How to Ensure Thermal Resistance in Polyvinyl Acetate Compositions?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Thermal Resistance Background and Objectives

Polyvinyl acetate (PVAc) has been a cornerstone in various industries since its development in the early 20th century. Initially used as an adhesive, PVAc's versatility has led to its widespread application in paints, coatings, and construction materials. However, as industrial demands have evolved, the need for enhanced thermal resistance in PVAc compositions has become increasingly critical.

The primary objective in improving PVAc's thermal resistance is to expand its applicability in high-temperature environments without compromising its desirable properties. This goal aligns with the broader trend in materials science towards developing more robust and versatile polymers capable of withstanding extreme conditions.

Historically, PVAc's thermal performance has been a limiting factor in its use. The polymer typically begins to soften at temperatures around 30-50°C, with significant degradation occurring at higher temperatures. This characteristic has restricted its use in applications exposed to elevated temperatures, such as automotive interiors or outdoor construction materials in warm climates.

Recent technological advancements have opened new avenues for enhancing PVAc's thermal resistance. These developments are driven by the growing demand for materials that can maintain structural integrity and functional properties under thermal stress. The push for improved thermal resistance in PVAc compositions is also influenced by sustainability concerns, as more durable materials can lead to longer-lasting products and reduced waste.

The evolution of PVAc thermal resistance technology is closely tied to advancements in polymer science and nanotechnology. Researchers are exploring various approaches, including the incorporation of heat-resistant additives, cross-linking techniques, and the development of PVAc-based composites. These efforts aim to create PVAc formulations that can withstand higher temperatures without sacrificing the polymer's beneficial properties such as adhesion strength, flexibility, and ease of processing.

As industries continue to push the boundaries of material performance, the quest for thermally resistant PVAc compositions represents a significant area of research and development. Success in this field could lead to the expansion of PVAc's use in high-value applications, potentially disrupting existing markets and creating new opportunities for innovation in sectors ranging from construction to electronics manufacturing.

The primary objective in improving PVAc's thermal resistance is to expand its applicability in high-temperature environments without compromising its desirable properties. This goal aligns with the broader trend in materials science towards developing more robust and versatile polymers capable of withstanding extreme conditions.

Historically, PVAc's thermal performance has been a limiting factor in its use. The polymer typically begins to soften at temperatures around 30-50°C, with significant degradation occurring at higher temperatures. This characteristic has restricted its use in applications exposed to elevated temperatures, such as automotive interiors or outdoor construction materials in warm climates.

Recent technological advancements have opened new avenues for enhancing PVAc's thermal resistance. These developments are driven by the growing demand for materials that can maintain structural integrity and functional properties under thermal stress. The push for improved thermal resistance in PVAc compositions is also influenced by sustainability concerns, as more durable materials can lead to longer-lasting products and reduced waste.

The evolution of PVAc thermal resistance technology is closely tied to advancements in polymer science and nanotechnology. Researchers are exploring various approaches, including the incorporation of heat-resistant additives, cross-linking techniques, and the development of PVAc-based composites. These efforts aim to create PVAc formulations that can withstand higher temperatures without sacrificing the polymer's beneficial properties such as adhesion strength, flexibility, and ease of processing.

As industries continue to push the boundaries of material performance, the quest for thermally resistant PVAc compositions represents a significant area of research and development. Success in this field could lead to the expansion of PVAc's use in high-value applications, potentially disrupting existing markets and creating new opportunities for innovation in sectors ranging from construction to electronics manufacturing.

Market Analysis for Heat-Resistant PVAc Products

The market for heat-resistant polyvinyl acetate (PVAc) products has been experiencing significant growth in recent years, driven by increasing demand across various industries. The global PVAc market is expected to reach substantial value by 2025, with heat-resistant formulations playing a crucial role in this expansion. Key sectors contributing to this growth include construction, packaging, and automotive industries.

In the construction sector, heat-resistant PVAc adhesives are gaining traction due to their improved performance in high-temperature environments. These products offer enhanced bonding strength and durability, making them ideal for applications in building materials, flooring, and furniture manufacturing. The increasing focus on energy-efficient buildings and stringent fire safety regulations further propel the demand for heat-resistant PVAc products in this sector.

The packaging industry represents another significant market for heat-resistant PVAc compositions. With the rise of e-commerce and the need for robust packaging solutions, there is a growing demand for adhesives that can withstand varying temperature conditions during transportation and storage. Heat-resistant PVAc formulations provide improved package integrity and longer shelf life for products, particularly in the food and beverage sector.

In the automotive industry, heat-resistant PVAc products are finding applications in interior components, upholstery, and sound insulation materials. The ability to maintain structural integrity and adhesive properties under high-temperature conditions makes these products valuable in automotive manufacturing processes.

Market trends indicate a shift towards environmentally friendly and sustainable heat-resistant PVAc formulations. Manufacturers are investing in research and development to create bio-based alternatives and reduce the environmental impact of their products. This trend aligns with the growing consumer preference for eco-friendly materials and stricter environmental regulations in many regions.

Geographically, Asia-Pacific is emerging as a key market for heat-resistant PVAc products, driven by rapid industrialization, infrastructure development, and increasing automotive production in countries like China and India. North America and Europe continue to be significant markets, with a focus on innovation and high-performance applications.

The competitive landscape of the heat-resistant PVAc market is characterized by the presence of both large multinational corporations and specialized manufacturers. Key players are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

In the construction sector, heat-resistant PVAc adhesives are gaining traction due to their improved performance in high-temperature environments. These products offer enhanced bonding strength and durability, making them ideal for applications in building materials, flooring, and furniture manufacturing. The increasing focus on energy-efficient buildings and stringent fire safety regulations further propel the demand for heat-resistant PVAc products in this sector.

The packaging industry represents another significant market for heat-resistant PVAc compositions. With the rise of e-commerce and the need for robust packaging solutions, there is a growing demand for adhesives that can withstand varying temperature conditions during transportation and storage. Heat-resistant PVAc formulations provide improved package integrity and longer shelf life for products, particularly in the food and beverage sector.

In the automotive industry, heat-resistant PVAc products are finding applications in interior components, upholstery, and sound insulation materials. The ability to maintain structural integrity and adhesive properties under high-temperature conditions makes these products valuable in automotive manufacturing processes.

Market trends indicate a shift towards environmentally friendly and sustainable heat-resistant PVAc formulations. Manufacturers are investing in research and development to create bio-based alternatives and reduce the environmental impact of their products. This trend aligns with the growing consumer preference for eco-friendly materials and stricter environmental regulations in many regions.

Geographically, Asia-Pacific is emerging as a key market for heat-resistant PVAc products, driven by rapid industrialization, infrastructure development, and increasing automotive production in countries like China and India. North America and Europe continue to be significant markets, with a focus on innovation and high-performance applications.

The competitive landscape of the heat-resistant PVAc market is characterized by the presence of both large multinational corporations and specialized manufacturers. Key players are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

Current Challenges in PVAc Thermal Stability

Polyvinyl acetate (PVAc) compositions face significant challenges in maintaining thermal stability, which is crucial for their performance and longevity in various applications. The primary issue stems from the inherent chemical structure of PVAc, which is susceptible to degradation at elevated temperatures. This degradation process typically involves deacetylation, chain scission, and crosslinking reactions, leading to changes in the material's physical and mechanical properties.

One of the key challenges is preventing the loss of acetyl groups from the polymer backbone when exposed to high temperatures. This deacetylation process not only alters the chemical composition of the material but also leads to the formation of acetic acid, which can catalyze further degradation. The release of acetic acid creates a self-accelerating degradation cycle, rapidly compromising the integrity of the PVAc composition.

Another significant hurdle is the prevention of chain scission, which occurs when the polymer chains break down under thermal stress. This process results in a reduction of molecular weight, leading to decreased mechanical strength and altered viscoelastic properties. The challenge lies in developing stabilization techniques that can effectively inhibit these chain-breaking reactions without compromising the desired properties of the PVAc composition.

Crosslinking reactions present a dual challenge in PVAc thermal stability. While some degree of crosslinking can enhance thermal resistance, excessive crosslinking can lead to brittleness and loss of flexibility. Controlling the extent and nature of crosslinking reactions under thermal stress is crucial for maintaining the balance between stability and desired material properties.

The development of effective thermal stabilizers for PVAc compositions is an ongoing challenge. Current stabilizers may not provide sufficient protection across a wide temperature range or may introduce undesirable side effects, such as discoloration or toxicity. Finding stabilizers that are both highly effective and environmentally friendly remains a significant research focus.

Additionally, the interaction between PVAc and other components in complex formulations poses challenges for thermal stability. Additives, fillers, and plasticizers can influence the degradation pathways and thermal behavior of PVAc. Understanding and optimizing these interactions to enhance overall thermal resistance is a complex task that requires extensive research and testing.

Lastly, the challenge of maintaining thermal stability while preserving other critical properties of PVAc compositions, such as adhesion strength, flexibility, and optical clarity, adds another layer of complexity to the problem. Balancing these often competing requirements necessitates innovative approaches in polymer design and formulation strategies.

One of the key challenges is preventing the loss of acetyl groups from the polymer backbone when exposed to high temperatures. This deacetylation process not only alters the chemical composition of the material but also leads to the formation of acetic acid, which can catalyze further degradation. The release of acetic acid creates a self-accelerating degradation cycle, rapidly compromising the integrity of the PVAc composition.

Another significant hurdle is the prevention of chain scission, which occurs when the polymer chains break down under thermal stress. This process results in a reduction of molecular weight, leading to decreased mechanical strength and altered viscoelastic properties. The challenge lies in developing stabilization techniques that can effectively inhibit these chain-breaking reactions without compromising the desired properties of the PVAc composition.

Crosslinking reactions present a dual challenge in PVAc thermal stability. While some degree of crosslinking can enhance thermal resistance, excessive crosslinking can lead to brittleness and loss of flexibility. Controlling the extent and nature of crosslinking reactions under thermal stress is crucial for maintaining the balance between stability and desired material properties.

The development of effective thermal stabilizers for PVAc compositions is an ongoing challenge. Current stabilizers may not provide sufficient protection across a wide temperature range or may introduce undesirable side effects, such as discoloration or toxicity. Finding stabilizers that are both highly effective and environmentally friendly remains a significant research focus.

Additionally, the interaction between PVAc and other components in complex formulations poses challenges for thermal stability. Additives, fillers, and plasticizers can influence the degradation pathways and thermal behavior of PVAc. Understanding and optimizing these interactions to enhance overall thermal resistance is a complex task that requires extensive research and testing.

Lastly, the challenge of maintaining thermal stability while preserving other critical properties of PVAc compositions, such as adhesion strength, flexibility, and optical clarity, adds another layer of complexity to the problem. Balancing these often competing requirements necessitates innovative approaches in polymer design and formulation strategies.

Existing PVAc Thermal Resistance Solutions

01 Incorporation of additives for thermal resistance

Various additives can be incorporated into polyvinyl acetate compositions to enhance their thermal resistance. These additives may include flame retardants, heat stabilizers, or other compounds that improve the material's ability to withstand high temperatures. The specific additives used can be tailored to meet the desired thermal properties of the final product.- Incorporation of additives for thermal resistance: Various additives can be incorporated into polyvinyl acetate compositions to enhance their thermal resistance. These additives may include flame retardants, heat stabilizers, or other compounds that improve the material's ability to withstand high temperatures. The specific additives used can be tailored to meet the desired thermal properties of the final product.

- Copolymerization with heat-resistant monomers: Polyvinyl acetate can be copolymerized with other monomers that possess inherent heat-resistant properties. This approach allows for the creation of copolymers with improved thermal stability compared to pure polyvinyl acetate. The selection of appropriate co-monomers and their ratios can be optimized to achieve the desired balance of thermal resistance and other properties.

- Cross-linking for improved thermal stability: Cross-linking techniques can be applied to polyvinyl acetate compositions to enhance their thermal resistance. This process involves creating chemical bonds between polymer chains, resulting in a more rigid and heat-resistant structure. Various cross-linking agents and methods can be employed to achieve the desired level of thermal stability.

- Blending with heat-resistant polymers: Polyvinyl acetate can be blended with other heat-resistant polymers to create compositions with improved thermal properties. This approach allows for the combination of the desirable characteristics of polyvinyl acetate with the thermal resistance of other polymers. The selection and ratio of polymers in the blend can be optimized to achieve the desired thermal performance.

- Surface treatment for enhanced thermal resistance: Surface treatment techniques can be applied to polyvinyl acetate compositions to improve their thermal resistance. These treatments may involve the application of heat-resistant coatings or the modification of the surface structure to enhance the material's ability to withstand high temperatures. Various methods and materials can be used for surface treatment, depending on the specific requirements of the application.

02 Copolymerization with heat-resistant monomers

Polyvinyl acetate can be copolymerized with other monomers that possess inherent heat-resistant properties. This approach allows for the creation of copolymers with improved thermal stability compared to pure polyvinyl acetate. The selection of appropriate co-monomers and their ratios can be optimized to achieve the desired balance of thermal resistance and other properties.Expand Specific Solutions03 Cross-linking for improved thermal stability

Cross-linking techniques can be applied to polyvinyl acetate compositions to enhance their thermal resistance. This process involves creating chemical bonds between polymer chains, resulting in a more rigid and heat-resistant structure. Various cross-linking agents and methods can be employed to achieve the desired level of thermal stability.Expand Specific Solutions04 Blending with heat-resistant polymers

Polyvinyl acetate can be blended with other heat-resistant polymers to create compositions with improved thermal properties. This approach allows for the combination of the desirable characteristics of polyvinyl acetate with the thermal resistance of other polymers. The selection and ratio of polymers in the blend can be optimized to achieve the desired thermal and mechanical properties.Expand Specific Solutions05 Surface treatment for enhanced thermal resistance

Surface treatments can be applied to polyvinyl acetate compositions to improve their thermal resistance. These treatments may involve the application of heat-resistant coatings or the modification of the surface structure to enhance the material's ability to withstand high temperatures. Various techniques and materials can be used for surface treatment, depending on the specific requirements of the application.Expand Specific Solutions

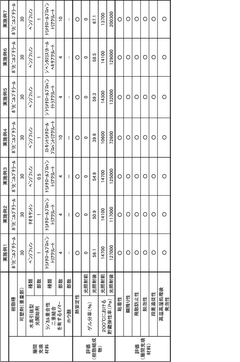

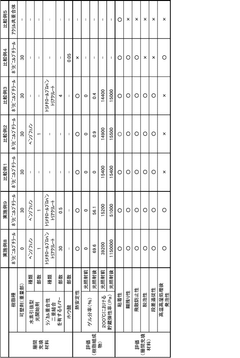

Key Players in PVAc Industry

The thermal resistance of polyvinyl acetate compositions is a critical area of research in the advanced materials industry, currently in a growth phase. The market for thermally resistant polymers is expanding, driven by increasing demand in electronics, automotive, and construction sectors. Technologically, the field is progressing rapidly, with companies like Kuraray Co., Ltd., Wacker Chemie AG, and Henkel AG & Co. KGaA leading innovation. These firms are developing enhanced formulations and manufacturing processes to improve thermal stability. While the technology is advancing, there's still room for significant improvements in performance and cost-effectiveness, indicating a competitive landscape with opportunities for breakthrough innovations.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed a novel approach to enhance thermal resistance in polyvinyl acetate compositions by incorporating cross-linking agents and heat-resistant monomers. Their method involves copolymerizing vinyl acetate with specialized heat-resistant monomers, such as N-methylolacrylamide or N-methylolmethacrylamide, which form a more stable polymer backbone[1]. Additionally, they utilize cross-linking agents like epoxy compounds or isocyanates to create a three-dimensional network structure within the polymer matrix[2]. This combination significantly improves the thermal stability of the polyvinyl acetate, allowing it to maintain its structural integrity at higher temperatures. Kuraray's process also includes the addition of inorganic fillers, such as silica or alumina, which further enhance the thermal resistance and mechanical properties of the final composition[3].

Strengths: Improved thermal stability, enhanced mechanical properties, and versatility in applications. Weaknesses: Potentially higher production costs and complexity in formulation compared to standard polyvinyl acetate.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed a proprietary technology for improving thermal resistance in polyvinyl acetate compositions through the use of silane-modified polymers. Their approach involves grafting silane functional groups onto the polyvinyl acetate backbone, which can then undergo hydrolysis and condensation reactions to form a siloxane network within the polymer matrix[4]. This siloxane network significantly enhances the thermal stability and mechanical properties of the material. Wacker's process also incorporates specialized heat-stabilizing additives, such as organometallic compounds or hindered phenols, which act as radical scavengers and prevent thermal degradation[5]. Furthermore, they have developed a unique emulsion polymerization technique that allows for better control of particle size and distribution, resulting in improved film formation and thermal resistance properties[6].

Strengths: Excellent thermal stability, improved water resistance, and enhanced adhesion properties. Weaknesses: May require specialized processing equipment and potentially higher raw material costs.

Innovative PVAc Heat Stabilization Techniques

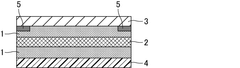

Polyvinyl acetal resin for thermoforming

PatentWO2012043455A1

Innovation

- A polyvinyl acetal resin with specific properties is developed, including a viscosity average polymerization degree of 500 to 2000, a saponification degree of 99.5 mol% or more, and a degree of acetalization between 65 to 88 mol%, along with controlled alkali metal or alkaline earth metal content and the use of aldehydes like butyraldehyde, to enhance thermal stability and heat resistance without impairing mechanical properties.

Poly(vinyl acetal) resin composition, adhesive sheet, interlaminar filling material for touch panel, and laminate

PatentWO2017061545A1

Innovation

- A polyvinyl acetal resin composition containing polyvinyl acetal, a photoradical polymerization initiator, and a monomer or oligomer with a radically polymerizable double bond, which can be crosslinked by light irradiation after molding, maintaining high storage modulus even at high temperatures and preventing gel formation during extrusion.

Environmental Impact of PVAc Thermal Additives

The environmental impact of thermal additives used in polyvinyl acetate (PVAc) compositions is a critical consideration in the development and application of these materials. As the demand for thermally resistant PVAc products grows, so does the need to assess the ecological footprint of the additives employed to enhance their thermal properties.

Thermal additives for PVAc typically include inorganic fillers, flame retardants, and heat stabilizers. These components, while effective in improving thermal resistance, can pose significant environmental challenges throughout their lifecycle. The production of these additives often involves energy-intensive processes and the use of non-renewable resources, contributing to greenhouse gas emissions and resource depletion.

During the use phase of PVAc products containing thermal additives, there is potential for leaching of these substances into the environment. This is particularly concerning for outdoor applications or products that come into contact with water. Some thermal additives, especially halogenated flame retardants, have been associated with bioaccumulation and persistence in ecosystems, potentially affecting wildlife and human health.

End-of-life disposal of PVAc products with thermal additives presents another set of environmental challenges. Incineration of these materials can release toxic compounds into the atmosphere, while landfilling may lead to soil and groundwater contamination as additives leach out over time. Recycling processes for PVAc products are complicated by the presence of these additives, often requiring specialized treatment or rendering the material unsuitable for certain recycling streams.

Recent research has focused on developing more environmentally friendly alternatives to traditional thermal additives. Bio-based additives derived from renewable resources show promise in reducing the carbon footprint of PVAc thermal resistance solutions. Additionally, nanocomposite technologies are being explored to enhance thermal properties with minimal additive content, potentially mitigating environmental impact.

Regulatory bodies worldwide are increasingly scrutinizing the environmental impact of chemical additives in polymers. This has led to stricter regulations on the use of certain thermal additives, particularly those with known environmental persistence or toxicity. Manufacturers are now required to conduct comprehensive life cycle assessments and provide detailed environmental impact data for their products.

The push towards circular economy principles is driving innovation in PVAc thermal additive technology. Researchers are exploring additives that not only improve thermal resistance but also enhance the recyclability and biodegradability of PVAc products. This holistic approach aims to minimize environmental impact across the entire product lifecycle, from production to disposal or reuse.

As the industry moves forward, balancing thermal performance with environmental sustainability remains a key challenge. The development of green chemistry solutions and the adoption of eco-design principles in PVAc formulations will be crucial in addressing the environmental concerns associated with thermal additives while meeting the growing demand for heat-resistant PVAc compositions.

Thermal additives for PVAc typically include inorganic fillers, flame retardants, and heat stabilizers. These components, while effective in improving thermal resistance, can pose significant environmental challenges throughout their lifecycle. The production of these additives often involves energy-intensive processes and the use of non-renewable resources, contributing to greenhouse gas emissions and resource depletion.

During the use phase of PVAc products containing thermal additives, there is potential for leaching of these substances into the environment. This is particularly concerning for outdoor applications or products that come into contact with water. Some thermal additives, especially halogenated flame retardants, have been associated with bioaccumulation and persistence in ecosystems, potentially affecting wildlife and human health.

End-of-life disposal of PVAc products with thermal additives presents another set of environmental challenges. Incineration of these materials can release toxic compounds into the atmosphere, while landfilling may lead to soil and groundwater contamination as additives leach out over time. Recycling processes for PVAc products are complicated by the presence of these additives, often requiring specialized treatment or rendering the material unsuitable for certain recycling streams.

Recent research has focused on developing more environmentally friendly alternatives to traditional thermal additives. Bio-based additives derived from renewable resources show promise in reducing the carbon footprint of PVAc thermal resistance solutions. Additionally, nanocomposite technologies are being explored to enhance thermal properties with minimal additive content, potentially mitigating environmental impact.

Regulatory bodies worldwide are increasingly scrutinizing the environmental impact of chemical additives in polymers. This has led to stricter regulations on the use of certain thermal additives, particularly those with known environmental persistence or toxicity. Manufacturers are now required to conduct comprehensive life cycle assessments and provide detailed environmental impact data for their products.

The push towards circular economy principles is driving innovation in PVAc thermal additive technology. Researchers are exploring additives that not only improve thermal resistance but also enhance the recyclability and biodegradability of PVAc products. This holistic approach aims to minimize environmental impact across the entire product lifecycle, from production to disposal or reuse.

As the industry moves forward, balancing thermal performance with environmental sustainability remains a key challenge. The development of green chemistry solutions and the adoption of eco-design principles in PVAc formulations will be crucial in addressing the environmental concerns associated with thermal additives while meeting the growing demand for heat-resistant PVAc compositions.

Cost-Benefit Analysis of Heat-Resistant PVAc

The cost-benefit analysis of heat-resistant polyvinyl acetate (PVAc) compositions is a crucial aspect of determining the feasibility and economic viability of implementing thermal resistance improvements in PVAc-based products. This analysis involves evaluating the financial implications of developing and producing heat-resistant PVAc against the potential benefits and market advantages it may offer.

One of the primary costs associated with enhancing the thermal resistance of PVAc compositions is the research and development expenditure. This includes investments in laboratory equipment, materials for experimentation, and the salaries of skilled researchers and technicians. The development process may require extensive testing and iteration, which can significantly impact the overall cost structure.

Manufacturing costs also play a significant role in the analysis. Heat-resistant PVAc compositions often require specialized additives or modified production processes, which can increase the cost per unit compared to standard PVAc formulations. These additional expenses may include higher-grade raw materials, more sophisticated processing equipment, or extended production times to achieve the desired thermal properties.

On the benefits side, heat-resistant PVAc compositions offer several advantages that can justify the increased costs. Improved thermal stability expands the potential applications of PVAc-based products, potentially opening up new market segments and increasing the overall demand. This can lead to higher sales volumes and potentially higher profit margins for products that meet specific thermal performance requirements.

Enhanced durability and longevity of products made with heat-resistant PVAc can also contribute to customer satisfaction and brand reputation. This may result in increased customer loyalty and repeat business, which can have long-term positive impacts on a company's financial performance.

Furthermore, the ability to offer heat-resistant PVAc compositions can provide a competitive edge in the market. Companies that successfully develop and commercialize these advanced materials may be able to command premium prices or secure exclusive contracts with customers in industries where thermal resistance is a critical factor.

When conducting the cost-benefit analysis, it is essential to consider the time horizon for realizing returns on investment. While the initial costs may be substantial, the long-term benefits of establishing a strong position in the heat-resistant PVAc market could outweigh these upfront expenses.

Additionally, potential regulatory advantages should be factored into the analysis. As environmental and safety standards become more stringent, heat-resistant PVAc compositions that meet or exceed these requirements may become increasingly valuable, potentially offsetting the higher production costs through reduced compliance expenses and improved market access.

One of the primary costs associated with enhancing the thermal resistance of PVAc compositions is the research and development expenditure. This includes investments in laboratory equipment, materials for experimentation, and the salaries of skilled researchers and technicians. The development process may require extensive testing and iteration, which can significantly impact the overall cost structure.

Manufacturing costs also play a significant role in the analysis. Heat-resistant PVAc compositions often require specialized additives or modified production processes, which can increase the cost per unit compared to standard PVAc formulations. These additional expenses may include higher-grade raw materials, more sophisticated processing equipment, or extended production times to achieve the desired thermal properties.

On the benefits side, heat-resistant PVAc compositions offer several advantages that can justify the increased costs. Improved thermal stability expands the potential applications of PVAc-based products, potentially opening up new market segments and increasing the overall demand. This can lead to higher sales volumes and potentially higher profit margins for products that meet specific thermal performance requirements.

Enhanced durability and longevity of products made with heat-resistant PVAc can also contribute to customer satisfaction and brand reputation. This may result in increased customer loyalty and repeat business, which can have long-term positive impacts on a company's financial performance.

Furthermore, the ability to offer heat-resistant PVAc compositions can provide a competitive edge in the market. Companies that successfully develop and commercialize these advanced materials may be able to command premium prices or secure exclusive contracts with customers in industries where thermal resistance is a critical factor.

When conducting the cost-benefit analysis, it is essential to consider the time horizon for realizing returns on investment. While the initial costs may be substantial, the long-term benefits of establishing a strong position in the heat-resistant PVAc market could outweigh these upfront expenses.

Additionally, potential regulatory advantages should be factored into the analysis. As environmental and safety standards become more stringent, heat-resistant PVAc compositions that meet or exceed these requirements may become increasingly valuable, potentially offsetting the higher production costs through reduced compliance expenses and improved market access.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!