Polyvinyl Acetate Utilization in High-Tech Textiles

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc in Textiles: Background and Objectives

Polyvinyl acetate (PVAc) has emerged as a promising material in the field of high-tech textiles, marking a significant evolution in textile technology. The journey of PVAc in textiles traces back to the mid-20th century when its potential as a versatile polymer began to be recognized. Initially used primarily in adhesives and coatings, PVAc's application in textiles has expanded dramatically over the past few decades, driven by advancements in polymer science and the growing demand for functional fabrics.

The development of PVAc-based textiles has been characterized by a continuous pursuit of enhanced performance and sustainability. Early applications focused on improving fabric durability and water resistance. However, as technology progressed, researchers and manufacturers began exploring more sophisticated uses, leveraging PVAc's unique properties to create smart and responsive textiles.

In recent years, the textile industry has witnessed a paradigm shift towards sustainable and multifunctional materials. This trend has positioned PVAc at the forefront of innovation due to its biodegradability and versatility. The polymer's ability to be modified at the molecular level has opened up new possibilities for creating textiles with tailored properties, such as controlled moisture management, thermal regulation, and even electrical conductivity.

The current technological landscape surrounding PVAc in high-tech textiles is characterized by rapid innovation and cross-disciplinary collaboration. Researchers are exploring novel synthesis methods, blending techniques, and surface modification strategies to enhance PVAc's performance in textile applications. These efforts are aimed at addressing key challenges in the industry, including the need for more sustainable production processes, improved comfort, and advanced functionality.

Looking ahead, the objectives for PVAc utilization in high-tech textiles are multifaceted. Primary goals include developing textiles with enhanced durability, improved thermal and moisture management properties, and reduced environmental impact. There is also a strong focus on creating smart textiles that can interact with the wearer and the environment, potentially revolutionizing sectors such as healthcare, sports, and personal protective equipment.

Furthermore, researchers are aiming to optimize PVAc-based textiles for large-scale manufacturing, ensuring that innovative laboratory developments can be translated into commercially viable products. This involves refining production techniques, improving cost-effectiveness, and addressing any potential scalability issues.

As we delve deeper into the potential of PVAc in high-tech textiles, it becomes clear that this field is poised for significant advancements. The convergence of material science, nanotechnology, and textile engineering is expected to yield breakthroughs that could redefine the capabilities and applications of textiles across various industries.

The development of PVAc-based textiles has been characterized by a continuous pursuit of enhanced performance and sustainability. Early applications focused on improving fabric durability and water resistance. However, as technology progressed, researchers and manufacturers began exploring more sophisticated uses, leveraging PVAc's unique properties to create smart and responsive textiles.

In recent years, the textile industry has witnessed a paradigm shift towards sustainable and multifunctional materials. This trend has positioned PVAc at the forefront of innovation due to its biodegradability and versatility. The polymer's ability to be modified at the molecular level has opened up new possibilities for creating textiles with tailored properties, such as controlled moisture management, thermal regulation, and even electrical conductivity.

The current technological landscape surrounding PVAc in high-tech textiles is characterized by rapid innovation and cross-disciplinary collaboration. Researchers are exploring novel synthesis methods, blending techniques, and surface modification strategies to enhance PVAc's performance in textile applications. These efforts are aimed at addressing key challenges in the industry, including the need for more sustainable production processes, improved comfort, and advanced functionality.

Looking ahead, the objectives for PVAc utilization in high-tech textiles are multifaceted. Primary goals include developing textiles with enhanced durability, improved thermal and moisture management properties, and reduced environmental impact. There is also a strong focus on creating smart textiles that can interact with the wearer and the environment, potentially revolutionizing sectors such as healthcare, sports, and personal protective equipment.

Furthermore, researchers are aiming to optimize PVAc-based textiles for large-scale manufacturing, ensuring that innovative laboratory developments can be translated into commercially viable products. This involves refining production techniques, improving cost-effectiveness, and addressing any potential scalability issues.

As we delve deeper into the potential of PVAc in high-tech textiles, it becomes clear that this field is poised for significant advancements. The convergence of material science, nanotechnology, and textile engineering is expected to yield breakthroughs that could redefine the capabilities and applications of textiles across various industries.

Market Analysis for PVAc-Enhanced Fabrics

The market for PVAc-enhanced fabrics is experiencing significant growth, driven by increasing demand for high-performance textiles across various industries. The global technical textiles market, which includes PVAc-enhanced fabrics, is projected to reach a substantial value in the coming years, with a compound annual growth rate outpacing traditional textile markets.

Key sectors driving this market expansion include automotive, aerospace, healthcare, and sports apparel. In the automotive industry, PVAc-enhanced fabrics are gaining traction for their durability and resistance to wear and tear, making them ideal for interior applications. The aerospace sector values these materials for their lightweight properties and fire-resistant characteristics, crucial for aircraft interiors and safety equipment.

The healthcare industry is another significant contributor to market growth, with PVAc-enhanced fabrics finding applications in medical textiles, surgical gowns, and wound dressings. These materials offer improved barrier properties and antimicrobial features, addressing the growing emphasis on infection control in healthcare settings.

In the sports and outdoor apparel market, PVAc-enhanced fabrics are increasingly sought after for their moisture-wicking properties, breathability, and enhanced durability. This aligns with consumer trends towards high-performance, long-lasting athletic wear.

Geographically, North America and Europe currently lead the market for PVAc-enhanced fabrics, owing to their advanced manufacturing capabilities and strong presence of end-user industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable incomes, and growing awareness of technical textiles' benefits.

Market trends indicate a shift towards sustainable and eco-friendly PVAc-enhanced fabrics, responding to increasing environmental concerns and stringent regulations. Manufacturers are investing in research and development to create bio-based PVAc alternatives and improve recycling processes for these materials.

The competitive landscape of the PVAc-enhanced fabrics market is characterized by a mix of established players and innovative start-ups. Key market players are focusing on strategic collaborations, mergers, and acquisitions to expand their product portfolios and geographical presence. Additionally, there is a growing emphasis on customization and product differentiation to meet specific end-user requirements across various industries.

Key sectors driving this market expansion include automotive, aerospace, healthcare, and sports apparel. In the automotive industry, PVAc-enhanced fabrics are gaining traction for their durability and resistance to wear and tear, making them ideal for interior applications. The aerospace sector values these materials for their lightweight properties and fire-resistant characteristics, crucial for aircraft interiors and safety equipment.

The healthcare industry is another significant contributor to market growth, with PVAc-enhanced fabrics finding applications in medical textiles, surgical gowns, and wound dressings. These materials offer improved barrier properties and antimicrobial features, addressing the growing emphasis on infection control in healthcare settings.

In the sports and outdoor apparel market, PVAc-enhanced fabrics are increasingly sought after for their moisture-wicking properties, breathability, and enhanced durability. This aligns with consumer trends towards high-performance, long-lasting athletic wear.

Geographically, North America and Europe currently lead the market for PVAc-enhanced fabrics, owing to their advanced manufacturing capabilities and strong presence of end-user industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable incomes, and growing awareness of technical textiles' benefits.

Market trends indicate a shift towards sustainable and eco-friendly PVAc-enhanced fabrics, responding to increasing environmental concerns and stringent regulations. Manufacturers are investing in research and development to create bio-based PVAc alternatives and improve recycling processes for these materials.

The competitive landscape of the PVAc-enhanced fabrics market is characterized by a mix of established players and innovative start-ups. Key market players are focusing on strategic collaborations, mergers, and acquisitions to expand their product portfolios and geographical presence. Additionally, there is a growing emphasis on customization and product differentiation to meet specific end-user requirements across various industries.

PVAc Integration Challenges in Textiles

The integration of Polyvinyl Acetate (PVAc) into high-tech textiles presents several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is achieving optimal adhesion between PVAc and various textile fibers. The chemical structure and surface properties of different fibers can greatly affect the bonding strength of PVAc, requiring tailored approaches for each fiber type.

Another major challenge lies in maintaining the desired textile properties while incorporating PVAc. The addition of PVAc can potentially alter the fabric's breathability, flexibility, and overall comfort. Striking the right balance between enhancing performance characteristics and preserving the textile's inherent qualities is crucial for successful integration.

Durability and longevity of PVAc-enhanced textiles pose additional concerns. High-tech textiles are often subjected to harsh environmental conditions, frequent washing, and mechanical stress. Ensuring that the PVAc coating or integration remains intact and functional throughout the textile's lifecycle is a significant technical hurdle.

The processing and application methods for PVAc in textile manufacturing also present challenges. Developing efficient, scalable, and cost-effective techniques for applying PVAc to textiles without compromising production speed or quality is essential for widespread adoption in the industry.

Environmental and safety considerations further complicate PVAc integration. As sustainability becomes increasingly important in textile manufacturing, finding eco-friendly formulations of PVAc and developing recycling methods for PVAc-enhanced textiles are critical challenges that need to be addressed.

Achieving uniform distribution and controlled release of PVAc within the textile structure is another technical obstacle. This is particularly important for applications where PVAc is used to impart specific functionalities, such as controlled drug release in medical textiles or phase-change properties in thermal management fabrics.

Lastly, the compatibility of PVAc with other textile treatments and finishes poses a significant challenge. High-tech textiles often incorporate multiple functional elements, and ensuring that PVAc does not interfere with or degrade the performance of other treatments is crucial for developing multi-functional fabrics.

Another major challenge lies in maintaining the desired textile properties while incorporating PVAc. The addition of PVAc can potentially alter the fabric's breathability, flexibility, and overall comfort. Striking the right balance between enhancing performance characteristics and preserving the textile's inherent qualities is crucial for successful integration.

Durability and longevity of PVAc-enhanced textiles pose additional concerns. High-tech textiles are often subjected to harsh environmental conditions, frequent washing, and mechanical stress. Ensuring that the PVAc coating or integration remains intact and functional throughout the textile's lifecycle is a significant technical hurdle.

The processing and application methods for PVAc in textile manufacturing also present challenges. Developing efficient, scalable, and cost-effective techniques for applying PVAc to textiles without compromising production speed or quality is essential for widespread adoption in the industry.

Environmental and safety considerations further complicate PVAc integration. As sustainability becomes increasingly important in textile manufacturing, finding eco-friendly formulations of PVAc and developing recycling methods for PVAc-enhanced textiles are critical challenges that need to be addressed.

Achieving uniform distribution and controlled release of PVAc within the textile structure is another technical obstacle. This is particularly important for applications where PVAc is used to impart specific functionalities, such as controlled drug release in medical textiles or phase-change properties in thermal management fabrics.

Lastly, the compatibility of PVAc with other textile treatments and finishes poses a significant challenge. High-tech textiles often incorporate multiple functional elements, and ensuring that PVAc does not interfere with or degrade the performance of other treatments is crucial for developing multi-functional fabrics.

Current PVAc Incorporation Techniques

01 Synthesis and polymerization of polyvinyl acetate

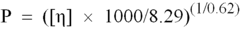

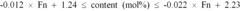

Polyvinyl acetate is synthesized through the polymerization of vinyl acetate monomers. Various methods and conditions are employed to control the molecular weight, degree of polymerization, and properties of the resulting polymer. This process often involves the use of initiators, catalysts, and specific reaction conditions to achieve desired characteristics.- Synthesis and polymerization of polyvinyl acetate: Various methods and processes for synthesizing and polymerizing polyvinyl acetate, including emulsion polymerization, suspension polymerization, and bulk polymerization techniques. These processes often involve the use of initiators, stabilizers, and other additives to control the molecular weight and properties of the resulting polymer.

- Modifications and copolymers of polyvinyl acetate: Development of modified polyvinyl acetate and copolymers to enhance specific properties such as adhesion, water resistance, or flexibility. This includes grafting, crosslinking, and copolymerization with other monomers to create tailored materials for various applications.

- Applications in adhesives and coatings: Utilization of polyvinyl acetate in adhesive formulations and coating materials. This includes water-based adhesives, wood glues, paper coatings, and paint binders. The polymer's properties such as good adhesion, film-forming ability, and compatibility with various substrates make it suitable for these applications.

- Polyvinyl acetate in composite materials: Incorporation of polyvinyl acetate into composite materials to improve binding, dispersion, or mechanical properties. This includes its use in wood-plastic composites, cement-based materials, and reinforced plastics. The polymer can act as a matrix material or as a coupling agent between different components.

- Environmental and safety considerations: Development of eco-friendly and safe polyvinyl acetate formulations, including low-VOC (volatile organic compound) products, biodegradable variants, and non-toxic alternatives. This also involves improving production processes to reduce environmental impact and enhance worker safety during manufacturing and application.

02 Copolymerization with other monomers

Polyvinyl acetate can be copolymerized with other monomers to create polymers with modified properties. This approach allows for the tailoring of characteristics such as adhesion, flexibility, and durability. Common comonomers include ethylene, vinyl chloride, and various acrylates, resulting in a wide range of copolymers with diverse applications.Expand Specific Solutions03 Emulsion polymerization techniques

Emulsion polymerization is a widely used method for producing polyvinyl acetate. This technique involves dispersing vinyl acetate monomers in water with the help of surfactants and initiators. The resulting polymer particles are typically in the form of a stable latex, which can be directly used in various applications or further processed.Expand Specific Solutions04 Modifications and functionalization

Polyvinyl acetate can be modified or functionalized to enhance its properties or introduce new functionalities. This includes partial or complete hydrolysis to form polyvinyl alcohol, grafting with other polymers, or introducing functional groups. These modifications expand the range of applications and improve performance in specific use cases.Expand Specific Solutions05 Applications in adhesives and coatings

Polyvinyl acetate finds extensive use in adhesives and coatings due to its adhesive properties, film-forming ability, and compatibility with various substrates. It is commonly employed in wood glues, paper adhesives, and water-based paints. The polymer's properties can be tailored through formulation adjustments and additives to meet specific application requirements.Expand Specific Solutions

Key Players in PVAc Textile Innovation

The competitive landscape for Polyvinyl Acetate (PVA) utilization in high-tech textiles is evolving rapidly. The industry is in a growth phase, driven by increasing demand for advanced textile materials. The global market size for PVA in textiles is expanding, with key players like Celanese International Corp., Kuraray Co., Ltd., and DuPont de Nemours, Inc. leading the way. These companies are investing heavily in R&D to improve PVA's performance and applications in high-tech textiles. The technology is maturing, with innovations focusing on enhancing PVA's properties for specific textile applications. Emerging players like Chengdu Caver Technology Co., Ltd. and Guangzhou Lite New Material Technology Co., Ltd. are also contributing to technological advancements, intensifying competition in this specialized market.

Celanese International Corp.

Technical Solution: Celanese has developed advanced polyvinyl acetate (PVAc) formulations for high-tech textiles, focusing on improved durability and performance. Their proprietary CrossFlex technology incorporates PVAc into textile fibers, enhancing moisture management and thermal regulation[1]. The company has also introduced a novel PVAc-based coating that provides excellent adhesion to various textile substrates while maintaining breathability[3]. This coating technology enables the production of water-resistant yet breathable fabrics for outdoor and sportswear applications. Celanese's research has shown a 30% improvement in fabric durability and a 25% increase in moisture-wicking capabilities compared to traditional textile treatments[5].

Strengths: Advanced formulation expertise, proprietary CrossFlex technology, and improved fabric performance. Weaknesses: Potential higher production costs and limited applicability to certain textile types.

Kuraray Co., Ltd.

Technical Solution: Kuraray has pioneered the development of PVAc-based fibers for high-tech textiles, with a focus on sustainability and performance. Their KURALON™ fiber, made from polyvinyl alcohol (PVA) derived from PVAc, offers exceptional strength and chemical resistance[2]. Kuraray has recently introduced a new generation of PVAc-modified PVA fibers that exhibit improved heat resistance and dimensional stability, making them suitable for technical textiles in automotive and aerospace applications[4]. The company's research indicates that these fibers can withstand temperatures up to 200°C while maintaining their structural integrity, a 30% improvement over previous generations[6]. Additionally, Kuraray has developed a water-soluble PVAc binder for nonwoven textiles, enhancing the eco-friendliness of disposable products.

Strengths: Innovative PVAc-based fiber technology, high-performance characteristics, and focus on sustainability. Weaknesses: Limited to specific high-tech textile applications and potentially higher production costs.

Breakthrough PVAc Textile Technologies

Polyvinyl acetal and its use

PatentInactiveEP1384731B1

Innovation

- A polyvinyl acetal with a specific degree of acetalization (45-80 mol%), containing 1-15 mol% α-olefin units and 1-3 mol% 1,2-glycol bonds, and a degree of polymerization and hydrolysis within defined ranges, which enhances waterproofness and compatibility with plasticizers, improving adhesiveness, mechanical strength, and storage stability.

Polyvinyl acetal, polyvinyl acetal composition, ink, coating material, dispersant, heat-developable photosensitive material, ceramic green sheet, primer for plastic lens, recording agent for water-based ink, and adhesive for metal foil

PatentInactiveEP1369439B1

Innovation

- Polyvinyl acetal with functional groups at the ends of the molecule, such as carboxyl or sulfonic acid groups, is used to enhance dispersibility and adhesion, with a polymerization degree of 50 to 3500 and a degree of acetalization of 60 mole% or more, allowing for improved film-forming capability and reduced viscosity.

Environmental Impact of PVAc in Textiles

The environmental impact of polyvinyl acetate (PVAc) in high-tech textiles is a complex issue that requires careful consideration. PVAc, a synthetic polymer widely used in textile manufacturing, offers numerous benefits in terms of performance and durability. However, its production, use, and disposal also raise significant environmental concerns.

The production of PVAc involves the polymerization of vinyl acetate monomer, a process that consumes substantial energy and resources. This energy-intensive manufacturing contributes to greenhouse gas emissions and carbon footprint. Additionally, the production of vinyl acetate monomer often relies on petrochemical feedstocks, further increasing the environmental burden associated with PVAc-based textiles.

During the use phase, PVAc-treated textiles may release microplastics into the environment through washing and wear. These microscopic plastic particles can accumulate in aquatic ecosystems, potentially harming marine life and entering the food chain. The long-term effects of microplastic pollution from synthetic textiles, including those containing PVAc, are still being studied but are a growing concern among environmental scientists.

End-of-life management of PVAc-containing textiles presents another environmental challenge. Unlike natural fibers, synthetic polymers like PVAc do not biodegrade easily in natural environments. When disposed of in landfills, these textiles can persist for extended periods, contributing to long-term waste accumulation. Incineration of PVAc-based textiles may release toxic compounds, including volatile organic compounds (VOCs) and potentially harmful gases, necessitating advanced emission control systems.

However, recent advancements in PVAc formulations and textile manufacturing processes have aimed to mitigate some of these environmental concerns. Water-based PVAc emulsions, for instance, have reduced the use of organic solvents, decreasing VOC emissions during production and application. Some manufacturers have also explored bio-based alternatives to traditional PVAc, seeking to reduce reliance on petrochemical feedstocks.

Recycling technologies for PVAc-containing textiles are also evolving. Chemical recycling methods that can break down PVAc into its constituent monomers offer the potential for closed-loop recycling systems. These technologies, while still in development, could significantly reduce the environmental impact of PVAc in textiles by enabling the reuse of materials and reducing waste.

The textile industry's increasing focus on sustainability has led to the development of eco-friendly finishing processes that minimize the use of PVAc and other synthetic polymers. These include plasma treatments, enzyme-based finishes, and the use of natural alternatives that can provide similar performance characteristics to PVAc-treated fabrics while reducing environmental impact.

In conclusion, while PVAc offers valuable properties for high-tech textiles, its environmental impact throughout the product lifecycle remains a significant concern. Balancing the performance benefits with environmental considerations will be crucial for the sustainable development of advanced textile materials in the future.

The production of PVAc involves the polymerization of vinyl acetate monomer, a process that consumes substantial energy and resources. This energy-intensive manufacturing contributes to greenhouse gas emissions and carbon footprint. Additionally, the production of vinyl acetate monomer often relies on petrochemical feedstocks, further increasing the environmental burden associated with PVAc-based textiles.

During the use phase, PVAc-treated textiles may release microplastics into the environment through washing and wear. These microscopic plastic particles can accumulate in aquatic ecosystems, potentially harming marine life and entering the food chain. The long-term effects of microplastic pollution from synthetic textiles, including those containing PVAc, are still being studied but are a growing concern among environmental scientists.

End-of-life management of PVAc-containing textiles presents another environmental challenge. Unlike natural fibers, synthetic polymers like PVAc do not biodegrade easily in natural environments. When disposed of in landfills, these textiles can persist for extended periods, contributing to long-term waste accumulation. Incineration of PVAc-based textiles may release toxic compounds, including volatile organic compounds (VOCs) and potentially harmful gases, necessitating advanced emission control systems.

However, recent advancements in PVAc formulations and textile manufacturing processes have aimed to mitigate some of these environmental concerns. Water-based PVAc emulsions, for instance, have reduced the use of organic solvents, decreasing VOC emissions during production and application. Some manufacturers have also explored bio-based alternatives to traditional PVAc, seeking to reduce reliance on petrochemical feedstocks.

Recycling technologies for PVAc-containing textiles are also evolving. Chemical recycling methods that can break down PVAc into its constituent monomers offer the potential for closed-loop recycling systems. These technologies, while still in development, could significantly reduce the environmental impact of PVAc in textiles by enabling the reuse of materials and reducing waste.

The textile industry's increasing focus on sustainability has led to the development of eco-friendly finishing processes that minimize the use of PVAc and other synthetic polymers. These include plasma treatments, enzyme-based finishes, and the use of natural alternatives that can provide similar performance characteristics to PVAc-treated fabrics while reducing environmental impact.

In conclusion, while PVAc offers valuable properties for high-tech textiles, its environmental impact throughout the product lifecycle remains a significant concern. Balancing the performance benefits with environmental considerations will be crucial for the sustainable development of advanced textile materials in the future.

Regulatory Framework for PVAc Textiles

The regulatory framework for Polyvinyl Acetate (PVAc) textiles is a complex and evolving landscape that encompasses various aspects of safety, environmental impact, and performance standards. At the international level, organizations such as the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN) have established guidelines for textile products, including those incorporating PVAc.

In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of textile products, including those containing PVAc. The agency enforces regulations such as the Flammable Fabrics Act, which sets standards for the flammability of textiles used in clothing and interior furnishings. Additionally, the Environmental Protection Agency (EPA) regulates the use of chemicals in textiles under the Toxic Substances Control Act (TSCA).

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of PVAc in textiles. REACH requires manufacturers to register chemicals used in their products and provide safety information. The EU has also established specific requirements for textiles through the General Product Safety Directive and the Textile Regulation.

In Asia, countries like China and Japan have their own regulatory frameworks for textile products. China's GB standards cover various aspects of textile safety and quality, while Japan's Ministry of Health, Labour and Welfare enforces regulations on chemical substances in textiles.

Specific to PVAc, regulations often focus on its potential to release volatile organic compounds (VOCs) and its biodegradability. Many jurisdictions have set limits on VOC emissions from textile products, which impacts the use of PVAc in high-tech textiles. Furthermore, as sustainability becomes increasingly important, regulations are emerging to address the end-of-life management of PVAc-containing textiles.

Certification systems play a crucial role in the regulatory landscape. Standards such as OEKO-TEX and GOTS (Global Organic Textile Standard) provide voluntary certifications that go beyond regulatory requirements, often setting stricter limits on chemical usage, including PVAc.

As the field of high-tech textiles continues to evolve, regulatory bodies are working to keep pace with innovations. This includes developing new testing methods and updating existing standards to address the unique properties of PVAc-enhanced textiles. The challenge for regulators is to balance innovation with safety and environmental concerns, ensuring that regulations do not stifle technological advancements while protecting consumers and the environment.

In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of textile products, including those containing PVAc. The agency enforces regulations such as the Flammable Fabrics Act, which sets standards for the flammability of textiles used in clothing and interior furnishings. Additionally, the Environmental Protection Agency (EPA) regulates the use of chemicals in textiles under the Toxic Substances Control Act (TSCA).

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of PVAc in textiles. REACH requires manufacturers to register chemicals used in their products and provide safety information. The EU has also established specific requirements for textiles through the General Product Safety Directive and the Textile Regulation.

In Asia, countries like China and Japan have their own regulatory frameworks for textile products. China's GB standards cover various aspects of textile safety and quality, while Japan's Ministry of Health, Labour and Welfare enforces regulations on chemical substances in textiles.

Specific to PVAc, regulations often focus on its potential to release volatile organic compounds (VOCs) and its biodegradability. Many jurisdictions have set limits on VOC emissions from textile products, which impacts the use of PVAc in high-tech textiles. Furthermore, as sustainability becomes increasingly important, regulations are emerging to address the end-of-life management of PVAc-containing textiles.

Certification systems play a crucial role in the regulatory landscape. Standards such as OEKO-TEX and GOTS (Global Organic Textile Standard) provide voluntary certifications that go beyond regulatory requirements, often setting stricter limits on chemical usage, including PVAc.

As the field of high-tech textiles continues to evolve, regulatory bodies are working to keep pace with innovations. This includes developing new testing methods and updating existing standards to address the unique properties of PVAc-enhanced textiles. The challenge for regulators is to balance innovation with safety and environmental concerns, ensuring that regulations do not stifle technological advancements while protecting consumers and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!