Polyvinyl Acetate for Enhanced Energy Efficient Windows

JUL 30, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Window Tech Evolution

The evolution of polyvinyl acetate (PVAc) technology for energy-efficient windows has been marked by significant advancements over the past few decades. Initially, PVAc was primarily used as an adhesive in various industries, including construction. However, its potential for enhancing window energy efficiency was recognized in the late 1980s, leading to focused research and development efforts.

In the early 1990s, researchers began exploring PVAc's properties as a potential interlayer material for laminated glass. The primary goal was to improve the thermal insulation properties of windows without compromising transparency. This period saw the development of basic PVAc formulations that could be applied between glass panes, offering modest improvements in energy efficiency.

The turn of the millennium brought about a significant leap in PVAc window technology. Scientists discovered that by modifying the molecular structure of PVAc, they could enhance its thermal resistance properties. This led to the creation of advanced PVAc interlayers that could significantly reduce heat transfer through windows. Concurrently, improvements in manufacturing processes allowed for the production of thinner, more uniform PVAc films, further enhancing their effectiveness.

Between 2005 and 2010, the focus shifted towards improving the durability and longevity of PVAc-enhanced windows. Researchers developed UV-resistant formulations to prevent degradation and yellowing of the interlayer over time. This period also saw the integration of PVAc technology with other window innovations, such as low-E coatings and gas-filled insulating units, creating synergistic effects for superior energy efficiency.

The past decade has witnessed a surge in nanotechnology applications in PVAc window technology. Nanoparticle-enhanced PVAc formulations have been developed, offering unprecedented levels of thermal insulation. These advanced materials can actively respond to temperature changes, providing optimal energy efficiency in various climates. Additionally, recent research has focused on incorporating phase-change materials into PVAc interlayers, allowing for dynamic heat storage and release capabilities.

Looking towards the future, the evolution of PVAc window technology is expected to continue along several promising paths. Current research is exploring the potential of smart PVAc interlayers that can change their properties in response to external stimuli, such as light or temperature. There is also growing interest in developing bio-based PVAc formulations, aligning with the global push towards sustainability in construction materials.

In the early 1990s, researchers began exploring PVAc's properties as a potential interlayer material for laminated glass. The primary goal was to improve the thermal insulation properties of windows without compromising transparency. This period saw the development of basic PVAc formulations that could be applied between glass panes, offering modest improvements in energy efficiency.

The turn of the millennium brought about a significant leap in PVAc window technology. Scientists discovered that by modifying the molecular structure of PVAc, they could enhance its thermal resistance properties. This led to the creation of advanced PVAc interlayers that could significantly reduce heat transfer through windows. Concurrently, improvements in manufacturing processes allowed for the production of thinner, more uniform PVAc films, further enhancing their effectiveness.

Between 2005 and 2010, the focus shifted towards improving the durability and longevity of PVAc-enhanced windows. Researchers developed UV-resistant formulations to prevent degradation and yellowing of the interlayer over time. This period also saw the integration of PVAc technology with other window innovations, such as low-E coatings and gas-filled insulating units, creating synergistic effects for superior energy efficiency.

The past decade has witnessed a surge in nanotechnology applications in PVAc window technology. Nanoparticle-enhanced PVAc formulations have been developed, offering unprecedented levels of thermal insulation. These advanced materials can actively respond to temperature changes, providing optimal energy efficiency in various climates. Additionally, recent research has focused on incorporating phase-change materials into PVAc interlayers, allowing for dynamic heat storage and release capabilities.

Looking towards the future, the evolution of PVAc window technology is expected to continue along several promising paths. Current research is exploring the potential of smart PVAc interlayers that can change their properties in response to external stimuli, such as light or temperature. There is also growing interest in developing bio-based PVAc formulations, aligning with the global push towards sustainability in construction materials.

Energy Efficient Window Market

The energy efficient window market has experienced significant growth in recent years, driven by increasing awareness of environmental issues and the need for energy conservation. This market segment is characterized by windows designed to minimize heat transfer between the interior and exterior of buildings, thereby reducing energy consumption for heating and cooling.

The global energy efficient window market size was valued at approximately $13.5 billion in 2020 and is projected to reach $25.3 billion by 2028, growing at a CAGR of 8.2% during the forecast period. This growth is primarily attributed to stringent building energy codes, rising energy costs, and growing consumer demand for sustainable building solutions.

Residential buildings represent the largest market segment for energy efficient windows, accounting for over 60% of the total market share. This is due to the increasing focus on home energy efficiency and the potential for long-term cost savings on utility bills. Commercial buildings, including offices, retail spaces, and educational institutions, make up the second-largest segment and are expected to witness rapid growth in the coming years.

Geographically, North America dominates the energy efficient window market, followed by Europe and Asia-Pacific. The United States, in particular, has been at the forefront of adopting energy efficient windows, driven by government initiatives such as the ENERGY STAR program and tax incentives for energy-efficient home improvements.

Key players in the energy efficient window market include Saint-Gobain, Asahi Glass, YKK AP, Jeld-Wen Holdings, Nippon Sheet Glass, PPG Industries, and Masco Corporation. These companies are continuously investing in research and development to improve the thermal performance of their products and gain a competitive edge in the market.

The market is witnessing several technological advancements, including the development of smart windows, vacuum-insulated glazing, and the integration of phase-change materials. These innovations aim to further enhance the energy efficiency of windows and provide additional functionalities such as dynamic tinting and self-cleaning properties.

Despite the positive growth outlook, the energy efficient window market faces challenges such as high initial costs and the long payback period for consumers. However, ongoing technological advancements and increasing awareness of the long-term benefits of energy efficient windows are expected to drive market growth in the coming years.

The global energy efficient window market size was valued at approximately $13.5 billion in 2020 and is projected to reach $25.3 billion by 2028, growing at a CAGR of 8.2% during the forecast period. This growth is primarily attributed to stringent building energy codes, rising energy costs, and growing consumer demand for sustainable building solutions.

Residential buildings represent the largest market segment for energy efficient windows, accounting for over 60% of the total market share. This is due to the increasing focus on home energy efficiency and the potential for long-term cost savings on utility bills. Commercial buildings, including offices, retail spaces, and educational institutions, make up the second-largest segment and are expected to witness rapid growth in the coming years.

Geographically, North America dominates the energy efficient window market, followed by Europe and Asia-Pacific. The United States, in particular, has been at the forefront of adopting energy efficient windows, driven by government initiatives such as the ENERGY STAR program and tax incentives for energy-efficient home improvements.

Key players in the energy efficient window market include Saint-Gobain, Asahi Glass, YKK AP, Jeld-Wen Holdings, Nippon Sheet Glass, PPG Industries, and Masco Corporation. These companies are continuously investing in research and development to improve the thermal performance of their products and gain a competitive edge in the market.

The market is witnessing several technological advancements, including the development of smart windows, vacuum-insulated glazing, and the integration of phase-change materials. These innovations aim to further enhance the energy efficiency of windows and provide additional functionalities such as dynamic tinting and self-cleaning properties.

Despite the positive growth outlook, the energy efficient window market faces challenges such as high initial costs and the long payback period for consumers. However, ongoing technological advancements and increasing awareness of the long-term benefits of energy efficient windows are expected to drive market growth in the coming years.

PVAc Challenges in Windows

While polyvinyl acetate (PVAc) shows promise for enhancing energy efficiency in windows, several challenges hinder its widespread adoption and optimal performance. One of the primary obstacles is the material's sensitivity to moisture. PVAc tends to absorb water, which can lead to swelling, reduced adhesion, and compromised structural integrity. This hygroscopic nature poses significant concerns for long-term durability, especially in humid environments or areas prone to condensation.

Another challenge lies in the thermal stability of PVAc. At elevated temperatures, the polymer can soften and lose its dimensional stability, potentially affecting the overall performance of the window system. This temperature sensitivity limits its application in regions with extreme climate conditions and necessitates careful consideration of thermal management strategies.

The adhesion properties of PVAc, while generally good, can be inconsistent across different substrates commonly used in window manufacturing. Achieving uniform and durable bonding with materials such as glass, wood, and various metals requires extensive research and development of specialized formulations and application techniques.

PVAc's optical properties present another set of challenges. While the material offers good transparency, achieving and maintaining optimal clarity over extended periods remains a concern. Factors such as UV exposure and thermal cycling can lead to yellowing or haze formation, potentially diminishing the aesthetic and functional qualities of the windows.

The processing and application of PVAc in window manufacturing also pose technical hurdles. Ensuring uniform thickness, bubble-free application, and proper curing conditions are critical for maximizing the material's energy-efficient properties. These factors necessitate precise control over manufacturing processes and may require specialized equipment or techniques.

Furthermore, the long-term performance and aging characteristics of PVAc in window applications are not yet fully understood. Accelerated weathering tests and real-world, long-term studies are needed to accurately predict the material's behavior over the typical lifespan of windows, which can extend several decades.

Lastly, the environmental impact and end-of-life considerations for PVAc-enhanced windows present additional challenges. While PVAc itself is generally considered environmentally friendly, its combination with other materials in window systems may complicate recycling efforts. Developing effective recycling or disposal methods for these composite structures is crucial for ensuring the overall sustainability of PVAc-based energy-efficient windows.

Another challenge lies in the thermal stability of PVAc. At elevated temperatures, the polymer can soften and lose its dimensional stability, potentially affecting the overall performance of the window system. This temperature sensitivity limits its application in regions with extreme climate conditions and necessitates careful consideration of thermal management strategies.

The adhesion properties of PVAc, while generally good, can be inconsistent across different substrates commonly used in window manufacturing. Achieving uniform and durable bonding with materials such as glass, wood, and various metals requires extensive research and development of specialized formulations and application techniques.

PVAc's optical properties present another set of challenges. While the material offers good transparency, achieving and maintaining optimal clarity over extended periods remains a concern. Factors such as UV exposure and thermal cycling can lead to yellowing or haze formation, potentially diminishing the aesthetic and functional qualities of the windows.

The processing and application of PVAc in window manufacturing also pose technical hurdles. Ensuring uniform thickness, bubble-free application, and proper curing conditions are critical for maximizing the material's energy-efficient properties. These factors necessitate precise control over manufacturing processes and may require specialized equipment or techniques.

Furthermore, the long-term performance and aging characteristics of PVAc in window applications are not yet fully understood. Accelerated weathering tests and real-world, long-term studies are needed to accurately predict the material's behavior over the typical lifespan of windows, which can extend several decades.

Lastly, the environmental impact and end-of-life considerations for PVAc-enhanced windows present additional challenges. While PVAc itself is generally considered environmentally friendly, its combination with other materials in window systems may complicate recycling efforts. Developing effective recycling or disposal methods for these composite structures is crucial for ensuring the overall sustainability of PVAc-based energy-efficient windows.

Current PVAc Window Solutions

01 Energy-efficient polyvinyl acetate production methods

Various techniques have been developed to improve the energy efficiency of polyvinyl acetate production processes. These methods focus on optimizing reaction conditions, reducing energy consumption during polymerization, and improving overall process efficiency.- Energy-efficient polyvinyl acetate production methods: Various methods have been developed to improve the energy efficiency of polyvinyl acetate production processes. These include optimizing reaction conditions, using more efficient catalysts, and implementing heat recovery systems. Such improvements can lead to reduced energy consumption and lower production costs.

- Polyvinyl acetate composites for thermal insulation: Polyvinyl acetate-based composites have been developed for use in thermal insulation applications. These materials can improve energy efficiency in buildings and industrial settings by reducing heat transfer. The composites may incorporate various fillers or additives to enhance their insulating properties.

- Energy-efficient adhesive formulations using polyvinyl acetate: Researchers have developed energy-efficient adhesive formulations incorporating polyvinyl acetate. These adhesives may require less energy for curing or drying, or may offer improved bonding strength at lower application temperatures. Such formulations can contribute to energy savings in various industries that use adhesives.

- Polyvinyl acetate in energy-efficient coatings: Polyvinyl acetate has been utilized in the development of energy-efficient coatings. These coatings may offer improved insulation properties, reflectivity, or durability, contributing to energy savings in buildings or other applications. The coatings may also be formulated for low-energy application or curing processes.

- Recycling and energy recovery of polyvinyl acetate materials: Methods have been developed for recycling polyvinyl acetate materials or recovering energy from them at the end of their lifecycle. These processes aim to reduce waste and improve overall energy efficiency by reusing materials or extracting their energy content. Such approaches contribute to more sustainable use of polyvinyl acetate in various applications.

02 Thermal insulation applications of polyvinyl acetate

Polyvinyl acetate-based materials are utilized in thermal insulation applications to improve energy efficiency in buildings and industrial settings. These materials offer good insulating properties while being cost-effective and easy to apply.Expand Specific Solutions03 Energy-efficient adhesive formulations using polyvinyl acetate

Researchers have developed energy-efficient adhesive formulations incorporating polyvinyl acetate. These formulations aim to reduce energy consumption during the application and curing processes while maintaining strong bonding properties.Expand Specific Solutions04 Polyvinyl acetate in energy-efficient coatings

Polyvinyl acetate is used in the development of energy-efficient coatings for various surfaces. These coatings can help reduce heat transfer, improve insulation, and contribute to overall energy savings in buildings and industrial applications.Expand Specific Solutions05 Recycling and energy recovery of polyvinyl acetate materials

Methods for recycling and energy recovery of polyvinyl acetate-based materials have been developed to improve overall energy efficiency and reduce environmental impact. These processes aim to recover valuable resources and energy from waste materials.Expand Specific Solutions

Key Players in PVAc Windows

The research on Polyvinyl Acetate for Enhanced Energy Efficient Windows is in a developing stage, with growing market potential due to increasing focus on energy efficiency in buildings. The global market for energy-efficient windows is expanding, driven by stringent building regulations and environmental concerns. Technologically, the field is advancing, with companies like Kuraray Co., Ltd. and Toyobo Co., Ltd. leading in polyvinyl acetate innovations. Other key players such as Corning, Inc. and Bayer AG are contributing to the development of advanced window materials. The competitive landscape is diverse, with both established chemical companies and specialized materials firms actively participating in research and development efforts.

Corning, Inc.

Technical Solution: Corning has developed a novel approach to energy-efficient windows using PVA-based coatings in conjunction with their advanced glass technologies. Their research focuses on creating ultra-thin, transparent PVA films that can be applied to glass surfaces to enhance insulation properties. Corning's PVA coatings are designed to work synergistically with their low-E glass products, providing additional thermal insulation without significantly reducing visible light transmission. The company has reported that their PVA-enhanced windows can improve energy efficiency by up to 25% compared to standard double-pane windows[2]. Corning has also explored the use of nanoparticle-doped PVA coatings to create dynamic, electrochromic windows that can adjust their tint in response to external conditions, further optimizing energy performance[4].

Strengths: Compatibility with existing glass manufacturing processes, significant improvement in energy efficiency. Weaknesses: May require additional processing steps in window production, potential for increased costs.

Sekisui Chemical Co., Ltd.

Technical Solution: Sekisui Chemical has made significant strides in PVA research for energy-efficient windows, focusing on the development of advanced interlayer materials. Their S-LEC™ PVA film technology has been engineered to provide superior thermal insulation properties while maintaining excellent optical clarity. Sekisui's research has led to the creation of multi-layer PVA films that incorporate infrared-reflecting nanoparticles, effectively reducing solar heat gain without compromising visible light transmission. The company has reported that windows using their advanced PVA interlayers can achieve a solar heat gain coefficient (SHGC) reduction of up to 40% compared to standard laminated glass[7]. Sekisui has also explored the use of PVA in combination with other polymers to create hybrid interlayers with enhanced mechanical properties and improved edge stability in insulated glass units[8].

Strengths: Advanced multi-layer PVA technology with superior thermal insulation, excellent optical properties. Weaknesses: Potentially higher production costs, may require specialized lamination processes.

PVAc Window Core Innovations

Energy efficient film

PatentInactiveIN5395DELNP2015A

Innovation

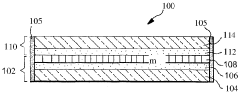

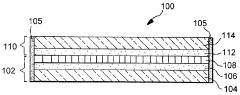

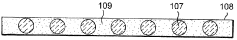

- A flexible energy-efficient window film comprising transparent substrates, a liquid crystal layer, and a gasket, optionally with conductive and reflective layers, applied to regular windows to enhance thermal insulation and light transmission while blocking solar radiation.

Polyvinylacetal with high flowing capability and film containing softeners produced using same

PatentActiveEP2336199A1

Innovation

- The production of polyvinyl acetals with a degree of acetalization above 75 mol% and specific OH blockiness, achieved through an acid-catalyzed reaction process involving controlled temperature and neutralization, enhances flowability by adjusting the secondary structure of the polymer chain, as determined by 13C NMR measurements.

Environmental Impact of PVAc

The environmental impact of polyvinyl acetate (PVAc) in the context of energy-efficient windows is a crucial consideration for sustainable building practices. PVAc, when used in window technologies, contributes to improved energy efficiency by enhancing thermal insulation properties. This reduction in heat transfer leads to decreased energy consumption for heating and cooling, thereby indirectly lowering greenhouse gas emissions associated with energy production.

However, the production of PVAc itself has environmental implications. The manufacturing process involves the polymerization of vinyl acetate monomer, which requires energy and petrochemical resources. This process can result in the emission of volatile organic compounds (VOCs) and other pollutants if not properly controlled. Manufacturers are increasingly adopting cleaner production methods and implementing emission control technologies to mitigate these impacts.

The durability of PVAc-enhanced windows is another factor influencing their environmental footprint. Longer-lasting windows reduce the need for frequent replacements, thus conserving resources and minimizing waste generation over time. Additionally, the improved insulation properties of these windows can lead to a reduction in the overall carbon footprint of buildings throughout their lifecycle.

End-of-life considerations for PVAc-containing windows are also important. While PVAc is not biodegradable, it can be recycled through mechanical or chemical processes. However, the composite nature of window materials can make recycling challenging, necessitating the development of more efficient separation and recycling technologies.

Water-based PVAc formulations have gained popularity due to their lower environmental impact compared to solvent-based alternatives. These formulations reduce VOC emissions during application and use, contributing to better indoor air quality and reduced atmospheric pollution.

The use of PVAc in energy-efficient windows also intersects with broader sustainability goals. By improving building energy performance, these windows contribute to urban sustainability initiatives and help meet increasingly stringent building energy codes and standards.

Research into bio-based alternatives to traditional PVAc is ongoing, with the aim of reducing reliance on petrochemical feedstocks. These alternatives, derived from renewable resources, have the potential to further decrease the environmental impact of window technologies while maintaining or improving performance characteristics.

In conclusion, while PVAc contributes positively to energy efficiency in windows, its overall environmental impact is complex. Balancing the benefits of improved energy performance against the environmental costs of production and end-of-life management remains a key challenge for researchers and manufacturers in the pursuit of truly sustainable window technologies.

However, the production of PVAc itself has environmental implications. The manufacturing process involves the polymerization of vinyl acetate monomer, which requires energy and petrochemical resources. This process can result in the emission of volatile organic compounds (VOCs) and other pollutants if not properly controlled. Manufacturers are increasingly adopting cleaner production methods and implementing emission control technologies to mitigate these impacts.

The durability of PVAc-enhanced windows is another factor influencing their environmental footprint. Longer-lasting windows reduce the need for frequent replacements, thus conserving resources and minimizing waste generation over time. Additionally, the improved insulation properties of these windows can lead to a reduction in the overall carbon footprint of buildings throughout their lifecycle.

End-of-life considerations for PVAc-containing windows are also important. While PVAc is not biodegradable, it can be recycled through mechanical or chemical processes. However, the composite nature of window materials can make recycling challenging, necessitating the development of more efficient separation and recycling technologies.

Water-based PVAc formulations have gained popularity due to their lower environmental impact compared to solvent-based alternatives. These formulations reduce VOC emissions during application and use, contributing to better indoor air quality and reduced atmospheric pollution.

The use of PVAc in energy-efficient windows also intersects with broader sustainability goals. By improving building energy performance, these windows contribute to urban sustainability initiatives and help meet increasingly stringent building energy codes and standards.

Research into bio-based alternatives to traditional PVAc is ongoing, with the aim of reducing reliance on petrochemical feedstocks. These alternatives, derived from renewable resources, have the potential to further decrease the environmental impact of window technologies while maintaining or improving performance characteristics.

In conclusion, while PVAc contributes positively to energy efficiency in windows, its overall environmental impact is complex. Balancing the benefits of improved energy performance against the environmental costs of production and end-of-life management remains a key challenge for researchers and manufacturers in the pursuit of truly sustainable window technologies.

PVAc Window Manufacturing

The manufacturing process of polyvinyl acetate (PVAc) windows involves several key steps and considerations to ensure the production of high-quality, energy-efficient windows. The process begins with the preparation of the PVAc material, which is typically produced through the polymerization of vinyl acetate monomer. This polymer is then formulated with various additives to enhance its properties for window applications, such as UV stabilizers, plasticizers, and cross-linking agents.

The next stage involves the extrusion of PVAc into window profiles. This process requires precise temperature control and pressure management to achieve the desired shape and thickness of the window components. The extruded profiles are then cut to size and undergo a cooling process to ensure dimensional stability.

Assembly of the PVAc window frames is a critical step in the manufacturing process. This involves joining the extruded profiles using specialized welding techniques or adhesives designed for PVAc materials. The corners of the frames are typically reinforced to enhance structural integrity and prevent deformation over time.

The glazing process follows, where energy-efficient glass panes are inserted into the PVAc frames. This step often includes the application of sealants and gaskets to ensure airtight and watertight seals between the glass and the frame. For enhanced energy efficiency, double or triple glazing with low-emissivity coatings and inert gas filling between panes is commonly employed.

Quality control is an integral part of PVAc window manufacturing. This includes rigorous testing for air and water infiltration, structural performance, and thermal insulation properties. Advanced testing equipment, such as thermal imaging cameras and air pressure differential systems, are used to verify the energy efficiency and overall performance of the windows.

The final stages of manufacturing involve the installation of hardware components, such as handles, locks, and hinges. These components are carefully selected to complement the PVAc material and ensure smooth operation and security of the windows. Additionally, surface treatments may be applied to enhance the aesthetic appeal and durability of the PVAc frames, including UV-resistant coatings or decorative finishes.

Throughout the manufacturing process, strict adherence to industry standards and regulations is essential. This includes compliance with energy efficiency ratings, such as U-factor and Solar Heat Gain Coefficient (SHGC), as well as safety and durability standards. Manufacturers must also consider the environmental impact of PVAc window production, implementing recycling programs and exploring sustainable manufacturing practices to minimize waste and energy consumption.

The next stage involves the extrusion of PVAc into window profiles. This process requires precise temperature control and pressure management to achieve the desired shape and thickness of the window components. The extruded profiles are then cut to size and undergo a cooling process to ensure dimensional stability.

Assembly of the PVAc window frames is a critical step in the manufacturing process. This involves joining the extruded profiles using specialized welding techniques or adhesives designed for PVAc materials. The corners of the frames are typically reinforced to enhance structural integrity and prevent deformation over time.

The glazing process follows, where energy-efficient glass panes are inserted into the PVAc frames. This step often includes the application of sealants and gaskets to ensure airtight and watertight seals between the glass and the frame. For enhanced energy efficiency, double or triple glazing with low-emissivity coatings and inert gas filling between panes is commonly employed.

Quality control is an integral part of PVAc window manufacturing. This includes rigorous testing for air and water infiltration, structural performance, and thermal insulation properties. Advanced testing equipment, such as thermal imaging cameras and air pressure differential systems, are used to verify the energy efficiency and overall performance of the windows.

The final stages of manufacturing involve the installation of hardware components, such as handles, locks, and hinges. These components are carefully selected to complement the PVAc material and ensure smooth operation and security of the windows. Additionally, surface treatments may be applied to enhance the aesthetic appeal and durability of the PVAc frames, including UV-resistant coatings or decorative finishes.

Throughout the manufacturing process, strict adherence to industry standards and regulations is essential. This includes compliance with energy efficiency ratings, such as U-factor and Solar Heat Gain Coefficient (SHGC), as well as safety and durability standards. Manufacturers must also consider the environmental impact of PVAc window production, implementing recycling programs and exploring sustainable manufacturing practices to minimize waste and energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!