How to Maximize Stiffness and Flexibility Balance in Polyvinyl Acetate?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVA Stiffness-Flexibility Optimization Background

Polyvinyl acetate (PVA) has been a subject of intense research and development in the field of polymer science for decades. The quest to optimize the balance between stiffness and flexibility in PVA materials has become increasingly crucial as industries seek advanced materials with tailored properties. This technological challenge stems from the inherent nature of PVA, which exhibits a unique combination of characteristics that make it suitable for a wide range of applications.

The development of PVA can be traced back to the early 20th century, with significant advancements occurring in the 1960s and 1970s. Initially, PVA was primarily valued for its adhesive properties, but as polymer science progressed, researchers began to explore ways to enhance its mechanical properties, particularly the balance between stiffness and flexibility.

The drive to maximize this balance is rooted in the diverse requirements of modern industries. From packaging materials that need to be both rigid and bendable, to biomedical applications requiring specific mechanical responses, the demand for optimized PVA has grown substantially. This has led to a convergence of various scientific disciplines, including materials science, chemical engineering, and nanotechnology, all focused on addressing this complex challenge.

Recent technological trends have shifted towards molecular-level modifications and composite formulations. Researchers are exploring various approaches, such as copolymerization, cross-linking, and the incorporation of nanofillers, to fine-tune the mechanical properties of PVA. These efforts aim to create materials that can maintain structural integrity while allowing for controlled deformation under stress.

The optimization of stiffness and flexibility in PVA is not merely an academic pursuit but a response to real-world industrial needs. Industries such as automotive, aerospace, and consumer electronics are constantly seeking materials that can withstand high loads while maintaining the ability to flex without failure. This dual requirement has positioned PVA as a material of significant interest, driving continuous innovation in polymer science.

As we delve deeper into this technological challenge, it becomes evident that the solution lies at the intersection of molecular architecture and macroscopic behavior. The goal is to develop PVA materials that can exhibit high stiffness under certain conditions while retaining flexibility when needed, essentially creating "smart" polymers that can adapt to their environment or applied stresses.

The development of PVA can be traced back to the early 20th century, with significant advancements occurring in the 1960s and 1970s. Initially, PVA was primarily valued for its adhesive properties, but as polymer science progressed, researchers began to explore ways to enhance its mechanical properties, particularly the balance between stiffness and flexibility.

The drive to maximize this balance is rooted in the diverse requirements of modern industries. From packaging materials that need to be both rigid and bendable, to biomedical applications requiring specific mechanical responses, the demand for optimized PVA has grown substantially. This has led to a convergence of various scientific disciplines, including materials science, chemical engineering, and nanotechnology, all focused on addressing this complex challenge.

Recent technological trends have shifted towards molecular-level modifications and composite formulations. Researchers are exploring various approaches, such as copolymerization, cross-linking, and the incorporation of nanofillers, to fine-tune the mechanical properties of PVA. These efforts aim to create materials that can maintain structural integrity while allowing for controlled deformation under stress.

The optimization of stiffness and flexibility in PVA is not merely an academic pursuit but a response to real-world industrial needs. Industries such as automotive, aerospace, and consumer electronics are constantly seeking materials that can withstand high loads while maintaining the ability to flex without failure. This dual requirement has positioned PVA as a material of significant interest, driving continuous innovation in polymer science.

As we delve deeper into this technological challenge, it becomes evident that the solution lies at the intersection of molecular architecture and macroscopic behavior. The goal is to develop PVA materials that can exhibit high stiffness under certain conditions while retaining flexibility when needed, essentially creating "smart" polymers that can adapt to their environment or applied stresses.

Market Demand Analysis

The market demand for polyvinyl acetate (PVA) with optimized stiffness and flexibility balance is driven by various industries seeking materials with enhanced performance characteristics. The construction sector, particularly in adhesives and sealants, shows a growing need for PVA formulations that can withstand diverse environmental conditions while maintaining structural integrity. This demand is fueled by the global construction market's expansion, projected to reach $15.2 trillion by 2030.

In the packaging industry, there's an increasing trend towards sustainable and versatile materials. PVA's biodegradability and potential for improved mechanical properties make it an attractive option for flexible packaging solutions. The global flexible packaging market, valued at $167.1 billion in 2021, is expected to grow at a CAGR of 4.5% through 2028, indicating a substantial opportunity for advanced PVA formulations.

The automotive sector presents another significant market for PVA with balanced stiffness and flexibility. As vehicle manufacturers strive for lighter, more fuel-efficient designs, there's a growing demand for materials that can provide structural support while allowing for energy absorption in impact scenarios. The global automotive plastics market, which includes PVA applications, is forecasted to reach $76.2 billion by 2027.

In the textile industry, PVA finds applications in fiber production and fabric coatings. The ability to fine-tune the balance between stiffness and flexibility could open new avenues in smart textiles and performance fabrics. The technical textiles market, valued at $176.8 billion in 2020, is projected to grow at a CAGR of 4.2% from 2021 to 2028.

The medical and healthcare sectors also show promising demand for advanced PVA formulations. Applications in wound dressings, drug delivery systems, and tissue engineering scaffolds require materials with precise mechanical properties. The global medical plastics market, encompassing PVA applications, is expected to reach $37.5 billion by 2027, growing at a CAGR of 7.5%.

Consumer electronics manufacturers are increasingly interested in materials that can provide both rigidity for structural components and flexibility for user interfaces. This sector's demand for innovative materials is driven by the need for durable, lightweight devices with enhanced tactile properties.

The growing focus on sustainability and circular economy principles across industries is likely to boost the demand for PVA-based solutions. As a biodegradable polymer, PVA with optimized mechanical properties could serve as a replacement for less environmentally friendly materials in various applications.

In the packaging industry, there's an increasing trend towards sustainable and versatile materials. PVA's biodegradability and potential for improved mechanical properties make it an attractive option for flexible packaging solutions. The global flexible packaging market, valued at $167.1 billion in 2021, is expected to grow at a CAGR of 4.5% through 2028, indicating a substantial opportunity for advanced PVA formulations.

The automotive sector presents another significant market for PVA with balanced stiffness and flexibility. As vehicle manufacturers strive for lighter, more fuel-efficient designs, there's a growing demand for materials that can provide structural support while allowing for energy absorption in impact scenarios. The global automotive plastics market, which includes PVA applications, is forecasted to reach $76.2 billion by 2027.

In the textile industry, PVA finds applications in fiber production and fabric coatings. The ability to fine-tune the balance between stiffness and flexibility could open new avenues in smart textiles and performance fabrics. The technical textiles market, valued at $176.8 billion in 2020, is projected to grow at a CAGR of 4.2% from 2021 to 2028.

The medical and healthcare sectors also show promising demand for advanced PVA formulations. Applications in wound dressings, drug delivery systems, and tissue engineering scaffolds require materials with precise mechanical properties. The global medical plastics market, encompassing PVA applications, is expected to reach $37.5 billion by 2027, growing at a CAGR of 7.5%.

Consumer electronics manufacturers are increasingly interested in materials that can provide both rigidity for structural components and flexibility for user interfaces. This sector's demand for innovative materials is driven by the need for durable, lightweight devices with enhanced tactile properties.

The growing focus on sustainability and circular economy principles across industries is likely to boost the demand for PVA-based solutions. As a biodegradable polymer, PVA with optimized mechanical properties could serve as a replacement for less environmentally friendly materials in various applications.

Current PVA Properties and Challenges

Polyvinyl acetate (PVA) is a versatile synthetic polymer with a wide range of applications across various industries. Its current properties offer a unique combination of adhesion, film-forming ability, and moderate flexibility. However, the challenge lies in optimizing the balance between stiffness and flexibility to meet diverse application requirements.

PVA's molecular structure, consisting of long chains of vinyl acetate monomers, contributes to its inherent properties. The polymer exhibits good adhesion to many substrates, excellent transparency, and resistance to oil, grease, and solvents. These characteristics make it suitable for use in adhesives, coatings, and films. However, the current formulation of PVA often struggles to provide the ideal balance of stiffness and flexibility needed for certain applications.

One of the primary challenges in PVA development is achieving high stiffness without compromising flexibility. Increased stiffness is desirable for applications requiring structural integrity and dimensional stability, such as in packaging materials or construction adhesives. However, excessive stiffness can lead to brittleness and reduced impact resistance, limiting the material's durability and performance in dynamic environments.

Conversely, enhancing flexibility is crucial for applications that require conformability and elongation, such as in flexible packaging or textile coatings. Yet, excessive flexibility can result in reduced tensile strength and dimensional stability, potentially compromising the material's load-bearing capacity and overall performance.

The current state of PVA technology faces limitations in simultaneously achieving high stiffness and flexibility. Traditional approaches often involve trade-offs between these properties, resulting in suboptimal performance in applications requiring both characteristics. This challenge is further compounded by the sensitivity of PVA to environmental factors such as humidity and temperature, which can significantly affect its mechanical properties.

Another significant hurdle in PVA development is its inherent water sensitivity. While this property is advantageous in certain applications, such as water-soluble packaging, it poses challenges in environments where moisture resistance is crucial. The water sensitivity of PVA can lead to reduced mechanical strength and dimensional stability in high-humidity conditions, limiting its use in outdoor or moisture-prone applications.

Furthermore, the current PVA formulations often struggle with long-term stability and aging resistance. Exposure to UV radiation, heat, and oxidative conditions can lead to degradation of the polymer chains, resulting in a loss of mechanical properties over time. This challenge is particularly relevant in applications requiring extended service life or exposure to harsh environmental conditions.

In conclusion, while PVA offers a range of desirable properties, the current challenges in balancing stiffness and flexibility, along with addressing water sensitivity and long-term stability, present significant opportunities for innovation and improvement. Overcoming these hurdles will be crucial in expanding the application range of PVA and enhancing its performance across various industries.

PVA's molecular structure, consisting of long chains of vinyl acetate monomers, contributes to its inherent properties. The polymer exhibits good adhesion to many substrates, excellent transparency, and resistance to oil, grease, and solvents. These characteristics make it suitable for use in adhesives, coatings, and films. However, the current formulation of PVA often struggles to provide the ideal balance of stiffness and flexibility needed for certain applications.

One of the primary challenges in PVA development is achieving high stiffness without compromising flexibility. Increased stiffness is desirable for applications requiring structural integrity and dimensional stability, such as in packaging materials or construction adhesives. However, excessive stiffness can lead to brittleness and reduced impact resistance, limiting the material's durability and performance in dynamic environments.

Conversely, enhancing flexibility is crucial for applications that require conformability and elongation, such as in flexible packaging or textile coatings. Yet, excessive flexibility can result in reduced tensile strength and dimensional stability, potentially compromising the material's load-bearing capacity and overall performance.

The current state of PVA technology faces limitations in simultaneously achieving high stiffness and flexibility. Traditional approaches often involve trade-offs between these properties, resulting in suboptimal performance in applications requiring both characteristics. This challenge is further compounded by the sensitivity of PVA to environmental factors such as humidity and temperature, which can significantly affect its mechanical properties.

Another significant hurdle in PVA development is its inherent water sensitivity. While this property is advantageous in certain applications, such as water-soluble packaging, it poses challenges in environments where moisture resistance is crucial. The water sensitivity of PVA can lead to reduced mechanical strength and dimensional stability in high-humidity conditions, limiting its use in outdoor or moisture-prone applications.

Furthermore, the current PVA formulations often struggle with long-term stability and aging resistance. Exposure to UV radiation, heat, and oxidative conditions can lead to degradation of the polymer chains, resulting in a loss of mechanical properties over time. This challenge is particularly relevant in applications requiring extended service life or exposure to harsh environmental conditions.

In conclusion, while PVA offers a range of desirable properties, the current challenges in balancing stiffness and flexibility, along with addressing water sensitivity and long-term stability, present significant opportunities for innovation and improvement. Overcoming these hurdles will be crucial in expanding the application range of PVA and enhancing its performance across various industries.

Existing PVA Balancing Techniques

01 Copolymerization to adjust stiffness and flexibility

Polyvinyl acetate can be copolymerized with other monomers to modify its stiffness and flexibility. By incorporating different monomers, the resulting copolymer can have tailored properties, allowing for a balance between rigidity and elasticity. This approach enables the creation of materials with specific mechanical characteristics suitable for various applications.- Copolymerization to adjust stiffness and flexibility: Polyvinyl acetate can be copolymerized with other monomers to modify its stiffness and flexibility. By incorporating different monomers, the resulting copolymer can have tailored properties, allowing for a balance between rigidity and elasticity. This approach enables the creation of materials with specific mechanical characteristics suitable for various applications.

- Plasticizer addition for improved flexibility: The addition of plasticizers to polyvinyl acetate can significantly enhance its flexibility. Plasticizers work by increasing the free volume between polymer chains, reducing intermolecular forces, and lowering the glass transition temperature. This results in a more pliable and less brittle material, suitable for applications requiring greater flexibility.

- Cross-linking for increased stiffness: Cross-linking of polyvinyl acetate chains can be employed to increase the stiffness of the material. This process involves forming chemical bonds between polymer chains, creating a three-dimensional network structure. The resulting cross-linked polyvinyl acetate exhibits higher rigidity, improved dimensional stability, and enhanced mechanical strength.

- Blending with other polymers: Blending polyvinyl acetate with other polymers can modify its stiffness and flexibility. By combining polyvinyl acetate with compatible polymers, it is possible to create composite materials with intermediate properties. This approach allows for fine-tuning of mechanical characteristics to meet specific application requirements.

- Molecular weight control: The stiffness and flexibility of polyvinyl acetate can be influenced by controlling its molecular weight during polymerization. Higher molecular weight typically results in increased stiffness, while lower molecular weight leads to improved flexibility. By adjusting polymerization conditions, it is possible to achieve the desired balance of properties for specific applications.

02 Plasticizer addition for improved flexibility

The addition of plasticizers to polyvinyl acetate can significantly enhance its flexibility. Plasticizers work by increasing the free volume between polymer chains, reducing intermolecular forces, and lowering the glass transition temperature. This results in a more pliable and less brittle material, suitable for applications requiring greater flexibility.Expand Specific Solutions03 Cross-linking for increased stiffness

Cross-linking of polyvinyl acetate chains can be employed to increase the stiffness of the material. This process involves forming chemical bonds between polymer chains, creating a three-dimensional network structure. The resulting cross-linked polyvinyl acetate exhibits enhanced mechanical strength and rigidity, making it suitable for applications requiring higher stiffness.Expand Specific Solutions04 Blending with other polymers

Polyvinyl acetate can be blended with other polymers to achieve a desired balance of stiffness and flexibility. By combining polyvinyl acetate with compatible polymers, it is possible to create composite materials that leverage the properties of each component. This approach allows for fine-tuning of mechanical properties to meet specific application requirements.Expand Specific Solutions05 Molecular weight control

The stiffness and flexibility of polyvinyl acetate can be influenced by controlling its molecular weight during synthesis. Higher molecular weight typically results in increased stiffness, while lower molecular weight tends to yield more flexible materials. By adjusting polymerization conditions and techniques, it is possible to tailor the molecular weight and, consequently, the mechanical properties of the polymer.Expand Specific Solutions

Key Players in PVA Industry

The polyvinyl acetate (PVA) market is in a mature stage, with a global market size estimated to reach $5.5 billion by 2027. The technology for balancing stiffness and flexibility in PVA is well-established, but ongoing research focuses on optimizing performance for specific applications. Key players like BASF, Kuraray, and Wacker Chemie are at the forefront of innovation, leveraging their extensive R&D capabilities to develop advanced PVA formulations. These companies, along with others such as Celanese and Sekisui Chemical, are continuously improving their products to meet evolving industry demands, particularly in sectors like adhesives, packaging, and construction materials. The competitive landscape is characterized by a mix of large multinational corporations and specialized chemical companies, each striving to differentiate their offerings through enhanced product properties and application-specific solutions.

BASF Corp.

Technical Solution: BASF has developed a novel approach to maximize the stiffness and flexibility balance in polyvinyl acetate (PVAc) through their proprietary Acrodur® technology. This water-based binder system combines the benefits of thermoplastic and thermoset materials, allowing for enhanced mechanical properties[1]. The process involves a controlled cross-linking mechanism that occurs during the drying and curing stages, resulting in a polymer network with improved stiffness without compromising flexibility[2]. BASF's method incorporates nano-sized silica particles into the PVAc matrix, which act as reinforcing agents and contribute to the overall balance of mechanical properties[3]. Additionally, they have implemented a multi-stage polymerization technique that allows for precise control over the molecular weight distribution, further optimizing the stiffness-flexibility ratio[4].

Strengths: Excellent balance of stiffness and flexibility, improved heat resistance, and reduced VOC emissions. Weaknesses: Potentially higher production costs and longer processing times compared to traditional PVAc formulations.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed an innovative approach to balancing stiffness and flexibility in polyvinyl acetate through their MOWIFLEX™ technology. This method involves the strategic incorporation of specific comonomers during the polymerization process, resulting in a tailored molecular structure[1]. The company utilizes a controlled branching technique, which introduces short-chain branches into the PVAc backbone, enhancing flexibility while maintaining overall stiffness[2]. Kuraray's process also includes a proprietary plasticization method that uses bio-based additives, allowing for fine-tuning of the mechanical properties without compromising environmental sustainability[3]. Furthermore, they have implemented a unique post-polymerization treatment that involves selective hydrolysis of acetate groups, creating localized regions of increased hydrogen bonding, which contributes to improved stiffness[4].

Strengths: Highly customizable mechanical properties, eco-friendly formulation, and excellent adhesion characteristics. Weaknesses: May require specialized processing equipment and potentially higher raw material costs.

Core Innovations in PVA Modification

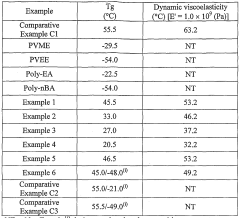

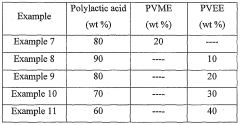

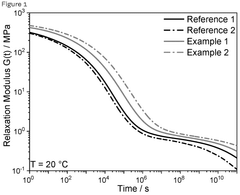

Polylactic acid containing resin composition, articles, and method for producing the same

PatentWO2007027896A1

Innovation

- Incorporating a polyvinyl alkyl ether with a repeat unit of [CH2-CH(OR)] into the polylactic acid resin composition, which is miscible and enhances flexibility and elongation characteristics without compromising transparency or mechanical properties, and prevents bleed-out.

Polyvinyl acetal films with improved stiffness

PatentWO2025103755A1

Innovation

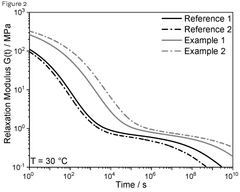

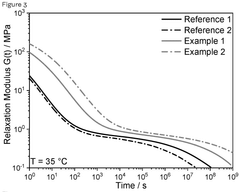

- The development of polyvinyl acetal films with a reduced amount of plasticizer, specifically within the range of 13.0% to 16.0% by weight, combined with a weight average molecular weight of at least 170,000 g/mol, and a shear relaxation modulus greater than 5 MPa at 30 °C and 5 min, addresses the need for increased stiffness and processibility.

Environmental Impact of PVA Production

The production of polyvinyl acetate (PVA) has significant environmental implications that must be carefully considered. The manufacturing process involves the polymerization of vinyl acetate monomer, which requires substantial energy inputs and generates various emissions. One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during production. These VOCs can contribute to air pollution and the formation of ground-level ozone, potentially impacting both human health and ecosystems.

Water pollution is another critical issue associated with PVA production. The process often generates wastewater containing residual monomers, solvents, and other chemical additives. If not properly treated, these effluents can contaminate water bodies, affecting aquatic life and potentially entering the food chain. Additionally, the disposal of PVA-containing products at the end of their lifecycle poses challenges, as the material is not readily biodegradable in natural environments.

The energy-intensive nature of PVA production contributes to its carbon footprint. The high temperatures and pressures required for polymerization typically rely on fossil fuel-based energy sources, leading to greenhouse gas emissions. As the demand for PVA continues to grow across various industries, the cumulative environmental impact of its production becomes increasingly significant.

Raw material sourcing for PVA production also raises sustainability concerns. Vinyl acetate monomer, the primary precursor, is derived from petrochemical sources, linking PVA production to the environmental issues associated with fossil fuel extraction and processing. This dependency on non-renewable resources underscores the need for more sustainable alternatives or improved production methods.

Efforts to mitigate the environmental impact of PVA production are ongoing. These include the development of more efficient production processes that reduce energy consumption and minimize waste generation. Some manufacturers are exploring the use of renewable energy sources to power their production facilities, thereby reducing the carbon footprint of PVA. Additionally, research into bio-based alternatives and recycling technologies for PVA products is gaining momentum, aiming to create a more circular and sustainable lifecycle for these materials.

Regulatory frameworks play a crucial role in addressing the environmental challenges of PVA production. Many countries have implemented strict emissions standards and waste management regulations for chemical manufacturing processes. Compliance with these regulations often drives innovation in cleaner production technologies and encourages the adoption of best practices in environmental management within the industry.

Water pollution is another critical issue associated with PVA production. The process often generates wastewater containing residual monomers, solvents, and other chemical additives. If not properly treated, these effluents can contaminate water bodies, affecting aquatic life and potentially entering the food chain. Additionally, the disposal of PVA-containing products at the end of their lifecycle poses challenges, as the material is not readily biodegradable in natural environments.

The energy-intensive nature of PVA production contributes to its carbon footprint. The high temperatures and pressures required for polymerization typically rely on fossil fuel-based energy sources, leading to greenhouse gas emissions. As the demand for PVA continues to grow across various industries, the cumulative environmental impact of its production becomes increasingly significant.

Raw material sourcing for PVA production also raises sustainability concerns. Vinyl acetate monomer, the primary precursor, is derived from petrochemical sources, linking PVA production to the environmental issues associated with fossil fuel extraction and processing. This dependency on non-renewable resources underscores the need for more sustainable alternatives or improved production methods.

Efforts to mitigate the environmental impact of PVA production are ongoing. These include the development of more efficient production processes that reduce energy consumption and minimize waste generation. Some manufacturers are exploring the use of renewable energy sources to power their production facilities, thereby reducing the carbon footprint of PVA. Additionally, research into bio-based alternatives and recycling technologies for PVA products is gaining momentum, aiming to create a more circular and sustainable lifecycle for these materials.

Regulatory frameworks play a crucial role in addressing the environmental challenges of PVA production. Many countries have implemented strict emissions standards and waste management regulations for chemical manufacturing processes. Compliance with these regulations often drives innovation in cleaner production technologies and encourages the adoption of best practices in environmental management within the industry.

Regulatory Landscape for PVA Applications

The regulatory landscape for Polyvinyl Acetate (PVA) applications is complex and multifaceted, reflecting the diverse uses of this versatile polymer across various industries. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PVA applications, particularly in food contact materials and pharmaceutical products. The FDA has approved PVA for use in food packaging and as an indirect food additive, subject to specific limitations and conditions outlined in the Code of Federal Regulations (CFR).

In the European Union, the European Chemicals Agency (ECHA) oversees the regulation of PVA under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register PVA and provide safety data when annual production or import exceeds one tonne. The European Food Safety Authority (EFSA) has also evaluated PVA for use in food contact materials, establishing specific migration limits and usage conditions.

For medical and pharmaceutical applications, regulatory bodies such as the FDA and the European Medicines Agency (EMA) have established guidelines for the use of PVA in drug delivery systems and medical devices. These regulations focus on ensuring the safety and efficacy of PVA-based products, including requirements for biocompatibility testing and quality control measures.

In the construction and adhesives industries, PVA applications are subject to various building codes and standards. For instance, the International Code Council (ICC) and ASTM International provide guidelines and specifications for PVA-based adhesives used in construction materials. These standards address factors such as bond strength, durability, and environmental resistance.

Environmental regulations also impact PVA applications, particularly concerning waste management and biodegradability. The Environmental Protection Agency (EPA) in the United States and similar agencies in other countries have established guidelines for the disposal and recycling of PVA-containing products. As sustainability concerns grow, there is an increasing focus on developing biodegradable PVA formulations that comply with emerging environmental regulations.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, govern the handling and use of PVA in industrial settings. These regulations address issues such as exposure limits, personal protective equipment requirements, and workplace safety protocols for PVA manufacturing and processing.

As the applications of PVA continue to expand and evolve, regulatory frameworks are likely to adapt to address new challenges and opportunities. Manufacturers and researchers working on maximizing the stiffness and flexibility balance in PVA must navigate this complex regulatory landscape to ensure compliance and market acceptance of their innovations.

In the European Union, the European Chemicals Agency (ECHA) oversees the regulation of PVA under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register PVA and provide safety data when annual production or import exceeds one tonne. The European Food Safety Authority (EFSA) has also evaluated PVA for use in food contact materials, establishing specific migration limits and usage conditions.

For medical and pharmaceutical applications, regulatory bodies such as the FDA and the European Medicines Agency (EMA) have established guidelines for the use of PVA in drug delivery systems and medical devices. These regulations focus on ensuring the safety and efficacy of PVA-based products, including requirements for biocompatibility testing and quality control measures.

In the construction and adhesives industries, PVA applications are subject to various building codes and standards. For instance, the International Code Council (ICC) and ASTM International provide guidelines and specifications for PVA-based adhesives used in construction materials. These standards address factors such as bond strength, durability, and environmental resistance.

Environmental regulations also impact PVA applications, particularly concerning waste management and biodegradability. The Environmental Protection Agency (EPA) in the United States and similar agencies in other countries have established guidelines for the disposal and recycling of PVA-containing products. As sustainability concerns grow, there is an increasing focus on developing biodegradable PVA formulations that comply with emerging environmental regulations.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, govern the handling and use of PVA in industrial settings. These regulations address issues such as exposure limits, personal protective equipment requirements, and workplace safety protocols for PVA manufacturing and processing.

As the applications of PVA continue to expand and evolve, regulatory frameworks are likely to adapt to address new challenges and opportunities. Manufacturers and researchers working on maximizing the stiffness and flexibility balance in PVA must navigate this complex regulatory landscape to ensure compliance and market acceptance of their innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!