Polyvinyl Acetate in Electronic Devices: Functional Advancements

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc in Electronics: Evolution and Objectives

Polyvinyl acetate (PVAc) has emerged as a versatile material in the electronics industry, with its journey spanning several decades. Initially used primarily as an adhesive, PVAc's role in electronic devices has evolved significantly, driven by advancements in material science and the ever-increasing demands of modern technology.

The evolution of PVAc in electronics can be traced back to the mid-20th century when it was first recognized for its dielectric properties. As electronic devices became more compact and sophisticated, the need for materials with specific electrical and mechanical characteristics grew. PVAc's unique combination of properties, including its flexibility, thermal stability, and electrical insulation capabilities, made it an attractive option for various electronic applications.

Throughout the 1970s and 1980s, researchers began exploring PVAc's potential in more advanced electronic components. Its ability to form thin, uniform films led to its use in capacitors and as a protective coating for circuit boards. The material's low cost and ease of processing further contributed to its adoption in the rapidly expanding electronics manufacturing sector.

The 1990s and early 2000s saw a surge in research focused on enhancing PVAc's properties for specific electronic applications. Scientists and engineers worked on modifying PVAc through copolymerization and blending with other materials, aiming to improve its thermal stability, adhesion strength, and electrical characteristics. These efforts resulted in the development of specialized PVAc formulations tailored for use in various electronic devices, from consumer electronics to industrial equipment.

In recent years, the objectives for PVAc in electronics have shifted towards addressing the challenges posed by emerging technologies. With the advent of flexible and wearable electronics, researchers are now exploring ways to leverage PVAc's inherent flexibility while enhancing its durability and conductivity. The material's potential in energy storage devices, such as supercapacitors and batteries, is also being investigated, with a focus on improving its ion conductivity and electrochemical stability.

Looking ahead, the goals for PVAc in electronic devices are multifaceted. There is a strong emphasis on developing environmentally friendly formulations that align with the growing demand for sustainable electronics. Additionally, researchers are working on enhancing PVAc's compatibility with advanced manufacturing techniques, such as 3D printing and roll-to-roll processing, to enable more efficient and versatile production of electronic components.

The evolution of PVAc in electronics can be traced back to the mid-20th century when it was first recognized for its dielectric properties. As electronic devices became more compact and sophisticated, the need for materials with specific electrical and mechanical characteristics grew. PVAc's unique combination of properties, including its flexibility, thermal stability, and electrical insulation capabilities, made it an attractive option for various electronic applications.

Throughout the 1970s and 1980s, researchers began exploring PVAc's potential in more advanced electronic components. Its ability to form thin, uniform films led to its use in capacitors and as a protective coating for circuit boards. The material's low cost and ease of processing further contributed to its adoption in the rapidly expanding electronics manufacturing sector.

The 1990s and early 2000s saw a surge in research focused on enhancing PVAc's properties for specific electronic applications. Scientists and engineers worked on modifying PVAc through copolymerization and blending with other materials, aiming to improve its thermal stability, adhesion strength, and electrical characteristics. These efforts resulted in the development of specialized PVAc formulations tailored for use in various electronic devices, from consumer electronics to industrial equipment.

In recent years, the objectives for PVAc in electronics have shifted towards addressing the challenges posed by emerging technologies. With the advent of flexible and wearable electronics, researchers are now exploring ways to leverage PVAc's inherent flexibility while enhancing its durability and conductivity. The material's potential in energy storage devices, such as supercapacitors and batteries, is also being investigated, with a focus on improving its ion conductivity and electrochemical stability.

Looking ahead, the goals for PVAc in electronic devices are multifaceted. There is a strong emphasis on developing environmentally friendly formulations that align with the growing demand for sustainable electronics. Additionally, researchers are working on enhancing PVAc's compatibility with advanced manufacturing techniques, such as 3D printing and roll-to-roll processing, to enable more efficient and versatile production of electronic components.

Market Demand Analysis for PVAc-Enhanced Devices

The market demand for electronic devices enhanced with Polyvinyl Acetate (PVAc) is experiencing significant growth, driven by the increasing need for more durable and versatile electronic products. PVAc's unique properties, including its adhesive strength, flexibility, and resistance to environmental factors, make it an attractive material for various applications in the electronics industry.

In the consumer electronics sector, there is a growing demand for devices with improved durability and water resistance. PVAc-enhanced coatings and adhesives are being utilized to create more robust smartphones, tablets, and wearable devices that can withstand everyday wear and tear. This trend is particularly evident in the outdoor and rugged device market, where consumers expect their electronics to perform reliably in challenging environments.

The automotive industry is another key driver of demand for PVAc-enhanced electronic devices. As vehicles become increasingly connected and electrified, there is a rising need for electronic components that can withstand the harsh conditions found in automotive applications. PVAc's ability to provide excellent adhesion and protection against moisture and vibration makes it an ideal material for automotive electronics, including infotainment systems, sensors, and control units.

In the industrial sector, the demand for PVAc-enhanced electronic devices is growing due to the increasing adoption of Internet of Things (IoT) technologies and smart manufacturing systems. Industrial sensors, control panels, and communication devices enhanced with PVAc coatings offer improved reliability and longevity in challenging factory environments, reducing maintenance costs and downtime.

The medical device industry is also showing interest in PVAc-enhanced electronics. As medical devices become more sophisticated and miniaturized, there is a need for materials that can provide both protection and biocompatibility. PVAc's non-toxic nature and ability to form thin, flexible coatings make it suitable for use in various medical electronic devices, including wearable health monitors and implantable sensors.

The global shift towards renewable energy and smart grid technologies is creating new opportunities for PVAc-enhanced electronic devices. Solar inverters, energy storage systems, and smart meters require robust protection against environmental factors, driving the demand for PVAc-based solutions in the energy sector.

As the electronics industry continues to evolve, the market for PVAc-enhanced devices is expected to expand further. Manufacturers are increasingly recognizing the value of incorporating PVAc into their products to meet consumer demands for durability, reliability, and performance across various applications and industries.

In the consumer electronics sector, there is a growing demand for devices with improved durability and water resistance. PVAc-enhanced coatings and adhesives are being utilized to create more robust smartphones, tablets, and wearable devices that can withstand everyday wear and tear. This trend is particularly evident in the outdoor and rugged device market, where consumers expect their electronics to perform reliably in challenging environments.

The automotive industry is another key driver of demand for PVAc-enhanced electronic devices. As vehicles become increasingly connected and electrified, there is a rising need for electronic components that can withstand the harsh conditions found in automotive applications. PVAc's ability to provide excellent adhesion and protection against moisture and vibration makes it an ideal material for automotive electronics, including infotainment systems, sensors, and control units.

In the industrial sector, the demand for PVAc-enhanced electronic devices is growing due to the increasing adoption of Internet of Things (IoT) technologies and smart manufacturing systems. Industrial sensors, control panels, and communication devices enhanced with PVAc coatings offer improved reliability and longevity in challenging factory environments, reducing maintenance costs and downtime.

The medical device industry is also showing interest in PVAc-enhanced electronics. As medical devices become more sophisticated and miniaturized, there is a need for materials that can provide both protection and biocompatibility. PVAc's non-toxic nature and ability to form thin, flexible coatings make it suitable for use in various medical electronic devices, including wearable health monitors and implantable sensors.

The global shift towards renewable energy and smart grid technologies is creating new opportunities for PVAc-enhanced electronic devices. Solar inverters, energy storage systems, and smart meters require robust protection against environmental factors, driving the demand for PVAc-based solutions in the energy sector.

As the electronics industry continues to evolve, the market for PVAc-enhanced devices is expected to expand further. Manufacturers are increasingly recognizing the value of incorporating PVAc into their products to meet consumer demands for durability, reliability, and performance across various applications and industries.

Current PVAc Applications and Challenges in Electronics

Polyvinyl acetate (PVAc) has emerged as a versatile material in the electronics industry, finding applications in various components and devices. Currently, PVAc is primarily utilized in adhesives, coatings, and encapsulants for electronic assemblies. Its excellent dielectric properties, coupled with good adhesion to a wide range of substrates, make it an attractive choice for insulation and protection of electronic components.

In printed circuit boards (PCBs), PVAc-based adhesives are employed for bonding components and providing structural integrity. These adhesives offer reliable performance under varying temperature and humidity conditions, ensuring the longevity of electronic devices. Additionally, PVAc coatings are used to protect PCBs from environmental factors, such as moisture and dust, which can compromise the functionality of electronic circuits.

PVAc has also found applications in flexible electronics, where its ability to form thin, flexible films is particularly advantageous. It is used in the fabrication of flexible displays, wearable devices, and bendable sensors. The material's flexibility and durability contribute to the development of more robust and versatile electronic products.

Despite its widespread use, PVAc faces several challenges in electronic applications. One significant issue is its limited thermal stability, which can lead to degradation at elevated temperatures commonly encountered in electronic devices. This thermal limitation restricts its use in high-temperature applications and necessitates careful consideration of operating conditions.

Another challenge is the moisture sensitivity of PVAc. While it provides good initial protection against moisture, prolonged exposure can lead to swelling and loss of adhesion, potentially compromising the integrity of electronic assemblies. This necessitates the development of improved formulations or protective measures to enhance long-term reliability in humid environments.

The electrical properties of PVAc, while generally favorable, may not meet the stringent requirements of certain high-frequency or high-power electronic applications. Enhancing its dielectric strength and reducing dielectric losses are areas of ongoing research to expand its applicability in advanced electronic systems.

Furthermore, as the electronics industry moves towards more environmentally friendly and sustainable practices, there is a growing need to address the end-of-life disposal and recyclability of PVAc-containing electronic components. Developing eco-friendly formulations and recycling methods for PVAc in electronics is becoming increasingly important to meet sustainability goals.

In printed circuit boards (PCBs), PVAc-based adhesives are employed for bonding components and providing structural integrity. These adhesives offer reliable performance under varying temperature and humidity conditions, ensuring the longevity of electronic devices. Additionally, PVAc coatings are used to protect PCBs from environmental factors, such as moisture and dust, which can compromise the functionality of electronic circuits.

PVAc has also found applications in flexible electronics, where its ability to form thin, flexible films is particularly advantageous. It is used in the fabrication of flexible displays, wearable devices, and bendable sensors. The material's flexibility and durability contribute to the development of more robust and versatile electronic products.

Despite its widespread use, PVAc faces several challenges in electronic applications. One significant issue is its limited thermal stability, which can lead to degradation at elevated temperatures commonly encountered in electronic devices. This thermal limitation restricts its use in high-temperature applications and necessitates careful consideration of operating conditions.

Another challenge is the moisture sensitivity of PVAc. While it provides good initial protection against moisture, prolonged exposure can lead to swelling and loss of adhesion, potentially compromising the integrity of electronic assemblies. This necessitates the development of improved formulations or protective measures to enhance long-term reliability in humid environments.

The electrical properties of PVAc, while generally favorable, may not meet the stringent requirements of certain high-frequency or high-power electronic applications. Enhancing its dielectric strength and reducing dielectric losses are areas of ongoing research to expand its applicability in advanced electronic systems.

Furthermore, as the electronics industry moves towards more environmentally friendly and sustainable practices, there is a growing need to address the end-of-life disposal and recyclability of PVAc-containing electronic components. Developing eco-friendly formulations and recycling methods for PVAc in electronics is becoming increasingly important to meet sustainability goals.

Existing PVAc Integration Solutions for Electronics

01 Improved adhesive properties

Advancements in polyvinyl acetate formulations have led to enhanced adhesive properties, making it suitable for a wider range of applications. These improvements include better bonding strength, increased durability, and improved resistance to environmental factors such as moisture and temperature fluctuations.- Improved adhesive properties: Advancements in polyvinyl acetate formulations have led to enhanced adhesive properties, making it suitable for a wider range of applications. These improvements include better bonding strength, increased durability, and improved resistance to environmental factors such as moisture and temperature fluctuations.

- Enhanced water resistance: Recent developments in polyvinyl acetate technology have focused on improving its water resistance. This has been achieved through various methods, including the incorporation of cross-linking agents and the development of specialized copolymers. The resulting materials exhibit better performance in high-humidity environments and underwater applications.

- Eco-friendly formulations: In response to growing environmental concerns, researchers have developed more sustainable and eco-friendly polyvinyl acetate formulations. These advancements include the use of bio-based raw materials, reduction of volatile organic compounds (VOCs), and improved biodegradability of the final product.

- Improved thermal stability: Functional advancements in polyvinyl acetate have led to improved thermal stability, allowing for its use in high-temperature applications. This has been achieved through the incorporation of heat-resistant additives and the development of specialized copolymers that maintain their properties at elevated temperatures.

- Enhanced compatibility with other materials: Recent research has focused on improving the compatibility of polyvinyl acetate with other materials, such as plastics, fibers, and inorganic substances. This has resulted in the development of new composite materials with enhanced properties, expanding the range of potential applications for polyvinyl acetate-based products.

02 Enhanced water resistance

Recent developments in polyvinyl acetate technology have focused on improving its water resistance. This has been achieved through various methods, including the incorporation of cross-linking agents and the development of specialized copolymers. These advancements have expanded the use of polyvinyl acetate in outdoor and high-humidity applications.Expand Specific Solutions03 Improved thermal stability

Functional advancements in polyvinyl acetate have resulted in improved thermal stability. This has been achieved through the incorporation of heat-resistant additives and the development of new polymerization techniques. The enhanced thermal stability allows for the use of polyvinyl acetate in high-temperature applications and improves its overall durability.Expand Specific Solutions04 Eco-friendly formulations

Recent advancements in polyvinyl acetate technology have focused on developing more environmentally friendly formulations. These include the use of bio-based raw materials, reduction of volatile organic compounds (VOCs), and improved biodegradability. These eco-friendly formulations maintain the desired functional properties while reducing environmental impact.Expand Specific Solutions05 Improved compatibility with other materials

Functional advancements in polyvinyl acetate have led to improved compatibility with a wide range of materials. This includes better adhesion to various substrates, improved miscibility with other polymers, and enhanced performance in composite materials. These advancements have expanded the potential applications of polyvinyl acetate in diverse industries.Expand Specific Solutions

Key Players in PVAc-Based Electronic Materials

The market for polyvinyl acetate in electronic devices is in a growth phase, driven by increasing demand for functional advancements in consumer electronics and industrial applications. The global market size is expanding, with major players like DuPont, LG Chem, and Samsung Electronics leading innovation. Technological maturity varies across applications, with established uses in adhesives and emerging applications in flexible displays and energy storage. Companies like Kuraray and Sekisui Chemical are developing specialized formulations, while research institutions such as Guangxi University of Technology are exploring novel functionalities. The competitive landscape is characterized by a mix of large chemical conglomerates and specialized materials firms, with ongoing R&D efforts focused on enhancing performance and sustainability.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced polyvinyl acetate (PVA) formulations for electronic devices, focusing on enhancing adhesion and flexibility. Their PVA-based materials incorporate nanoparticles to improve thermal conductivity, crucial for heat management in compact electronics[1]. DuPont's research has led to PVA composites with enhanced dielectric properties, suitable for capacitive touch screens and flexible displays[3]. They have also engineered PVA variants with improved moisture resistance, addressing a common weakness of traditional PVA in electronic applications[5]. DuPont's innovations extend to PVA-based encapsulants for solar cells, improving durability and efficiency in photovoltaic modules[7].

Strengths: Superior adhesion properties, enhanced thermal management, improved flexibility for wearable electronics. Weaknesses: Higher cost compared to standard PVA, potential for reduced transparency in some formulations.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered the use of modified polyvinyl acetate in battery technologies for electronic devices. Their research focuses on PVA-based gel polymer electrolytes, which enhance the safety and energy density of lithium-ion batteries[2]. LG Chem's PVA formulations incorporate ionic liquids, resulting in improved ionic conductivity and electrochemical stability[4]. They have also developed PVA-based separators with enhanced thermal resistance, crucial for preventing short circuits in high-power electronic devices[6]. Additionally, LG Chem has explored PVA's potential in flexible and stretchable electronics, creating conductive PVA composites for use in next-generation wearable devices[8].

Strengths: Enhanced battery safety, improved energy density, potential for flexible electronics. Weaknesses: Complex manufacturing process, higher material costs compared to traditional electrolytes.

Innovative PVAc Formulations for Electronic Applications

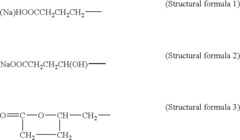

Polyvinyl acetal and its use

PatentInactiveUS6992130B2

Innovation

- A polyvinyl acetal with a specific degree of acetalization (45-80 mol%), containing 1-15 mol% α-olefin units, 1-3 mol% 1,2-glycol bonds, and a degree of polymerization and hydrolysis within defined ranges, which balances hydrophilicity and hydrophobicity, enhancing waterproofness and compatibility with plasticizers.

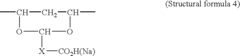

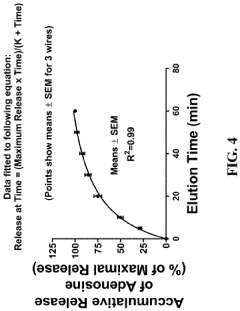

Medical devices for continuous delivery of therapeutic agents

PatentActiveUS20220288284A1

Innovation

- A hydrogel-coated guidewire with a therapeutic agent, such as adenosine, is developed, which releases the agent continuously when in contact with body fluids, providing localized treatment to improve tissue perfusion and prevent MVO by incorporating a polymer blend of polyvinyl alcohol (PVA) and polyvinylpyrrolidone (PVP) that forms a stable coating on the guidewire, allowing for controlled drug release.

Environmental Impact of PVAc in Electronic Devices

The environmental impact of Polyvinyl Acetate (PVAc) in electronic devices is a critical consideration as the use of this versatile polymer continues to expand in the industry. PVAc, known for its adhesive properties and flexibility, has found applications in various components of electronic devices, including adhesives, coatings, and encapsulants. However, its widespread use raises concerns about its ecological footprint throughout the product lifecycle.

During the manufacturing process, the production of PVAc involves the use of volatile organic compounds (VOCs) and potentially hazardous chemicals. These substances can contribute to air and water pollution if not properly managed. Additionally, the energy-intensive nature of PVAc synthesis contributes to greenhouse gas emissions, further impacting the environment.

In the usage phase, PVAc-containing electronic devices generally have a low direct environmental impact. The polymer's stability under normal operating conditions means it does not readily release harmful substances during use. However, the durability and longevity it imparts to devices can be a double-edged sword from an environmental perspective. While increased product lifespan reduces waste, it may also slow down the adoption of more energy-efficient technologies.

The end-of-life stage presents significant environmental challenges. Electronic waste (e-waste) containing PVAc can be difficult to recycle due to the polymer's strong adhesive properties. When incinerated, PVAc can release toxic fumes, including acetic acid and carbon monoxide. In landfills, although PVAc is not considered highly toxic, its slow degradation rate contributes to long-term waste accumulation.

Efforts to mitigate the environmental impact of PVAc in electronic devices are ongoing. Research into bio-based alternatives and more environmentally friendly production methods shows promise. Some manufacturers are exploring PVAc formulations with improved recyclability and biodegradability. Additionally, advancements in e-waste recycling technologies are being developed to better handle PVAc-containing components.

The electronics industry is also adopting design for environment (DfE) principles, considering the entire lifecycle of PVAc-containing products. This approach includes minimizing the use of harmful additives, improving energy efficiency in production, and designing for easier disassembly and recycling at end-of-life.

Regulatory bodies worldwide are increasingly focusing on the environmental impact of electronic devices, including the materials used in their construction. This has led to stricter guidelines on the use of certain chemicals and requirements for improved recyclability, which in turn is driving innovation in PVAc formulations and applications in the electronics sector.

During the manufacturing process, the production of PVAc involves the use of volatile organic compounds (VOCs) and potentially hazardous chemicals. These substances can contribute to air and water pollution if not properly managed. Additionally, the energy-intensive nature of PVAc synthesis contributes to greenhouse gas emissions, further impacting the environment.

In the usage phase, PVAc-containing electronic devices generally have a low direct environmental impact. The polymer's stability under normal operating conditions means it does not readily release harmful substances during use. However, the durability and longevity it imparts to devices can be a double-edged sword from an environmental perspective. While increased product lifespan reduces waste, it may also slow down the adoption of more energy-efficient technologies.

The end-of-life stage presents significant environmental challenges. Electronic waste (e-waste) containing PVAc can be difficult to recycle due to the polymer's strong adhesive properties. When incinerated, PVAc can release toxic fumes, including acetic acid and carbon monoxide. In landfills, although PVAc is not considered highly toxic, its slow degradation rate contributes to long-term waste accumulation.

Efforts to mitigate the environmental impact of PVAc in electronic devices are ongoing. Research into bio-based alternatives and more environmentally friendly production methods shows promise. Some manufacturers are exploring PVAc formulations with improved recyclability and biodegradability. Additionally, advancements in e-waste recycling technologies are being developed to better handle PVAc-containing components.

The electronics industry is also adopting design for environment (DfE) principles, considering the entire lifecycle of PVAc-containing products. This approach includes minimizing the use of harmful additives, improving energy efficiency in production, and designing for easier disassembly and recycling at end-of-life.

Regulatory bodies worldwide are increasingly focusing on the environmental impact of electronic devices, including the materials used in their construction. This has led to stricter guidelines on the use of certain chemicals and requirements for improved recyclability, which in turn is driving innovation in PVAc formulations and applications in the electronics sector.

Regulatory Framework for PVAc Use in Electronics

The regulatory framework for Polyvinyl Acetate (PVAc) use in electronics is a complex and evolving landscape that reflects the growing importance of this versatile polymer in electronic devices. As PVAc finds increasing applications in functional advancements, regulatory bodies worldwide have been adapting their guidelines to ensure safety, environmental protection, and performance standards.

In the United States, the Environmental Protection Agency (EPA) and the Consumer Product Safety Commission (CPSC) play crucial roles in regulating PVAc use in electronics. The EPA, under the Toxic Substances Control Act (TSCA), monitors the environmental impact and potential health risks associated with PVAc production and disposal. Meanwhile, the CPSC focuses on consumer safety, particularly concerning the use of PVAc in electronic devices that may come into contact with children or be used in household settings.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This comprehensive approach requires manufacturers and importers to provide detailed information on the properties and potential risks of PVAc when used in electronic applications. Additionally, the Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, indirectly affecting PVAc formulations and applications.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both address the use of PVAc in electronics, focusing on risk assessment and management throughout the product lifecycle.

Globally, the International Electrotechnical Commission (IEC) has developed standards that impact the use of PVAc in electronic devices. These standards often serve as benchmarks for national regulations and industry practices, ensuring consistency in safety and performance across borders.

As the functional advancements of PVAc in electronic devices continue to evolve, regulatory bodies are increasingly focusing on specific applications. For instance, regulations surrounding the use of PVAc in flexible electronics, wearable devices, and energy storage systems are becoming more nuanced. This includes considerations for biocompatibility in medical devices, durability in extreme environments, and recyclability at the end of product life.

The regulatory landscape also reflects growing environmental concerns. Many jurisdictions are implementing extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including the disposal and recycling of PVAc-containing components. This shift is driving innovation in PVAc formulations to enhance biodegradability and recyclability without compromising performance in electronic applications.

In the United States, the Environmental Protection Agency (EPA) and the Consumer Product Safety Commission (CPSC) play crucial roles in regulating PVAc use in electronics. The EPA, under the Toxic Substances Control Act (TSCA), monitors the environmental impact and potential health risks associated with PVAc production and disposal. Meanwhile, the CPSC focuses on consumer safety, particularly concerning the use of PVAc in electronic devices that may come into contact with children or be used in household settings.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This comprehensive approach requires manufacturers and importers to provide detailed information on the properties and potential risks of PVAc when used in electronic applications. Additionally, the Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, indirectly affecting PVAc formulations and applications.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both address the use of PVAc in electronics, focusing on risk assessment and management throughout the product lifecycle.

Globally, the International Electrotechnical Commission (IEC) has developed standards that impact the use of PVAc in electronic devices. These standards often serve as benchmarks for national regulations and industry practices, ensuring consistency in safety and performance across borders.

As the functional advancements of PVAc in electronic devices continue to evolve, regulatory bodies are increasingly focusing on specific applications. For instance, regulations surrounding the use of PVAc in flexible electronics, wearable devices, and energy storage systems are becoming more nuanced. This includes considerations for biocompatibility in medical devices, durability in extreme environments, and recyclability at the end of product life.

The regulatory landscape also reflects growing environmental concerns. Many jurisdictions are implementing extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including the disposal and recycling of PVAc-containing components. This shift is driving innovation in PVAc formulations to enhance biodegradability and recyclability without compromising performance in electronic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!