Polyvinyl Acetate for High-Performance Security Features

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Security Features Background and Objectives

Polyvinyl acetate (PVAc) has emerged as a promising material for developing high-performance security features in recent years. The evolution of this technology can be traced back to the mid-20th century when PVAc was first synthesized and utilized in various industrial applications. Over time, researchers and manufacturers have recognized its potential in the security sector, particularly for its unique optical and physical properties.

The primary objective of researching PVAc for security features is to create innovative, tamper-evident, and difficult-to-replicate elements that can be incorporated into a wide range of products, including banknotes, identification documents, and high-value goods. This research aims to enhance the overall security of these items, making them more resistant to counterfeiting and fraud attempts.

One of the key drivers behind the increased interest in PVAc-based security features is the growing sophistication of counterfeiting techniques. As traditional security measures become more vulnerable to advanced reproduction methods, there is a pressing need for novel approaches that can stay ahead of potential threats. PVAc offers a promising solution due to its versatility and the ability to manipulate its properties at the molecular level.

The development of PVAc security features aligns with the broader trend of integrating advanced materials science into security applications. This interdisciplinary approach combines polymer chemistry, nanotechnology, and optical engineering to create multi-layered security elements that are both visually striking and technically complex.

Recent technological advancements have enabled researchers to explore new ways of modifying PVAc to enhance its security-related properties. These modifications include the incorporation of nanoparticles, photochromic compounds, and other functional additives that can impart unique optical, mechanical, or responsive characteristics to the material.

The research on PVAc for security features is also driven by the need for cost-effective solutions that can be implemented on a large scale. As global demand for secure documents and products continues to rise, developing economically viable yet highly effective security measures becomes increasingly important. PVAc's relatively low cost and ease of processing make it an attractive option for widespread adoption in various security applications.

Looking ahead, the research aims to push the boundaries of what is possible with PVAc-based security features. This includes exploring novel manufacturing techniques, such as 3D printing and microfluidics, to create intricate and highly customized security elements. Additionally, there is a focus on developing smart PVAc materials that can respond to external stimuli, providing an extra layer of authentication and anti-counterfeiting protection.

The primary objective of researching PVAc for security features is to create innovative, tamper-evident, and difficult-to-replicate elements that can be incorporated into a wide range of products, including banknotes, identification documents, and high-value goods. This research aims to enhance the overall security of these items, making them more resistant to counterfeiting and fraud attempts.

One of the key drivers behind the increased interest in PVAc-based security features is the growing sophistication of counterfeiting techniques. As traditional security measures become more vulnerable to advanced reproduction methods, there is a pressing need for novel approaches that can stay ahead of potential threats. PVAc offers a promising solution due to its versatility and the ability to manipulate its properties at the molecular level.

The development of PVAc security features aligns with the broader trend of integrating advanced materials science into security applications. This interdisciplinary approach combines polymer chemistry, nanotechnology, and optical engineering to create multi-layered security elements that are both visually striking and technically complex.

Recent technological advancements have enabled researchers to explore new ways of modifying PVAc to enhance its security-related properties. These modifications include the incorporation of nanoparticles, photochromic compounds, and other functional additives that can impart unique optical, mechanical, or responsive characteristics to the material.

The research on PVAc for security features is also driven by the need for cost-effective solutions that can be implemented on a large scale. As global demand for secure documents and products continues to rise, developing economically viable yet highly effective security measures becomes increasingly important. PVAc's relatively low cost and ease of processing make it an attractive option for widespread adoption in various security applications.

Looking ahead, the research aims to push the boundaries of what is possible with PVAc-based security features. This includes exploring novel manufacturing techniques, such as 3D printing and microfluidics, to create intricate and highly customized security elements. Additionally, there is a focus on developing smart PVAc materials that can respond to external stimuli, providing an extra layer of authentication and anti-counterfeiting protection.

Market Analysis for Advanced Security Solutions

The market for advanced security solutions has been experiencing significant growth in recent years, driven by increasing concerns over counterfeiting, fraud, and the need for enhanced product authentication. Polyvinyl acetate (PVA) has emerged as a promising material for developing high-performance security features, attracting attention from various industries seeking to protect their products and documents.

The global market for anti-counterfeiting packaging is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other sectors. This growth is fueled by the rising demand for secure packaging solutions across industries such as pharmaceuticals, luxury goods, electronics, and government documents. PVA-based security features are poised to capture a significant portion of this market due to their versatility and effectiveness.

In the pharmaceutical industry, where patient safety is paramount, the demand for tamper-evident and anti-counterfeiting solutions is particularly strong. PVA-based security features can provide a cost-effective means of ensuring product authenticity and protecting brand reputation. The food and beverage sector is another key market, with increasing concerns over food safety and the need for traceability driving the adoption of advanced security solutions.

The luxury goods market, including high-end fashion, watches, and accessories, represents another significant opportunity for PVA-based security features. As counterfeiters become more sophisticated, brands are seeking innovative ways to protect their products and maintain consumer trust. PVA's ability to create unique, difficult-to-replicate visual and tactile effects makes it an attractive option for this sector.

Government and official documents, such as passports, identity cards, and banknotes, constitute a critical market for advanced security solutions. The integration of PVA-based features in these documents can significantly enhance their security, making them more resistant to forgery and tampering. This market segment is expected to show steady growth as governments worldwide continue to invest in improving document security.

The electronics industry, facing challenges from counterfeit components and devices, is another potential growth area for PVA-based security solutions. As supply chains become more complex and global, the need for reliable authentication methods has increased, creating opportunities for innovative security features.

Geographically, North America and Europe currently lead the market for advanced security solutions, with Asia-Pacific expected to show the fastest growth in the coming years. This growth is driven by rapid industrialization, increasing awareness of intellectual property rights, and stringent regulations against counterfeiting in emerging economies.

The global market for anti-counterfeiting packaging is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other sectors. This growth is fueled by the rising demand for secure packaging solutions across industries such as pharmaceuticals, luxury goods, electronics, and government documents. PVA-based security features are poised to capture a significant portion of this market due to their versatility and effectiveness.

In the pharmaceutical industry, where patient safety is paramount, the demand for tamper-evident and anti-counterfeiting solutions is particularly strong. PVA-based security features can provide a cost-effective means of ensuring product authenticity and protecting brand reputation. The food and beverage sector is another key market, with increasing concerns over food safety and the need for traceability driving the adoption of advanced security solutions.

The luxury goods market, including high-end fashion, watches, and accessories, represents another significant opportunity for PVA-based security features. As counterfeiters become more sophisticated, brands are seeking innovative ways to protect their products and maintain consumer trust. PVA's ability to create unique, difficult-to-replicate visual and tactile effects makes it an attractive option for this sector.

Government and official documents, such as passports, identity cards, and banknotes, constitute a critical market for advanced security solutions. The integration of PVA-based features in these documents can significantly enhance their security, making them more resistant to forgery and tampering. This market segment is expected to show steady growth as governments worldwide continue to invest in improving document security.

The electronics industry, facing challenges from counterfeit components and devices, is another potential growth area for PVA-based security solutions. As supply chains become more complex and global, the need for reliable authentication methods has increased, creating opportunities for innovative security features.

Geographically, North America and Europe currently lead the market for advanced security solutions, with Asia-Pacific expected to show the fastest growth in the coming years. This growth is driven by rapid industrialization, increasing awareness of intellectual property rights, and stringent regulations against counterfeiting in emerging economies.

PVAc Technology Status and Challenges

Polyvinyl acetate (PVAc) has emerged as a promising material for high-performance security features, yet its current technological status presents both opportunities and challenges. The global research community has made significant strides in understanding and manipulating PVAc's properties, particularly its adhesive characteristics and film-forming abilities. These advancements have positioned PVAc as a potential game-changer in the security printing industry.

One of the primary challenges in PVAc technology lies in achieving consistent and reliable performance across various environmental conditions. Researchers are grappling with issues related to temperature sensitivity and moisture resistance, which can affect the integrity of security features over time. Efforts are underway to develop PVAc formulations that maintain their structural integrity and functional properties under diverse climatic conditions.

Another significant hurdle is the optimization of PVAc's optical properties for advanced security applications. While PVAc offers excellent transparency and gloss, fine-tuning these characteristics for specific security feature requirements, such as holographic effects or color-shifting properties, remains a complex task. Scientists are exploring various additives and processing techniques to enhance PVAc's optical performance without compromising its other beneficial properties.

The integration of PVAc with other materials to create multi-layered security features presents both opportunities and technical difficulties. Researchers are investigating ways to improve the adhesion and compatibility of PVAc with substrates like paper, plastic, and metal, ensuring durable and tamper-evident security elements. This area of research is particularly crucial for developing next-generation security documents and packaging.

From a manufacturing perspective, scaling up the production of high-performance PVAc formulations for security applications poses significant challenges. Current production methods often struggle to maintain consistent quality at large scales, necessitating innovations in process engineering and quality control. Additionally, the development of eco-friendly and sustainable PVAc formulations is gaining traction, driven by increasing environmental regulations and market demands.

Geographically, PVAc technology for security features is seeing varied levels of development. North America and Europe lead in research and innovation, with several patents and academic publications originating from these regions. However, Asia, particularly China and Japan, is rapidly catching up, demonstrating significant progress in applied research and industrial applications of PVAc-based security solutions.

In conclusion, while PVAc shows immense potential for high-performance security features, overcoming current technological challenges is crucial for its widespread adoption. The focus areas for future research and development include enhancing environmental stability, improving optical properties, optimizing material integration, scaling up production processes, and developing sustainable formulations. As these challenges are addressed, PVAc is poised to play a pivotal role in the next generation of advanced security technologies.

One of the primary challenges in PVAc technology lies in achieving consistent and reliable performance across various environmental conditions. Researchers are grappling with issues related to temperature sensitivity and moisture resistance, which can affect the integrity of security features over time. Efforts are underway to develop PVAc formulations that maintain their structural integrity and functional properties under diverse climatic conditions.

Another significant hurdle is the optimization of PVAc's optical properties for advanced security applications. While PVAc offers excellent transparency and gloss, fine-tuning these characteristics for specific security feature requirements, such as holographic effects or color-shifting properties, remains a complex task. Scientists are exploring various additives and processing techniques to enhance PVAc's optical performance without compromising its other beneficial properties.

The integration of PVAc with other materials to create multi-layered security features presents both opportunities and technical difficulties. Researchers are investigating ways to improve the adhesion and compatibility of PVAc with substrates like paper, plastic, and metal, ensuring durable and tamper-evident security elements. This area of research is particularly crucial for developing next-generation security documents and packaging.

From a manufacturing perspective, scaling up the production of high-performance PVAc formulations for security applications poses significant challenges. Current production methods often struggle to maintain consistent quality at large scales, necessitating innovations in process engineering and quality control. Additionally, the development of eco-friendly and sustainable PVAc formulations is gaining traction, driven by increasing environmental regulations and market demands.

Geographically, PVAc technology for security features is seeing varied levels of development. North America and Europe lead in research and innovation, with several patents and academic publications originating from these regions. However, Asia, particularly China and Japan, is rapidly catching up, demonstrating significant progress in applied research and industrial applications of PVAc-based security solutions.

In conclusion, while PVAc shows immense potential for high-performance security features, overcoming current technological challenges is crucial for its widespread adoption. The focus areas for future research and development include enhancing environmental stability, improving optical properties, optimizing material integration, scaling up production processes, and developing sustainable formulations. As these challenges are addressed, PVAc is poised to play a pivotal role in the next generation of advanced security technologies.

Current PVAc-based Security Solutions

01 Incorporation of security features in polyvinyl acetate coatings

Polyvinyl acetate can be used as a base material for security coatings. These coatings can incorporate various security features such as fluorescent markers, color-shifting pigments, or microparticles to enhance document or product authentication. The security features can be embedded within the polyvinyl acetate matrix, providing tamper-evident properties and making counterfeiting more difficult.- Incorporation of security features in polyvinyl acetate coatings: Polyvinyl acetate can be used as a base material for security coatings. These coatings can incorporate various security features such as fluorescent markers, color-shifting pigments, or microparticles to enhance document or product authentication. The security features can be embedded within the polyvinyl acetate matrix, providing tamper-evident properties and making counterfeiting more difficult.

- Polyvinyl acetate-based adhesives with security properties: Specialized adhesives based on polyvinyl acetate can be formulated to include security features. These adhesives may contain traceable additives, such as DNA markers or nanoparticles, which can be detected using specific methods. When used in packaging or labeling applications, these adhesives provide an additional layer of security and authenticity verification.

- Polyvinyl acetate copolymers for enhanced security applications: Copolymers of polyvinyl acetate with other monomers can be developed to improve security features. These copolymers may exhibit unique properties such as controlled degradation, specific spectral responses, or enhanced durability. By tailoring the copolymer composition, security features can be fine-tuned for specific applications in document security, anti-counterfeiting measures, or secure packaging.

- Polyvinyl acetate films with embedded security elements: Thin films made from polyvinyl acetate can be engineered to contain various security elements. These may include holographic patterns, microprinted text, or reactive compounds that change appearance under specific conditions. Such films can be applied to documents, products, or packaging to provide visible and covert security features for authentication purposes.

- Modification of polyvinyl acetate for unique identification properties: Polyvinyl acetate can be chemically or physically modified to exhibit unique identification properties. This may involve the incorporation of specific molecular markers, the creation of distinct surface textures, or the addition of responsive elements that change under certain stimuli. These modifications allow for the development of materials with inherent security features that are difficult to replicate.

02 Use of polyvinyl acetate in security paper production

Polyvinyl acetate can be utilized in the production of security paper for banknotes, passports, and other sensitive documents. It can be incorporated into the paper pulp or applied as a coating to enhance durability and provide a substrate for additional security features. The polymer's properties allow for the integration of watermarks, security threads, and other anti-counterfeiting measures.Expand Specific Solutions03 Development of polyvinyl acetate-based security inks

Security inks formulated with polyvinyl acetate as a binder can offer enhanced adhesion and durability on various substrates. These inks can be designed to exhibit special properties such as color-changing effects, invisible fluorescent markings, or resistance to chemical tampering. The use of polyvinyl acetate allows for the creation of complex, multi-layered security printing systems.Expand Specific Solutions04 Modification of polyvinyl acetate for improved security properties

Chemical modifications of polyvinyl acetate can enhance its security features. This may include copolymerization with other monomers, grafting of functional groups, or the incorporation of nanoparticles. These modifications can result in polymers with unique optical, mechanical, or responsive properties that are difficult to replicate, thus improving their effectiveness in security applications.Expand Specific Solutions05 Polyvinyl acetate in tamper-evident packaging

Polyvinyl acetate can be used in the production of tamper-evident packaging and seals. When formulated with specific additives, it can create films or adhesives that show visible signs of tampering when disturbed. This technology can be applied to product packaging, security labels, and document seals to provide visual indication of unauthorized access or manipulation.Expand Specific Solutions

Key Players in PVAc Security Industry

The research on Polyvinyl Acetate for high-performance security features is in a growth phase, with increasing market demand driven by the need for advanced security solutions. The global market size for security features is expanding, estimated to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with companies like Kuraray Co., Ltd., DuPont de Nemours, Inc., and BASF Corp. leading innovation. These firms are developing sophisticated polyvinyl acetate formulations with enhanced properties for security applications. Emerging players such as Ningbo Xianfeng New Material Co., Ltd. and Chengdu Caver Technology Co., Ltd. are also contributing to technological advancements, intensifying competition in this specialized market.

DuPont de Nemours, Inc.

Technical Solution: DuPont has engineered a novel polyvinyl acetate-based security feature that incorporates advanced fluorescent and phosphorescent materials. This technology allows for the creation of multi-layered security elements that are visible under different light conditions, including UV and IR spectrums[2]. The company has also developed a proprietary process to create micro-structured PVA films with unique diffractive properties, enabling the production of holographic-like effects without traditional hologram technology[4]. DuPont's PVA security features are designed to be compatible with high-speed production processes, making them suitable for large-scale implementation in banknotes, identification documents, and high-value product authentication[6].

Strengths: Multi-spectral visibility, innovative optical effects, and high-volume production capability. Weaknesses: May require specialized equipment for implementation and verification.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed a high-performance polyvinyl acetate (PVA) resin specifically for security features. Their advanced PVA formulation incorporates nano-scale particles that create unique optical properties, enhancing the material's ability to produce complex, difficult-to-replicate patterns[1]. The company has also introduced a proprietary cross-linking technology that significantly improves the PVA's durability and resistance to environmental factors, making it ideal for long-lasting security applications[3]. Kuraray's PVA-based security features can be seamlessly integrated into various substrates, including paper, plastic, and textiles, offering versatility in application[5].

Strengths: Superior optical properties, enhanced durability, and versatile application. Weaknesses: Potentially higher production costs and complexity in manufacturing process.

Innovative PVAc Security Technologies

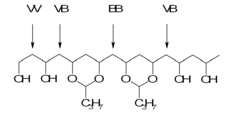

Polyvinyl acetal, polyvinyl acetal composition, ink coating material, dispersant, heat-developable photosensitive material,ceramic green sheet, primer for plastic lens, recording agent for water-based ink and adhesive for metal foil

PatentInactiveUS20040157078A1

Innovation

- Polyvinyl acetal with functional groups, such as carboxyl or sulfonic acid groups, strategically located at the ends or in the main chain, which enhances dispersibility and adhesion by increasing adsorption points and interaction with pigments and other polymers, allowing for higher solid content formulations without excessive viscosity increase.

Polyvinylacetal with high flowing capability and film containing softeners produced using same

PatentActiveEP2336199A1

Innovation

- The production of polyvinyl acetals with a degree of acetalization above 75 mol% and specific OH blockiness, achieved through an acid-catalyzed reaction process involving controlled temperature and neutralization, enhances flowability by adjusting the secondary structure of the polymer chain, as determined by 13C NMR measurements.

Regulatory Framework for Security Materials

The regulatory framework for security materials plays a crucial role in ensuring the integrity and effectiveness of high-performance security features, particularly those utilizing polyvinyl acetate (PVA). Governments and international organizations have established comprehensive guidelines and standards to govern the production, distribution, and use of security materials.

At the national level, many countries have implemented specific regulations for security materials used in official documents, currency, and identification cards. These regulations often mandate the use of certain types of materials, including PVA-based solutions, and specify the required security features. For instance, the United States Department of Homeland Security has set forth stringent requirements for security features in passports and other identification documents.

International bodies, such as the International Civil Aviation Organization (ICAO), have developed global standards for security materials used in travel documents. The ICAO's Document 9303 provides detailed specifications for machine-readable travel documents, including the use of advanced security features that may incorporate PVA-based technologies.

The European Union has established the EU Regulation 2252/2004, which sets minimum security standards for passports and travel documents issued by Member States. This regulation includes provisions for the use of advanced security features, some of which may involve PVA-based materials.

In the realm of currency production, central banks worldwide have implemented strict regulations governing the materials and technologies used in banknote security features. The European Central Bank, for example, has established the Eurosystem Cash Strategy, which outlines the requirements for security features in euro banknotes, potentially including those based on PVA technology.

Regulatory bodies also focus on the environmental and health aspects of security materials. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union impacts the use of chemical substances, including those used in PVA-based security features, ensuring they meet safety and environmental standards.

Compliance with these regulations is typically enforced through a combination of certification processes, regular audits, and penalties for non-compliance. Manufacturers of security materials, including those working with PVA for high-performance features, must navigate this complex regulatory landscape to ensure their products meet all applicable standards and can be legally used in their intended applications.

As technology evolves, regulatory frameworks are continuously updated to address new security threats and incorporate emerging technologies. This dynamic regulatory environment necessitates ongoing research and development in the field of security materials, driving innovation in PVA-based solutions to meet increasingly stringent regulatory requirements.

At the national level, many countries have implemented specific regulations for security materials used in official documents, currency, and identification cards. These regulations often mandate the use of certain types of materials, including PVA-based solutions, and specify the required security features. For instance, the United States Department of Homeland Security has set forth stringent requirements for security features in passports and other identification documents.

International bodies, such as the International Civil Aviation Organization (ICAO), have developed global standards for security materials used in travel documents. The ICAO's Document 9303 provides detailed specifications for machine-readable travel documents, including the use of advanced security features that may incorporate PVA-based technologies.

The European Union has established the EU Regulation 2252/2004, which sets minimum security standards for passports and travel documents issued by Member States. This regulation includes provisions for the use of advanced security features, some of which may involve PVA-based materials.

In the realm of currency production, central banks worldwide have implemented strict regulations governing the materials and technologies used in banknote security features. The European Central Bank, for example, has established the Eurosystem Cash Strategy, which outlines the requirements for security features in euro banknotes, potentially including those based on PVA technology.

Regulatory bodies also focus on the environmental and health aspects of security materials. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union impacts the use of chemical substances, including those used in PVA-based security features, ensuring they meet safety and environmental standards.

Compliance with these regulations is typically enforced through a combination of certification processes, regular audits, and penalties for non-compliance. Manufacturers of security materials, including those working with PVA for high-performance features, must navigate this complex regulatory landscape to ensure their products meet all applicable standards and can be legally used in their intended applications.

As technology evolves, regulatory frameworks are continuously updated to address new security threats and incorporate emerging technologies. This dynamic regulatory environment necessitates ongoing research and development in the field of security materials, driving innovation in PVA-based solutions to meet increasingly stringent regulatory requirements.

Environmental Impact of PVAc Security Features

The environmental impact of Polyvinyl Acetate (PVAc) security features is a crucial consideration in the development and implementation of high-performance security solutions. PVAc, a synthetic polymer widely used in adhesives and coatings, offers unique properties that make it suitable for security applications. However, its environmental footprint must be carefully evaluated to ensure sustainable practices in the security industry.

PVAc-based security features generally have a lower environmental impact compared to traditional metal-based or holographic security elements. The production process of PVAc involves fewer toxic chemicals and consumes less energy than many alternative materials. Additionally, PVAc is derived from renewable resources, primarily vinyl acetate monomer, which can be produced from ethylene and acetic acid.

One of the primary environmental concerns associated with PVAc security features is their end-of-life disposal. While PVAc is not biodegradable, it can be recycled through mechanical and chemical processes. However, the presence of additives and other materials in security features may complicate the recycling process. Efforts are being made to develop more easily recyclable PVAc formulations specifically for security applications.

Water-based PVAc emulsions used in security printing have a lower volatile organic compound (VOC) content compared to solvent-based alternatives, reducing air pollution and health risks during manufacturing and application processes. This aligns with increasingly stringent environmental regulations in many countries.

The durability of PVAc security features contributes to their environmental sustainability. High-performance PVAc coatings can extend the lifespan of security documents and products, reducing the need for frequent replacements and thereby minimizing waste generation. Ongoing research focuses on enhancing the durability of PVAc security features while maintaining their recyclability.

Biodegradable alternatives to traditional PVAc are being explored for security applications. These include modified PVAc formulations incorporating biodegradable additives or blends with other biodegradable polymers. While promising, these alternatives often face challenges in meeting the stringent performance requirements of security features.

Life cycle assessments (LCAs) of PVAc security features have shown that their environmental impact is largely dependent on the specific application and end-of-life scenarios. Efforts to optimize the entire life cycle, from raw material sourcing to disposal or recycling, are ongoing within the industry.

As environmental concerns continue to shape industry practices, the development of PVAc security features is increasingly focused on eco-friendly innovations. This includes the use of bio-based precursors for PVAc production, the incorporation of recycled content, and the design of easily separable multi-material security elements to facilitate recycling.

PVAc-based security features generally have a lower environmental impact compared to traditional metal-based or holographic security elements. The production process of PVAc involves fewer toxic chemicals and consumes less energy than many alternative materials. Additionally, PVAc is derived from renewable resources, primarily vinyl acetate monomer, which can be produced from ethylene and acetic acid.

One of the primary environmental concerns associated with PVAc security features is their end-of-life disposal. While PVAc is not biodegradable, it can be recycled through mechanical and chemical processes. However, the presence of additives and other materials in security features may complicate the recycling process. Efforts are being made to develop more easily recyclable PVAc formulations specifically for security applications.

Water-based PVAc emulsions used in security printing have a lower volatile organic compound (VOC) content compared to solvent-based alternatives, reducing air pollution and health risks during manufacturing and application processes. This aligns with increasingly stringent environmental regulations in many countries.

The durability of PVAc security features contributes to their environmental sustainability. High-performance PVAc coatings can extend the lifespan of security documents and products, reducing the need for frequent replacements and thereby minimizing waste generation. Ongoing research focuses on enhancing the durability of PVAc security features while maintaining their recyclability.

Biodegradable alternatives to traditional PVAc are being explored for security applications. These include modified PVAc formulations incorporating biodegradable additives or blends with other biodegradable polymers. While promising, these alternatives often face challenges in meeting the stringent performance requirements of security features.

Life cycle assessments (LCAs) of PVAc security features have shown that their environmental impact is largely dependent on the specific application and end-of-life scenarios. Efforts to optimize the entire life cycle, from raw material sourcing to disposal or recycling, are ongoing within the industry.

As environmental concerns continue to shape industry practices, the development of PVAc security features is increasingly focused on eco-friendly innovations. This includes the use of bio-based precursors for PVAc production, the incorporation of recycled content, and the design of easily separable multi-material security elements to facilitate recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!