Polyvinyl Acetate for Water-Resistant Paper Products

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc for Paper: Background and Objectives

Polyvinyl acetate (PVAc) has emerged as a promising material for enhancing the water resistance of paper products. The development of water-resistant paper has been a long-standing challenge in the paper industry, driven by the need for durable and versatile paper-based materials in various applications. PVAc, a synthetic polymer, has gained attention due to its unique properties that make it suitable for improving paper's water resistance without compromising its other desirable characteristics.

The evolution of PVAc technology in paper production can be traced back to the mid-20th century when researchers began exploring synthetic polymers for paper coating. Over the decades, advancements in polymer chemistry and paper manufacturing techniques have led to more sophisticated applications of PVAc in paper products. The primary objective of incorporating PVAc into paper is to create a hydrophobic barrier that prevents water absorption while maintaining the paper's flexibility, printability, and recyclability.

Recent technological trends in PVAc application for water-resistant paper focus on developing environmentally friendly formulations, improving adhesion to paper fibers, and enhancing the overall performance of PVAc-treated papers. Researchers are exploring various methods of PVAc application, including surface coating, bulk addition during paper formation, and hybrid approaches that combine multiple techniques.

The goals of current research on PVAc for water-resistant paper products are multifaceted. Firstly, there is a drive to optimize the PVAc formulation to achieve maximum water resistance with minimal impact on other paper properties. This includes investigating different molecular weights, crosslinking agents, and additives that can enhance PVAc's performance. Secondly, researchers aim to develop cost-effective and scalable production methods that can be easily integrated into existing paper manufacturing processes.

Another critical objective is to address environmental concerns associated with synthetic polymers. This involves developing biodegradable or recyclable PVAc formulations that align with sustainability goals while maintaining the desired water-resistant properties. Additionally, there is a focus on reducing the use of volatile organic compounds (VOCs) in PVAc-based coatings to meet stringent environmental regulations.

The potential applications of PVAc-enhanced water-resistant paper are vast, ranging from packaging materials and outdoor advertising to specialized industrial papers. As such, researchers are also exploring ways to tailor PVAc formulations for specific end-use requirements, such as food-grade packaging or high-humidity environments.

The evolution of PVAc technology in paper production can be traced back to the mid-20th century when researchers began exploring synthetic polymers for paper coating. Over the decades, advancements in polymer chemistry and paper manufacturing techniques have led to more sophisticated applications of PVAc in paper products. The primary objective of incorporating PVAc into paper is to create a hydrophobic barrier that prevents water absorption while maintaining the paper's flexibility, printability, and recyclability.

Recent technological trends in PVAc application for water-resistant paper focus on developing environmentally friendly formulations, improving adhesion to paper fibers, and enhancing the overall performance of PVAc-treated papers. Researchers are exploring various methods of PVAc application, including surface coating, bulk addition during paper formation, and hybrid approaches that combine multiple techniques.

The goals of current research on PVAc for water-resistant paper products are multifaceted. Firstly, there is a drive to optimize the PVAc formulation to achieve maximum water resistance with minimal impact on other paper properties. This includes investigating different molecular weights, crosslinking agents, and additives that can enhance PVAc's performance. Secondly, researchers aim to develop cost-effective and scalable production methods that can be easily integrated into existing paper manufacturing processes.

Another critical objective is to address environmental concerns associated with synthetic polymers. This involves developing biodegradable or recyclable PVAc formulations that align with sustainability goals while maintaining the desired water-resistant properties. Additionally, there is a focus on reducing the use of volatile organic compounds (VOCs) in PVAc-based coatings to meet stringent environmental regulations.

The potential applications of PVAc-enhanced water-resistant paper are vast, ranging from packaging materials and outdoor advertising to specialized industrial papers. As such, researchers are also exploring ways to tailor PVAc formulations for specific end-use requirements, such as food-grade packaging or high-humidity environments.

Market Analysis for Water-Resistant Paper

The water-resistant paper market has been experiencing significant growth in recent years, driven by increasing demand across various industries. This market segment is characterized by paper products that have been treated or coated with substances like polyvinyl acetate to enhance their resistance to water and moisture. The global water-resistant paper market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the primary drivers of this market growth is the packaging industry, particularly in the food and beverage sector. As consumers become more environmentally conscious, there is a growing preference for sustainable packaging solutions that can withstand moisture while remaining recyclable. This trend has led to increased adoption of water-resistant paper products as an alternative to plastic packaging in many applications.

The e-commerce boom has also contributed significantly to the demand for water-resistant paper products. With the rise in online shopping and home deliveries, there is a greater need for packaging materials that can protect goods from moisture during transit. Water-resistant paper offers an eco-friendly solution that meets both the functional requirements and sustainability goals of many e-commerce businesses.

In the construction industry, water-resistant paper products are gaining traction for applications such as building wraps and underlayment. These materials provide an additional layer of protection against moisture infiltration, enhancing the durability and longevity of structures. The growing focus on energy-efficient and sustainable building practices is expected to further drive demand in this sector.

The printing and publishing industry represents another significant market for water-resistant paper. With the increasing use of digital printing technologies, there is a demand for paper substrates that can withstand the heat and moisture associated with these processes while maintaining print quality. Water-resistant papers are also finding applications in outdoor advertising and signage, where durability in various weather conditions is crucial.

Geographically, Asia-Pacific is emerging as a key market for water-resistant paper products, driven by rapid industrialization, urbanization, and changing consumer preferences in countries like China and India. North America and Europe continue to be significant markets, with a strong focus on sustainable packaging solutions and stringent regulations promoting the use of environmentally friendly materials.

However, the market faces challenges, including the higher cost of water-resistant paper compared to conventional paper products and competition from alternative materials such as plastics and biodegradable polymers. Manufacturers are investing in research and development to improve the performance and cost-effectiveness of water-resistant paper products, exploring new coating technologies and sustainable raw materials to address these challenges and capitalize on the growing market opportunities.

One of the primary drivers of this market growth is the packaging industry, particularly in the food and beverage sector. As consumers become more environmentally conscious, there is a growing preference for sustainable packaging solutions that can withstand moisture while remaining recyclable. This trend has led to increased adoption of water-resistant paper products as an alternative to plastic packaging in many applications.

The e-commerce boom has also contributed significantly to the demand for water-resistant paper products. With the rise in online shopping and home deliveries, there is a greater need for packaging materials that can protect goods from moisture during transit. Water-resistant paper offers an eco-friendly solution that meets both the functional requirements and sustainability goals of many e-commerce businesses.

In the construction industry, water-resistant paper products are gaining traction for applications such as building wraps and underlayment. These materials provide an additional layer of protection against moisture infiltration, enhancing the durability and longevity of structures. The growing focus on energy-efficient and sustainable building practices is expected to further drive demand in this sector.

The printing and publishing industry represents another significant market for water-resistant paper. With the increasing use of digital printing technologies, there is a demand for paper substrates that can withstand the heat and moisture associated with these processes while maintaining print quality. Water-resistant papers are also finding applications in outdoor advertising and signage, where durability in various weather conditions is crucial.

Geographically, Asia-Pacific is emerging as a key market for water-resistant paper products, driven by rapid industrialization, urbanization, and changing consumer preferences in countries like China and India. North America and Europe continue to be significant markets, with a strong focus on sustainable packaging solutions and stringent regulations promoting the use of environmentally friendly materials.

However, the market faces challenges, including the higher cost of water-resistant paper compared to conventional paper products and competition from alternative materials such as plastics and biodegradable polymers. Manufacturers are investing in research and development to improve the performance and cost-effectiveness of water-resistant paper products, exploring new coating technologies and sustainable raw materials to address these challenges and capitalize on the growing market opportunities.

Current PVAc Technology and Challenges

Polyvinyl acetate (PVAc) has been widely used in the paper industry for its adhesive properties and ability to enhance paper strength. However, its application in water-resistant paper products faces several challenges. The current PVAc technology primarily relies on emulsion polymerization, resulting in a water-based adhesive that is susceptible to moisture.

One of the main challenges in developing water-resistant paper products using PVAc is its inherent hydrophilic nature. When exposed to water, PVAc tends to soften and lose its adhesive properties, compromising the integrity of the paper product. This limitation has led researchers to explore various modifications and additives to enhance the water resistance of PVAc-based adhesives.

Cross-linking agents have been introduced to improve the water resistance of PVAc. These agents form chemical bonds between PVAc molecules, creating a more robust network that is less susceptible to water penetration. However, the effectiveness of cross-linking agents can vary depending on the specific formulation and application method, presenting challenges in achieving consistent results across different paper products.

Another approach to enhance water resistance involves the incorporation of hydrophobic additives into PVAc formulations. These additives, such as silicones or fluoropolymers, can create a water-repellent surface on the paper. However, finding the right balance between water resistance and maintaining other desirable paper properties, such as printability and recyclability, remains a significant challenge.

The development of PVAc-based nanocomposites has shown promise in improving water resistance. By incorporating nanoparticles, such as clay or silica, into the PVAc matrix, researchers have observed enhanced barrier properties. However, the uniform dispersion of nanoparticles and the potential impact on paper recycling processes pose ongoing challenges in this area.

Environmental concerns and regulatory pressures have also influenced the development of PVAc technology for water-resistant paper products. The industry is moving towards more sustainable and biodegradable solutions, which presents challenges in maintaining the desired water resistance while meeting environmental standards.

The scalability of new PVAc technologies for water-resistant paper products is another significant challenge. Many promising laboratory-scale developments face difficulties in transitioning to large-scale industrial production. Factors such as cost-effectiveness, compatibility with existing manufacturing processes, and long-term stability of the modified PVAc adhesives need to be carefully addressed.

In conclusion, while PVAc continues to be a valuable material in the paper industry, its application in water-resistant paper products faces multiple technological challenges. Overcoming these hurdles requires innovative approaches in polymer chemistry, materials science, and process engineering to develop PVAc-based solutions that meet the demanding requirements of water-resistant paper products.

One of the main challenges in developing water-resistant paper products using PVAc is its inherent hydrophilic nature. When exposed to water, PVAc tends to soften and lose its adhesive properties, compromising the integrity of the paper product. This limitation has led researchers to explore various modifications and additives to enhance the water resistance of PVAc-based adhesives.

Cross-linking agents have been introduced to improve the water resistance of PVAc. These agents form chemical bonds between PVAc molecules, creating a more robust network that is less susceptible to water penetration. However, the effectiveness of cross-linking agents can vary depending on the specific formulation and application method, presenting challenges in achieving consistent results across different paper products.

Another approach to enhance water resistance involves the incorporation of hydrophobic additives into PVAc formulations. These additives, such as silicones or fluoropolymers, can create a water-repellent surface on the paper. However, finding the right balance between water resistance and maintaining other desirable paper properties, such as printability and recyclability, remains a significant challenge.

The development of PVAc-based nanocomposites has shown promise in improving water resistance. By incorporating nanoparticles, such as clay or silica, into the PVAc matrix, researchers have observed enhanced barrier properties. However, the uniform dispersion of nanoparticles and the potential impact on paper recycling processes pose ongoing challenges in this area.

Environmental concerns and regulatory pressures have also influenced the development of PVAc technology for water-resistant paper products. The industry is moving towards more sustainable and biodegradable solutions, which presents challenges in maintaining the desired water resistance while meeting environmental standards.

The scalability of new PVAc technologies for water-resistant paper products is another significant challenge. Many promising laboratory-scale developments face difficulties in transitioning to large-scale industrial production. Factors such as cost-effectiveness, compatibility with existing manufacturing processes, and long-term stability of the modified PVAc adhesives need to be carefully addressed.

In conclusion, while PVAc continues to be a valuable material in the paper industry, its application in water-resistant paper products faces multiple technological challenges. Overcoming these hurdles requires innovative approaches in polymer chemistry, materials science, and process engineering to develop PVAc-based solutions that meet the demanding requirements of water-resistant paper products.

Existing PVAc Waterproofing Solutions

01 Copolymerization with hydrophobic monomers

Improving water resistance of polyvinyl acetate by copolymerizing it with hydrophobic monomers. This method creates a more water-resistant polymer structure by incorporating water-repelling components into the polyvinyl acetate chain.- Copolymerization with hydrophobic monomers: Improving water resistance of polyvinyl acetate by copolymerizing it with hydrophobic monomers. This method creates a more water-resistant polymer structure by incorporating water-repelling components into the polyvinyl acetate chain.

- Crosslinking agents: Enhancing water resistance by introducing crosslinking agents to the polyvinyl acetate formulation. These agents create chemical bonds between polymer chains, forming a more tightly linked network that resists water penetration.

- Surface modification: Modifying the surface of polyvinyl acetate films or coatings to increase hydrophobicity. This can be achieved through various treatments or by applying additional water-repellent layers on top of the polyvinyl acetate.

- Blending with water-resistant polymers: Improving water resistance by blending polyvinyl acetate with other water-resistant polymers or resins. This creates a composite material that combines the properties of both components, resulting in enhanced water resistance.

- Incorporation of water-repellent additives: Adding water-repellent additives to polyvinyl acetate formulations to enhance their water resistance. These additives can include silicones, waxes, or other hydrophobic substances that help repel water from the polymer surface.

02 Addition of crosslinking agents

Enhancing water resistance by incorporating crosslinking agents into polyvinyl acetate formulations. These agents create chemical bonds between polymer chains, forming a more tightly linked network that resists water penetration.Expand Specific Solutions03 Surface modification techniques

Applying surface modification techniques to polyvinyl acetate films or coatings to improve water resistance. This can include treatments that alter the surface chemistry or create a hydrophobic layer on the polymer surface.Expand Specific Solutions04 Blending with water-resistant polymers

Improving water resistance by blending polyvinyl acetate with other water-resistant polymers or resins. This creates a composite material that combines the properties of both polymers, enhancing overall water resistance.Expand Specific Solutions05 Incorporation of water-repelling additives

Enhancing water resistance by incorporating water-repelling additives into polyvinyl acetate formulations. These additives can include silicones, waxes, or other hydrophobic substances that create a barrier against water penetration.Expand Specific Solutions

Key Players in PVAc and Paper Industry

The research on polyvinyl acetate for water-resistant paper products is in a growth phase, with increasing market demand driven by sustainability concerns. The global market size for water-resistant paper is projected to expand significantly in the coming years. Technologically, while the basic principles are established, there is ongoing innovation to improve performance and eco-friendliness. Companies like Wacker Chemie AG, DuPont, and Chang Chun Petrochemical are at the forefront, leveraging their expertise in chemical engineering to develop advanced formulations. Academic institutions such as South China University of Technology and Wuhan Textile University are also contributing to R&D efforts, indicating a collaborative ecosystem between industry and academia.

South China University of Technology

Technical Solution: South China University of Technology has conducted extensive research on polyvinyl acetate for water-resistant paper products, focusing on eco-friendly and cost-effective solutions. Their approach involves the development of novel polyvinyl acetate copolymers that exhibit enhanced water resistance while maintaining paper recyclability[10]. The university's research team has explored the incorporation of natural additives, such as modified starches and cellulose derivatives, to improve the overall performance of polyvinyl acetate coatings[11]. They have also investigated the use of plasma treatment techniques to enhance the adhesion of polyvinyl acetate to paper surfaces, resulting in improved water resistance and durability[12].

Strengths: Innovative research approaches, focus on eco-friendly solutions, potential for cost-effective implementations. Weaknesses: Technologies may still be in developmental stages, potential challenges in scaling up to industrial production.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed VINNAPAS® dispersions, a range of polyvinyl acetate-based products specifically designed for water-resistant paper applications. Their technology focuses on creating a fine balance between water resistance and recyclability. The VINNAPAS® dispersions form a protective film on paper fibers, significantly enhancing water resistance without compromising the paper's ability to be recycled[1]. The company has also introduced VINNOL® surface coating resins, which provide excellent adhesion to paper substrates and superior water resistance[2]. Wacker's approach involves modifying the polymer structure to achieve optimal performance in various environmental conditions, ensuring the coated paper maintains its integrity even when exposed to moisture[3].

Strengths: High-performance water resistance, maintains paper recyclability, versatile application across different paper types. Weaknesses: May require specialized application equipment, potential for higher cost compared to traditional solutions.

Core PVAc Innovations for Paper

Water-resistant adhesive compositions

PatentInactiveUS3925289A

Innovation

- Aqueous dispersion of polyvinyl acetate emulsion with polyvinyl alcohol and persulfate, combined with a multifunctional compound, forming a water-resistant adhesive composition that eliminates formaldehyde and provides excellent bonding properties.

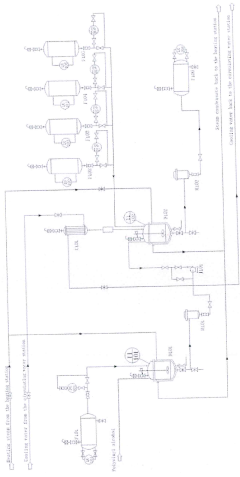

Polyvinyl acetate production plant

PatentUndeterminedIES20180484A2

Innovation

- A polyvinyl acetate production plant design incorporating specific tanks, a stirring vessel, filter, condenser, feedstock pump, polymerizer, and emulsion tank, with controlled temperature and chemical additions to optimize polymerization reaction conditions, including the use of deionized water, dibutyl phthalate, vinyl acetate, sodium bicarbonate, and ammonium persulfate, to streamline the production process and enhance reaction efficiency.

Environmental Impact of PVAc Use

The use of polyvinyl acetate (PVAc) in water-resistant paper products has significant environmental implications that warrant careful consideration. PVAc, while effective in enhancing paper durability, poses challenges in terms of biodegradability and recycling processes.

One of the primary environmental concerns associated with PVAc is its persistence in ecosystems. Unlike natural paper fibers, PVAc does not readily decompose in natural environments. This longevity can lead to accumulation in landfills and potential contamination of soil and water systems if not properly managed.

The recycling of paper products containing PVAc presents another set of challenges. Traditional paper recycling processes are not optimized for handling PVAc-coated materials. The presence of PVAc can interfere with the separation of paper fibers, potentially reducing the quality and yield of recycled paper. This may result in increased energy consumption and waste generation during the recycling process.

Water pollution is another potential consequence of PVAc use in paper products. During the paper production process, residual PVAc may be released into wastewater streams. If not adequately treated, these polymer particles can enter aquatic ecosystems, potentially affecting marine life and water quality.

However, it's important to note that the environmental impact of PVAc is not entirely negative. The water-resistant properties imparted by PVAc can extend the lifespan of paper products, potentially reducing overall paper consumption and the associated environmental footprint of paper production.

Recent research has focused on developing more environmentally friendly alternatives to traditional PVAc formulations. Bio-based and biodegradable variants of PVAc are being explored, which could mitigate some of the long-term environmental concerns while maintaining the desired water-resistant properties.

The manufacturing process of PVAc also has environmental implications. The production of vinyl acetate monomer, the precursor to PVAc, involves petrochemical processes that contribute to greenhouse gas emissions and energy consumption. Efforts to improve the efficiency of these processes and explore renewable feedstocks are ongoing in the chemical industry.

In conclusion, while PVAc offers valuable water-resistant properties for paper products, its environmental impact is complex and multifaceted. Balancing the benefits of enhanced paper durability against the challenges of waste management and ecosystem effects remains a key consideration for manufacturers and policymakers in the paper industry.

One of the primary environmental concerns associated with PVAc is its persistence in ecosystems. Unlike natural paper fibers, PVAc does not readily decompose in natural environments. This longevity can lead to accumulation in landfills and potential contamination of soil and water systems if not properly managed.

The recycling of paper products containing PVAc presents another set of challenges. Traditional paper recycling processes are not optimized for handling PVAc-coated materials. The presence of PVAc can interfere with the separation of paper fibers, potentially reducing the quality and yield of recycled paper. This may result in increased energy consumption and waste generation during the recycling process.

Water pollution is another potential consequence of PVAc use in paper products. During the paper production process, residual PVAc may be released into wastewater streams. If not adequately treated, these polymer particles can enter aquatic ecosystems, potentially affecting marine life and water quality.

However, it's important to note that the environmental impact of PVAc is not entirely negative. The water-resistant properties imparted by PVAc can extend the lifespan of paper products, potentially reducing overall paper consumption and the associated environmental footprint of paper production.

Recent research has focused on developing more environmentally friendly alternatives to traditional PVAc formulations. Bio-based and biodegradable variants of PVAc are being explored, which could mitigate some of the long-term environmental concerns while maintaining the desired water-resistant properties.

The manufacturing process of PVAc also has environmental implications. The production of vinyl acetate monomer, the precursor to PVAc, involves petrochemical processes that contribute to greenhouse gas emissions and energy consumption. Efforts to improve the efficiency of these processes and explore renewable feedstocks are ongoing in the chemical industry.

In conclusion, while PVAc offers valuable water-resistant properties for paper products, its environmental impact is complex and multifaceted. Balancing the benefits of enhanced paper durability against the challenges of waste management and ecosystem effects remains a key consideration for manufacturers and policymakers in the paper industry.

Regulatory Framework for PVAc in Paper

The regulatory framework for polyvinyl acetate (PVAc) in paper products is a complex and evolving landscape that significantly impacts the development and commercialization of water-resistant paper solutions. At the global level, organizations such as the Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) in the European Union play crucial roles in establishing guidelines for the use of PVAc in food-contact materials, including paper products.

In the United States, the FDA regulates PVAc under the Code of Federal Regulations (CFR) Title 21, specifically in sections 175.105 and 176.180. These regulations outline the permissible uses of PVAc in adhesives and components of paper and paperboard in contact with dry food. The FDA has established specific migration limits and purity criteria for PVAc to ensure its safe use in paper products.

The European Union, through the EFSA, has implemented stringent regulations on food contact materials, including paper products containing PVAc. The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food provides a framework for assessing the safety of PVAc in paper applications. Additionally, the EU has established specific migration limits for vinyl acetate monomer, a key component in PVAc production.

In Asia, countries like Japan and China have their own regulatory bodies and standards for PVAc in paper products. The Japan Food Sanitation Law and China's GB standards provide guidelines for the use of PVAc in food-contact materials, including specific requirements for migration testing and overall composition.

Environmental regulations also play a significant role in shaping the use of PVAc in water-resistant paper products. Many countries have implemented restrictions on volatile organic compounds (VOCs) emissions, which can impact the formulation and application of PVAc-based coatings. For instance, the California Air Resources Board (CARB) in the United States has established strict VOC limits for adhesives and sealants, including those used in paper products.

The regulatory landscape for PVAc in paper is further complicated by the growing emphasis on sustainability and recyclability. Many jurisdictions are implementing regulations to promote the circular economy, which may impact the use of PVAc in paper products. For example, the EU's Circular Economy Action Plan includes measures to ensure that all packaging, including paper-based materials, is reusable or recyclable by 2030.

As the demand for water-resistant paper products continues to grow, manufacturers must navigate this complex regulatory environment. Compliance with these diverse regulations requires ongoing research and development efforts to optimize PVAc formulations that meet both performance requirements and regulatory standards across different markets.

In the United States, the FDA regulates PVAc under the Code of Federal Regulations (CFR) Title 21, specifically in sections 175.105 and 176.180. These regulations outline the permissible uses of PVAc in adhesives and components of paper and paperboard in contact with dry food. The FDA has established specific migration limits and purity criteria for PVAc to ensure its safe use in paper products.

The European Union, through the EFSA, has implemented stringent regulations on food contact materials, including paper products containing PVAc. The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food provides a framework for assessing the safety of PVAc in paper applications. Additionally, the EU has established specific migration limits for vinyl acetate monomer, a key component in PVAc production.

In Asia, countries like Japan and China have their own regulatory bodies and standards for PVAc in paper products. The Japan Food Sanitation Law and China's GB standards provide guidelines for the use of PVAc in food-contact materials, including specific requirements for migration testing and overall composition.

Environmental regulations also play a significant role in shaping the use of PVAc in water-resistant paper products. Many countries have implemented restrictions on volatile organic compounds (VOCs) emissions, which can impact the formulation and application of PVAc-based coatings. For instance, the California Air Resources Board (CARB) in the United States has established strict VOC limits for adhesives and sealants, including those used in paper products.

The regulatory landscape for PVAc in paper is further complicated by the growing emphasis on sustainability and recyclability. Many jurisdictions are implementing regulations to promote the circular economy, which may impact the use of PVAc in paper products. For example, the EU's Circular Economy Action Plan includes measures to ensure that all packaging, including paper-based materials, is reusable or recyclable by 2030.

As the demand for water-resistant paper products continues to grow, manufacturers must navigate this complex regulatory environment. Compliance with these diverse regulations requires ongoing research and development efforts to optimize PVAc formulations that meet both performance requirements and regulatory standards across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!