streams can complicate the recycling process for other materials.

Water pollution is another concern associated with PVAc adhesives. Improper disposal of liquid adhesive waste or cleaning solvents can contaminate water sources. Once in aquatic environments, PVAc can form microplastics that may be ingested by marine life, potentially entering the food chain.

Despite these environmental concerns, efforts are being made to mitigate the impact of PVAc adhesives. Manufacturers are developing low-VOC and water-based formulations that reduce harmful emissions. Some companies are exploring bio-based alternatives to traditional PVAc, using renewable resources as raw materials.

Recycling technologies for PVAc-bonded products are also advancing. Researchers are investigating methods to separate PVAc from other materials, enabling more efficient recycling processes. Additionally, there is growing interest in developing biodegradable adhesives that maintain the performance characteristics of PVAc while reducing environmental persistence.

As environmental regulations become more stringent, the adhesive industry is likely to continue innovating towards more sustainable PVAc formulations and application methods. This shift may include the adoption of green chemistry principles, life cycle assessments, and circular economy approaches to minimize the overall environmental footprint of PVAc adhesives.

During the manufacturing process of PVAc adhesives, volatile organic compounds (VOCs) are released into the atmosphere. These emissions contribute to air pollution and can lead to the formation of ground-level ozone, a major component of smog. Additionally, the production of PVAc requires petroleum-based raw materials, which are non-renewable resources and contribute to carbon emissions.

When PVAc adhesives are applied, they continue to emit VOCs as they cure and dry. This off-gassing can persist for extended periods, potentially affecting indoor air quality in residential and commercial spaces. Prolonged exposure to these emissions may cause respiratory irritation and other health issues, particularly in sensitive individuals.

The disposal of PVAc adhesives and products bonded with them presents another environmental challenge. While PVAc is not considered highly toxic, it is not biodegradable. When discarded in landfills, PVAc-based products can persist for many years, contributing to long-term waste accumulation. Furthermore, the presence of PVAc in recycling streams can complicate the recycling process for other materials.

Water pollution is another concern associated with PVAc adhesives. Improper disposal of liquid adhesive waste or cleaning solvents can contaminate water sources. Once in aquatic environments, PVAc can form microplastics that may be ingested by marine life, potentially entering the food chain.

Despite these environmental concerns, efforts are being made to mitigate the impact of PVAc adhesives. Manufacturers are developing low-VOC and water-based formulations that reduce harmful emissions. Some companies are exploring bio-based alternatives to traditional PVAc, using renewable resources as raw materials.

Recycling technologies for PVAc-bonded products are also advancing. Researchers are investigating methods to separate PVAc from other materials, enabling more efficient recycling processes. Additionally, there is growing interest in developing biodegradable adhesives that maintain the performance characteristics of PVAc while reducing environmental persistence.

As environmental regulations become more stringent, the adhesive industry is likely to continue innovating towards more sustainable PVAc formulations and application methods. This shift may include the adoption of green chemistry principles, life cycle assessments, and circular economy approaches to minimize the overall environmental footprint of PVAc adhesives.

Regulatory Landscape for Adhesive Products

The regulatory landscape for adhesive products, particularly those containing polyvinyl acetate (PVA), is complex and multifaceted. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating adhesives used in food packaging and medical devices. The FDA's 21 CFR 175.105 specifically addresses adhesives in food contact materials, setting guidelines for the safe use of PVA and other adhesive components.

The Environmental Protection Agency (EPA) also has significant oversight in this area, particularly through the Toxic Substances Control Act (TSCA). This act requires manufacturers to report new chemical substances, including novel adhesive formulations, and provides the EPA with authority to require testing of chemicals that may pose environmental or health risks.

In the European Union, the regulatory framework is even more stringent. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those in adhesives. REACH requires companies to register chemical substances and provide safety data, which has significant implications for PVA-based adhesive manufacturers.

The EU's Food Contact Materials Regulation (EC) No 1935/2004 is another critical piece of legislation, setting out requirements for materials that come into contact with food. This regulation impacts the use of PVA adhesives in food packaging and labeling applications.

Occupational safety regulations also play a role in the adhesive industry. In the US, the Occupational Safety and Health Administration (OSHA) sets standards for workplace exposure to chemicals used in adhesive manufacturing and application. Similarly, the EU's Occupational Safety and Health Framework Directive establishes principles for managing occupational safety risks associated with chemical exposure.

Globally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been widely adopted, influencing how adhesive products are labeled and how safety information is communicated. This system aims to standardize hazard classification and labeling across different countries, affecting how PVA-based adhesives are marketed and distributed internationally.

As environmental concerns grow, regulations around the disposal and recycling of adhesive products are becoming increasingly important. Many countries are implementing extended producer responsibility (EPR) programs, which could impact manufacturers of PVA adhesives, particularly in packaging applications.

The regulatory landscape is continually evolving, with increasing focus on sustainability and circular economy principles. This trend is likely to drive further regulations aimed at promoting the use of bio-based and recyclable adhesives, potentially influencing the development and application of PVA-based products in the future.

The Environmental Protection Agency (EPA) also has significant oversight in this area, particularly through the Toxic Substances Control Act (TSCA). This act requires manufacturers to report new chemical substances, including novel adhesive formulations, and provides the EPA with authority to require testing of chemicals that may pose environmental or health risks.

In the European Union, the regulatory framework is even more stringent. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those in adhesives. REACH requires companies to register chemical substances and provide safety data, which has significant implications for PVA-based adhesive manufacturers.

The EU's Food Contact Materials Regulation (EC) No 1935/2004 is another critical piece of legislation, setting out requirements for materials that come into contact with food. This regulation impacts the use of PVA adhesives in food packaging and labeling applications.

Occupational safety regulations also play a role in the adhesive industry. In the US, the Occupational Safety and Health Administration (OSHA) sets standards for workplace exposure to chemicals used in adhesive manufacturing and application. Similarly, the EU's Occupational Safety and Health Framework Directive establishes principles for managing occupational safety risks associated with chemical exposure.

Globally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been widely adopted, influencing how adhesive products are labeled and how safety information is communicated. This system aims to standardize hazard classification and labeling across different countries, affecting how PVA-based adhesives are marketed and distributed internationally.

As environmental concerns grow, regulations around the disposal and recycling of adhesive products are becoming increasingly important. Many countries are implementing extended producer responsibility (EPR) programs, which could impact manufacturers of PVA adhesives, particularly in packaging applications.

The regulatory landscape is continually evolving, with increasing focus on sustainability and circular economy principles. This trend is likely to drive further regulations aimed at promoting the use of bio-based and recyclable adhesives, potentially influencing the development and application of PVA-based products in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!