Polyvinyl Acetate's Impact on Innovations in Tactile Applications

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc in Tactile Tech: Background and Objectives

Polyvinyl acetate (PVAc) has emerged as a pivotal material in the realm of tactile applications, revolutionizing the way we interact with surfaces and devices. This synthetic polymer, first discovered in the early 20th century, has undergone significant developments to become a cornerstone in various industries, particularly in the field of haptic technology.

The evolution of PVAc in tactile applications can be traced back to its initial use in adhesives and coatings. As researchers began to explore its unique properties, including its flexibility, durability, and ability to form thin films, the potential for PVAc in tactile interfaces became increasingly apparent. The material's viscoelastic nature, which allows it to exhibit both viscous and elastic characteristics, has proven instrumental in creating surfaces that can mimic a wide range of tactile sensations.

In recent years, the focus on enhancing user experiences in digital interfaces has driven the exploration of PVAc's capabilities in tactile feedback systems. The growing demand for more intuitive and responsive touch screens, wearable devices, and virtual reality interfaces has accelerated research into PVAc-based solutions. These innovations aim to bridge the gap between digital and physical interactions, providing users with a more immersive and natural tactile experience.

The primary objective of current research and development efforts is to harness PVAc's unique properties to create advanced tactile interfaces that can dynamically change their surface characteristics. This includes altering texture, temperature, and even simulating various materials' feel. Such advancements have far-reaching implications across multiple sectors, including consumer electronics, medical simulation, automotive interfaces, and assistive technologies for the visually impaired.

Another critical goal is to improve the durability and longevity of PVAc-based tactile surfaces. As these interfaces are subjected to frequent physical interactions, ensuring their resilience and maintaining consistent performance over time is paramount. Researchers are exploring various formulations and manufacturing techniques to enhance PVAc's resistance to wear, environmental factors, and repeated deformation cycles.

Furthermore, the integration of PVAc with other materials and technologies, such as conductive polymers and microfluidics, is opening new avenues for multifunctional tactile interfaces. These hybrid systems aim to combine tactile feedback with other sensory inputs or outputs, creating more comprehensive and versatile user interaction paradigms.

As we look towards the future, the continued development of PVAc in tactile applications is expected to play a crucial role in shaping the next generation of human-machine interfaces. The ongoing research aims not only to refine existing applications but also to uncover novel uses that could potentially transform various aspects of our daily lives, from how we interact with our devices to how we perceive and manipulate virtual environments.

The evolution of PVAc in tactile applications can be traced back to its initial use in adhesives and coatings. As researchers began to explore its unique properties, including its flexibility, durability, and ability to form thin films, the potential for PVAc in tactile interfaces became increasingly apparent. The material's viscoelastic nature, which allows it to exhibit both viscous and elastic characteristics, has proven instrumental in creating surfaces that can mimic a wide range of tactile sensations.

In recent years, the focus on enhancing user experiences in digital interfaces has driven the exploration of PVAc's capabilities in tactile feedback systems. The growing demand for more intuitive and responsive touch screens, wearable devices, and virtual reality interfaces has accelerated research into PVAc-based solutions. These innovations aim to bridge the gap between digital and physical interactions, providing users with a more immersive and natural tactile experience.

The primary objective of current research and development efforts is to harness PVAc's unique properties to create advanced tactile interfaces that can dynamically change their surface characteristics. This includes altering texture, temperature, and even simulating various materials' feel. Such advancements have far-reaching implications across multiple sectors, including consumer electronics, medical simulation, automotive interfaces, and assistive technologies for the visually impaired.

Another critical goal is to improve the durability and longevity of PVAc-based tactile surfaces. As these interfaces are subjected to frequent physical interactions, ensuring their resilience and maintaining consistent performance over time is paramount. Researchers are exploring various formulations and manufacturing techniques to enhance PVAc's resistance to wear, environmental factors, and repeated deformation cycles.

Furthermore, the integration of PVAc with other materials and technologies, such as conductive polymers and microfluidics, is opening new avenues for multifunctional tactile interfaces. These hybrid systems aim to combine tactile feedback with other sensory inputs or outputs, creating more comprehensive and versatile user interaction paradigms.

As we look towards the future, the continued development of PVAc in tactile applications is expected to play a crucial role in shaping the next generation of human-machine interfaces. The ongoing research aims not only to refine existing applications but also to uncover novel uses that could potentially transform various aspects of our daily lives, from how we interact with our devices to how we perceive and manipulate virtual environments.

Market Analysis for PVAc-based Tactile Solutions

The market for PVAc-based tactile solutions has shown significant growth in recent years, driven by increasing demand for innovative touch-sensitive interfaces across various industries. The global tactile sensors market, which includes PVAc-based solutions, is expected to expand at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This growth is primarily fueled by the rising adoption of touch-sensitive devices in consumer electronics, automotive, healthcare, and industrial applications.

In the consumer electronics sector, PVAc-based tactile solutions are gaining traction due to their ability to enhance user experience in smartphones, tablets, and wearable devices. The automotive industry is another key market, with manufacturers incorporating advanced tactile feedback systems in vehicle interiors to improve driver safety and comfort. The healthcare sector is also embracing PVAc-based tactile technologies for applications such as robotic surgery and rehabilitation devices.

The market demand for PVAc-based tactile solutions is driven by several factors. Firstly, there is a growing preference for intuitive and responsive user interfaces across various devices and applications. PVAc's unique properties, including its flexibility, durability, and sensitivity to pressure, make it an ideal material for developing advanced tactile sensors. Secondly, the increasing focus on haptic feedback in virtual and augmented reality applications is creating new opportunities for PVAc-based solutions.

Geographically, North America and Asia-Pacific are the leading markets for PVAc-based tactile solutions. North America's dominance is attributed to the presence of major technology companies and early adoption of innovative technologies. The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is experiencing rapid growth due to the strong presence of consumer electronics manufacturers and increasing investments in research and development.

Looking ahead, the market for PVAc-based tactile solutions is expected to witness further expansion as emerging technologies like the Internet of Things (IoT) and smart homes create new application areas. The integration of artificial intelligence and machine learning with tactile sensing technologies is also likely to drive market growth, enabling more sophisticated and context-aware tactile interfaces.

However, the market faces challenges such as the high cost of advanced tactile sensing technologies and the need for standardization in tactile feedback systems. Overcoming these hurdles will be crucial for the widespread adoption of PVAc-based tactile solutions across various industries and applications.

In the consumer electronics sector, PVAc-based tactile solutions are gaining traction due to their ability to enhance user experience in smartphones, tablets, and wearable devices. The automotive industry is another key market, with manufacturers incorporating advanced tactile feedback systems in vehicle interiors to improve driver safety and comfort. The healthcare sector is also embracing PVAc-based tactile technologies for applications such as robotic surgery and rehabilitation devices.

The market demand for PVAc-based tactile solutions is driven by several factors. Firstly, there is a growing preference for intuitive and responsive user interfaces across various devices and applications. PVAc's unique properties, including its flexibility, durability, and sensitivity to pressure, make it an ideal material for developing advanced tactile sensors. Secondly, the increasing focus on haptic feedback in virtual and augmented reality applications is creating new opportunities for PVAc-based solutions.

Geographically, North America and Asia-Pacific are the leading markets for PVAc-based tactile solutions. North America's dominance is attributed to the presence of major technology companies and early adoption of innovative technologies. The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is experiencing rapid growth due to the strong presence of consumer electronics manufacturers and increasing investments in research and development.

Looking ahead, the market for PVAc-based tactile solutions is expected to witness further expansion as emerging technologies like the Internet of Things (IoT) and smart homes create new application areas. The integration of artificial intelligence and machine learning with tactile sensing technologies is also likely to drive market growth, enabling more sophisticated and context-aware tactile interfaces.

However, the market faces challenges such as the high cost of advanced tactile sensing technologies and the need for standardization in tactile feedback systems. Overcoming these hurdles will be crucial for the widespread adoption of PVAc-based tactile solutions across various industries and applications.

Current PVAc Applications and Challenges

Polyvinyl acetate (PVAc) has found widespread applications in various industries due to its unique properties, particularly in tactile applications. Currently, PVAc is extensively used in adhesives, coatings, and textiles, where its tactile properties play a crucial role. In the adhesive industry, PVAc-based glues are popular for their strong bonding capabilities and flexibility, making them ideal for wood, paper, and fabric applications. The textile sector utilizes PVAc in fabric finishes to enhance softness and durability.

Despite its versatility, PVAc faces several challenges in tactile applications. One significant issue is its sensitivity to moisture and temperature. In high humidity environments, PVAc-based adhesives can lose their bonding strength, limiting their use in certain outdoor or high-moisture applications. Temperature fluctuations can also affect the polymer's performance, causing it to become brittle in cold conditions or excessively soft in high temperatures.

Another challenge lies in the balance between adhesion strength and tactile properties. While increasing PVAc concentration can improve adhesion, it may compromise the desired tactile feel, particularly in applications where a soft touch is crucial. This trade-off necessitates careful formulation and often requires the use of additives or copolymers to achieve optimal performance.

The environmental impact of PVAc is also a growing concern. Although it is generally considered less harmful than some other polymers, its production still relies on petrochemical sources. The disposal of PVAc-containing products can contribute to plastic pollution, as the material is not biodegradable. This has led to increased research into developing more environmentally friendly alternatives or improving the recyclability of PVAc-based products.

In the realm of tactile sensors and interfaces, PVAc shows promise but faces challenges in achieving the right balance of flexibility, durability, and sensitivity. Its use in capacitive touch sensors, for instance, requires careful engineering to maintain consistent performance across varying environmental conditions. The development of PVAc-based materials with enhanced conductivity and stability is an ongoing area of research.

The medical and healthcare sectors present both opportunities and challenges for PVAc in tactile applications. While its biocompatibility makes it suitable for certain medical devices and wound dressings, concerns about long-term exposure and potential allergic reactions in some individuals limit its use in more invasive applications. Researchers are exploring ways to modify PVAc to enhance its biocompatibility and reduce potential adverse reactions.

Despite its versatility, PVAc faces several challenges in tactile applications. One significant issue is its sensitivity to moisture and temperature. In high humidity environments, PVAc-based adhesives can lose their bonding strength, limiting their use in certain outdoor or high-moisture applications. Temperature fluctuations can also affect the polymer's performance, causing it to become brittle in cold conditions or excessively soft in high temperatures.

Another challenge lies in the balance between adhesion strength and tactile properties. While increasing PVAc concentration can improve adhesion, it may compromise the desired tactile feel, particularly in applications where a soft touch is crucial. This trade-off necessitates careful formulation and often requires the use of additives or copolymers to achieve optimal performance.

The environmental impact of PVAc is also a growing concern. Although it is generally considered less harmful than some other polymers, its production still relies on petrochemical sources. The disposal of PVAc-containing products can contribute to plastic pollution, as the material is not biodegradable. This has led to increased research into developing more environmentally friendly alternatives or improving the recyclability of PVAc-based products.

In the realm of tactile sensors and interfaces, PVAc shows promise but faces challenges in achieving the right balance of flexibility, durability, and sensitivity. Its use in capacitive touch sensors, for instance, requires careful engineering to maintain consistent performance across varying environmental conditions. The development of PVAc-based materials with enhanced conductivity and stability is an ongoing area of research.

The medical and healthcare sectors present both opportunities and challenges for PVAc in tactile applications. While its biocompatibility makes it suitable for certain medical devices and wound dressings, concerns about long-term exposure and potential allergic reactions in some individuals limit its use in more invasive applications. Researchers are exploring ways to modify PVAc to enhance its biocompatibility and reduce potential adverse reactions.

Existing PVAc-based Tactile Solutions

01 Tactile properties of polyvinyl acetate films

Polyvinyl acetate films can be formulated to exhibit various tactile properties, including softness, flexibility, and adhesion. These properties can be adjusted by modifying the molecular weight, degree of hydrolysis, and plasticizer content of the polyvinyl acetate. The resulting films can be used in applications where specific tactile characteristics are desired.- Tactile properties of polyvinyl acetate films: Polyvinyl acetate can be used to create films with specific tactile properties. These films can be engineered to have various textures, from smooth to rough, depending on the formulation and processing methods. The tactile properties can be adjusted by modifying factors such as molecular weight, degree of polymerization, and the addition of plasticizers or other additives.

- Adhesive properties and tactile feel: Polyvinyl acetate is widely used in adhesives, and its tactile properties play a crucial role in adhesive performance. The tackiness, peel strength, and overall feel of the adhesive can be tailored by adjusting the polymer composition and additives. This allows for the creation of adhesives with specific tactile characteristics suitable for various applications.

- Surface modification for enhanced tactile properties: The surface of polyvinyl acetate materials can be modified to enhance their tactile properties. Techniques such as chemical treatments, plasma processing, or the incorporation of nanoparticles can alter the surface texture and feel. These modifications can result in improved grip, softness, or other desired tactile characteristics.

- Blending with other polymers for tactile enhancement: Polyvinyl acetate can be blended with other polymers to create materials with unique tactile properties. These blends can combine the characteristics of multiple polymers, resulting in materials with improved softness, elasticity, or durability. The tactile feel of the final product can be fine-tuned by adjusting the ratios of the polymer components.

- Temperature-dependent tactile properties: The tactile properties of polyvinyl acetate materials can change with temperature. This temperature sensitivity can be utilized to create materials that exhibit different tactile characteristics at various temperatures. By carefully controlling the polymer composition and additives, it is possible to design materials with specific tactile responses to temperature changes.

02 Polyvinyl acetate in adhesive formulations

Polyvinyl acetate is commonly used in adhesive formulations due to its unique tactile properties. These adhesives can be tailored to provide specific levels of tack, peel strength, and shear resistance. The tactile characteristics of polyvinyl acetate adhesives can be modified by incorporating additives or blending with other polymers to achieve desired performance in various applications.Expand Specific Solutions03 Surface modification of polyvinyl acetate

The tactile properties of polyvinyl acetate can be enhanced through surface modification techniques. These methods may include chemical treatments, plasma treatments, or the application of coatings. By altering the surface characteristics, it is possible to improve properties such as smoothness, friction, and water repellency, leading to enhanced tactile performance in various products.Expand Specific Solutions04 Polyvinyl acetate blends for improved tactile properties

Blending polyvinyl acetate with other polymers or materials can result in improved tactile properties. These blends can combine the desirable characteristics of polyvinyl acetate with complementary properties from other components. The resulting materials may exhibit enhanced softness, durability, or specific texture profiles, making them suitable for applications where tactile performance is crucial.Expand Specific Solutions05 Tactile properties in polyvinyl acetate coatings

Polyvinyl acetate-based coatings can be formulated to provide specific tactile properties on various substrates. These coatings can be designed to impart characteristics such as smoothness, grip, or a specific texture. The tactile properties of the coatings can be fine-tuned by adjusting the composition, application method, and curing conditions, allowing for customization in different industrial and consumer applications.Expand Specific Solutions

Key Players in PVAc Tactile Innovations

The polyvinyl acetate market for tactile applications is in a growth phase, driven by increasing demand in various industries. The market size is expanding, with a projected CAGR of 5-6% over the next five years. Technologically, the field is moderately mature but continues to evolve. Key players like Sekisui Chemical, Kuraray, and BASF are leading innovation, focusing on enhancing adhesive properties and developing eco-friendly formulations. Emerging companies such as Wacker Chemie and DuPont are also making significant strides in specialized applications, indicating a competitive and dynamic market landscape.

BASF Corp.

Technical Solution: BASF has developed innovative polyvinyl acetate (PVA) formulations for tactile applications. Their advanced PVA-based adhesives offer enhanced bonding strength and flexibility, crucial for touchscreens and haptic feedback devices[1]. BASF's water-based PVA dispersions provide excellent adhesion to various substrates while maintaining high transparency, making them ideal for laminating touch-sensitive panels[2]. The company has also introduced PVA-based coatings with adjustable tactile properties, allowing manufacturers to create customized textures and sensations for user interfaces[3].

Strengths: Wide range of PVA formulations for diverse tactile applications, strong R&D capabilities. Weaknesses: Potential higher costs compared to generic alternatives, may require specialized application processes.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has made significant strides in PVA-based innovations for tactile applications. Their VINNOL® product line includes specialized PVA resins engineered for pressure-sensitive adhesives used in touch-sensitive devices[4]. Wacker has developed PVA copolymers with improved moisture resistance and flexibility, addressing common limitations of traditional PVA in tactile applications[5]. The company's PVA-based binders for 3D printing filaments have enabled the creation of objects with customizable tactile properties, opening new possibilities in prototyping and manufacturing[6].

Strengths: Expertise in PVA modifications for enhanced performance, diverse product portfolio. Weaknesses: May face competition from alternative polymer technologies, potential supply chain dependencies.

Breakthrough PVAc Formulations for Tactile Applications

Polyvinyl acetal, polyvinyl acetal composition, ink coating material, dispersant, heat-developable photosensitive material,ceramic green sheet, primer for plastic lens, recording agent for water-based ink and adhesive for metal foil

PatentInactiveUS20040157078A1

Innovation

- Polyvinyl acetal with functional groups, such as carboxyl or sulfonic acid groups, strategically located at the ends or in the main chain, which enhances dispersibility and adhesion by increasing adsorption points and interaction with pigments and other polymers, allowing for higher solid content formulations without excessive viscosity increase.

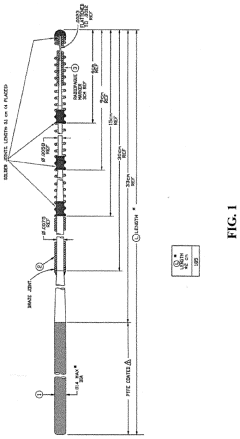

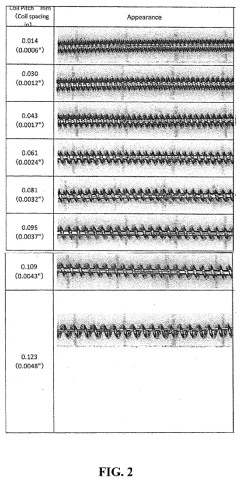

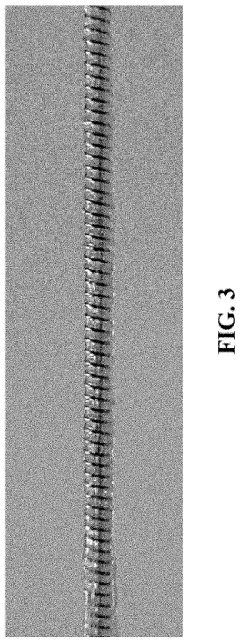

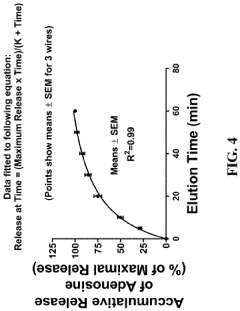

Medical devices for continuous delivery of therapeutic agents

PatentActiveUS20220288284A1

Innovation

- A hydrogel-coated guidewire with a therapeutic agent, such as adenosine, is developed, which releases the agent continuously when in contact with body fluids, providing localized treatment to improve tissue perfusion and prevent MVO by incorporating a polymer blend of polyvinyl alcohol (PVA) and polyvinylpyrrolidone (PVP) that forms a stable coating on the guidewire, allowing for controlled drug release.

Environmental Impact of PVAc in Tactile Products

The environmental impact of polyvinyl acetate (PVAc) in tactile products is a growing concern as the use of these materials becomes more widespread in various applications. PVAc, a synthetic polymer, is widely used in adhesives, coatings, and tactile products due to its versatility and cost-effectiveness. However, its production, use, and disposal can have significant environmental implications.

The manufacturing process of PVAc involves the polymerization of vinyl acetate monomer, which requires energy-intensive processes and the use of potentially harmful chemicals. This production phase contributes to greenhouse gas emissions and the depletion of non-renewable resources. Additionally, the use of solvents and other additives in PVAc production can lead to air and water pollution if not properly managed.

During the use phase of tactile products containing PVAc, there are concerns about the potential release of volatile organic compounds (VOCs) and other chemicals. While PVAc is generally considered safe for consumer use, prolonged exposure to these emissions may have health implications, particularly in indoor environments with poor ventilation.

The end-of-life stage of PVAc-based tactile products presents significant environmental challenges. PVAc is not biodegradable, meaning it persists in the environment for extended periods. When disposed of in landfills, PVAc products can take hundreds of years to decompose, contributing to long-term waste management issues. Incineration of PVAc waste can release toxic fumes and contribute to air pollution.

Recycling PVAc-based tactile products is challenging due to the complex nature of many of these products, which often combine PVAc with other materials. This makes separation and recycling processes difficult and often economically unfeasible. As a result, a significant portion of PVAc-containing products end up in landfills or incinerators.

The accumulation of PVAc in the environment, particularly in aquatic ecosystems, is an emerging concern. Microplastics derived from PVAc products can enter water systems, potentially affecting marine life and entering the food chain. This raises questions about the long-term ecological impact of widespread PVAc use in tactile applications.

In response to these environmental concerns, there is a growing focus on developing more sustainable alternatives to PVAc for tactile applications. Research is being conducted on bio-based polymers and environmentally friendly adhesives that could provide similar tactile properties with reduced environmental impact. Additionally, efforts are being made to improve the recyclability and biodegradability of PVAc-based products.

The manufacturing process of PVAc involves the polymerization of vinyl acetate monomer, which requires energy-intensive processes and the use of potentially harmful chemicals. This production phase contributes to greenhouse gas emissions and the depletion of non-renewable resources. Additionally, the use of solvents and other additives in PVAc production can lead to air and water pollution if not properly managed.

During the use phase of tactile products containing PVAc, there are concerns about the potential release of volatile organic compounds (VOCs) and other chemicals. While PVAc is generally considered safe for consumer use, prolonged exposure to these emissions may have health implications, particularly in indoor environments with poor ventilation.

The end-of-life stage of PVAc-based tactile products presents significant environmental challenges. PVAc is not biodegradable, meaning it persists in the environment for extended periods. When disposed of in landfills, PVAc products can take hundreds of years to decompose, contributing to long-term waste management issues. Incineration of PVAc waste can release toxic fumes and contribute to air pollution.

Recycling PVAc-based tactile products is challenging due to the complex nature of many of these products, which often combine PVAc with other materials. This makes separation and recycling processes difficult and often economically unfeasible. As a result, a significant portion of PVAc-containing products end up in landfills or incinerators.

The accumulation of PVAc in the environment, particularly in aquatic ecosystems, is an emerging concern. Microplastics derived from PVAc products can enter water systems, potentially affecting marine life and entering the food chain. This raises questions about the long-term ecological impact of widespread PVAc use in tactile applications.

In response to these environmental concerns, there is a growing focus on developing more sustainable alternatives to PVAc for tactile applications. Research is being conducted on bio-based polymers and environmentally friendly adhesives that could provide similar tactile properties with reduced environmental impact. Additionally, efforts are being made to improve the recyclability and biodegradability of PVAc-based products.

Regulatory Framework for PVAc in Consumer Goods

The regulatory framework for Polyvinyl Acetate (PVAc) in consumer goods is a complex and evolving landscape that significantly impacts the development and application of tactile innovations. Governments and regulatory bodies worldwide have established guidelines and standards to ensure the safe use of PVAc in various consumer products, particularly those involving direct skin contact or potential ingestion.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PVAc in consumer goods. The FDA has approved PVAc for use in certain food contact applications, such as adhesives and coatings, under specific conditions. These regulations are outlined in the Code of Federal Regulations (CFR) Title 21, which specifies the permissible uses and limitations of PVAc in food-related products.

The European Union (EU) has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of PVAc in consumer goods. Under REACH, manufacturers and importers must register substances like PVAc and provide safety data to the European Chemicals Agency (ECHA). This regulatory framework ensures that potential risks associated with PVAc are assessed and managed throughout the supply chain.

In addition to general chemical regulations, specific product categories have their own set of rules governing the use of PVAc. For instance, in the toy industry, the EU Toy Safety Directive and the US Consumer Product Safety Improvement Act (CPSIA) set strict limits on the use of certain chemicals, including PVAc, to protect children's health and safety.

The cosmetics industry is another area where PVAc regulations are particularly relevant for tactile applications. The EU Cosmetics Regulation and the FDA's cosmetic regulations in the US provide guidelines on the use of PVAc in personal care products, ensuring that its application in items like nail polishes and hair styling products meets safety standards.

Environmental concerns have also shaped the regulatory landscape for PVAc. Many countries have implemented regulations to address the environmental impact of PVAc-based products, particularly in terms of biodegradability and waste management. These regulations often encourage the development of more eco-friendly alternatives or improved recycling processes for PVAc-containing products.

As innovations in tactile applications continue to emerge, regulatory bodies are adapting their frameworks to address new uses of PVAc. This includes ongoing assessments of its safety in novel applications, such as smart textiles or advanced haptic devices. Manufacturers and researchers must stay abreast of these evolving regulations to ensure compliance and foster responsible innovation in PVAc-based tactile technologies.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PVAc in consumer goods. The FDA has approved PVAc for use in certain food contact applications, such as adhesives and coatings, under specific conditions. These regulations are outlined in the Code of Federal Regulations (CFR) Title 21, which specifies the permissible uses and limitations of PVAc in food-related products.

The European Union (EU) has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of PVAc in consumer goods. Under REACH, manufacturers and importers must register substances like PVAc and provide safety data to the European Chemicals Agency (ECHA). This regulatory framework ensures that potential risks associated with PVAc are assessed and managed throughout the supply chain.

In addition to general chemical regulations, specific product categories have their own set of rules governing the use of PVAc. For instance, in the toy industry, the EU Toy Safety Directive and the US Consumer Product Safety Improvement Act (CPSIA) set strict limits on the use of certain chemicals, including PVAc, to protect children's health and safety.

The cosmetics industry is another area where PVAc regulations are particularly relevant for tactile applications. The EU Cosmetics Regulation and the FDA's cosmetic regulations in the US provide guidelines on the use of PVAc in personal care products, ensuring that its application in items like nail polishes and hair styling products meets safety standards.

Environmental concerns have also shaped the regulatory landscape for PVAc. Many countries have implemented regulations to address the environmental impact of PVAc-based products, particularly in terms of biodegradability and waste management. These regulations often encourage the development of more eco-friendly alternatives or improved recycling processes for PVAc-containing products.

As innovations in tactile applications continue to emerge, regulatory bodies are adapting their frameworks to address new uses of PVAc. This includes ongoing assessments of its safety in novel applications, such as smart textiles or advanced haptic devices. Manufacturers and researchers must stay abreast of these evolving regulations to ensure compliance and foster responsible innovation in PVAc-based tactile technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!