How to Ensure Mechanical Stability in Polyvinyl Acetate-Based Films?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Film Stability Background and Objectives

Polyvinyl acetate (PVAc) films have gained significant attention in various industries due to their versatile properties and wide range of applications. The development of PVAc-based films can be traced back to the early 20th century, with continuous advancements in polymer science and technology driving their evolution. These films have found extensive use in adhesives, coatings, and packaging materials, among other applications.

The mechanical stability of PVAc films is a critical factor that determines their performance and longevity in different environments. Over the years, researchers and industry professionals have focused on enhancing the mechanical properties of these films to meet the growing demands of various sectors. The primary objective in this field is to develop PVAc films with improved tensile strength, elongation at break, and resistance to environmental factors such as temperature and humidity.

One of the key challenges in ensuring mechanical stability of PVAc films lies in their inherent viscoelastic nature. PVAc exhibits both viscous and elastic properties, which can lead to creep and stress relaxation under prolonged load. This behavior can compromise the long-term stability and performance of PVAc-based products. Consequently, a significant portion of research efforts has been directed towards modifying the polymer structure and composition to mitigate these issues.

The technological evolution in this field has seen a shift from simple PVAc homopolymers to more complex copolymer and blend systems. These advancements aim to combine the desirable properties of PVAc with those of other polymers, resulting in films with enhanced mechanical stability. Additionally, the incorporation of various additives and fillers has emerged as a promising approach to tailor the mechanical properties of PVAc films for specific applications.

Recent trends in PVAc film technology focus on developing environmentally friendly and sustainable solutions. This includes the use of bio-based additives, exploring biodegradable PVAc formulations, and optimizing production processes to reduce environmental impact. These efforts align with the growing global emphasis on sustainable materials and manufacturing practices.

The future objectives in PVAc film stability research are multifaceted. They include developing novel crosslinking mechanisms to improve mechanical strength, exploring nanocomposite structures for enhanced stability, and leveraging advanced characterization techniques to gain deeper insights into the structure-property relationships of PVAc films. Furthermore, there is a growing interest in smart PVAc films that can adapt their mechanical properties in response to external stimuli, opening up new possibilities for advanced applications.

The mechanical stability of PVAc films is a critical factor that determines their performance and longevity in different environments. Over the years, researchers and industry professionals have focused on enhancing the mechanical properties of these films to meet the growing demands of various sectors. The primary objective in this field is to develop PVAc films with improved tensile strength, elongation at break, and resistance to environmental factors such as temperature and humidity.

One of the key challenges in ensuring mechanical stability of PVAc films lies in their inherent viscoelastic nature. PVAc exhibits both viscous and elastic properties, which can lead to creep and stress relaxation under prolonged load. This behavior can compromise the long-term stability and performance of PVAc-based products. Consequently, a significant portion of research efforts has been directed towards modifying the polymer structure and composition to mitigate these issues.

The technological evolution in this field has seen a shift from simple PVAc homopolymers to more complex copolymer and blend systems. These advancements aim to combine the desirable properties of PVAc with those of other polymers, resulting in films with enhanced mechanical stability. Additionally, the incorporation of various additives and fillers has emerged as a promising approach to tailor the mechanical properties of PVAc films for specific applications.

Recent trends in PVAc film technology focus on developing environmentally friendly and sustainable solutions. This includes the use of bio-based additives, exploring biodegradable PVAc formulations, and optimizing production processes to reduce environmental impact. These efforts align with the growing global emphasis on sustainable materials and manufacturing practices.

The future objectives in PVAc film stability research are multifaceted. They include developing novel crosslinking mechanisms to improve mechanical strength, exploring nanocomposite structures for enhanced stability, and leveraging advanced characterization techniques to gain deeper insights into the structure-property relationships of PVAc films. Furthermore, there is a growing interest in smart PVAc films that can adapt their mechanical properties in response to external stimuli, opening up new possibilities for advanced applications.

Market Analysis for Stable PVAc Films

The market for stable polyvinyl acetate (PVAc) films is experiencing significant growth, driven by increasing demand across various industries. PVAc films are widely used in packaging, construction, automotive, and consumer goods sectors due to their versatility, cost-effectiveness, and eco-friendly nature. The global PVAc market is expected to expand at a steady rate over the next five years, with a particular focus on mechanically stable films.

In the packaging industry, stable PVAc films are gaining traction as an alternative to traditional plastic materials. The food and beverage sector, in particular, is adopting these films for their excellent barrier properties and potential for biodegradability. This shift is largely influenced by growing consumer awareness of environmental issues and stringent regulations on single-use plastics in many countries.

The construction industry represents another significant market for stable PVAc films. These films are used in various applications, including adhesives, sealants, and coatings. The ongoing trend towards sustainable building materials is driving the adoption of PVAc-based products, as they offer improved durability and reduced environmental impact compared to conventional alternatives.

In the automotive sector, the demand for stable PVAc films is rising due to their application in interior components and sound dampening materials. As vehicle manufacturers focus on lightweight materials to improve fuel efficiency, PVAc films offer an attractive solution that combines performance with weight reduction.

The consumer goods industry is also contributing to the market growth of stable PVAc films. These films are used in a wide range of products, from furniture to electronics, where mechanical stability is crucial for product longevity and performance.

Geographically, Asia-Pacific is expected to be the fastest-growing market for stable PVAc films, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe remain significant markets, with a focus on innovation and development of high-performance PVAc films.

Key market challenges include the need for continuous improvement in mechanical stability and the development of cost-effective production methods. Additionally, competition from alternative materials and fluctuations in raw material prices may impact market growth.

Despite these challenges, the overall market outlook for stable PVAc films remains positive. Ongoing research and development efforts are focused on enhancing the mechanical properties of these films, which is expected to open up new application areas and drive further market expansion in the coming years.

In the packaging industry, stable PVAc films are gaining traction as an alternative to traditional plastic materials. The food and beverage sector, in particular, is adopting these films for their excellent barrier properties and potential for biodegradability. This shift is largely influenced by growing consumer awareness of environmental issues and stringent regulations on single-use plastics in many countries.

The construction industry represents another significant market for stable PVAc films. These films are used in various applications, including adhesives, sealants, and coatings. The ongoing trend towards sustainable building materials is driving the adoption of PVAc-based products, as they offer improved durability and reduced environmental impact compared to conventional alternatives.

In the automotive sector, the demand for stable PVAc films is rising due to their application in interior components and sound dampening materials. As vehicle manufacturers focus on lightweight materials to improve fuel efficiency, PVAc films offer an attractive solution that combines performance with weight reduction.

The consumer goods industry is also contributing to the market growth of stable PVAc films. These films are used in a wide range of products, from furniture to electronics, where mechanical stability is crucial for product longevity and performance.

Geographically, Asia-Pacific is expected to be the fastest-growing market for stable PVAc films, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe remain significant markets, with a focus on innovation and development of high-performance PVAc films.

Key market challenges include the need for continuous improvement in mechanical stability and the development of cost-effective production methods. Additionally, competition from alternative materials and fluctuations in raw material prices may impact market growth.

Despite these challenges, the overall market outlook for stable PVAc films remains positive. Ongoing research and development efforts are focused on enhancing the mechanical properties of these films, which is expected to open up new application areas and drive further market expansion in the coming years.

Current Challenges in PVAc Film Mechanical Stability

Polyvinyl acetate (PVAc) films face several significant challenges in maintaining mechanical stability, which hinder their widespread application in various industries. One of the primary issues is the inherent brittleness of PVAc at room temperature. This characteristic leads to poor flexibility and a tendency to crack or fracture under stress, limiting the film's durability and longevity in practical applications.

Another major challenge is the moisture sensitivity of PVAc films. When exposed to humid environments, these films tend to absorb water, leading to swelling and softening. This not only affects the dimensional stability of the film but also compromises its mechanical properties, including tensile strength and elastic modulus. The moisture-induced plasticization can result in a significant decrease in the film's overall performance and reliability.

Temperature fluctuations pose additional challenges to PVAc film stability. At elevated temperatures, PVAc films soften and lose their structural integrity, while at low temperatures, they become increasingly brittle. This temperature-dependent behavior makes it difficult to maintain consistent mechanical properties across a wide range of environmental conditions, limiting the film's applicability in diverse settings.

The aging process of PVAc films presents another hurdle in ensuring long-term mechanical stability. Over time, these films may undergo chemical changes, such as crosslinking or chain scission, which can alter their mechanical properties. This aging effect can lead to embrittlement, reduced flexibility, and decreased adhesion to substrates, compromising the film's performance and longevity.

Furthermore, the molecular weight distribution of PVAc plays a crucial role in determining the film's mechanical properties. Achieving the optimal balance between high and low molecular weight fractions is challenging but essential for obtaining films with the desired combination of strength, flexibility, and processability. Inconsistencies in molecular weight distribution can result in films with unpredictable and variable mechanical properties.

Lastly, the incorporation of additives, while often necessary to enhance certain properties, can introduce new challenges in maintaining mechanical stability. Plasticizers, for instance, are commonly used to improve flexibility, but their migration or evaporation over time can lead to changes in the film's mechanical behavior. Similarly, fillers added to modify properties such as barrier performance or cost-effectiveness may adversely affect the film's mechanical integrity if not properly dispersed or if they interfere with polymer chain interactions.

Addressing these challenges requires a multifaceted approach, combining polymer science, materials engineering, and process optimization to develop PVAc films with enhanced mechanical stability across various environmental conditions and throughout their intended service life.

Another major challenge is the moisture sensitivity of PVAc films. When exposed to humid environments, these films tend to absorb water, leading to swelling and softening. This not only affects the dimensional stability of the film but also compromises its mechanical properties, including tensile strength and elastic modulus. The moisture-induced plasticization can result in a significant decrease in the film's overall performance and reliability.

Temperature fluctuations pose additional challenges to PVAc film stability. At elevated temperatures, PVAc films soften and lose their structural integrity, while at low temperatures, they become increasingly brittle. This temperature-dependent behavior makes it difficult to maintain consistent mechanical properties across a wide range of environmental conditions, limiting the film's applicability in diverse settings.

The aging process of PVAc films presents another hurdle in ensuring long-term mechanical stability. Over time, these films may undergo chemical changes, such as crosslinking or chain scission, which can alter their mechanical properties. This aging effect can lead to embrittlement, reduced flexibility, and decreased adhesion to substrates, compromising the film's performance and longevity.

Furthermore, the molecular weight distribution of PVAc plays a crucial role in determining the film's mechanical properties. Achieving the optimal balance between high and low molecular weight fractions is challenging but essential for obtaining films with the desired combination of strength, flexibility, and processability. Inconsistencies in molecular weight distribution can result in films with unpredictable and variable mechanical properties.

Lastly, the incorporation of additives, while often necessary to enhance certain properties, can introduce new challenges in maintaining mechanical stability. Plasticizers, for instance, are commonly used to improve flexibility, but their migration or evaporation over time can lead to changes in the film's mechanical behavior. Similarly, fillers added to modify properties such as barrier performance or cost-effectiveness may adversely affect the film's mechanical integrity if not properly dispersed or if they interfere with polymer chain interactions.

Addressing these challenges requires a multifaceted approach, combining polymer science, materials engineering, and process optimization to develop PVAc films with enhanced mechanical stability across various environmental conditions and throughout their intended service life.

Existing Methods for Enhancing PVAc Film Stability

01 Copolymerization with other monomers

Improving the mechanical stability of polyvinyl acetate-based films can be achieved through copolymerization with other monomers. This process allows for the incorporation of different properties from various monomers, resulting in enhanced mechanical strength and durability of the final film.- Copolymerization with other monomers: Improving the mechanical stability of polyvinyl acetate-based films can be achieved through copolymerization with other monomers. This process modifies the polymer structure, enhancing properties such as tensile strength, flexibility, and durability. The resulting copolymers often exhibit better mechanical performance compared to pure polyvinyl acetate films.

- Plasticizer incorporation: The addition of plasticizers to polyvinyl acetate-based films can significantly improve their mechanical stability. Plasticizers increase flexibility and reduce brittleness, allowing the films to withstand mechanical stress better. Careful selection and optimization of plasticizer type and concentration are crucial for achieving the desired mechanical properties.

- Cross-linking agents: Introducing cross-linking agents into polyvinyl acetate-based films can enhance their mechanical stability. These agents form chemical bonds between polymer chains, creating a more robust network structure. This results in improved tensile strength, tear resistance, and overall durability of the films.

- Nanocomposite formulation: Incorporating nanoparticles or nanofibers into polyvinyl acetate-based films can significantly enhance their mechanical stability. These nanocomposites often exhibit improved strength, stiffness, and barrier properties compared to conventional polyvinyl acetate films. The type, size, and distribution of nanofillers play crucial roles in determining the final mechanical properties.

- Surface modification techniques: Various surface modification techniques can be applied to polyvinyl acetate-based films to improve their mechanical stability. These may include plasma treatment, chemical grafting, or the application of protective coatings. Such modifications can enhance adhesion, wear resistance, and overall durability of the films, leading to improved mechanical performance.

02 Addition of plasticizers

The incorporation of plasticizers into polyvinyl acetate-based films can significantly improve their mechanical stability. Plasticizers increase the flexibility and elongation of the films, reducing brittleness and enhancing overall durability.Expand Specific Solutions03 Cross-linking agents

The use of cross-linking agents in polyvinyl acetate-based films can greatly enhance their mechanical stability. These agents create chemical bonds between polymer chains, resulting in improved strength, hardness, and resistance to deformation.Expand Specific Solutions04 Nanocomposite reinforcement

Incorporating nanoparticles or nanofibers into polyvinyl acetate-based films can significantly improve their mechanical properties. These nanocomposites enhance the film's strength, stiffness, and resistance to tearing, resulting in improved overall mechanical stability.Expand Specific Solutions05 Optimization of film formation conditions

The mechanical stability of polyvinyl acetate-based films can be enhanced by optimizing the film formation conditions. This includes controlling factors such as temperature, humidity, and drying time during the film-forming process, which can lead to improved film structure and mechanical properties.Expand Specific Solutions

Key Players in PVAc Film Industry

The mechanical stability of polyvinyl acetate-based films is a critical issue in an industry that is currently in a mature stage, with a global market size estimated to be in the billions of dollars. The technology's maturity is evident from the involvement of major players like Kuraray Co., Ltd., BASF Corp., and Wacker Chemie AG, who have extensive experience in polymer science and film production. These companies, along with others such as Sekisui Chemical Co., Ltd. and Mitsubishi Polyester Film GmbH, are actively engaged in research and development to enhance film properties, including mechanical stability. The competitive landscape is characterized by ongoing innovation in formulation techniques, additives, and processing methods to meet the evolving demands of various applications across industries.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed advanced polyvinyl acetate (PVA) film technologies to enhance mechanical stability. Their approach involves optimizing the molecular weight distribution and degree of hydrolysis of PVA[1]. They utilize a proprietary cross-linking process that creates a more robust polymer network, significantly improving the film's tensile strength and elongation properties[2]. Additionally, Kuraray incorporates nano-scale inorganic fillers, such as silica particles, which act as reinforcing agents within the PVA matrix[3]. This nanocomposite structure enhances the film's resistance to tearing and puncture while maintaining flexibility. The company also employs a controlled drying process that minimizes internal stresses, resulting in films with improved dimensional stability and reduced curling tendencies[4].

Strengths: Superior mechanical properties, excellent barrier characteristics, and versatility in applications. Weaknesses: Higher production costs and potential limitations in extreme environmental conditions.

BASF Corp.

Technical Solution: BASF has developed a comprehensive approach to ensure mechanical stability in polyvinyl acetate-based films. Their strategy involves the use of specially designed copolymers and additives to enhance film performance[1]. BASF's technology incorporates a blend of high and low molecular weight PVA grades, optimizing the balance between strength and flexibility[2]. They have also introduced a novel plasticizer system that maintains film pliability without compromising mechanical integrity over time[3]. Furthermore, BASF employs a unique surface treatment process that improves adhesion properties and resistance to environmental factors[4]. Their films often include UV stabilizers and antioxidants to prevent degradation and maintain long-term stability[5].

Strengths: Excellent chemical resistance, good thermal stability, and broad formulation flexibility. Weaknesses: Potential higher costs and complexity in processing for some applications.

Core Innovations in PVAc Film Stabilization

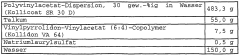

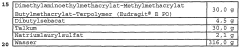

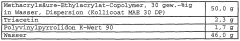

Combination of polyvinyl acetate and water-insoluble, acid-insoluble, or alkali-insoluble polymers used for the production of film coatings with highly controlled release and high stability

PatentWO2003075898A2

Innovation

- Combining polyvinyl acetate with acid- or alkali-insoluble polymers to create film coatings that adjust permeability based on pH, ensuring pH-independent drug release, enhanced mechanical stability, and reduced plasticizer usage, while maintaining flexibility and adhesion to prevent premature drug release.

Film coatings with controlled release and high stability

PatentInactiveEP1487422A2

Innovation

- Combining polyvinyl acetate with water-insoluble, acid-insoluble, or alkali-insoluble polymers to create film coatings that adjust permeability based on pH, ensuring pH-independent release and enhanced mechanical stability, while reducing plasticizer content and avoiding organic solvents.

Environmental Impact of PVAc Film Production

The production of polyvinyl acetate (PVAc) films has significant environmental implications that warrant careful consideration. The manufacturing process involves several stages, each with potential environmental impacts. The primary raw material, vinyl acetate monomer, is derived from petrochemicals, which raises concerns about resource depletion and carbon footprint. The polymerization process requires energy inputs and may release volatile organic compounds (VOCs) if not properly controlled.

Water-based PVAc emulsions, while less harmful than solvent-based alternatives, still pose challenges. The wastewater from production can contain residual monomers, additives, and other chemicals that require treatment before discharge. Improper handling or disposal of these effluents may lead to water pollution and harm aquatic ecosystems.

The use of plasticizers in PVAc films to enhance flexibility and durability introduces additional environmental concerns. Some plasticizers, particularly phthalates, have been associated with endocrine disruption and other health issues. As these additives can leach from the films over time, they may contaminate soil and water systems.

Energy consumption during film production is another significant factor. The drying and curing processes often require substantial heat input, contributing to greenhouse gas emissions if fossil fuels are the primary energy source. Implementing energy-efficient technologies and renewable energy sources can help mitigate this impact.

End-of-life considerations for PVAc films are crucial from an environmental perspective. While PVAc is biodegradable under certain conditions, the rate of degradation can be slow, potentially contributing to plastic pollution if not properly managed. Recycling PVAc films presents challenges due to contamination and the presence of additives, often resulting in downcycling rather than true recycling.

Efforts to improve the environmental profile of PVAc film production include developing bio-based alternatives to petrochemical-derived vinyl acetate, implementing closed-loop manufacturing systems to minimize waste and emissions, and exploring more environmentally friendly plasticizers. Additionally, research into enhancing the biodegradability of PVAc films without compromising their mechanical stability could lead to more sustainable product lifecycles.

The environmental impact of PVAc film production extends beyond manufacturing to include transportation and distribution. The lightweight nature of these films can reduce fuel consumption in transport compared to heavier alternatives, potentially offsetting some of the environmental costs associated with production.

Water-based PVAc emulsions, while less harmful than solvent-based alternatives, still pose challenges. The wastewater from production can contain residual monomers, additives, and other chemicals that require treatment before discharge. Improper handling or disposal of these effluents may lead to water pollution and harm aquatic ecosystems.

The use of plasticizers in PVAc films to enhance flexibility and durability introduces additional environmental concerns. Some plasticizers, particularly phthalates, have been associated with endocrine disruption and other health issues. As these additives can leach from the films over time, they may contaminate soil and water systems.

Energy consumption during film production is another significant factor. The drying and curing processes often require substantial heat input, contributing to greenhouse gas emissions if fossil fuels are the primary energy source. Implementing energy-efficient technologies and renewable energy sources can help mitigate this impact.

End-of-life considerations for PVAc films are crucial from an environmental perspective. While PVAc is biodegradable under certain conditions, the rate of degradation can be slow, potentially contributing to plastic pollution if not properly managed. Recycling PVAc films presents challenges due to contamination and the presence of additives, often resulting in downcycling rather than true recycling.

Efforts to improve the environmental profile of PVAc film production include developing bio-based alternatives to petrochemical-derived vinyl acetate, implementing closed-loop manufacturing systems to minimize waste and emissions, and exploring more environmentally friendly plasticizers. Additionally, research into enhancing the biodegradability of PVAc films without compromising their mechanical stability could lead to more sustainable product lifecycles.

The environmental impact of PVAc film production extends beyond manufacturing to include transportation and distribution. The lightweight nature of these films can reduce fuel consumption in transport compared to heavier alternatives, potentially offsetting some of the environmental costs associated with production.

Regulatory Compliance for PVAc-Based Products

Regulatory compliance is a critical aspect of developing and marketing polyvinyl acetate (PVAc) based products, including films with enhanced mechanical stability. Manufacturers must navigate a complex landscape of regulations to ensure their products meet safety, environmental, and quality standards across different markets.

In the United States, the Food and Drug Administration (FDA) regulates PVAc-based products that come into contact with food. The FDA's Code of Federal Regulations Title 21, Part 175, Subpart C specifically addresses adhesives and components of coatings, including PVAc. Manufacturers must ensure their PVAc films comply with these regulations, particularly if they are intended for food packaging applications.

The European Union has its own set of regulations for PVAc-based products. The European Food Safety Authority (EFSA) evaluates the safety of materials intended to come into contact with food, including PVAc films. Manufacturers must comply with Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food, as well as specific measures for plastic materials (Regulation (EU) No 10/2011).

Environmental regulations also play a significant role in PVAc product compliance. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in the EU requires manufacturers to register chemical substances and assess their potential risks. Similarly, the Toxic Substances Control Act (TSCA) in the US regulates the introduction of new or existing chemicals.

When developing PVAc films with improved mechanical stability, manufacturers must consider the regulatory implications of any additives or modifications. For instance, plasticizers used to enhance flexibility may be subject to specific regulations. The use of nanomaterials to improve mechanical properties must comply with emerging regulations on nanotechnology in various jurisdictions.

Occupational safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, must be considered during the manufacturing process of PVAc films. This includes proper handling of chemicals, ventilation requirements, and personal protective equipment for workers.

To ensure compliance, manufacturers should implement robust quality management systems that align with international standards such as ISO 9001. Regular testing and documentation of product properties, including mechanical stability, are essential for demonstrating compliance with relevant regulations and standards.

As regulations continue to evolve, particularly in response to environmental concerns and new scientific findings, manufacturers must stay informed and adapt their processes accordingly. This may involve participating in industry associations, engaging with regulatory bodies, and investing in ongoing research and development to meet changing compliance requirements while maintaining the desired mechanical stability of PVAc-based films.

In the United States, the Food and Drug Administration (FDA) regulates PVAc-based products that come into contact with food. The FDA's Code of Federal Regulations Title 21, Part 175, Subpart C specifically addresses adhesives and components of coatings, including PVAc. Manufacturers must ensure their PVAc films comply with these regulations, particularly if they are intended for food packaging applications.

The European Union has its own set of regulations for PVAc-based products. The European Food Safety Authority (EFSA) evaluates the safety of materials intended to come into contact with food, including PVAc films. Manufacturers must comply with Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food, as well as specific measures for plastic materials (Regulation (EU) No 10/2011).

Environmental regulations also play a significant role in PVAc product compliance. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in the EU requires manufacturers to register chemical substances and assess their potential risks. Similarly, the Toxic Substances Control Act (TSCA) in the US regulates the introduction of new or existing chemicals.

When developing PVAc films with improved mechanical stability, manufacturers must consider the regulatory implications of any additives or modifications. For instance, plasticizers used to enhance flexibility may be subject to specific regulations. The use of nanomaterials to improve mechanical properties must comply with emerging regulations on nanotechnology in various jurisdictions.

Occupational safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, must be considered during the manufacturing process of PVAc films. This includes proper handling of chemicals, ventilation requirements, and personal protective equipment for workers.

To ensure compliance, manufacturers should implement robust quality management systems that align with international standards such as ISO 9001. Regular testing and documentation of product properties, including mechanical stability, are essential for demonstrating compliance with relevant regulations and standards.

As regulations continue to evolve, particularly in response to environmental concerns and new scientific findings, manufacturers must stay informed and adapt their processes accordingly. This may involve participating in industry associations, engaging with regulatory bodies, and investing in ongoing research and development to meet changing compliance requirements while maintaining the desired mechanical stability of PVAc-based films.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!