How to Produce Eco-Conscious Products with Polyvinyl Acetate?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVA Eco-Product Background and Objectives

Polyvinyl acetate (PVA) has emerged as a versatile polymer with a wide range of applications across various industries. As environmental concerns continue to grow, there is an increasing demand for eco-conscious products that minimize their impact on the planet. The objective of this technical research report is to explore innovative approaches to produce environmentally friendly products using PVA as a key component.

The development of PVA-based eco-products is driven by the need to address global sustainability challenges. PVA's unique properties, including its biodegradability and water solubility, make it an attractive option for creating environmentally responsible alternatives to conventional materials. This research aims to investigate cutting-edge techniques and methodologies that can enhance the eco-friendliness of PVA-based products while maintaining their performance and functionality.

One of the primary goals of this study is to examine the entire lifecycle of PVA products, from raw material sourcing to end-of-life disposal. By analyzing each stage of the production process, we can identify opportunities for improvement and develop strategies to minimize environmental impact. This holistic approach will enable us to create truly sustainable solutions that align with circular economy principles.

The evolution of PVA technology has been marked by significant advancements in polymer science and manufacturing processes. From its initial discovery in the early 20th century to its current applications in adhesives, coatings, and packaging, PVA has undergone continuous refinement. This research will build upon this rich history, exploring novel techniques to further enhance the eco-credentials of PVA-based products.

A key focus of this investigation will be the development of bio-based PVA alternatives. By utilizing renewable resources as feedstock for PVA production, we can reduce reliance on fossil fuels and decrease the carbon footprint associated with these products. Additionally, we will explore innovative methods to improve the biodegradability and compostability of PVA materials, ensuring that they break down safely and efficiently in natural environments.

The potential applications for eco-conscious PVA products span numerous industries, including packaging, textiles, construction, and healthcare. This research will assess the specific requirements and challenges associated with each sector, tailoring our approach to meet diverse needs while maintaining a strong commitment to environmental stewardship.

By leveraging cutting-edge technologies and interdisciplinary collaboration, we aim to push the boundaries of what is possible in eco-friendly product design. The insights gained from this research will not only contribute to the development of more sustainable PVA-based solutions but also pave the way for broader innovations in green chemistry and materials science.

The development of PVA-based eco-products is driven by the need to address global sustainability challenges. PVA's unique properties, including its biodegradability and water solubility, make it an attractive option for creating environmentally responsible alternatives to conventional materials. This research aims to investigate cutting-edge techniques and methodologies that can enhance the eco-friendliness of PVA-based products while maintaining their performance and functionality.

One of the primary goals of this study is to examine the entire lifecycle of PVA products, from raw material sourcing to end-of-life disposal. By analyzing each stage of the production process, we can identify opportunities for improvement and develop strategies to minimize environmental impact. This holistic approach will enable us to create truly sustainable solutions that align with circular economy principles.

The evolution of PVA technology has been marked by significant advancements in polymer science and manufacturing processes. From its initial discovery in the early 20th century to its current applications in adhesives, coatings, and packaging, PVA has undergone continuous refinement. This research will build upon this rich history, exploring novel techniques to further enhance the eco-credentials of PVA-based products.

A key focus of this investigation will be the development of bio-based PVA alternatives. By utilizing renewable resources as feedstock for PVA production, we can reduce reliance on fossil fuels and decrease the carbon footprint associated with these products. Additionally, we will explore innovative methods to improve the biodegradability and compostability of PVA materials, ensuring that they break down safely and efficiently in natural environments.

The potential applications for eco-conscious PVA products span numerous industries, including packaging, textiles, construction, and healthcare. This research will assess the specific requirements and challenges associated with each sector, tailoring our approach to meet diverse needs while maintaining a strong commitment to environmental stewardship.

By leveraging cutting-edge technologies and interdisciplinary collaboration, we aim to push the boundaries of what is possible in eco-friendly product design. The insights gained from this research will not only contribute to the development of more sustainable PVA-based solutions but also pave the way for broader innovations in green chemistry and materials science.

Market Analysis for Green PVA Products

The market for eco-conscious products utilizing polyvinyl acetate (PVA) has shown significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global green PVA market is expected to expand at a compound annual growth rate of 6.8% from 2021 to 2026, reaching a value of $1.2 billion by the end of the forecast period.

Consumer demand for sustainable packaging solutions has been a key driver in this market. Industries such as food and beverage, personal care, and household products are increasingly adopting green PVA-based materials for packaging applications. These materials offer biodegradability and compostability, addressing consumer concerns about plastic pollution and aligning with corporate sustainability goals.

The construction industry has also emerged as a significant market for green PVA products. Water-based PVA adhesives and sealants are gaining traction due to their low volatile organic compound (VOC) emissions and improved indoor air quality. The shift towards green building practices and certifications like LEED has further boosted the demand for eco-friendly PVA-based construction materials.

In the textile industry, green PVA fibers are finding applications in the production of water-soluble fabrics and yarns. These materials are used in medical textiles, dissolvable laundry bags, and embroidery backings, offering both functionality and environmental benefits. The market for green PVA in textiles is projected to grow at a CAGR of 7.5% over the next five years.

Geographically, Europe leads the market for green PVA products, accounting for approximately 35% of the global market share. This is attributed to stringent environmental regulations and high consumer awareness in the region. North America follows closely, with the United States being a major contributor to market growth. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization and increasing adoption of sustainable practices.

However, the market faces challenges in terms of production costs and performance limitations compared to traditional petroleum-based alternatives. Manufacturers are investing in research and development to improve the properties of green PVA products while maintaining their eco-friendly characteristics. Innovations in bio-based and recycled PVA formulations are expected to address these challenges and further expand market opportunities.

In conclusion, the market for green PVA products shows promising growth potential across various industries. As sustainability becomes increasingly important to consumers and businesses alike, the demand for eco-conscious PVA-based solutions is expected to continue its upward trajectory, presenting significant opportunities for manufacturers and innovators in this space.

Consumer demand for sustainable packaging solutions has been a key driver in this market. Industries such as food and beverage, personal care, and household products are increasingly adopting green PVA-based materials for packaging applications. These materials offer biodegradability and compostability, addressing consumer concerns about plastic pollution and aligning with corporate sustainability goals.

The construction industry has also emerged as a significant market for green PVA products. Water-based PVA adhesives and sealants are gaining traction due to their low volatile organic compound (VOC) emissions and improved indoor air quality. The shift towards green building practices and certifications like LEED has further boosted the demand for eco-friendly PVA-based construction materials.

In the textile industry, green PVA fibers are finding applications in the production of water-soluble fabrics and yarns. These materials are used in medical textiles, dissolvable laundry bags, and embroidery backings, offering both functionality and environmental benefits. The market for green PVA in textiles is projected to grow at a CAGR of 7.5% over the next five years.

Geographically, Europe leads the market for green PVA products, accounting for approximately 35% of the global market share. This is attributed to stringent environmental regulations and high consumer awareness in the region. North America follows closely, with the United States being a major contributor to market growth. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization and increasing adoption of sustainable practices.

However, the market faces challenges in terms of production costs and performance limitations compared to traditional petroleum-based alternatives. Manufacturers are investing in research and development to improve the properties of green PVA products while maintaining their eco-friendly characteristics. Innovations in bio-based and recycled PVA formulations are expected to address these challenges and further expand market opportunities.

In conclusion, the market for green PVA products shows promising growth potential across various industries. As sustainability becomes increasingly important to consumers and businesses alike, the demand for eco-conscious PVA-based solutions is expected to continue its upward trajectory, presenting significant opportunities for manufacturers and innovators in this space.

PVA Eco-Production Challenges

The production of eco-conscious products using polyvinyl acetate (PVA) faces several significant challenges. One of the primary obstacles is the sourcing of raw materials. Traditional PVA production relies heavily on petroleum-based inputs, which are not renewable and contribute to carbon emissions. Shifting towards bio-based alternatives, such as ethanol derived from plant sources, presents technical difficulties in maintaining consistent quality and performance characteristics of the final PVA product.

Another major challenge lies in the energy-intensive nature of PVA production processes. The polymerization of vinyl acetate monomer requires substantial heat and pressure, typically generated through fossil fuel consumption. Transitioning to renewable energy sources for these processes involves significant infrastructure changes and potential disruptions to existing manufacturing setups.

Water usage and management pose additional environmental concerns. PVA production often involves substantial water consumption, both as a reaction medium and for cooling purposes. Developing closed-loop water systems and improving water treatment technologies are crucial steps towards more sustainable production, but they require substantial investment and process modifications.

The use of solvents and additives in PVA formulations presents another eco-challenge. Many conventional additives are derived from non-renewable sources and may have negative environmental impacts. Finding bio-based or less harmful alternatives that maintain the desired properties of PVA products is an ongoing research challenge.

End-of-life considerations for PVA products also present significant hurdles. While PVA is biodegradable under certain conditions, ensuring proper disposal and degradation in various environments remains problematic. Developing PVA formulations that maintain functionality during use but degrade more readily after disposal requires a delicate balance of material properties.

Scaling up eco-friendly PVA production technologies from laboratory to industrial levels presents its own set of challenges. Many promising green chemistry approaches struggle with issues of cost-effectiveness, process stability, and product consistency when implemented at larger scales. Overcoming these scaling barriers is crucial for widespread adoption of more sustainable PVA production methods.

Regulatory compliance and certification pose additional challenges for eco-conscious PVA products. Meeting stringent environmental standards while maintaining product performance and economic viability requires careful navigation of complex regulatory landscapes across different markets and regions.

Addressing these multifaceted challenges demands a holistic approach, combining innovations in green chemistry, process engineering, and supply chain management. It requires collaboration between material scientists, chemical engineers, environmental experts, and industry stakeholders to develop and implement sustainable solutions throughout the PVA product lifecycle.

Another major challenge lies in the energy-intensive nature of PVA production processes. The polymerization of vinyl acetate monomer requires substantial heat and pressure, typically generated through fossil fuel consumption. Transitioning to renewable energy sources for these processes involves significant infrastructure changes and potential disruptions to existing manufacturing setups.

Water usage and management pose additional environmental concerns. PVA production often involves substantial water consumption, both as a reaction medium and for cooling purposes. Developing closed-loop water systems and improving water treatment technologies are crucial steps towards more sustainable production, but they require substantial investment and process modifications.

The use of solvents and additives in PVA formulations presents another eco-challenge. Many conventional additives are derived from non-renewable sources and may have negative environmental impacts. Finding bio-based or less harmful alternatives that maintain the desired properties of PVA products is an ongoing research challenge.

End-of-life considerations for PVA products also present significant hurdles. While PVA is biodegradable under certain conditions, ensuring proper disposal and degradation in various environments remains problematic. Developing PVA formulations that maintain functionality during use but degrade more readily after disposal requires a delicate balance of material properties.

Scaling up eco-friendly PVA production technologies from laboratory to industrial levels presents its own set of challenges. Many promising green chemistry approaches struggle with issues of cost-effectiveness, process stability, and product consistency when implemented at larger scales. Overcoming these scaling barriers is crucial for widespread adoption of more sustainable PVA production methods.

Regulatory compliance and certification pose additional challenges for eco-conscious PVA products. Meeting stringent environmental standards while maintaining product performance and economic viability requires careful navigation of complex regulatory landscapes across different markets and regions.

Addressing these multifaceted challenges demands a holistic approach, combining innovations in green chemistry, process engineering, and supply chain management. It requires collaboration between material scientists, chemical engineers, environmental experts, and industry stakeholders to develop and implement sustainable solutions throughout the PVA product lifecycle.

Current Eco-PVA Production Methods

01 Synthesis and polymerization of polyvinyl acetate

Various methods and processes for synthesizing and polymerizing polyvinyl acetate, including different catalysts, reaction conditions, and techniques to control molecular weight and properties of the resulting polymer.- Synthesis and polymerization of polyvinyl acetate: Polyvinyl acetate is synthesized through the polymerization of vinyl acetate monomers. Various methods and conditions are employed to control the molecular weight, degree of polymerization, and properties of the resulting polymer. This process often involves the use of initiators, catalysts, and specific reaction conditions to achieve desired characteristics.

- Applications in adhesives and coatings: Polyvinyl acetate is widely used in adhesive and coating formulations due to its excellent binding properties and film-forming capabilities. It is utilized in wood glues, paper adhesives, and various coating applications. The polymer's properties can be modified through copolymerization or blending with other materials to enhance performance for specific uses.

- Emulsion polymerization techniques: Emulsion polymerization is a common method for producing polyvinyl acetate. This technique involves dispersing vinyl acetate monomers in water with the help of surfactants and initiators. The process allows for control over particle size, molecular weight distribution, and other properties of the resulting polymer emulsion.

- Modifications and copolymers: Polyvinyl acetate can be modified or copolymerized with other monomers to enhance its properties or create new materials. This includes partial hydrolysis to form polyvinyl alcohol, copolymerization with ethylene or acrylates, and grafting with other polymers. These modifications allow for tailoring the polymer's characteristics for specific applications.

- Environmental and safety considerations: Research and development efforts focus on improving the environmental profile and safety of polyvinyl acetate production and use. This includes developing low-VOC formulations, exploring bio-based alternatives, and enhancing the biodegradability of polyvinyl acetate products. Additionally, efforts are made to reduce the use of harmful solvents and improve workplace safety in manufacturing processes.

02 Polyvinyl acetate compositions and formulations

Development of polyvinyl acetate-based compositions and formulations for various applications, including adhesives, coatings, and films. These formulations may include additives, plasticizers, or other polymers to enhance specific properties.Expand Specific Solutions03 Modification and copolymerization of polyvinyl acetate

Techniques for modifying polyvinyl acetate or copolymerizing it with other monomers to create new materials with improved or tailored properties for specific applications.Expand Specific Solutions04 Polyvinyl acetate in emulsion and dispersion systems

Preparation and characterization of polyvinyl acetate emulsions and dispersions, including methods to control particle size, stability, and rheological properties for various industrial applications.Expand Specific Solutions05 Applications of polyvinyl acetate in various industries

Exploration of diverse applications of polyvinyl acetate in industries such as construction, packaging, textiles, and pharmaceuticals, highlighting its versatility and adaptability to different use cases.Expand Specific Solutions

Key Players in Eco-PVA Industry

The eco-conscious polyvinyl acetate (PVA) product market is in a growth phase, driven by increasing environmental awareness and regulatory pressures. The global market size for eco-friendly PVA is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Kuraray, Celanese, and Wacker Chemie leading innovation. These firms are developing bio-based PVA formulations and improving production processes to reduce environmental impact. Emerging players such as Chengdu Caver Technology and Velocys are also contributing to technological advancements, focusing on sustainable production methods and novel applications for eco-conscious PVA products.

Celanese International Corp.

Technical Solution: Celanese has developed a range of sustainable polyvinyl acetate emulsions under their EcoVAE® brand. These products are formulated with up to 20% renewable content derived from plant-based feedstocks, reducing reliance on fossil fuels[4]. The company employs a low-VOC (Volatile Organic Compound) manufacturing process, minimizing environmental impact. Celanese's eco-conscious PVA products feature improved adhesion properties and faster setting times, making them suitable for various applications such as wood glues, packaging adhesives, and paper coatings[5]. They have also implemented energy-efficient production methods and waste reduction strategies to further enhance the sustainability of their PVA offerings[6].

Strengths: High renewable content, low-VOC production, and versatile application range. Weaknesses: Limited to 20% renewable content, potential cost implications for high-performance applications.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed eco-friendly polyvinyl acetate (PVA) solutions for various applications. Their EXCEVAL™ series of PVA resins are designed for improved biodegradability and reduced environmental impact[1]. The company utilizes a water-based production process, significantly reducing organic solvent emissions. They have also implemented a closed-loop recycling system for PVA, allowing for the recovery and reuse of the material in production[2]. Kuraray's approach includes the use of bio-based raw materials and the optimization of energy consumption during manufacturing, resulting in a lower carbon footprint for their PVA products[3].

Strengths: Advanced biodegradable PVA formulations, closed-loop recycling system, and use of bio-based materials. Weaknesses: Potentially higher production costs and limited applications compared to traditional PVA.

Innovative PVA Eco-Technologies

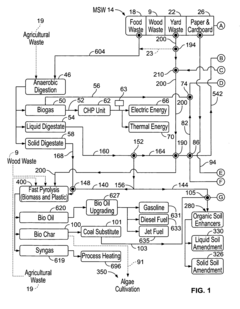

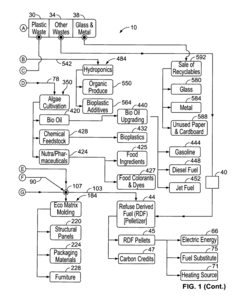

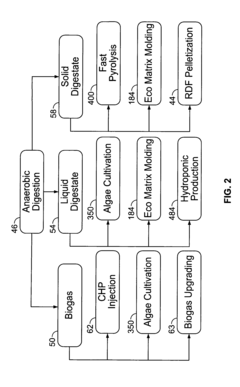

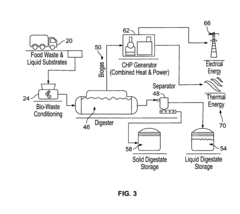

Apparatus and method for generating eco-conscious products from waste

PatentInactiveUS20150118723A1

Innovation

- An apparatus and method that utilizes an anaerobic digester to process waste, producing anaerobic products which are then conveyed to eco-assemblies such as eco-matrix molders, algae cultivators, fast-pyrolysis systems, RDF pelletizers, and hydroponic apparatuses to generate eco-conscious products like organic composites, biofuels, and soil enhancers, all while avoiding the introduction of outside air to minimize environmental impact.

Method for producing polyvinylacetals

PatentWO2004026917A1

Innovation

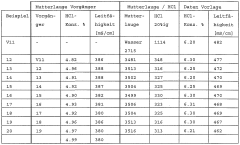

- A process where polyvinyl alcohol is acetalized in an aqueous medium with reused mother liquor from a previous batch, adjusting the pH and adding aldehydes to initiate precipitation, allowing for the reuse of up to 100% of the filtrate as the aqueous medium, thereby reducing waste and conserving raw materials.

Environmental Regulations for PVA

The production of eco-conscious products using Polyvinyl Acetate (PVA) is subject to a complex web of environmental regulations that vary across regions and jurisdictions. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating PVA production and usage under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to report new uses of PVA and conduct environmental and health assessments before introducing new PVA-based products to the market.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, companies producing or importing PVA in quantities exceeding one tonne per year must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information. This regulation aims to ensure the protection of human health and the environment from potential risks associated with chemical substances.

In Asia, countries like China and Japan have also established their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the Measures for Environmental Management of New Chemical Substances, which requires manufacturers to obtain approval before producing or importing new PVA-based materials. Japan's Chemical Substances Control Law (CSCL) similarly regulates the manufacture, import, and use of PVA and its derivatives.

Global initiatives, such as the United Nations' Strategic Approach to International Chemicals Management (SAICM), provide guidelines for the sustainable management of chemicals throughout their lifecycle. These initiatives encourage the adoption of green chemistry principles in PVA production, promoting the use of renewable resources and minimizing environmental impact.

Regulations often focus on specific aspects of PVA production and use. For instance, many jurisdictions have implemented restrictions on volatile organic compound (VOC) emissions associated with PVA-based adhesives and coatings. This has led to the development of low-VOC and zero-VOC formulations to comply with air quality standards.

Water pollution control is another critical area of regulation. Effluent guidelines set by environmental agencies limit the discharge of PVA and its byproducts into water bodies. Manufacturers are required to implement wastewater treatment systems and adopt closed-loop processes to minimize environmental contamination.

As sustainability becomes increasingly important, regulations are evolving to promote the circular economy. Extended Producer Responsibility (EPR) schemes in various countries mandate that manufacturers take responsibility for the entire lifecycle of their PVA products, including collection and recycling at the end of use. This approach encourages the development of more easily recyclable PVA formulations and the establishment of efficient recycling infrastructure.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, companies producing or importing PVA in quantities exceeding one tonne per year must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information. This regulation aims to ensure the protection of human health and the environment from potential risks associated with chemical substances.

In Asia, countries like China and Japan have also established their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the Measures for Environmental Management of New Chemical Substances, which requires manufacturers to obtain approval before producing or importing new PVA-based materials. Japan's Chemical Substances Control Law (CSCL) similarly regulates the manufacture, import, and use of PVA and its derivatives.

Global initiatives, such as the United Nations' Strategic Approach to International Chemicals Management (SAICM), provide guidelines for the sustainable management of chemicals throughout their lifecycle. These initiatives encourage the adoption of green chemistry principles in PVA production, promoting the use of renewable resources and minimizing environmental impact.

Regulations often focus on specific aspects of PVA production and use. For instance, many jurisdictions have implemented restrictions on volatile organic compound (VOC) emissions associated with PVA-based adhesives and coatings. This has led to the development of low-VOC and zero-VOC formulations to comply with air quality standards.

Water pollution control is another critical area of regulation. Effluent guidelines set by environmental agencies limit the discharge of PVA and its byproducts into water bodies. Manufacturers are required to implement wastewater treatment systems and adopt closed-loop processes to minimize environmental contamination.

As sustainability becomes increasingly important, regulations are evolving to promote the circular economy. Extended Producer Responsibility (EPR) schemes in various countries mandate that manufacturers take responsibility for the entire lifecycle of their PVA products, including collection and recycling at the end of use. This approach encourages the development of more easily recyclable PVA formulations and the establishment of efficient recycling infrastructure.

Life Cycle Assessment of PVA Products

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of Polyvinyl Acetate (PVA) products throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to disposal or recycling, providing valuable insights into the eco-consciousness of PVA-based products.

The production phase of PVA products typically begins with the synthesis of vinyl acetate monomer from ethylene and acetic acid. This process requires significant energy input and may involve the use of catalysts, which can have environmental implications. The polymerization of vinyl acetate to form PVA is generally less energy-intensive but still contributes to the overall environmental footprint.

During the use phase, PVA products often demonstrate favorable environmental characteristics. Many PVA-based adhesives, coatings, and films are water-soluble and biodegradable, reducing their long-term environmental impact. However, the durability and performance of these products in various applications must be carefully balanced against their eco-friendly properties.

End-of-life considerations for PVA products are generally positive from an environmental perspective. The biodegradability of PVA means that many products can be composted or will naturally degrade in the environment without leaving persistent pollutants. However, the rate and completeness of biodegradation can vary depending on environmental conditions and product formulations.

LCA studies on PVA products have revealed several key areas for improvement in eco-consciousness. These include optimizing energy efficiency in the production process, exploring renewable feedstocks for vinyl acetate monomer synthesis, and developing more efficient recycling and recovery methods for PVA-containing waste streams.

Water consumption and wastewater treatment are significant factors in the LCA of PVA products. While PVA itself is not toxic to aquatic life, the high biochemical oxygen demand (BOD) associated with its biodegradation in water systems must be carefully managed to prevent ecosystem disruption.

Transportation and packaging also contribute to the overall environmental impact of PVA products. Optimizing logistics and using eco-friendly packaging materials can help reduce the carbon footprint associated with product distribution.

By conducting thorough LCAs, manufacturers can identify hotspots in the environmental profile of their PVA products and implement targeted improvements. This may involve redesigning products for easier recycling, incorporating bio-based components, or adopting cleaner production technologies. Such assessments are essential for developing truly eco-conscious PVA products that minimize environmental impact across their entire lifecycle.

The production phase of PVA products typically begins with the synthesis of vinyl acetate monomer from ethylene and acetic acid. This process requires significant energy input and may involve the use of catalysts, which can have environmental implications. The polymerization of vinyl acetate to form PVA is generally less energy-intensive but still contributes to the overall environmental footprint.

During the use phase, PVA products often demonstrate favorable environmental characteristics. Many PVA-based adhesives, coatings, and films are water-soluble and biodegradable, reducing their long-term environmental impact. However, the durability and performance of these products in various applications must be carefully balanced against their eco-friendly properties.

End-of-life considerations for PVA products are generally positive from an environmental perspective. The biodegradability of PVA means that many products can be composted or will naturally degrade in the environment without leaving persistent pollutants. However, the rate and completeness of biodegradation can vary depending on environmental conditions and product formulations.

LCA studies on PVA products have revealed several key areas for improvement in eco-consciousness. These include optimizing energy efficiency in the production process, exploring renewable feedstocks for vinyl acetate monomer synthesis, and developing more efficient recycling and recovery methods for PVA-containing waste streams.

Water consumption and wastewater treatment are significant factors in the LCA of PVA products. While PVA itself is not toxic to aquatic life, the high biochemical oxygen demand (BOD) associated with its biodegradation in water systems must be carefully managed to prevent ecosystem disruption.

Transportation and packaging also contribute to the overall environmental impact of PVA products. Optimizing logistics and using eco-friendly packaging materials can help reduce the carbon footprint associated with product distribution.

By conducting thorough LCAs, manufacturers can identify hotspots in the environmental profile of their PVA products and implement targeted improvements. This may involve redesigning products for easier recycling, incorporating bio-based components, or adopting cleaner production technologies. Such assessments are essential for developing truly eco-conscious PVA products that minimize environmental impact across their entire lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!