Polyvinyl Acetate as a Biodegradable Binder for Eco-Conscious Applications

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Biodegradability Background and Objectives

Polyvinyl acetate (PVAc) has emerged as a promising biodegradable binder for eco-conscious applications, addressing the growing global concern over environmental sustainability. The development of PVAc as a biodegradable alternative stems from the urgent need to reduce plastic pollution and minimize the environmental impact of synthetic materials. This research aims to explore the potential of PVAc in various eco-friendly applications, focusing on its biodegradability and performance as a binder.

The evolution of PVAc technology can be traced back to the early 20th century when it was first synthesized. Initially used in adhesives and coatings, PVAc has since found applications in diverse industries, including packaging, textiles, and construction. However, the recent shift towards sustainable materials has reignited interest in PVAc due to its biodegradable properties.

The primary objective of this research is to comprehensively evaluate the biodegradability of PVAc and its suitability as an eco-friendly binder. This involves investigating the degradation mechanisms of PVAc under various environmental conditions, assessing its compatibility with different substrates, and comparing its performance to traditional, non-biodegradable binders.

Another crucial aspect of this study is to explore the potential applications of PVAc as a biodegradable binder in eco-conscious products. This includes examining its use in packaging materials, disposable consumer goods, and agricultural products. The research aims to identify optimal formulations and processing techniques that enhance PVAc's biodegradability while maintaining its binding properties.

Furthermore, this investigation seeks to address the challenges associated with PVAc biodegradation, such as the influence of environmental factors, the role of microbial activity, and the potential formation of intermediate products. Understanding these aspects is essential for developing strategies to optimize PVAc's biodegradation rate and ensure its environmental safety.

The research also aims to evaluate the economic viability and scalability of PVAc as a biodegradable binder. This involves analyzing production costs, assessing the availability of raw materials, and exploring potential modifications to improve its performance and biodegradability.

By conducting this comprehensive study on PVAc as a biodegradable binder, we anticipate contributing to the development of more sustainable materials and products. The findings from this research are expected to provide valuable insights for industries seeking eco-friendly alternatives to conventional synthetic binders, ultimately supporting the transition towards a more circular and environmentally responsible economy.

The evolution of PVAc technology can be traced back to the early 20th century when it was first synthesized. Initially used in adhesives and coatings, PVAc has since found applications in diverse industries, including packaging, textiles, and construction. However, the recent shift towards sustainable materials has reignited interest in PVAc due to its biodegradable properties.

The primary objective of this research is to comprehensively evaluate the biodegradability of PVAc and its suitability as an eco-friendly binder. This involves investigating the degradation mechanisms of PVAc under various environmental conditions, assessing its compatibility with different substrates, and comparing its performance to traditional, non-biodegradable binders.

Another crucial aspect of this study is to explore the potential applications of PVAc as a biodegradable binder in eco-conscious products. This includes examining its use in packaging materials, disposable consumer goods, and agricultural products. The research aims to identify optimal formulations and processing techniques that enhance PVAc's biodegradability while maintaining its binding properties.

Furthermore, this investigation seeks to address the challenges associated with PVAc biodegradation, such as the influence of environmental factors, the role of microbial activity, and the potential formation of intermediate products. Understanding these aspects is essential for developing strategies to optimize PVAc's biodegradation rate and ensure its environmental safety.

The research also aims to evaluate the economic viability and scalability of PVAc as a biodegradable binder. This involves analyzing production costs, assessing the availability of raw materials, and exploring potential modifications to improve its performance and biodegradability.

By conducting this comprehensive study on PVAc as a biodegradable binder, we anticipate contributing to the development of more sustainable materials and products. The findings from this research are expected to provide valuable insights for industries seeking eco-friendly alternatives to conventional synthetic binders, ultimately supporting the transition towards a more circular and environmentally responsible economy.

Market Analysis for Eco-Friendly Binders

The market for eco-friendly binders, particularly biodegradable options like polyvinyl acetate (PVA), has been experiencing significant growth in recent years. This surge is primarily driven by increasing environmental awareness, stringent regulations on plastic usage, and a growing demand for sustainable products across various industries.

In the packaging sector, the shift towards biodegradable binders has been particularly pronounced. As consumers become more environmentally conscious, there is a rising demand for packaging materials that can decompose naturally without harming the ecosystem. This trend has led to a substantial increase in the adoption of PVA-based binders in paper and cardboard packaging applications.

The construction industry has also shown a keen interest in eco-friendly binders. With the push for green building practices, biodegradable binders like PVA are finding applications in adhesives, sealants, and coatings. The market in this sector is expected to grow as more countries implement regulations promoting sustainable construction materials.

In the textile industry, PVA is gaining traction as a biodegradable alternative to traditional synthetic binders. Its use in textile printing and finishing processes aligns with the industry's efforts to reduce environmental impact and meet consumer demands for sustainable fashion.

The personal care and cosmetics industry is another significant market for eco-friendly binders. As consumers increasingly seek natural and biodegradable products, PVA-based binders are being incorporated into various formulations, from hair styling products to skincare items.

Geographically, Europe and North America currently lead the market for eco-friendly binders, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable development.

Despite the positive outlook, challenges remain in the widespread adoption of biodegradable binders like PVA. These include higher production costs compared to traditional synthetic binders and the need for further research to improve performance characteristics. However, ongoing technological advancements and increasing economies of scale are expected to address these challenges over time.

The market for eco-friendly binders, including PVA, is projected to continue its upward trajectory in the coming years. This growth will be fueled by ongoing innovations in biodegradable materials, increasing environmental regulations, and shifting consumer preferences towards sustainable products across various industries.

In the packaging sector, the shift towards biodegradable binders has been particularly pronounced. As consumers become more environmentally conscious, there is a rising demand for packaging materials that can decompose naturally without harming the ecosystem. This trend has led to a substantial increase in the adoption of PVA-based binders in paper and cardboard packaging applications.

The construction industry has also shown a keen interest in eco-friendly binders. With the push for green building practices, biodegradable binders like PVA are finding applications in adhesives, sealants, and coatings. The market in this sector is expected to grow as more countries implement regulations promoting sustainable construction materials.

In the textile industry, PVA is gaining traction as a biodegradable alternative to traditional synthetic binders. Its use in textile printing and finishing processes aligns with the industry's efforts to reduce environmental impact and meet consumer demands for sustainable fashion.

The personal care and cosmetics industry is another significant market for eco-friendly binders. As consumers increasingly seek natural and biodegradable products, PVA-based binders are being incorporated into various formulations, from hair styling products to skincare items.

Geographically, Europe and North America currently lead the market for eco-friendly binders, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable development.

Despite the positive outlook, challenges remain in the widespread adoption of biodegradable binders like PVA. These include higher production costs compared to traditional synthetic binders and the need for further research to improve performance characteristics. However, ongoing technological advancements and increasing economies of scale are expected to address these challenges over time.

The market for eco-friendly binders, including PVA, is projected to continue its upward trajectory in the coming years. This growth will be fueled by ongoing innovations in biodegradable materials, increasing environmental regulations, and shifting consumer preferences towards sustainable products across various industries.

Current PVAc Technology and Environmental Challenges

Polyvinyl acetate (PVAc) has been widely used as a binder in various industries due to its excellent adhesive properties and versatility. However, the increasing focus on environmental sustainability has brought attention to the challenges associated with traditional PVAc formulations. Current PVAc technology primarily relies on petroleum-based raw materials, which contribute to carbon emissions and environmental pollution.

One of the main environmental concerns surrounding PVAc is its limited biodegradability. While PVAc can degrade under certain conditions, the process is often slow and incomplete, leading to the accumulation of microplastics in ecosystems. This persistence in the environment has raised concerns about long-term ecological impacts and potential harm to wildlife.

Another challenge is the presence of volatile organic compounds (VOCs) in many PVAc formulations. These VOCs are released during the application and curing processes, contributing to air pollution and potentially causing health issues for workers and end-users. Regulatory bodies worldwide have been implementing stricter controls on VOC emissions, pushing manufacturers to develop low-VOC or VOC-free alternatives.

The production of PVAc also raises sustainability concerns due to its energy-intensive manufacturing process. The polymerization of vinyl acetate monomers requires significant energy inputs, often derived from fossil fuels. This not only contributes to greenhouse gas emissions but also raises questions about the long-term viability of PVAc production in a carbon-constrained future.

Water pollution is another environmental challenge associated with PVAc production and use. Wastewater from manufacturing facilities may contain unreacted monomers, additives, and other chemicals that can harm aquatic ecosystems if not properly treated. Additionally, the disposal of PVAc-containing products can lead to leaching of potentially harmful substances into soil and water systems.

To address these environmental challenges, researchers and industry players are exploring various approaches to improve the sustainability of PVAc. One promising direction is the development of bio-based PVAc formulations, which utilize renewable resources as raw materials. These bio-based alternatives aim to reduce the carbon footprint of PVAc production while maintaining its desirable performance characteristics.

Efforts are also underway to enhance the biodegradability of PVAc through the incorporation of biodegradable additives or the modification of the polymer structure. These innovations seek to create PVAc formulations that can break down more readily in natural environments, reducing their long-term ecological impact.

The pursuit of eco-friendly PVAc technologies presents both opportunities and challenges for the industry. While there is a clear demand for more sustainable binder solutions, balancing environmental performance with cost-effectiveness and functional properties remains a significant hurdle. As research in this field progresses, it is likely that we will see the emergence of new PVAc formulations and production methods that better align with the principles of environmental stewardship and circular economy.

One of the main environmental concerns surrounding PVAc is its limited biodegradability. While PVAc can degrade under certain conditions, the process is often slow and incomplete, leading to the accumulation of microplastics in ecosystems. This persistence in the environment has raised concerns about long-term ecological impacts and potential harm to wildlife.

Another challenge is the presence of volatile organic compounds (VOCs) in many PVAc formulations. These VOCs are released during the application and curing processes, contributing to air pollution and potentially causing health issues for workers and end-users. Regulatory bodies worldwide have been implementing stricter controls on VOC emissions, pushing manufacturers to develop low-VOC or VOC-free alternatives.

The production of PVAc also raises sustainability concerns due to its energy-intensive manufacturing process. The polymerization of vinyl acetate monomers requires significant energy inputs, often derived from fossil fuels. This not only contributes to greenhouse gas emissions but also raises questions about the long-term viability of PVAc production in a carbon-constrained future.

Water pollution is another environmental challenge associated with PVAc production and use. Wastewater from manufacturing facilities may contain unreacted monomers, additives, and other chemicals that can harm aquatic ecosystems if not properly treated. Additionally, the disposal of PVAc-containing products can lead to leaching of potentially harmful substances into soil and water systems.

To address these environmental challenges, researchers and industry players are exploring various approaches to improve the sustainability of PVAc. One promising direction is the development of bio-based PVAc formulations, which utilize renewable resources as raw materials. These bio-based alternatives aim to reduce the carbon footprint of PVAc production while maintaining its desirable performance characteristics.

Efforts are also underway to enhance the biodegradability of PVAc through the incorporation of biodegradable additives or the modification of the polymer structure. These innovations seek to create PVAc formulations that can break down more readily in natural environments, reducing their long-term ecological impact.

The pursuit of eco-friendly PVAc technologies presents both opportunities and challenges for the industry. While there is a clear demand for more sustainable binder solutions, balancing environmental performance with cost-effectiveness and functional properties remains a significant hurdle. As research in this field progresses, it is likely that we will see the emergence of new PVAc formulations and production methods that better align with the principles of environmental stewardship and circular economy.

Existing PVAc Biodegradation Enhancement Methods

01 Biodegradable polyvinyl acetate compositions

Development of biodegradable polyvinyl acetate compositions through modification of the polymer structure or incorporation of biodegradable additives. These compositions aim to improve the environmental profile of polyvinyl acetate while maintaining its desirable properties for various applications.- Biodegradable polyvinyl acetate compositions: Development of biodegradable polyvinyl acetate compositions through modification of the polymer structure or incorporation of biodegradable additives. These compositions aim to improve the environmental profile of polyvinyl acetate while maintaining its desirable properties for various applications.

- Enzymatic degradation of polyvinyl acetate: Research on enzymatic degradation methods for polyvinyl acetate, focusing on identifying and optimizing enzymes capable of breaking down the polymer. This approach aims to enhance the biodegradability of polyvinyl acetate in natural environments.

- Blending with biodegradable polymers: Techniques for blending polyvinyl acetate with biodegradable polymers to create composite materials with improved biodegradability. This approach aims to balance the properties of polyvinyl acetate with the environmental benefits of biodegradable polymers.

- Chemical modification for enhanced biodegradability: Methods for chemically modifying polyvinyl acetate to introduce biodegradable linkages or functional groups. These modifications aim to make the polymer more susceptible to environmental degradation while retaining its useful properties.

- Environmental impact assessment of polyvinyl acetate: Studies and methodologies for assessing the environmental impact and biodegradability of polyvinyl acetate in various conditions. This research aims to provide a comprehensive understanding of the polymer's lifecycle and its effects on ecosystems.

02 Enzymatic degradation of polyvinyl acetate

Research into enzymatic degradation methods for polyvinyl acetate, focusing on identifying and optimizing enzymes capable of breaking down the polymer. This approach aims to enhance the biodegradability of polyvinyl acetate in natural environments.Expand Specific Solutions03 Blending with biodegradable polymers

Techniques for blending polyvinyl acetate with biodegradable polymers to create composite materials with improved biodegradability. This method allows for the retention of some polyvinyl acetate properties while enhancing overall environmental friendliness.Expand Specific Solutions04 Chemical modification for enhanced biodegradability

Chemical modification strategies to introduce biodegradable linkages or functional groups into the polyvinyl acetate structure. These modifications aim to make the polymer more susceptible to environmental degradation while preserving its core characteristics.Expand Specific Solutions05 Biodegradation testing and standards

Development and implementation of standardized testing methods to assess the biodegradability of polyvinyl acetate and its derivatives. This includes creating protocols for measuring degradation rates and environmental impact under various conditions.Expand Specific Solutions

Key Players in Biodegradable Polymer Industry

The research on Polyvinyl Acetate as a biodegradable binder is in a growth phase, with increasing market demand driven by eco-conscious applications. The global market size for biodegradable polymers is expanding, expected to reach several billion dollars in the coming years. Technologically, the field is advancing rapidly, with companies like Kuraray, Wacker Chemie, and Arkema leading innovation. These firms are developing enhanced formulations with improved biodegradability and performance characteristics. Emerging players such as Bio-On and Chengdu Caver Technology are also contributing to technological advancements, indicating a competitive and dynamic landscape in this eco-friendly materials sector.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed a range of biodegradable polyvinyl acetate (PVA) binders for eco-conscious applications. Their MOWIFLEX® line of PVA-based products offers excellent film-forming properties and high binding strength[1]. These binders are water-soluble and fully biodegradable, making them ideal for various applications such as paper coatings, adhesives, and packaging materials. Kuraray's PVA binders have been engineered to provide enhanced moisture resistance while maintaining their biodegradability, addressing a common challenge in eco-friendly materials[2]. The company has also focused on improving the thermal stability of their PVA binders, allowing for a wider range of processing conditions and applications[3].

Strengths: Excellent biodegradability, water-solubility, and strong binding properties. Improved moisture resistance and thermal stability. Weaknesses: May have limited resistance to extreme environmental conditions compared to non-biodegradable alternatives.

Arkema, Inc.

Technical Solution: Arkema has developed a range of biodegradable binders based on polyvinyl acetate technology, focusing on sustainability and performance. Their Evatane® range includes ethylene-vinyl acetate (EVA) copolymers that can be used as biodegradable binders in various applications[7]. These binders offer a balance between biodegradability and durability, making them suitable for packaging, agricultural films, and consumer goods. Arkema has also invested in bio-based feedstocks for their PVA production, further enhancing the environmental profile of their products[8]. The company's research has led to the development of PVA binders with improved water resistance while maintaining biodegradability, addressing a key challenge in eco-conscious applications[9].

Strengths: Balance between biodegradability and performance, use of bio-based feedstocks, improved water resistance. Weaknesses: May have higher production costs due to the use of specialized bio-based raw materials.

Innovative PVAc Modification Techniques

Method for the preparation of an article

PatentInactiveUS20190022918A1

Innovation

- A method involving flash-cooling of the starch-based thermoplastic sheet to a temperature of 40°C or less within 10 seconds while it is still on the mold, using a mold temperature of 15°C or less, to achieve a flexible and water-absorbing article suitable for packaging perishable items.

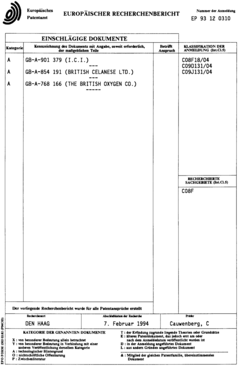

Aqueous biodegradable dispersions

PatentInactiveEP0603746A1

Innovation

- Development of biodegradable, aqueous dispersions of vinyl ester polymers produced through emulsion polymerization with specific compositions including biodegradable plasticizers and emulsifiers, which accelerate degradation by increasing surface area and rate of hydrolysis, suitable for use as coatings and adhesives.

Environmental Regulations on Biodegradable Materials

Environmental regulations on biodegradable materials have become increasingly stringent in recent years, reflecting growing global concerns about plastic pollution and environmental sustainability. These regulations aim to promote the use of eco-friendly alternatives and reduce the environmental impact of conventional plastics.

In the European Union, the Single-Use Plastics Directive (EU) 2019/904 has set ambitious targets for reducing plastic waste and promoting biodegradable alternatives. This directive requires member states to implement measures to reduce the consumption of single-use plastic products and transition towards more sustainable materials.

The United States has also taken steps to regulate biodegradable materials. The Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims and prohibit misleading marketing practices.

Many countries have implemented or are in the process of implementing extended producer responsibility (EPR) schemes for packaging materials. These regulations hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. This approach incentivizes the use of biodegradable materials and encourages innovation in sustainable packaging solutions.

In the context of polyvinyl acetate (PVA) as a biodegradable binder, regulatory bodies are increasingly focusing on the environmental impact of adhesives and binders used in various industries. The European Chemicals Agency (ECHA) has established regulations under REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) that require manufacturers to assess and manage the risks associated with chemicals, including those used in biodegradable materials.

Certification standards for biodegradable materials have also emerged as a crucial aspect of environmental regulations. Organizations such as the Biodegradable Products Institute (BPI) and TÜV Austria provide certification programs that verify the biodegradability and compostability of materials according to international standards like ASTM D6400 and EN 13432.

As research on polyvinyl acetate as a biodegradable binder progresses, it is essential to consider these regulatory frameworks and certification standards. Manufacturers and researchers must ensure that PVA-based biodegradable binders meet the increasingly stringent requirements for environmental safety, biodegradability, and overall sustainability.

The regulatory landscape for biodegradable materials continues to evolve, with many countries introducing new legislation or updating existing regulations to address emerging environmental challenges. This dynamic regulatory environment underscores the importance of ongoing research and development in biodegradable materials, including innovative applications of polyvinyl acetate as an eco-conscious binder solution.

In the European Union, the Single-Use Plastics Directive (EU) 2019/904 has set ambitious targets for reducing plastic waste and promoting biodegradable alternatives. This directive requires member states to implement measures to reduce the consumption of single-use plastic products and transition towards more sustainable materials.

The United States has also taken steps to regulate biodegradable materials. The Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims and prohibit misleading marketing practices.

Many countries have implemented or are in the process of implementing extended producer responsibility (EPR) schemes for packaging materials. These regulations hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. This approach incentivizes the use of biodegradable materials and encourages innovation in sustainable packaging solutions.

In the context of polyvinyl acetate (PVA) as a biodegradable binder, regulatory bodies are increasingly focusing on the environmental impact of adhesives and binders used in various industries. The European Chemicals Agency (ECHA) has established regulations under REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) that require manufacturers to assess and manage the risks associated with chemicals, including those used in biodegradable materials.

Certification standards for biodegradable materials have also emerged as a crucial aspect of environmental regulations. Organizations such as the Biodegradable Products Institute (BPI) and TÜV Austria provide certification programs that verify the biodegradability and compostability of materials according to international standards like ASTM D6400 and EN 13432.

As research on polyvinyl acetate as a biodegradable binder progresses, it is essential to consider these regulatory frameworks and certification standards. Manufacturers and researchers must ensure that PVA-based biodegradable binders meet the increasingly stringent requirements for environmental safety, biodegradability, and overall sustainability.

The regulatory landscape for biodegradable materials continues to evolve, with many countries introducing new legislation or updating existing regulations to address emerging environmental challenges. This dynamic regulatory environment underscores the importance of ongoing research and development in biodegradable materials, including innovative applications of polyvinyl acetate as an eco-conscious binder solution.

Life Cycle Assessment of PVAc-based Products

Life Cycle Assessment (LCA) of PVAc-based products is a crucial component in evaluating the environmental impact and sustainability of polyvinyl acetate as a biodegradable binder. This comprehensive analysis examines the entire lifecycle of PVAc products, from raw material extraction to disposal or recycling.

The production phase of PVAc involves the polymerization of vinyl acetate monomer, which is derived from ethylene and acetic acid. This process requires energy inputs and may result in emissions of volatile organic compounds (VOCs). However, compared to some traditional petroleum-based binders, PVAc production generally has a lower carbon footprint due to its water-based nature.

During the use phase, PVAc-based products demonstrate favorable environmental characteristics. Their durability and long service life contribute to reduced replacement frequency, thereby minimizing overall resource consumption. Additionally, PVAc's low toxicity and minimal off-gassing during use make it a safer option for various applications, including adhesives, coatings, and packaging materials.

End-of-life considerations for PVAc products are particularly significant in the context of eco-conscious applications. While PVAc is not inherently biodegradable, recent research has shown promising results in enhancing its biodegradability through various modifications. These include the incorporation of natural fibers, enzymatic treatments, and the development of PVAc-starch blends.

The disposal and potential recycling of PVAc products play a crucial role in their overall environmental impact. Traditional disposal methods, such as landfilling, may lead to long-term environmental persistence. However, emerging recycling technologies and composting methods for modified PVAc formulations offer more sustainable end-of-life options.

Water consumption and wastewater generation are important factors to consider in the LCA of PVAc products. The water-based nature of PVAc production and its use in many applications can lead to significant water usage. However, advancements in water recycling and treatment technologies in manufacturing processes have the potential to mitigate these impacts.

Energy consumption across the lifecycle of PVAc products is another critical aspect of the LCA. While the production phase may be energy-intensive, the energy savings during use and potential energy recovery through recycling or waste-to-energy processes should be factored into the overall assessment.

In conclusion, the Life Cycle Assessment of PVAc-based products reveals a complex interplay of environmental impacts and benefits. While challenges remain, particularly in end-of-life management, ongoing research and development in biodegradable formulations and recycling technologies are paving the way for more sustainable PVAc applications in eco-conscious products.

The production phase of PVAc involves the polymerization of vinyl acetate monomer, which is derived from ethylene and acetic acid. This process requires energy inputs and may result in emissions of volatile organic compounds (VOCs). However, compared to some traditional petroleum-based binders, PVAc production generally has a lower carbon footprint due to its water-based nature.

During the use phase, PVAc-based products demonstrate favorable environmental characteristics. Their durability and long service life contribute to reduced replacement frequency, thereby minimizing overall resource consumption. Additionally, PVAc's low toxicity and minimal off-gassing during use make it a safer option for various applications, including adhesives, coatings, and packaging materials.

End-of-life considerations for PVAc products are particularly significant in the context of eco-conscious applications. While PVAc is not inherently biodegradable, recent research has shown promising results in enhancing its biodegradability through various modifications. These include the incorporation of natural fibers, enzymatic treatments, and the development of PVAc-starch blends.

The disposal and potential recycling of PVAc products play a crucial role in their overall environmental impact. Traditional disposal methods, such as landfilling, may lead to long-term environmental persistence. However, emerging recycling technologies and composting methods for modified PVAc formulations offer more sustainable end-of-life options.

Water consumption and wastewater generation are important factors to consider in the LCA of PVAc products. The water-based nature of PVAc production and its use in many applications can lead to significant water usage. However, advancements in water recycling and treatment technologies in manufacturing processes have the potential to mitigate these impacts.

Energy consumption across the lifecycle of PVAc products is another critical aspect of the LCA. While the production phase may be energy-intensive, the energy savings during use and potential energy recovery through recycling or waste-to-energy processes should be factored into the overall assessment.

In conclusion, the Life Cycle Assessment of PVAc-based products reveals a complex interplay of environmental impacts and benefits. While challenges remain, particularly in end-of-life management, ongoing research and development in biodegradable formulations and recycling technologies are paving the way for more sustainable PVAc applications in eco-conscious products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!