How to Control Particle Size Distribution in Polyvinyl Acetate Emulsions?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Emulsion Background and Objectives

Polyvinyl acetate (PVAc) emulsions have been a cornerstone in various industries for decades, serving as a versatile material in adhesives, paints, coatings, and textile applications. The history of PVAc emulsions dates back to the early 20th century, with significant advancements in production techniques and applications occurring throughout the years. As the demand for more specialized and high-performance materials grows, controlling the particle size distribution in PVAc emulsions has become a critical focus in research and development.

The particle size distribution in PVAc emulsions plays a crucial role in determining the final product's properties, including adhesion strength, film formation, rheology, and stability. Achieving precise control over this distribution is essential for meeting the diverse requirements of different applications and improving overall product performance. The ability to tailor particle sizes allows manufacturers to optimize emulsion properties for specific end-uses, enhancing product quality and expanding potential applications.

Recent technological advancements have opened up new possibilities for controlling particle size distribution in PVAc emulsions. These include innovations in emulsion polymerization techniques, the development of novel surfactants and stabilizers, and the integration of advanced process control systems. However, challenges remain in achieving consistent and reproducible results across different production scales and in meeting increasingly stringent performance requirements.

The primary objective of this technical research is to explore and evaluate current and emerging methods for controlling particle size distribution in PVAc emulsions. This investigation aims to identify the most promising approaches, assess their feasibility for industrial implementation, and anticipate future developments in this field. By examining various strategies, from traditional emulsion polymerization techniques to cutting-edge nanotechnology applications, we seek to provide a comprehensive overview of the state of the art in PVAc emulsion particle size control.

Furthermore, this research aims to address the growing demand for sustainable and environmentally friendly production methods. As global regulations become more stringent, there is an increasing need for PVAc emulsion production techniques that minimize environmental impact while maintaining or improving product performance. This aspect will be considered throughout the analysis, with a focus on identifying methods that align with sustainability goals without compromising on quality or efficiency.

The particle size distribution in PVAc emulsions plays a crucial role in determining the final product's properties, including adhesion strength, film formation, rheology, and stability. Achieving precise control over this distribution is essential for meeting the diverse requirements of different applications and improving overall product performance. The ability to tailor particle sizes allows manufacturers to optimize emulsion properties for specific end-uses, enhancing product quality and expanding potential applications.

Recent technological advancements have opened up new possibilities for controlling particle size distribution in PVAc emulsions. These include innovations in emulsion polymerization techniques, the development of novel surfactants and stabilizers, and the integration of advanced process control systems. However, challenges remain in achieving consistent and reproducible results across different production scales and in meeting increasingly stringent performance requirements.

The primary objective of this technical research is to explore and evaluate current and emerging methods for controlling particle size distribution in PVAc emulsions. This investigation aims to identify the most promising approaches, assess their feasibility for industrial implementation, and anticipate future developments in this field. By examining various strategies, from traditional emulsion polymerization techniques to cutting-edge nanotechnology applications, we seek to provide a comprehensive overview of the state of the art in PVAc emulsion particle size control.

Furthermore, this research aims to address the growing demand for sustainable and environmentally friendly production methods. As global regulations become more stringent, there is an increasing need for PVAc emulsion production techniques that minimize environmental impact while maintaining or improving product performance. This aspect will be considered throughout the analysis, with a focus on identifying methods that align with sustainability goals without compromising on quality or efficiency.

Market Analysis for PVAc Emulsions

The global market for polyvinyl acetate (PVAc) emulsions has been experiencing steady growth, driven by increasing demand across various industries. PVAc emulsions find extensive applications in adhesives, paints, coatings, textiles, and construction materials, contributing to their widespread adoption and market expansion.

In the adhesives sector, PVAc emulsions are widely used for wood bonding, packaging, and bookbinding applications. The growing furniture industry and increasing demand for eco-friendly adhesives have been key factors propelling market growth. The construction industry also plays a significant role in driving demand for PVAc emulsions, particularly in the production of water-based paints, sealants, and cementitious waterproofing materials.

The Asia-Pacific region has emerged as the largest market for PVAc emulsions, with China and India leading the growth. Rapid industrialization, urbanization, and infrastructure development in these countries have significantly boosted demand. North America and Europe follow as mature markets, with steady demand primarily from the construction and packaging industries.

Environmental regulations favoring water-based formulations over solvent-based alternatives have further accelerated the adoption of PVAc emulsions. This shift towards more sustainable products has opened new opportunities for market players to develop innovative, eco-friendly formulations with enhanced performance characteristics.

The market is characterized by the presence of both global chemical companies and regional manufacturers. Key players are focusing on research and development to improve product performance, particularly in terms of adhesion strength, water resistance, and durability. Innovations in controlling particle size distribution have become a critical area of focus, as it directly impacts the end-use properties of PVAc emulsions.

Market trends indicate a growing demand for customized PVAc emulsions tailored to specific applications. This has led to increased collaboration between manufacturers and end-users to develop products that meet precise requirements. Additionally, there is a rising interest in bio-based and hybrid PVAc emulsions, which offer improved sustainability profiles while maintaining or enhancing performance characteristics.

The COVID-19 pandemic initially disrupted supply chains and manufacturing activities, causing a temporary slowdown in market growth. However, the market has shown resilience, with demand rebounding as economic activities resumed. The pandemic has also accelerated certain trends, such as increased focus on hygiene and safety, potentially opening new application areas for PVAc emulsions in antimicrobial coatings and packaging materials.

In the adhesives sector, PVAc emulsions are widely used for wood bonding, packaging, and bookbinding applications. The growing furniture industry and increasing demand for eco-friendly adhesives have been key factors propelling market growth. The construction industry also plays a significant role in driving demand for PVAc emulsions, particularly in the production of water-based paints, sealants, and cementitious waterproofing materials.

The Asia-Pacific region has emerged as the largest market for PVAc emulsions, with China and India leading the growth. Rapid industrialization, urbanization, and infrastructure development in these countries have significantly boosted demand. North America and Europe follow as mature markets, with steady demand primarily from the construction and packaging industries.

Environmental regulations favoring water-based formulations over solvent-based alternatives have further accelerated the adoption of PVAc emulsions. This shift towards more sustainable products has opened new opportunities for market players to develop innovative, eco-friendly formulations with enhanced performance characteristics.

The market is characterized by the presence of both global chemical companies and regional manufacturers. Key players are focusing on research and development to improve product performance, particularly in terms of adhesion strength, water resistance, and durability. Innovations in controlling particle size distribution have become a critical area of focus, as it directly impacts the end-use properties of PVAc emulsions.

Market trends indicate a growing demand for customized PVAc emulsions tailored to specific applications. This has led to increased collaboration between manufacturers and end-users to develop products that meet precise requirements. Additionally, there is a rising interest in bio-based and hybrid PVAc emulsions, which offer improved sustainability profiles while maintaining or enhancing performance characteristics.

The COVID-19 pandemic initially disrupted supply chains and manufacturing activities, causing a temporary slowdown in market growth. However, the market has shown resilience, with demand rebounding as economic activities resumed. The pandemic has also accelerated certain trends, such as increased focus on hygiene and safety, potentially opening new application areas for PVAc emulsions in antimicrobial coatings and packaging materials.

Technical Challenges in Particle Size Control

Controlling particle size distribution in polyvinyl acetate (PVA) emulsions presents several significant technical challenges. One of the primary difficulties lies in maintaining consistent nucleation and growth rates during the emulsion polymerization process. Variations in these rates can lead to a broad or multimodal particle size distribution, which is often undesirable for many applications.

The stability of the emulsion system poses another major challenge. PVA emulsions are prone to coalescence and Ostwald ripening, processes that can alter the particle size distribution over time. Preventing these phenomena requires careful selection and optimization of surfactants and stabilizers, which must be compatible with the PVA system while providing adequate colloidal stability.

Temperature control during polymerization is crucial yet challenging. Fluctuations in temperature can significantly affect reaction kinetics and particle growth rates, leading to inconsistencies in particle size. Maintaining uniform temperature throughout the reaction vessel, especially in large-scale production, requires sophisticated heat transfer systems and precise process control.

The choice and concentration of initiators present another technical hurdle. Initiators influence the number of nucleation sites and, consequently, the final particle size distribution. Balancing initiator concentration to achieve the desired particle size while maintaining an acceptable reaction rate is a delicate process that often requires extensive experimentation and optimization.

Monomer feed rate and composition control are also critical factors. Gradual addition of monomer can help control particle growth, but maintaining a consistent feed rate and composition over extended periods can be technically challenging, especially when scaling up production.

Agitation speed and uniformity play a significant role in particle size control. Insufficient mixing can lead to localized concentration gradients and non-uniform particle growth, while excessive agitation may cause particle breakage or coalescence. Designing an agitation system that provides uniform mixing without disrupting the delicate balance of the emulsion system is a complex engineering challenge.

Lastly, the characterization and monitoring of particle size distribution in real-time during the polymerization process remain technically demanding. Current analytical techniques often require sample preparation and off-line analysis, making it difficult to implement rapid adjustments to process parameters in response to deviations from the target particle size distribution.

The stability of the emulsion system poses another major challenge. PVA emulsions are prone to coalescence and Ostwald ripening, processes that can alter the particle size distribution over time. Preventing these phenomena requires careful selection and optimization of surfactants and stabilizers, which must be compatible with the PVA system while providing adequate colloidal stability.

Temperature control during polymerization is crucial yet challenging. Fluctuations in temperature can significantly affect reaction kinetics and particle growth rates, leading to inconsistencies in particle size. Maintaining uniform temperature throughout the reaction vessel, especially in large-scale production, requires sophisticated heat transfer systems and precise process control.

The choice and concentration of initiators present another technical hurdle. Initiators influence the number of nucleation sites and, consequently, the final particle size distribution. Balancing initiator concentration to achieve the desired particle size while maintaining an acceptable reaction rate is a delicate process that often requires extensive experimentation and optimization.

Monomer feed rate and composition control are also critical factors. Gradual addition of monomer can help control particle growth, but maintaining a consistent feed rate and composition over extended periods can be technically challenging, especially when scaling up production.

Agitation speed and uniformity play a significant role in particle size control. Insufficient mixing can lead to localized concentration gradients and non-uniform particle growth, while excessive agitation may cause particle breakage or coalescence. Designing an agitation system that provides uniform mixing without disrupting the delicate balance of the emulsion system is a complex engineering challenge.

Lastly, the characterization and monitoring of particle size distribution in real-time during the polymerization process remain technically demanding. Current analytical techniques often require sample preparation and off-line analysis, making it difficult to implement rapid adjustments to process parameters in response to deviations from the target particle size distribution.

Current Particle Size Control Methods

01 Emulsion polymerization techniques for controlling particle size

Various emulsion polymerization techniques are employed to control the particle size distribution of polyvinyl acetate emulsions. These methods include adjusting monomer feed rates, surfactant concentrations, and reaction conditions to achieve desired particle sizes ranging from nanometers to micrometers.- Emulsion polymerization techniques: Various emulsion polymerization techniques are used to control the particle size distribution of polyvinyl acetate emulsions. These methods involve careful selection of initiators, surfactants, and reaction conditions to achieve desired particle sizes and distributions. The process may include seed emulsion polymerization or controlled addition of monomers to regulate particle growth.

- Particle size measurement methods: Different techniques are employed to measure and analyze the particle size distribution of polyvinyl acetate emulsions. These may include light scattering methods, microscopy, or sedimentation analysis. The choice of measurement technique can affect the reported particle size distribution and should be considered when comparing results across different studies or applications.

- Influence of reaction parameters on particle size: Various reaction parameters, such as temperature, pH, monomer concentration, and agitation speed, can significantly affect the particle size distribution of polyvinyl acetate emulsions. Controlling these parameters allows for tailoring of the emulsion properties to suit specific applications, such as adhesives, coatings, or binders.

- Stabilization of emulsion particles: Stabilizers and surfactants play a crucial role in maintaining the desired particle size distribution of polyvinyl acetate emulsions. These additives prevent particle agglomeration and coalescence, ensuring the stability of the emulsion over time. The choice and concentration of stabilizers can significantly impact the final particle size distribution.

- Applications and performance related to particle size: The particle size distribution of polyvinyl acetate emulsions greatly influences their performance in various applications. Smaller particle sizes generally lead to improved film formation, adhesion, and optical properties, while larger particles may provide better rheological control. Understanding the relationship between particle size distribution and end-use properties is crucial for optimizing emulsion formulations.

02 Use of stabilizers and surfactants

Stabilizers and surfactants play a crucial role in determining the particle size distribution of polyvinyl acetate emulsions. Proper selection and concentration of these additives help maintain emulsion stability and control particle growth during polymerization.Expand Specific Solutions03 Post-polymerization particle size modification

Various post-polymerization techniques are used to modify the particle size distribution of polyvinyl acetate emulsions. These methods include mechanical shearing, homogenization, and controlled aggregation to achieve desired particle size ranges for specific applications.Expand Specific Solutions04 Characterization methods for particle size distribution

Advanced characterization techniques are employed to analyze the particle size distribution of polyvinyl acetate emulsions. These methods include dynamic light scattering, laser diffraction, and electron microscopy, providing accurate measurements of particle sizes and their distribution within the emulsion.Expand Specific Solutions05 Influence of particle size on emulsion properties

The particle size distribution of polyvinyl acetate emulsions significantly affects their properties and performance in various applications. Smaller particle sizes generally lead to improved stability, film formation, and adhesion properties, while larger particles may offer advantages in specific use cases.Expand Specific Solutions

Key Players in PVAc Emulsion Industry

The market for controlling particle size distribution in polyvinyl acetate emulsions is in a mature stage, with established players and well-developed technologies. The global market size for polyvinyl acetate emulsions is estimated to be in the billions of dollars, driven by demand from industries such as adhesives, paints, and coatings. Technologically, the field is relatively advanced, with companies like BASF, Wacker Chemie, and Celanese leading innovation. These firms have developed sophisticated methods for controlling particle size, including emulsion polymerization techniques and advanced reactor designs. However, there is ongoing research to improve efficiency and sustainability, with companies like Kuraray and Arkema investing in new formulations and processes to meet evolving market demands.

BASF Corp.

Technical Solution: BASF employs a multi-faceted approach to control particle size distribution in polyvinyl acetate emulsions. They utilize a combination of emulsion polymerization techniques and advanced reactor designs. Their process involves carefully controlling reaction parameters such as temperature, pressure, and monomer feed rates. BASF has developed proprietary surfactant systems that help stabilize emulsion droplets and prevent coalescence during polymerization[1]. They also employ in-line particle size monitoring and feedback control systems to make real-time adjustments to reaction conditions, ensuring consistent particle size distribution throughout the production process[3].

Strengths: Precise control over particle size, consistent product quality, and scalability for industrial production. Weaknesses: Complex process control requirements and potential sensitivity to raw material variations.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed an innovative approach to control particle size distribution in polyvinyl acetate emulsions using their VINNOL® technology. Their method involves a controlled feed of monomers and initiators during the emulsion polymerization process. Wacker utilizes a unique combination of anionic and non-ionic surfactants to stabilize emulsion particles and control their growth[2]. They have also implemented advanced reactor designs with precise temperature control and agitation systems. Wacker's process includes a post-polymerization treatment step that allows for fine-tuning of the final particle size distribution[4]. This approach enables them to produce emulsions with tailored particle sizes for specific applications, such as adhesives and coatings.

Strengths: Flexibility in producing a wide range of particle sizes, high degree of control over final product properties. Weaknesses: May require specialized equipment and expertise to implement effectively.

Innovations in PVAc Emulsion Synthesis

Method for producing vinyl ester polymers having specifically settable dispersity and low polydispersity

PatentActiveUS20150057405A1

Innovation

- The process involves metering in vinyl esters and protective colloids during the initial phase of emulsion polymerization, with specific concentration ranges and addition rates of protective colloids to control particle diameters between 120 nm and 1500 nm, and maintaining low polydispersities by avoiding particle aggregation, thereby producing non-flocculated, low-residue dispersions with controllable viscosities.

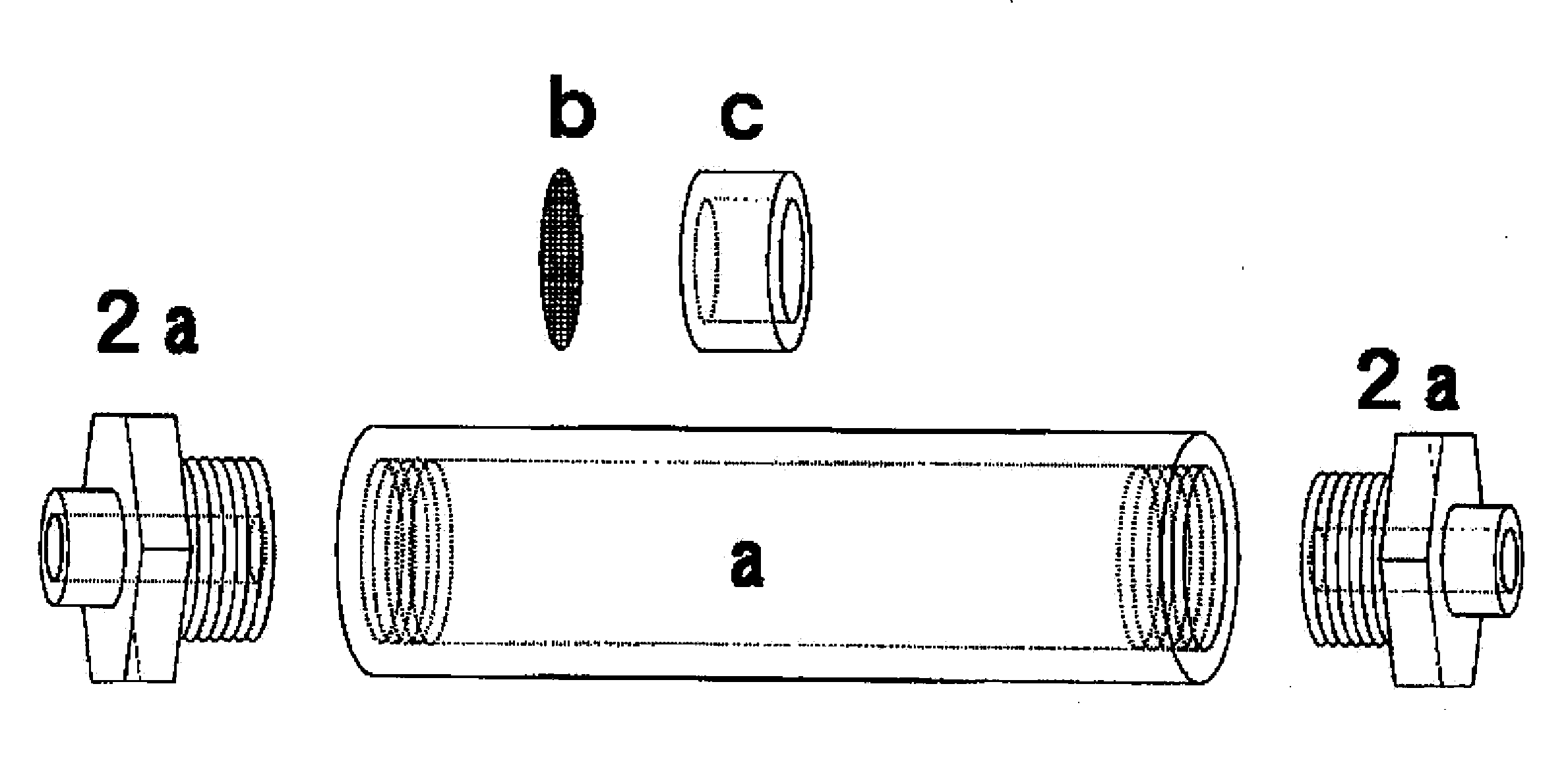

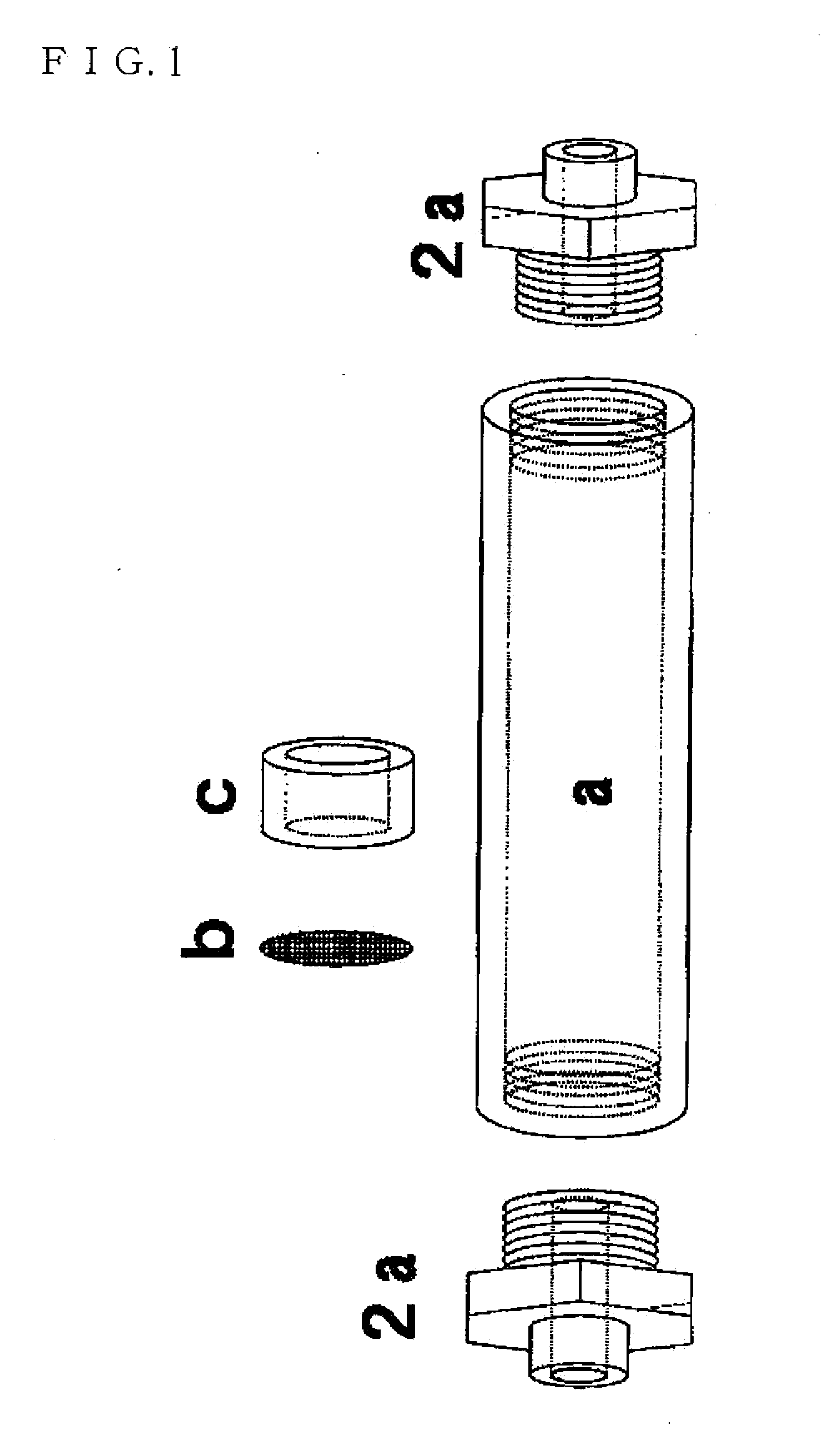

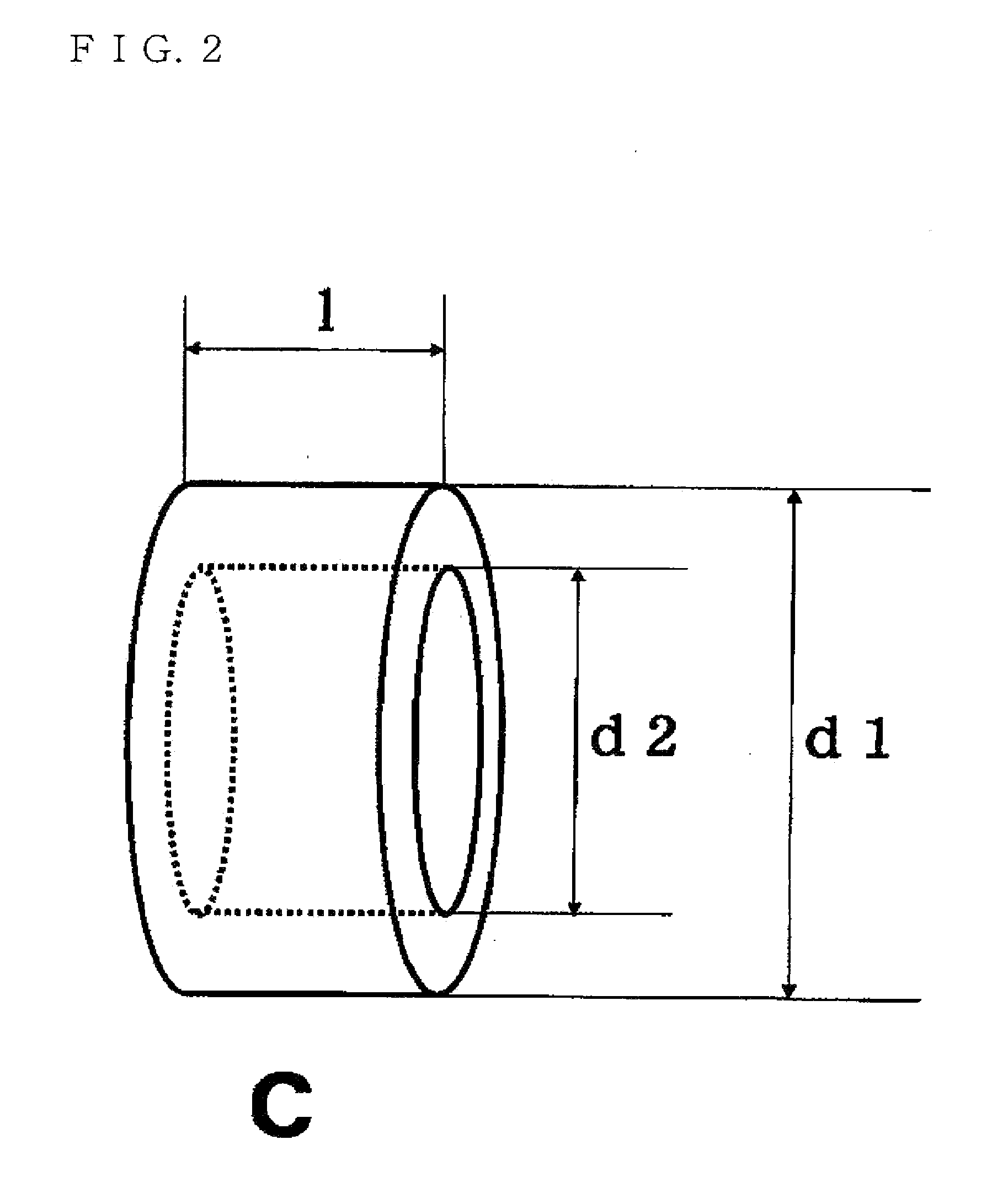

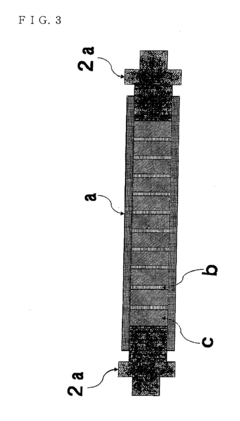

Method and apparatus for controlling particle diameter and particle diameter distribution of emulsion particles in emulsion

PatentInactiveUS20110135933A1

Innovation

- A continuous emulsification method and apparatus using a cylindrical flow passage with net bodies, such as gauzes, disposed at intervals to control particle diameter and distribution, allowing two immiscible liquids to pass through, ensuring a desired narrow particle diameter distribution.

Environmental Impact of PVAc Emulsions

The environmental impact of polyvinyl acetate (PVAc) emulsions is a critical consideration in their production and application. These emulsions, widely used in adhesives, paints, and coatings, have both direct and indirect effects on the environment throughout their lifecycle.

During the manufacturing process of PVAc emulsions, the primary environmental concerns are related to the emission of volatile organic compounds (VOCs) and the generation of wastewater. VOCs, such as residual vinyl acetate monomer, can contribute to air pollution and the formation of ground-level ozone. Proper emission control systems and process optimization are essential to minimize these releases.

Water usage and contamination are significant issues in PVAc emulsion production. The process requires substantial amounts of water, and the resulting wastewater may contain polymer residues, surfactants, and other chemicals. Effective wastewater treatment systems are necessary to prevent the release of pollutants into aquatic ecosystems.

The disposal of PVAc emulsion products at the end of their lifecycle presents another environmental challenge. While PVAc is not considered highly toxic, improper disposal can lead to soil and water contamination. Biodegradability of PVAc is limited, potentially contributing to long-term environmental persistence.

Particle size distribution in PVAc emulsions indirectly affects their environmental impact. Smaller particle sizes generally result in improved film formation and adhesion properties, potentially reducing the amount of material needed for a given application. This can lead to decreased resource consumption and waste generation.

However, the production of emulsions with finer particle sizes often requires more energy-intensive processes and may involve the use of additional chemicals. This trade-off between improved product performance and increased manufacturing impact must be carefully balanced.

The use of PVAc emulsions in various applications can have positive environmental effects. For instance, water-based PVAc emulsions used in paints and coatings have significantly lower VOC emissions compared to solvent-based alternatives, contributing to improved air quality.

Efforts to enhance the environmental profile of PVAc emulsions include the development of bio-based alternatives, using renewable raw materials to partially replace petroleum-derived components. Additionally, research into improving the biodegradability of PVAc and exploring recycling options for PVAc-containing products is ongoing.

In conclusion, while PVAc emulsions offer certain environmental advantages over alternative materials, their production and use still pose significant environmental challenges. Continued research and development in sustainable manufacturing processes, improved particle size control techniques, and end-of-life management strategies are crucial for minimizing the environmental footprint of PVAc emulsions.

During the manufacturing process of PVAc emulsions, the primary environmental concerns are related to the emission of volatile organic compounds (VOCs) and the generation of wastewater. VOCs, such as residual vinyl acetate monomer, can contribute to air pollution and the formation of ground-level ozone. Proper emission control systems and process optimization are essential to minimize these releases.

Water usage and contamination are significant issues in PVAc emulsion production. The process requires substantial amounts of water, and the resulting wastewater may contain polymer residues, surfactants, and other chemicals. Effective wastewater treatment systems are necessary to prevent the release of pollutants into aquatic ecosystems.

The disposal of PVAc emulsion products at the end of their lifecycle presents another environmental challenge. While PVAc is not considered highly toxic, improper disposal can lead to soil and water contamination. Biodegradability of PVAc is limited, potentially contributing to long-term environmental persistence.

Particle size distribution in PVAc emulsions indirectly affects their environmental impact. Smaller particle sizes generally result in improved film formation and adhesion properties, potentially reducing the amount of material needed for a given application. This can lead to decreased resource consumption and waste generation.

However, the production of emulsions with finer particle sizes often requires more energy-intensive processes and may involve the use of additional chemicals. This trade-off between improved product performance and increased manufacturing impact must be carefully balanced.

The use of PVAc emulsions in various applications can have positive environmental effects. For instance, water-based PVAc emulsions used in paints and coatings have significantly lower VOC emissions compared to solvent-based alternatives, contributing to improved air quality.

Efforts to enhance the environmental profile of PVAc emulsions include the development of bio-based alternatives, using renewable raw materials to partially replace petroleum-derived components. Additionally, research into improving the biodegradability of PVAc and exploring recycling options for PVAc-containing products is ongoing.

In conclusion, while PVAc emulsions offer certain environmental advantages over alternative materials, their production and use still pose significant environmental challenges. Continued research and development in sustainable manufacturing processes, improved particle size control techniques, and end-of-life management strategies are crucial for minimizing the environmental footprint of PVAc emulsions.

Quality Control and Characterization Techniques

Quality control and characterization techniques play a crucial role in managing particle size distribution in polyvinyl acetate emulsions. These methods ensure consistent product quality and enable manufacturers to meet specific application requirements. One of the primary techniques used is dynamic light scattering (DLS), which provides rapid and accurate measurements of particle size distribution in emulsions. DLS analyzes the fluctuations in scattered light intensity caused by Brownian motion of particles, offering real-time data on particle size and polydispersity.

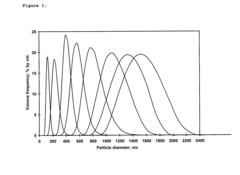

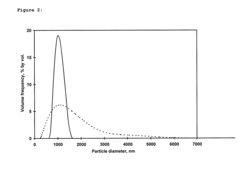

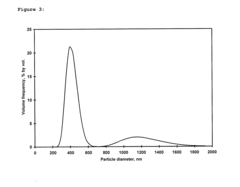

Another widely employed method is laser diffraction, which measures the angular variation in intensity of scattered light as it passes through a dispersed particulate sample. This technique is particularly useful for analyzing a wide range of particle sizes, from nanometers to millimeters, making it versatile for various polyvinyl acetate emulsion formulations. Laser diffraction provides detailed information on particle size distribution, including volume-weighted mean diameter and specific surface area.

Electron microscopy techniques, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), offer high-resolution imaging of individual particles. These methods allow for direct visualization of particle morphology, size, and aggregation state. While more time-consuming than light scattering techniques, electron microscopy provides valuable insights into particle shape and surface characteristics, which can significantly influence emulsion properties.

Rheological measurements are essential for assessing the flow behavior and stability of polyvinyl acetate emulsions. Viscosity analysis at different shear rates helps predict emulsion performance during application and storage. Additionally, oscillatory rheology tests can reveal information about the emulsion's microstructure and long-term stability, which are closely related to particle size distribution.

Zeta potential measurements are crucial for evaluating the stability of polyvinyl acetate emulsions. This technique quantifies the electrical charge on the particle surface, which influences particle-particle interactions and overall emulsion stability. A high absolute zeta potential value typically indicates good stability, as particles are less likely to aggregate or coalesce.

Particle tracking analysis (PTA) is an emerging technique that combines laser light scattering with a charge-coupled device (CCD) camera to track individual particles in real-time. This method provides both size distribution and particle concentration data, offering advantages in analyzing polydisperse samples and detecting minor populations of particles that may be overlooked by ensemble techniques.

Implementing a comprehensive quality control program that integrates these characterization techniques ensures consistent particle size distribution in polyvinyl acetate emulsions. Regular monitoring and analysis throughout the production process allow for timely adjustments to formulation or processing parameters, maintaining product quality and performance. Furthermore, combining multiple techniques provides a more complete understanding of emulsion properties, enabling manufacturers to optimize their products for specific applications and market demands.

Another widely employed method is laser diffraction, which measures the angular variation in intensity of scattered light as it passes through a dispersed particulate sample. This technique is particularly useful for analyzing a wide range of particle sizes, from nanometers to millimeters, making it versatile for various polyvinyl acetate emulsion formulations. Laser diffraction provides detailed information on particle size distribution, including volume-weighted mean diameter and specific surface area.

Electron microscopy techniques, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), offer high-resolution imaging of individual particles. These methods allow for direct visualization of particle morphology, size, and aggregation state. While more time-consuming than light scattering techniques, electron microscopy provides valuable insights into particle shape and surface characteristics, which can significantly influence emulsion properties.

Rheological measurements are essential for assessing the flow behavior and stability of polyvinyl acetate emulsions. Viscosity analysis at different shear rates helps predict emulsion performance during application and storage. Additionally, oscillatory rheology tests can reveal information about the emulsion's microstructure and long-term stability, which are closely related to particle size distribution.

Zeta potential measurements are crucial for evaluating the stability of polyvinyl acetate emulsions. This technique quantifies the electrical charge on the particle surface, which influences particle-particle interactions and overall emulsion stability. A high absolute zeta potential value typically indicates good stability, as particles are less likely to aggregate or coalesce.

Particle tracking analysis (PTA) is an emerging technique that combines laser light scattering with a charge-coupled device (CCD) camera to track individual particles in real-time. This method provides both size distribution and particle concentration data, offering advantages in analyzing polydisperse samples and detecting minor populations of particles that may be overlooked by ensemble techniques.

Implementing a comprehensive quality control program that integrates these characterization techniques ensures consistent particle size distribution in polyvinyl acetate emulsions. Regular monitoring and analysis throughout the production process allow for timely adjustments to formulation or processing parameters, maintaining product quality and performance. Furthermore, combining multiple techniques provides a more complete understanding of emulsion properties, enabling manufacturers to optimize their products for specific applications and market demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!