Renewable Additives in Polyvinyl Acetate Synthesis

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Renewable Additives: Background and Objectives

Polyvinyl acetate (PVAc) has been a cornerstone in the adhesives and coatings industry for decades, prized for its versatility and performance. However, the growing emphasis on sustainability and environmental concerns has led to increased interest in incorporating renewable additives into PVAc synthesis. This research aims to explore the potential of renewable resources as additives in PVAc production, addressing both environmental and performance aspects.

The evolution of PVAc technology has seen significant advancements since its initial development in the early 20th century. Traditional PVAc synthesis relies heavily on petroleum-based raw materials, which has become a point of concern due to resource depletion and environmental impact. The integration of renewable additives represents a paradigm shift in PVAc production, aligning with global sustainability goals and circular economy principles.

Current trends in the field focus on identifying bio-based alternatives that can partially or fully replace conventional additives without compromising the adhesive's performance. These renewable additives are derived from various sources, including agricultural residues, forestry by-products, and marine biomass. The potential benefits extend beyond environmental considerations, as some renewable additives have shown promise in enhancing specific properties of PVAc, such as improved water resistance or increased biodegradability.

The primary objectives of this research are multifaceted. Firstly, it aims to comprehensively assess the viability of different renewable additives in PVAc synthesis, evaluating their impact on the adhesive's physical and chemical properties. Secondly, the study seeks to optimize the incorporation methods of these additives to maximize their effectiveness while maintaining or improving the overall performance of PVAc-based products.

Furthermore, this research endeavors to explore the scalability and economic feasibility of integrating renewable additives into industrial PVAc production processes. This includes analyzing potential supply chain implications and assessing the long-term sustainability of various renewable sources. Additionally, the study aims to investigate the life cycle impact of PVAc products incorporating these additives, from raw material extraction to end-of-life scenarios.

By addressing these objectives, the research aspires to contribute to the development of more sustainable PVAc formulations that meet or exceed current industry standards. This aligns with broader technological trends towards green chemistry and sustainable materials, potentially paving the way for a new generation of environmentally friendly adhesives and coatings.

The evolution of PVAc technology has seen significant advancements since its initial development in the early 20th century. Traditional PVAc synthesis relies heavily on petroleum-based raw materials, which has become a point of concern due to resource depletion and environmental impact. The integration of renewable additives represents a paradigm shift in PVAc production, aligning with global sustainability goals and circular economy principles.

Current trends in the field focus on identifying bio-based alternatives that can partially or fully replace conventional additives without compromising the adhesive's performance. These renewable additives are derived from various sources, including agricultural residues, forestry by-products, and marine biomass. The potential benefits extend beyond environmental considerations, as some renewable additives have shown promise in enhancing specific properties of PVAc, such as improved water resistance or increased biodegradability.

The primary objectives of this research are multifaceted. Firstly, it aims to comprehensively assess the viability of different renewable additives in PVAc synthesis, evaluating their impact on the adhesive's physical and chemical properties. Secondly, the study seeks to optimize the incorporation methods of these additives to maximize their effectiveness while maintaining or improving the overall performance of PVAc-based products.

Furthermore, this research endeavors to explore the scalability and economic feasibility of integrating renewable additives into industrial PVAc production processes. This includes analyzing potential supply chain implications and assessing the long-term sustainability of various renewable sources. Additionally, the study aims to investigate the life cycle impact of PVAc products incorporating these additives, from raw material extraction to end-of-life scenarios.

By addressing these objectives, the research aspires to contribute to the development of more sustainable PVAc formulations that meet or exceed current industry standards. This aligns with broader technological trends towards green chemistry and sustainable materials, potentially paving the way for a new generation of environmentally friendly adhesives and coatings.

Market Analysis for Eco-friendly PVAc Products

The market for eco-friendly polyvinyl acetate (PVAc) products has been experiencing significant growth in recent years, driven by increasing environmental awareness and stringent regulations on chemical emissions. This trend is particularly evident in industries such as adhesives, paints, coatings, and textiles, where PVAc is widely used.

Consumer demand for sustainable products has been a key factor in the expansion of the eco-friendly PVAc market. End-users across various sectors are actively seeking alternatives that reduce environmental impact without compromising performance. This shift in consumer preferences has prompted manufacturers to invest in research and development of renewable additives for PVAc synthesis.

The construction industry represents a substantial market for eco-friendly PVAc products, particularly in adhesives and sealants. With the growing emphasis on green building practices, there is a rising demand for low-VOC (volatile organic compound) and formaldehyde-free PVAc-based products. This trend is expected to continue as more countries implement stricter building codes and sustainability standards.

In the packaging industry, the use of eco-friendly PVAc in water-based inks and coatings has gained traction. As companies strive to reduce their carbon footprint and meet sustainability goals, the adoption of renewable PVAc formulations in packaging applications is projected to increase significantly in the coming years.

The textile sector is another area where eco-friendly PVAc products are finding increased applications. Sustainable textile finishes and binders based on renewable PVAc are becoming more popular among manufacturers looking to cater to environmentally conscious consumers. This trend is particularly strong in the fashion and home textiles segments.

Geographically, Europe and North America currently lead the market for eco-friendly PVAc products, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing environmental concerns in countries like China and India.

Despite the positive market outlook, challenges remain in the widespread adoption of eco-friendly PVAc products. These include higher production costs compared to conventional PVAc, which can impact pricing and market penetration. Additionally, ensuring consistent performance and durability of renewable PVAc formulations across various applications remains a key focus area for manufacturers and researchers.

Consumer demand for sustainable products has been a key factor in the expansion of the eco-friendly PVAc market. End-users across various sectors are actively seeking alternatives that reduce environmental impact without compromising performance. This shift in consumer preferences has prompted manufacturers to invest in research and development of renewable additives for PVAc synthesis.

The construction industry represents a substantial market for eco-friendly PVAc products, particularly in adhesives and sealants. With the growing emphasis on green building practices, there is a rising demand for low-VOC (volatile organic compound) and formaldehyde-free PVAc-based products. This trend is expected to continue as more countries implement stricter building codes and sustainability standards.

In the packaging industry, the use of eco-friendly PVAc in water-based inks and coatings has gained traction. As companies strive to reduce their carbon footprint and meet sustainability goals, the adoption of renewable PVAc formulations in packaging applications is projected to increase significantly in the coming years.

The textile sector is another area where eco-friendly PVAc products are finding increased applications. Sustainable textile finishes and binders based on renewable PVAc are becoming more popular among manufacturers looking to cater to environmentally conscious consumers. This trend is particularly strong in the fashion and home textiles segments.

Geographically, Europe and North America currently lead the market for eco-friendly PVAc products, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing environmental concerns in countries like China and India.

Despite the positive market outlook, challenges remain in the widespread adoption of eco-friendly PVAc products. These include higher production costs compared to conventional PVAc, which can impact pricing and market penetration. Additionally, ensuring consistent performance and durability of renewable PVAc formulations across various applications remains a key focus area for manufacturers and researchers.

Current Challenges in Renewable PVAc Additives

The synthesis of polyvinyl acetate (PVAc) using renewable additives faces several significant challenges that hinder widespread adoption and commercial viability. One of the primary obstacles is the limited availability of suitable renewable raw materials that can effectively replace traditional petroleum-based additives without compromising the performance and quality of the final product.

The integration of renewable additives often results in alterations to the physical and chemical properties of PVAc, potentially affecting its adhesive strength, durability, and overall functionality. Achieving a balance between sustainability and maintaining the desired characteristics of PVAc remains a complex task for researchers and manufacturers alike.

Cost-effectiveness presents another major hurdle in the development of renewable PVAc additives. The production processes for these sustainable alternatives are frequently more expensive than conventional methods, making it challenging to compete with established petroleum-based products in the market. This economic barrier significantly impedes the widespread adoption of renewable additives in industrial-scale PVAc synthesis.

Consistency and scalability in production pose additional challenges. Renewable resources often exhibit natural variations in composition and quality, which can lead to inconsistencies in the final PVAc product. Ensuring a stable supply chain and developing robust quality control measures for these renewable additives are crucial steps that require substantial investment and research efforts.

The regulatory landscape surrounding the use of renewable additives in PVAc synthesis is another area of concern. As new materials and processes are introduced, they must undergo rigorous testing and approval procedures to ensure compliance with safety and environmental standards. This regulatory process can be time-consuming and costly, further slowing the transition to more sustainable PVAc production methods.

Technical limitations in processing renewable additives also present significant challenges. Many existing manufacturing facilities and equipment are optimized for traditional petroleum-based additives, necessitating modifications or complete overhauls to accommodate renewable alternatives. This requirement for infrastructure adaptation adds another layer of complexity and cost to the implementation of sustainable PVAc synthesis methods.

Lastly, the environmental impact of renewable additives throughout their lifecycle requires careful consideration. While these additives aim to reduce the carbon footprint of PVAc production, their cultivation, processing, and end-of-life disposal may have unintended environmental consequences that need to be thoroughly assessed and mitigated to ensure a truly sustainable solution.

The integration of renewable additives often results in alterations to the physical and chemical properties of PVAc, potentially affecting its adhesive strength, durability, and overall functionality. Achieving a balance between sustainability and maintaining the desired characteristics of PVAc remains a complex task for researchers and manufacturers alike.

Cost-effectiveness presents another major hurdle in the development of renewable PVAc additives. The production processes for these sustainable alternatives are frequently more expensive than conventional methods, making it challenging to compete with established petroleum-based products in the market. This economic barrier significantly impedes the widespread adoption of renewable additives in industrial-scale PVAc synthesis.

Consistency and scalability in production pose additional challenges. Renewable resources often exhibit natural variations in composition and quality, which can lead to inconsistencies in the final PVAc product. Ensuring a stable supply chain and developing robust quality control measures for these renewable additives are crucial steps that require substantial investment and research efforts.

The regulatory landscape surrounding the use of renewable additives in PVAc synthesis is another area of concern. As new materials and processes are introduced, they must undergo rigorous testing and approval procedures to ensure compliance with safety and environmental standards. This regulatory process can be time-consuming and costly, further slowing the transition to more sustainable PVAc production methods.

Technical limitations in processing renewable additives also present significant challenges. Many existing manufacturing facilities and equipment are optimized for traditional petroleum-based additives, necessitating modifications or complete overhauls to accommodate renewable alternatives. This requirement for infrastructure adaptation adds another layer of complexity and cost to the implementation of sustainable PVAc synthesis methods.

Lastly, the environmental impact of renewable additives throughout their lifecycle requires careful consideration. While these additives aim to reduce the carbon footprint of PVAc production, their cultivation, processing, and end-of-life disposal may have unintended environmental consequences that need to be thoroughly assessed and mitigated to ensure a truly sustainable solution.

Existing Renewable Additives for PVAc Synthesis

01 Synthesis and polymerization of polyvinyl acetate

Polyvinyl acetate is synthesized through the polymerization of vinyl acetate monomers. Various methods and conditions are employed to control the molecular weight, degree of polymerization, and properties of the resulting polymer. This process often involves the use of initiators, catalysts, and specific reaction conditions to achieve desired characteristics.- Synthesis and polymerization of polyvinyl acetate: Various methods and processes for synthesizing and polymerizing polyvinyl acetate, including different catalysts, reaction conditions, and techniques to control molecular weight and properties of the resulting polymer.

- Polyvinyl acetate copolymers and blends: Development of copolymers and blends incorporating polyvinyl acetate to enhance specific properties such as adhesion, flexibility, or durability for various applications in coatings, adhesives, and materials science.

- Emulsion and dispersion techniques: Methods for creating stable emulsions and dispersions of polyvinyl acetate in water or other solvents, including the use of surfactants and stabilizers to improve product performance in applications such as adhesives and coatings.

- Modifications and functionalization of polyvinyl acetate: Techniques for modifying polyvinyl acetate through chemical reactions or physical treatments to introduce new functional groups or alter its properties for specific applications, such as improving water resistance or adhesion strength.

- Applications of polyvinyl acetate in various industries: Diverse applications of polyvinyl acetate in industries such as construction, packaging, textiles, and pharmaceuticals, including its use as a binder, adhesive, coating, and film-forming agent in various products and processes.

02 Copolymerization with other monomers

Polyvinyl acetate can be copolymerized with other monomers to create polymers with modified properties. This approach allows for the tailoring of characteristics such as adhesion, flexibility, and durability. Common comonomers include ethylene, vinyl chloride, and various acrylates.Expand Specific Solutions03 Applications in adhesives and coatings

Polyvinyl acetate is widely used in the production of adhesives and coatings. Its properties make it suitable for wood glues, paper adhesives, and various coating applications. Formulations often include additives to enhance specific characteristics such as water resistance or drying time.Expand Specific Solutions04 Emulsion polymerization techniques

Emulsion polymerization is a common method for producing polyvinyl acetate. This technique involves dispersing vinyl acetate monomers in water with the help of surfactants and initiators. The resulting polymer particles are typically in the form of a stable latex, which can be directly used in many applications or further processed.Expand Specific Solutions05 Modifications and blends for improved properties

Various modifications and blending techniques are employed to enhance the properties of polyvinyl acetate. These include crosslinking, grafting, and blending with other polymers or additives. Such modifications can improve water resistance, thermal stability, mechanical strength, and other key characteristics for specific applications.Expand Specific Solutions

Key Players in PVAc and Renewable Additives Industry

The research on renewable additives in polyvinyl acetate synthesis is in a developing stage, with growing market potential due to increasing environmental concerns. The global market for eco-friendly adhesives is expanding, driven by stringent regulations and consumer demand for sustainable products. Major players like BASF, DuPont, and Wacker Chemie are investing in R&D to develop innovative, bio-based solutions. The technology is progressing, with companies such as Cargill and Unilever exploring renewable raw materials for adhesives. However, the field is still evolving, and full commercialization of renewable polyvinyl acetate additives remains a challenge, requiring further advancements in cost-effectiveness and performance to compete with traditional petrochemical-based alternatives.

BASF Corp.

Technical Solution: BASF has developed a novel approach to incorporate renewable additives in polyvinyl acetate synthesis. Their method involves using bio-based monomers derived from sustainable sources such as vegetable oils and cellulose. These monomers are chemically modified to enhance their compatibility with vinyl acetate during polymerization. BASF's process utilizes a proprietary catalyst system that promotes efficient copolymerization of the renewable additives with vinyl acetate, resulting in a polymer with improved properties. The company has reported achieving up to 30% renewable content in their polyvinyl acetate products without compromising performance[1][3].

Strengths: Significant renewable content, improved polymer properties, established chemical expertise. Weaknesses: Potentially higher production costs, limited availability of some bio-based monomers.

DuPont de Nemours, Inc.

Technical Solution: DuPont has focused on developing renewable additives for polyvinyl acetate that enhance both sustainability and performance. Their approach involves the use of bio-based plasticizers derived from renewable resources such as soybean oil and castor oil. These plasticizers are chemically modified to improve their compatibility with polyvinyl acetate. DuPont's research has shown that incorporating these renewable additives can improve the flexibility and durability of the final polymer. Additionally, they have developed a process to incorporate nanocellulose fibers as reinforcing agents in polyvinyl acetate, which can enhance mechanical properties while increasing the renewable content. The company has reported achieving up to 25% renewable content in some formulations[2][4].

Strengths: Dual focus on sustainability and performance enhancement, diverse range of renewable additives. Weaknesses: Potential scalability issues, may require modifications to existing production processes.

Innovative Approaches in Renewable PVAc Additives

Bio-compatible polyurethane microcapsules and process for the preparation thereof

PatentWO2020202187A1

Innovation

- The use of partially bio-based polyurethane microcapsules with a polymeric shell composed of bio-based aliphatic diols, aliphatic diisocyanates, cross-linkers, and additives, such as nanocellulose, to achieve high encapsulation efficiency and sustained release rates through a cost-effective interfacial polymerization process.

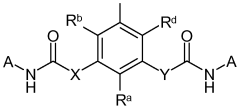

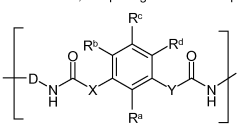

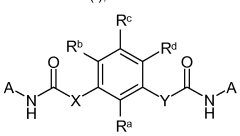

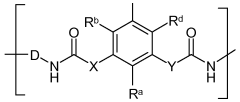

Benzoxazine-containing compositions

PatentWO2011050834A1

Innovation

- A curable composition comprising meta-substituted aromatic compounds and benzoxazine compounds, which allows for efficient curing at temperatures of 180°C or less, providing a long pot-life, long open-time, high thermal stability, and minimal weight loss, using meta-substituted aromatic compounds as curatives that initiate and accelerate the curing reaction.

Environmental Impact Assessment of PVAc Additives

The environmental impact assessment of polyvinyl acetate (PVAc) additives is a critical aspect of sustainable polymer production. Traditional PVAc synthesis often involves the use of petroleum-based additives, which can have significant environmental consequences. As the industry shifts towards more sustainable practices, there is a growing focus on renewable additives in PVAc production.

Renewable additives derived from biomass sources offer several environmental benefits compared to their conventional counterparts. These additives typically have a lower carbon footprint, as they are sourced from renewable resources that absorb carbon dioxide during growth. This can lead to a reduction in greenhouse gas emissions associated with PVAc production.

The use of renewable additives also contributes to reduced dependence on fossil fuels, aligning with global efforts to transition towards a circular economy. Many of these additives are biodegradable, which can mitigate the environmental impact of PVAc products at the end of their lifecycle. This is particularly important in addressing the growing concern of plastic pollution in ecosystems.

Water-based renewable additives have shown promise in reducing volatile organic compound (VOC) emissions during PVAc synthesis and application. This improvement in air quality not only benefits the environment but also enhances workplace safety for industry personnel. Additionally, some renewable additives have demonstrated the ability to improve the overall performance of PVAc products, potentially leading to longer-lasting materials and reduced waste generation.

However, the environmental impact of renewable additives is not uniformly positive. The cultivation and processing of biomass for additive production can have land-use implications, potentially competing with food crops or contributing to deforestation if not managed sustainably. The energy requirements for processing these additives must also be considered in a comprehensive environmental assessment.

Life cycle analysis (LCA) studies have been conducted to quantify the environmental impacts of renewable additives in PVAc synthesis. These studies typically consider factors such as energy consumption, water usage, and emissions throughout the entire production chain. Results have generally shown a net positive environmental impact when compared to traditional additives, though the magnitude of benefit varies depending on the specific renewable source and production methods employed.

The adoption of renewable additives in PVAc synthesis also has implications for waste management and recycling processes. Some renewable additives may enhance the biodegradability of PVAc products, potentially offering new end-of-life options. However, this can also complicate existing recycling streams, necessitating the development of new sorting and processing technologies to effectively manage these materials.

Renewable additives derived from biomass sources offer several environmental benefits compared to their conventional counterparts. These additives typically have a lower carbon footprint, as they are sourced from renewable resources that absorb carbon dioxide during growth. This can lead to a reduction in greenhouse gas emissions associated with PVAc production.

The use of renewable additives also contributes to reduced dependence on fossil fuels, aligning with global efforts to transition towards a circular economy. Many of these additives are biodegradable, which can mitigate the environmental impact of PVAc products at the end of their lifecycle. This is particularly important in addressing the growing concern of plastic pollution in ecosystems.

Water-based renewable additives have shown promise in reducing volatile organic compound (VOC) emissions during PVAc synthesis and application. This improvement in air quality not only benefits the environment but also enhances workplace safety for industry personnel. Additionally, some renewable additives have demonstrated the ability to improve the overall performance of PVAc products, potentially leading to longer-lasting materials and reduced waste generation.

However, the environmental impact of renewable additives is not uniformly positive. The cultivation and processing of biomass for additive production can have land-use implications, potentially competing with food crops or contributing to deforestation if not managed sustainably. The energy requirements for processing these additives must also be considered in a comprehensive environmental assessment.

Life cycle analysis (LCA) studies have been conducted to quantify the environmental impacts of renewable additives in PVAc synthesis. These studies typically consider factors such as energy consumption, water usage, and emissions throughout the entire production chain. Results have generally shown a net positive environmental impact when compared to traditional additives, though the magnitude of benefit varies depending on the specific renewable source and production methods employed.

The adoption of renewable additives in PVAc synthesis also has implications for waste management and recycling processes. Some renewable additives may enhance the biodegradability of PVAc products, potentially offering new end-of-life options. However, this can also complicate existing recycling streams, necessitating the development of new sorting and processing technologies to effectively manage these materials.

Regulatory Framework for Renewable Chemicals in PVAc

The regulatory framework for renewable chemicals in polyvinyl acetate (PVAc) synthesis is evolving to address environmental concerns and promote sustainability. Governments worldwide are implementing policies to encourage the use of renewable resources in chemical production, including PVAc synthesis.

In the United States, the Environmental Protection Agency (EPA) has established the Renewable Fuel Standard (RFS) program, which indirectly impacts the PVAc industry by promoting the use of bio-based materials. The EPA also oversees the registration and approval of new chemical substances under the Toxic Substances Control Act (TSCA), which applies to renewable additives in PVAc production.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers to register and assess the safety of chemical substances, including those used in PVAc synthesis. The EU's Renewable Energy Directive (RED) further promotes the use of renewable resources in various industries, indirectly affecting PVAc production.

Many countries have introduced eco-labeling schemes and green procurement policies that favor products containing renewable materials. These initiatives create market incentives for PVAc manufacturers to incorporate renewable additives into their formulations.

Regulatory bodies are also focusing on lifecycle assessments and carbon footprint reduction. This has led to the development of standards and guidelines for measuring and reporting the environmental impact of chemical production processes, including those used in PVAc synthesis.

International organizations, such as the International Organization for Standardization (ISO), have developed standards like ISO 14001 for environmental management systems, which can be applied to PVAc production facilities using renewable additives.

As research on renewable additives in PVAc synthesis progresses, regulatory frameworks are expected to adapt. This may include the introduction of specific guidelines for bio-based content in adhesives and coatings, as well as incentives for manufacturers who meet certain sustainability criteria.

Compliance with these regulations presents both challenges and opportunities for PVAc manufacturers. While adapting to new requirements may require initial investments, it also opens doors to new markets and enhances brand reputation in an increasingly environmentally conscious consumer landscape.

In the United States, the Environmental Protection Agency (EPA) has established the Renewable Fuel Standard (RFS) program, which indirectly impacts the PVAc industry by promoting the use of bio-based materials. The EPA also oversees the registration and approval of new chemical substances under the Toxic Substances Control Act (TSCA), which applies to renewable additives in PVAc production.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers to register and assess the safety of chemical substances, including those used in PVAc synthesis. The EU's Renewable Energy Directive (RED) further promotes the use of renewable resources in various industries, indirectly affecting PVAc production.

Many countries have introduced eco-labeling schemes and green procurement policies that favor products containing renewable materials. These initiatives create market incentives for PVAc manufacturers to incorporate renewable additives into their formulations.

Regulatory bodies are also focusing on lifecycle assessments and carbon footprint reduction. This has led to the development of standards and guidelines for measuring and reporting the environmental impact of chemical production processes, including those used in PVAc synthesis.

International organizations, such as the International Organization for Standardization (ISO), have developed standards like ISO 14001 for environmental management systems, which can be applied to PVAc production facilities using renewable additives.

As research on renewable additives in PVAc synthesis progresses, regulatory frameworks are expected to adapt. This may include the introduction of specific guidelines for bio-based content in adhesives and coatings, as well as incentives for manufacturers who meet certain sustainability criteria.

Compliance with these regulations presents both challenges and opportunities for PVAc manufacturers. While adapting to new requirements may require initial investments, it also opens doors to new markets and enhances brand reputation in an increasingly environmentally conscious consumer landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!