Polyvinyl Acetate for Structural Adhesives: Technological Improvements

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Adhesive Evolution

The evolution of polyvinyl acetate (PVAc) adhesives for structural applications has been marked by significant technological advancements over the years. Initially developed in the early 20th century, PVAc adhesives have undergone continuous improvements to enhance their performance and expand their applicability in various industries.

In the 1930s, PVAc adhesives were primarily used for wood bonding in furniture manufacturing. These early formulations had limited strength and durability, particularly in high-moisture environments. The 1950s saw the introduction of cross-linking agents, which significantly improved the water resistance and bond strength of PVAc adhesives. This breakthrough expanded their use in exterior applications and more demanding structural joints.

The 1970s marked a pivotal moment in PVAc adhesive evolution with the development of vinyl acetate-ethylene (VAE) copolymers. These copolymers offered improved flexibility, adhesion to a wider range of substrates, and enhanced resistance to temperature fluctuations. This innovation broadened the scope of PVAc adhesives in construction and industrial applications.

In the 1990s, researchers focused on enhancing the thermal stability of PVAc adhesives. The incorporation of heat-resistant monomers and the optimization of polymer chain structures led to formulations capable of withstanding higher temperatures without compromising bond strength. This advancement was crucial for expanding the use of PVAc adhesives in automotive and aerospace industries.

The turn of the millennium brought increased attention to environmental concerns, driving the development of low-VOC and formaldehyde-free PVAc adhesives. These eco-friendly formulations maintained high performance while meeting stringent environmental regulations, particularly in indoor applications and consumer products.

Recent years have seen a focus on nanotechnology in PVAc adhesive development. The incorporation of nanoparticles, such as silica and carbon nanotubes, has led to significant improvements in mechanical properties, including tensile strength and impact resistance. These nano-enhanced PVAc adhesives show promise for high-performance structural applications previously dominated by epoxy and polyurethane adhesives.

Current research is exploring bio-based alternatives to traditional PVAc formulations, aiming to reduce reliance on petroleum-derived raw materials. These efforts involve the use of renewable resources and the development of hybrid systems that combine PVAc with natural polymers, offering a more sustainable approach to adhesive technology.

The ongoing evolution of PVAc adhesives continues to push the boundaries of their capabilities, with researchers and manufacturers striving to develop formulations that offer superior strength, durability, and versatility while meeting the growing demand for environmentally friendly solutions in structural bonding applications.

In the 1930s, PVAc adhesives were primarily used for wood bonding in furniture manufacturing. These early formulations had limited strength and durability, particularly in high-moisture environments. The 1950s saw the introduction of cross-linking agents, which significantly improved the water resistance and bond strength of PVAc adhesives. This breakthrough expanded their use in exterior applications and more demanding structural joints.

The 1970s marked a pivotal moment in PVAc adhesive evolution with the development of vinyl acetate-ethylene (VAE) copolymers. These copolymers offered improved flexibility, adhesion to a wider range of substrates, and enhanced resistance to temperature fluctuations. This innovation broadened the scope of PVAc adhesives in construction and industrial applications.

In the 1990s, researchers focused on enhancing the thermal stability of PVAc adhesives. The incorporation of heat-resistant monomers and the optimization of polymer chain structures led to formulations capable of withstanding higher temperatures without compromising bond strength. This advancement was crucial for expanding the use of PVAc adhesives in automotive and aerospace industries.

The turn of the millennium brought increased attention to environmental concerns, driving the development of low-VOC and formaldehyde-free PVAc adhesives. These eco-friendly formulations maintained high performance while meeting stringent environmental regulations, particularly in indoor applications and consumer products.

Recent years have seen a focus on nanotechnology in PVAc adhesive development. The incorporation of nanoparticles, such as silica and carbon nanotubes, has led to significant improvements in mechanical properties, including tensile strength and impact resistance. These nano-enhanced PVAc adhesives show promise for high-performance structural applications previously dominated by epoxy and polyurethane adhesives.

Current research is exploring bio-based alternatives to traditional PVAc formulations, aiming to reduce reliance on petroleum-derived raw materials. These efforts involve the use of renewable resources and the development of hybrid systems that combine PVAc with natural polymers, offering a more sustainable approach to adhesive technology.

The ongoing evolution of PVAc adhesives continues to push the boundaries of their capabilities, with researchers and manufacturers striving to develop formulations that offer superior strength, durability, and versatility while meeting the growing demand for environmentally friendly solutions in structural bonding applications.

Market Demand Analysis

The market demand for structural adhesives based on polyvinyl acetate (PVAc) has been steadily growing due to their unique properties and versatile applications. These adhesives offer excellent bonding strength, durability, and environmental friendliness, making them increasingly popular in various industries.

In the construction sector, PVAc-based structural adhesives are witnessing a surge in demand. The global construction industry's growth, particularly in emerging economies, is driving the need for high-performance adhesives. PVAc adhesives are preferred for their ability to bond wood, concrete, and other building materials effectively, contributing to improved structural integrity and energy efficiency in buildings.

The automotive industry represents another significant market for PVAc structural adhesives. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is a growing trend towards replacing traditional mechanical fasteners with adhesive bonding solutions. PVAc-based adhesives offer advantages in terms of weight reduction, improved stress distribution, and enhanced crash performance, aligning well with the industry's evolving needs.

The furniture industry is also a key driver of market demand for PVAc structural adhesives. The global furniture market's expansion, fueled by urbanization and changing lifestyles, has led to increased adoption of these adhesives. PVAc adhesives are valued for their strong bonding capabilities, quick setting times, and resistance to creep under long-term loading, making them ideal for furniture assembly and wood bonding applications.

In the aerospace sector, there is a growing interest in PVAc-based structural adhesives for interior components and non-critical structural applications. The aerospace industry's focus on lightweight materials and fuel efficiency has created opportunities for advanced adhesive solutions, including those based on PVAc technology.

The packaging industry is another area where PVAc structural adhesives are gaining traction. With the rise of e-commerce and the need for robust packaging solutions, these adhesives are being increasingly used in the production of high-strength corrugated boxes and composite packaging materials.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the PVAc structural adhesives market. This is attributed to rapid industrialization, infrastructure development, and the expansion of end-use industries in countries like China and India.

Environmental regulations and sustainability concerns are also shaping market demand. PVAc adhesives, being water-based and low in volatile organic compounds (VOCs), are well-positioned to meet stringent environmental standards. This aspect is particularly important in regions with strict regulations on emissions and chemical use, such as Europe and North America.

In the construction sector, PVAc-based structural adhesives are witnessing a surge in demand. The global construction industry's growth, particularly in emerging economies, is driving the need for high-performance adhesives. PVAc adhesives are preferred for their ability to bond wood, concrete, and other building materials effectively, contributing to improved structural integrity and energy efficiency in buildings.

The automotive industry represents another significant market for PVAc structural adhesives. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is a growing trend towards replacing traditional mechanical fasteners with adhesive bonding solutions. PVAc-based adhesives offer advantages in terms of weight reduction, improved stress distribution, and enhanced crash performance, aligning well with the industry's evolving needs.

The furniture industry is also a key driver of market demand for PVAc structural adhesives. The global furniture market's expansion, fueled by urbanization and changing lifestyles, has led to increased adoption of these adhesives. PVAc adhesives are valued for their strong bonding capabilities, quick setting times, and resistance to creep under long-term loading, making them ideal for furniture assembly and wood bonding applications.

In the aerospace sector, there is a growing interest in PVAc-based structural adhesives for interior components and non-critical structural applications. The aerospace industry's focus on lightweight materials and fuel efficiency has created opportunities for advanced adhesive solutions, including those based on PVAc technology.

The packaging industry is another area where PVAc structural adhesives are gaining traction. With the rise of e-commerce and the need for robust packaging solutions, these adhesives are being increasingly used in the production of high-strength corrugated boxes and composite packaging materials.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the PVAc structural adhesives market. This is attributed to rapid industrialization, infrastructure development, and the expansion of end-use industries in countries like China and India.

Environmental regulations and sustainability concerns are also shaping market demand. PVAc adhesives, being water-based and low in volatile organic compounds (VOCs), are well-positioned to meet stringent environmental standards. This aspect is particularly important in regions with strict regulations on emissions and chemical use, such as Europe and North America.

Technical Challenges

Polyvinyl acetate (PVA) adhesives face several technical challenges in their application as structural adhesives. One of the primary issues is their limited strength and durability compared to other structural adhesive types. PVA adhesives typically exhibit lower tensile and shear strengths, which can limit their use in high-stress applications. This weakness is particularly evident in environments with fluctuating temperatures and humidity levels, where the adhesive bond may weaken over time.

Another significant challenge is the poor water resistance of traditional PVA adhesives. When exposed to moisture, these adhesives can soften and lose their bonding strength, leading to potential failure in structural applications. This characteristic severely restricts their use in outdoor or high-humidity environments, limiting their versatility as structural adhesives.

The creep behavior of PVA adhesives presents an additional technical hurdle. Under sustained loads, PVA adhesives tend to deform slowly over time, which can compromise the integrity of the bonded structure. This creep tendency is especially problematic in load-bearing applications where dimensional stability is crucial.

Temperature sensitivity is another area of concern for PVA-based structural adhesives. These adhesives often have a relatively low glass transition temperature, which means they can soften and lose their structural properties at elevated temperatures. This limitation restricts their use in applications where high-temperature resistance is required.

The curing process of PVA adhesives also poses challenges. Unlike some other structural adhesives that cure through chemical reactions, PVA adhesives typically dry through water evaporation. This process can be slow and may result in longer setting times, which can be inefficient in industrial applications requiring rapid bonding.

Furthermore, the adhesion to certain substrates, particularly non-porous materials, can be problematic for PVA adhesives. Their effectiveness is often limited to porous substrates like wood, paper, and fabrics, which narrows their range of applications in structural bonding.

Lastly, the environmental impact and sustainability of PVA adhesives present ongoing challenges. While PVA is generally considered less harmful than some other adhesive types, there is a growing demand for more eco-friendly alternatives. Developing PVA formulations that maintain structural integrity while improving biodegradability and reducing environmental impact remains a significant technical challenge in the industry.

Another significant challenge is the poor water resistance of traditional PVA adhesives. When exposed to moisture, these adhesives can soften and lose their bonding strength, leading to potential failure in structural applications. This characteristic severely restricts their use in outdoor or high-humidity environments, limiting their versatility as structural adhesives.

The creep behavior of PVA adhesives presents an additional technical hurdle. Under sustained loads, PVA adhesives tend to deform slowly over time, which can compromise the integrity of the bonded structure. This creep tendency is especially problematic in load-bearing applications where dimensional stability is crucial.

Temperature sensitivity is another area of concern for PVA-based structural adhesives. These adhesives often have a relatively low glass transition temperature, which means they can soften and lose their structural properties at elevated temperatures. This limitation restricts their use in applications where high-temperature resistance is required.

The curing process of PVA adhesives also poses challenges. Unlike some other structural adhesives that cure through chemical reactions, PVA adhesives typically dry through water evaporation. This process can be slow and may result in longer setting times, which can be inefficient in industrial applications requiring rapid bonding.

Furthermore, the adhesion to certain substrates, particularly non-porous materials, can be problematic for PVA adhesives. Their effectiveness is often limited to porous substrates like wood, paper, and fabrics, which narrows their range of applications in structural bonding.

Lastly, the environmental impact and sustainability of PVA adhesives present ongoing challenges. While PVA is generally considered less harmful than some other adhesive types, there is a growing demand for more eco-friendly alternatives. Developing PVA formulations that maintain structural integrity while improving biodegradability and reducing environmental impact remains a significant technical challenge in the industry.

Current PVAc Solutions

01 Composition of polyvinyl acetate structural adhesives

Polyvinyl acetate structural adhesives typically consist of a base polymer, crosslinking agents, and additives. The base polymer is polyvinyl acetate, which provides the adhesive properties. Crosslinking agents are added to improve the strength and durability of the adhesive bond. Various additives such as plasticizers, stabilizers, and fillers may be incorporated to enhance specific properties of the adhesive.- Composition of polyvinyl acetate structural adhesives: Polyvinyl acetate structural adhesives typically consist of a base polymer, additives, and solvents. The base polymer is polyvinyl acetate, which provides adhesive properties. Various additives such as plasticizers, stabilizers, and fillers are incorporated to enhance performance characteristics. Solvents may be used to control viscosity and aid in application.

- Modifications to improve adhesive properties: Modifications to polyvinyl acetate adhesives can enhance their structural properties. These may include copolymerization with other monomers, crosslinking agents, or the addition of reinforcing materials. Such modifications can improve strength, durability, and resistance to environmental factors, making the adhesives suitable for structural applications.

- Application methods for structural bonding: Various application methods are used for polyvinyl acetate structural adhesives, including spray, brush, or roller application. Some formulations may require specific application techniques or curing conditions to achieve optimal bonding strength. The choice of application method often depends on the specific structural requirements and the materials being bonded.

- Environmental and safety considerations: Development of environmentally friendly and safe polyvinyl acetate structural adhesives is a focus area. This includes formulations with low volatile organic compound (VOC) content, water-based systems, and adhesives free from harmful chemicals. These considerations aim to meet regulatory requirements and improve workplace safety in structural bonding applications.

- Specialized formulations for specific structural applications: Tailored polyvinyl acetate adhesive formulations are developed for specific structural applications. These may include adhesives for wood bonding, construction materials, automotive applications, or aerospace use. Each formulation is designed to meet the unique requirements of the application, such as load-bearing capacity, temperature resistance, or flexibility.

02 Modification of polyvinyl acetate for improved adhesion

Polyvinyl acetate can be modified to enhance its adhesive properties for structural applications. This may involve copolymerization with other monomers, grafting of functional groups, or blending with other polymers. These modifications can improve properties such as water resistance, heat resistance, and bond strength, making the adhesive more suitable for structural applications.Expand Specific Solutions03 Curing mechanisms for polyvinyl acetate structural adhesives

Various curing mechanisms can be employed for polyvinyl acetate structural adhesives. These may include thermal curing, UV-initiated curing, or moisture-activated curing. The choice of curing mechanism depends on the specific application requirements and can significantly affect the final properties of the adhesive bond.Expand Specific Solutions04 Application methods for polyvinyl acetate structural adhesives

Polyvinyl acetate structural adhesives can be applied using various methods, including spray application, roller coating, or extrusion. The choice of application method depends on factors such as the viscosity of the adhesive, the substrate material, and the desired bond thickness. Proper application techniques are crucial for achieving optimal adhesive performance.Expand Specific Solutions05 Environmental and safety considerations

Development of polyvinyl acetate structural adhesives often focuses on improving their environmental profile and safety characteristics. This may include reducing volatile organic compound (VOC) emissions, developing water-based formulations, and ensuring compliance with relevant regulations. Additionally, efforts are made to improve the recyclability and biodegradability of these adhesives.Expand Specific Solutions

Key Industry Players

The market for polyvinyl acetate in structural adhesives is experiencing steady growth, driven by increasing demand in construction and automotive industries. The technology is in a mature phase, with ongoing improvements focused on enhancing performance and sustainability. Key players like Henkel AG & Co. KGaA, DuPont de Nemours, Inc., and Wacker Chemie AG are leading innovation efforts, investing in R&D to develop advanced formulations with improved bonding strength and environmental profiles. The market is characterized by intense competition, with companies like Kuraray Co., Ltd. and Sekisui Chemical Co., Ltd. expanding their product portfolios to gain market share. As regulations on VOC emissions tighten, there's a growing emphasis on developing low-emission and bio-based alternatives, presenting opportunities for differentiation and market expansion.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed advanced polyvinyl acetate (PVAc) formulations for structural adhesives, focusing on improving bond strength and durability. Their technology incorporates cross-linking agents and nanoparticle reinforcements to enhance the mechanical properties of PVAc adhesives[1]. The company has also introduced water-resistant PVAc variants that maintain structural integrity in high-humidity environments[3]. Kuraray's research has led to the development of PVAc-based adhesives with improved thermal stability, allowing for use in a wider range of applications, including automotive and aerospace industries[5].

Strengths: Enhanced bond strength, improved water resistance, and broader application range. Weaknesses: Potentially higher cost due to advanced formulations and limited high-temperature performance compared to some alternative adhesives.

DuPont de Nemours, Inc.

Technical Solution: DuPont has made significant strides in PVAc technology for structural adhesives, focusing on sustainability and performance. Their research has led to the development of bio-based PVAc adhesives, incorporating renewable resources to reduce environmental impact[2]. DuPont's advanced PVAc formulations feature improved creep resistance and long-term durability, addressing common limitations of traditional PVAc adhesives[4]. The company has also introduced hybrid PVAc systems that combine the benefits of PVAc with other polymer types, resulting in adhesives with enhanced shear strength and temperature resistance[6].

Strengths: Eco-friendly formulations, improved creep resistance, and versatile hybrid systems. Weaknesses: Potentially higher production costs and the need for specialized application techniques.

Core PVAc Innovations

Polyvinyl acetate based polymeric emulsion/ adhesive with improved adhesive strength and a process of preparation thereof

PatentUndeterminedIN202221017188A

Innovation

- A polyvinyl acetate based polymeric emulsion is developed using emulsion polymerization without external crosslinkers or metal catalysts, incorporating Isobornyl methacrylate as a hydrophobic monomer added via power feed technique during the polymerization process, resulting in copolymer particles with enhanced wet adhesive strength and stability.

Adhesion improver consisting of polyvinyl acetal solution

PatentInactiveJPWO2015125689A1

Innovation

- Optimized polyvinyl acetal with specific degree of acetalization, vinyl ester monomer content, and viscosity-average degree of polymerization to balance adhesion and mechanical properties.

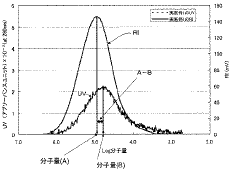

- Utilization of gel permeation chromatography with dual detection (refractive index and UV absorption) to characterize and control the molecular weight distribution and impurity content.

- Development of a formula to correlate peak molecular weights from different detectors, enabling better quality control and consistency in product performance.

Environmental Impact

The environmental impact of polyvinyl acetate (PVAc) in structural adhesives is a critical consideration as the industry moves towards more sustainable practices. PVAc adhesives have traditionally been viewed as relatively eco-friendly compared to some other adhesive types, primarily due to their water-based formulation and low volatile organic compound (VOC) emissions. However, recent technological improvements have further enhanced their environmental profile.

One significant advancement has been the development of bio-based PVAc adhesives. These formulations incorporate renewable resources, such as plant-derived monomers, reducing reliance on petroleum-based raw materials. This shift not only decreases the carbon footprint associated with production but also aligns with circular economy principles, promoting the use of sustainable feedstocks.

Improvements in PVAc production processes have also contributed to reduced energy consumption and waste generation. Advanced reactor designs and optimized polymerization techniques have increased efficiency, leading to lower environmental impact during manufacturing. Additionally, the implementation of closed-loop systems for water and solvent recovery has minimized resource consumption and emissions.

The end-of-life considerations for PVAc adhesives have been addressed through recent innovations. Researchers have developed biodegradable PVAc formulations that break down more readily in natural environments, reducing long-term ecological impact. Furthermore, advancements in recycling technologies have made it possible to separate PVAc adhesives from bonded materials more effectively, facilitating the recycling of composite products.

In terms of indoor air quality, low-emission PVAc adhesives have been formulated to meet stringent environmental standards. These products release minimal VOCs during application and curing, contributing to healthier indoor environments in both residential and commercial settings. This is particularly important for structural applications where large quantities of adhesive may be used.

The durability and longevity of PVAc-based structural adhesives have also been enhanced, indirectly benefiting the environment. Improved resistance to moisture, temperature fluctuations, and mechanical stress extends the lifespan of bonded structures, reducing the need for frequent repairs or replacements. This longevity translates to reduced material consumption and waste generation over time.

However, challenges remain in fully assessing and mitigating the environmental impact of PVAc adhesives. Life cycle assessments (LCAs) are being conducted to provide a comprehensive understanding of their ecological footprint from cradle to grave. These studies are crucial for identifying areas for further improvement and guiding future technological developments in the field of structural adhesives.

One significant advancement has been the development of bio-based PVAc adhesives. These formulations incorporate renewable resources, such as plant-derived monomers, reducing reliance on petroleum-based raw materials. This shift not only decreases the carbon footprint associated with production but also aligns with circular economy principles, promoting the use of sustainable feedstocks.

Improvements in PVAc production processes have also contributed to reduced energy consumption and waste generation. Advanced reactor designs and optimized polymerization techniques have increased efficiency, leading to lower environmental impact during manufacturing. Additionally, the implementation of closed-loop systems for water and solvent recovery has minimized resource consumption and emissions.

The end-of-life considerations for PVAc adhesives have been addressed through recent innovations. Researchers have developed biodegradable PVAc formulations that break down more readily in natural environments, reducing long-term ecological impact. Furthermore, advancements in recycling technologies have made it possible to separate PVAc adhesives from bonded materials more effectively, facilitating the recycling of composite products.

In terms of indoor air quality, low-emission PVAc adhesives have been formulated to meet stringent environmental standards. These products release minimal VOCs during application and curing, contributing to healthier indoor environments in both residential and commercial settings. This is particularly important for structural applications where large quantities of adhesive may be used.

The durability and longevity of PVAc-based structural adhesives have also been enhanced, indirectly benefiting the environment. Improved resistance to moisture, temperature fluctuations, and mechanical stress extends the lifespan of bonded structures, reducing the need for frequent repairs or replacements. This longevity translates to reduced material consumption and waste generation over time.

However, challenges remain in fully assessing and mitigating the environmental impact of PVAc adhesives. Life cycle assessments (LCAs) are being conducted to provide a comprehensive understanding of their ecological footprint from cradle to grave. These studies are crucial for identifying areas for further improvement and guiding future technological developments in the field of structural adhesives.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of polyvinyl acetate (PVA) for structural adhesives. As technological improvements continue to enhance the performance and versatility of PVA-based adhesives, manufacturers must navigate an increasingly complex landscape of regulations and standards.

In the United States, the Environmental Protection Agency (EPA) regulates the use of volatile organic compounds (VOCs) in adhesives under the Clean Air Act. PVA adhesives, while generally considered low-VOC, must still adhere to specific emission limits. Manufacturers are required to conduct rigorous testing and provide detailed documentation to demonstrate compliance with these regulations.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on the production and use of chemical substances, including those used in PVA adhesives. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU's Construction Products Regulation (CPR) sets standards for construction materials, including structural adhesives, requiring CE marking for products sold in the European market.

In Asia, countries like China and Japan have implemented their own regulatory frameworks. China's GB standards cover various aspects of adhesive production and application, while Japan's Industrial Standards (JIS) provide specific guidelines for structural adhesives. Compliance with these regional standards is essential for market access and product acceptance.

International standards, such as those developed by the International Organization for Standardization (ISO), play a significant role in ensuring global consistency in adhesive performance and safety. ISO 9001 for quality management systems and ISO 14001 for environmental management are particularly relevant for PVA adhesive manufacturers.

As the focus on sustainability intensifies, new regulations are emerging to address the environmental impact of adhesives throughout their lifecycle. This includes requirements for biodegradability, recyclability, and the use of renewable resources in adhesive formulations. Manufacturers are increasingly required to provide life cycle assessments (LCAs) and environmental product declarations (EPDs) to demonstrate the ecological footprint of their products.

Occupational health and safety regulations also impact the production and use of PVA structural adhesives. In many jurisdictions, manufacturers must comply with workplace exposure limits for chemical substances and provide comprehensive safety data sheets (SDS) detailing proper handling procedures and potential hazards.

To navigate this complex regulatory landscape, manufacturers of PVA structural adhesives must invest in robust compliance management systems. This includes staying abreast of regulatory changes, conducting regular audits, and maintaining detailed documentation of testing and certification processes. Collaboration with regulatory bodies and industry associations is essential to ensure ongoing compliance and to contribute to the development of future standards that balance technological innovation with safety and environmental concerns.

In the United States, the Environmental Protection Agency (EPA) regulates the use of volatile organic compounds (VOCs) in adhesives under the Clean Air Act. PVA adhesives, while generally considered low-VOC, must still adhere to specific emission limits. Manufacturers are required to conduct rigorous testing and provide detailed documentation to demonstrate compliance with these regulations.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on the production and use of chemical substances, including those used in PVA adhesives. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU's Construction Products Regulation (CPR) sets standards for construction materials, including structural adhesives, requiring CE marking for products sold in the European market.

In Asia, countries like China and Japan have implemented their own regulatory frameworks. China's GB standards cover various aspects of adhesive production and application, while Japan's Industrial Standards (JIS) provide specific guidelines for structural adhesives. Compliance with these regional standards is essential for market access and product acceptance.

International standards, such as those developed by the International Organization for Standardization (ISO), play a significant role in ensuring global consistency in adhesive performance and safety. ISO 9001 for quality management systems and ISO 14001 for environmental management are particularly relevant for PVA adhesive manufacturers.

As the focus on sustainability intensifies, new regulations are emerging to address the environmental impact of adhesives throughout their lifecycle. This includes requirements for biodegradability, recyclability, and the use of renewable resources in adhesive formulations. Manufacturers are increasingly required to provide life cycle assessments (LCAs) and environmental product declarations (EPDs) to demonstrate the ecological footprint of their products.

Occupational health and safety regulations also impact the production and use of PVA structural adhesives. In many jurisdictions, manufacturers must comply with workplace exposure limits for chemical substances and provide comprehensive safety data sheets (SDS) detailing proper handling procedures and potential hazards.

To navigate this complex regulatory landscape, manufacturers of PVA structural adhesives must invest in robust compliance management systems. This includes staying abreast of regulatory changes, conducting regular audits, and maintaining detailed documentation of testing and certification processes. Collaboration with regulatory bodies and industry associations is essential to ensure ongoing compliance and to contribute to the development of future standards that balance technological innovation with safety and environmental concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!