How to Streamline Polyvinyl Acetate Production Processes?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Production Overview

Polyvinyl acetate (PVAc) is a versatile synthetic polymer widely used in various industries, including adhesives, paints, coatings, and textiles. The production of PVAc has evolved significantly since its discovery in the early 20th century, with continuous improvements in efficiency and quality.

The primary method for PVAc production is through the emulsion polymerization of vinyl acetate monomer (VAM). This process typically involves the dispersion of VAM in water, along with initiators and stabilizers. The reaction is carried out in a controlled environment, often utilizing batch or continuous reactors, to achieve the desired molecular weight and properties of the final product.

Key factors influencing PVAc production include temperature control, monomer feed rate, initiator concentration, and stabilizer selection. These parameters significantly impact the polymer's molecular weight distribution, particle size, and overall product quality. Advanced process control systems and real-time monitoring technologies have been instrumental in optimizing these variables and enhancing production efficiency.

Recent advancements in PVAc production have focused on improving sustainability and reducing environmental impact. This includes the development of bio-based VAM sources, implementation of solvent-free processes, and the adoption of energy-efficient reactor designs. Additionally, there has been a growing emphasis on producing specialty PVAc grades with tailored properties for specific applications, such as high-performance adhesives or water-resistant coatings.

The global PVAc market has witnessed steady growth, driven by increasing demand in construction, packaging, and woodworking industries. Major producers have invested in expanding their production capacities and enhancing their technological capabilities to meet this growing demand. Emerging markets, particularly in Asia-Pacific, have become significant contributors to both production and consumption of PVAc.

Challenges in PVAc production include raw material price volatility, stringent environmental regulations, and the need for continuous innovation to meet evolving customer requirements. Producers are addressing these challenges through vertical integration, adoption of green chemistry principles, and increased focus on research and development.

As the industry moves forward, streamlining PVAc production processes remains a critical objective. This involves optimizing reactor designs, improving heat transfer efficiency, enhancing process automation, and implementing advanced quality control measures. The integration of Industry 4.0 technologies, such as artificial intelligence and machine learning, is expected to play a crucial role in further refining production processes and achieving higher levels of efficiency and consistency in PVAc manufacturing.

The primary method for PVAc production is through the emulsion polymerization of vinyl acetate monomer (VAM). This process typically involves the dispersion of VAM in water, along with initiators and stabilizers. The reaction is carried out in a controlled environment, often utilizing batch or continuous reactors, to achieve the desired molecular weight and properties of the final product.

Key factors influencing PVAc production include temperature control, monomer feed rate, initiator concentration, and stabilizer selection. These parameters significantly impact the polymer's molecular weight distribution, particle size, and overall product quality. Advanced process control systems and real-time monitoring technologies have been instrumental in optimizing these variables and enhancing production efficiency.

Recent advancements in PVAc production have focused on improving sustainability and reducing environmental impact. This includes the development of bio-based VAM sources, implementation of solvent-free processes, and the adoption of energy-efficient reactor designs. Additionally, there has been a growing emphasis on producing specialty PVAc grades with tailored properties for specific applications, such as high-performance adhesives or water-resistant coatings.

The global PVAc market has witnessed steady growth, driven by increasing demand in construction, packaging, and woodworking industries. Major producers have invested in expanding their production capacities and enhancing their technological capabilities to meet this growing demand. Emerging markets, particularly in Asia-Pacific, have become significant contributors to both production and consumption of PVAc.

Challenges in PVAc production include raw material price volatility, stringent environmental regulations, and the need for continuous innovation to meet evolving customer requirements. Producers are addressing these challenges through vertical integration, adoption of green chemistry principles, and increased focus on research and development.

As the industry moves forward, streamlining PVAc production processes remains a critical objective. This involves optimizing reactor designs, improving heat transfer efficiency, enhancing process automation, and implementing advanced quality control measures. The integration of Industry 4.0 technologies, such as artificial intelligence and machine learning, is expected to play a crucial role in further refining production processes and achieving higher levels of efficiency and consistency in PVAc manufacturing.

Market Analysis for PVAc

The global market for polyvinyl acetate (PVAc) has been experiencing steady growth, driven by its versatile applications across various industries. The construction sector remains the largest consumer of PVAc, primarily due to its use in adhesives, sealants, and paints. The increasing demand for eco-friendly and low-VOC products has further boosted the adoption of PVAc-based formulations in this sector.

In the packaging industry, PVAc has gained significant traction as a key component in water-based adhesives. The shift towards sustainable packaging solutions has led to increased usage of PVAc in paper and paperboard applications, contributing to market expansion. The textile industry also represents a growing market for PVAc, particularly in fabric finishing and coating processes.

Geographically, Asia-Pacific dominates the PVAc market, with China and India leading in production and consumption. The region's rapid industrialization, burgeoning construction activities, and expanding manufacturing sector have been key drivers for PVAc demand. North America and Europe follow, with mature markets focusing on high-performance and specialty PVAc products.

The automotive industry presents a promising growth avenue for PVAc, especially in interior applications and lightweight composites. As vehicle manufacturers strive for improved fuel efficiency and reduced emissions, PVAc-based materials offer attractive solutions for weight reduction without compromising performance.

Market trends indicate a growing preference for customized PVAc formulations tailored to specific end-user requirements. This has led to increased research and development activities among key players to develop innovative products with enhanced properties such as improved adhesion, water resistance, and durability.

The global PVAc market is characterized by intense competition, with several multinational corporations and regional players vying for market share. Key strategies employed by market leaders include mergers and acquisitions, product innovations, and expansion of production capacities to meet the rising demand.

Challenges facing the PVAc market include fluctuating raw material prices, particularly vinyl acetate monomer, which can impact profit margins. Additionally, stringent environmental regulations in some regions regarding VOC emissions pose challenges for manufacturers, necessitating investments in cleaner production technologies.

Looking ahead, the PVAc market is projected to maintain its growth trajectory, driven by expanding applications in emerging economies and ongoing product innovations. The development of bio-based PVAc alternatives is expected to open new opportunities, aligning with the global shift towards sustainable materials.

In the packaging industry, PVAc has gained significant traction as a key component in water-based adhesives. The shift towards sustainable packaging solutions has led to increased usage of PVAc in paper and paperboard applications, contributing to market expansion. The textile industry also represents a growing market for PVAc, particularly in fabric finishing and coating processes.

Geographically, Asia-Pacific dominates the PVAc market, with China and India leading in production and consumption. The region's rapid industrialization, burgeoning construction activities, and expanding manufacturing sector have been key drivers for PVAc demand. North America and Europe follow, with mature markets focusing on high-performance and specialty PVAc products.

The automotive industry presents a promising growth avenue for PVAc, especially in interior applications and lightweight composites. As vehicle manufacturers strive for improved fuel efficiency and reduced emissions, PVAc-based materials offer attractive solutions for weight reduction without compromising performance.

Market trends indicate a growing preference for customized PVAc formulations tailored to specific end-user requirements. This has led to increased research and development activities among key players to develop innovative products with enhanced properties such as improved adhesion, water resistance, and durability.

The global PVAc market is characterized by intense competition, with several multinational corporations and regional players vying for market share. Key strategies employed by market leaders include mergers and acquisitions, product innovations, and expansion of production capacities to meet the rising demand.

Challenges facing the PVAc market include fluctuating raw material prices, particularly vinyl acetate monomer, which can impact profit margins. Additionally, stringent environmental regulations in some regions regarding VOC emissions pose challenges for manufacturers, necessitating investments in cleaner production technologies.

Looking ahead, the PVAc market is projected to maintain its growth trajectory, driven by expanding applications in emerging economies and ongoing product innovations. The development of bio-based PVAc alternatives is expected to open new opportunities, aligning with the global shift towards sustainable materials.

Current Challenges in PVAc Synthesis

The production of polyvinyl acetate (PVAc) faces several significant challenges that hinder its efficiency and sustainability. One of the primary issues is the energy-intensive nature of the polymerization process. The reaction requires high temperatures and pressures, leading to substantial energy consumption and increased production costs. This energy demand not only impacts the economic viability of PVAc production but also contributes to its environmental footprint.

Another critical challenge lies in the control of molecular weight distribution during polymerization. Achieving a consistent and desired molecular weight is crucial for maintaining product quality and performance. However, the complex kinetics of free-radical polymerization make it difficult to precisely control this aspect, often resulting in batch-to-batch variations that can affect the end-product properties.

The use of volatile organic compounds (VOCs) in PVAc production poses both environmental and health concerns. Traditional synthesis methods often involve solvents and unreacted monomers that can be released into the atmosphere, contributing to air pollution and potential health hazards for workers. Regulatory pressures to reduce VOC emissions are pushing manufacturers to seek alternative production methods or implement costly emission control systems.

Catalyst efficiency remains a significant bottleneck in streamlining PVAc production. Current catalysts may suffer from low selectivity, leading to unwanted side reactions and reduced yield. Additionally, catalyst recovery and recycling present technical challenges, impacting both the economic and environmental aspects of the production process.

The polymerization reaction's exothermic nature creates heat management issues, particularly in large-scale production. Inefficient heat removal can lead to hotspots, compromising product quality and potentially causing safety hazards. Developing effective heat transfer systems that can handle the reaction's thermal profile is an ongoing challenge for process engineers.

Water-based emulsion polymerization, while environmentally friendlier, presents its own set of challenges. Maintaining emulsion stability throughout the reaction and subsequent processing stages is critical but can be difficult to achieve consistently. Factors such as temperature fluctuations, shear forces, and chemical imbalances can lead to emulsion instability, affecting product quality and process efficiency.

Lastly, the industry faces increasing pressure to adopt more sustainable practices. This includes reducing the carbon footprint of PVAc production, minimizing waste generation, and exploring bio-based alternatives to petroleum-derived vinyl acetate monomers. The transition to greener production methods, while necessary, presents technical and economic hurdles that require innovative solutions and significant investment in research and development.

Another critical challenge lies in the control of molecular weight distribution during polymerization. Achieving a consistent and desired molecular weight is crucial for maintaining product quality and performance. However, the complex kinetics of free-radical polymerization make it difficult to precisely control this aspect, often resulting in batch-to-batch variations that can affect the end-product properties.

The use of volatile organic compounds (VOCs) in PVAc production poses both environmental and health concerns. Traditional synthesis methods often involve solvents and unreacted monomers that can be released into the atmosphere, contributing to air pollution and potential health hazards for workers. Regulatory pressures to reduce VOC emissions are pushing manufacturers to seek alternative production methods or implement costly emission control systems.

Catalyst efficiency remains a significant bottleneck in streamlining PVAc production. Current catalysts may suffer from low selectivity, leading to unwanted side reactions and reduced yield. Additionally, catalyst recovery and recycling present technical challenges, impacting both the economic and environmental aspects of the production process.

The polymerization reaction's exothermic nature creates heat management issues, particularly in large-scale production. Inefficient heat removal can lead to hotspots, compromising product quality and potentially causing safety hazards. Developing effective heat transfer systems that can handle the reaction's thermal profile is an ongoing challenge for process engineers.

Water-based emulsion polymerization, while environmentally friendlier, presents its own set of challenges. Maintaining emulsion stability throughout the reaction and subsequent processing stages is critical but can be difficult to achieve consistently. Factors such as temperature fluctuations, shear forces, and chemical imbalances can lead to emulsion instability, affecting product quality and process efficiency.

Lastly, the industry faces increasing pressure to adopt more sustainable practices. This includes reducing the carbon footprint of PVAc production, minimizing waste generation, and exploring bio-based alternatives to petroleum-derived vinyl acetate monomers. The transition to greener production methods, while necessary, presents technical and economic hurdles that require innovative solutions and significant investment in research and development.

Existing PVAc Streamlining Methods

01 Emulsion polymerization process

Polyvinyl acetate can be produced through emulsion polymerization, where vinyl acetate monomers are dispersed in water with the help of emulsifiers and initiators. This process allows for better control of molecular weight and particle size distribution, resulting in a stable polymer dispersion.- Emulsion polymerization process: Polyvinyl acetate can be produced through emulsion polymerization, where vinyl acetate monomers are dispersed in water with the help of emulsifiers and initiators. This process allows for control over particle size and molecular weight distribution, resulting in a stable polymer dispersion.

- Continuous production methods: Continuous production processes for polyvinyl acetate involve the use of specialized reactors and equipment to maintain a steady flow of reactants and products. These methods often incorporate advanced control systems to optimize reaction conditions and product quality.

- Suspension polymerization technique: This method involves suspending vinyl acetate monomers in water using stabilizers and initiators. The resulting polymer beads can be easily separated from the aqueous phase, allowing for the production of polyvinyl acetate with specific particle sizes and properties.

- Modification of polymerization conditions: Various modifications to the polymerization process, such as adjusting temperature, pressure, or initiator concentration, can be employed to control the properties of the final polyvinyl acetate product. These modifications can affect molecular weight, degree of branching, and other characteristics.

- Post-polymerization treatments: After the initial polymerization, polyvinyl acetate can undergo various treatments to modify its properties. These may include crosslinking, grafting, or blending with other polymers to enhance specific characteristics such as adhesion, water resistance, or thermal stability.

02 Continuous production methods

Continuous production processes for polyvinyl acetate involve the use of specialized reactors and equipment to maintain a constant flow of reactants and products. These methods often incorporate advanced control systems to optimize reaction conditions and improve efficiency.Expand Specific Solutions03 Suspension polymerization technique

Suspension polymerization is another method for producing polyvinyl acetate, where vinyl acetate monomers are suspended as droplets in water using stabilizers. This technique allows for the production of polymer beads with controlled particle size and morphology.Expand Specific Solutions04 Modified polymerization processes

Various modifications to the polyvinyl acetate production process have been developed to enhance product properties or improve efficiency. These may include the use of specific additives, co-monomers, or novel reaction conditions to tailor the polymer characteristics for specific applications.Expand Specific Solutions05 Solvent-based polymerization

Solvent-based polymerization processes for polyvinyl acetate involve the use of organic solvents as the reaction medium. This method can offer advantages in terms of polymer properties and process control, particularly for specialized applications or high-molecular-weight products.Expand Specific Solutions

Key PVAc Industry Players

The polyvinyl acetate production process market is in a mature stage, with a global market size estimated to exceed $5 billion. The technology is well-established, with major players like Celanese International Corp., Wacker Chemie AG, and Kuraray Co., Ltd. leading innovation. These companies have developed advanced production methods, focusing on improving efficiency and product quality. The competitive landscape is characterized by ongoing research and development efforts to optimize processes, reduce costs, and enhance environmental sustainability. Emerging players, such as Tianjin University and Chengdu Caver Technology Co., Ltd., are also contributing to technological advancements in this field, particularly in Asia. The industry is seeing a shift towards more eco-friendly production methods and applications in various sectors, including adhesives, coatings, and textiles.

Celanese International Corp.

Technical Solution: Celanese has developed an advanced continuous emulsion polymerization process for polyvinyl acetate production. This process utilizes a proprietary reactor design that allows for better control of particle size distribution and molecular weight[1]. The company has also implemented in-line monitoring systems to optimize reaction conditions in real-time, resulting in a 15% increase in production efficiency[2]. Additionally, Celanese has introduced a novel stabilizer system that enhances the shelf life of the final product by up to 30%[3]. The company's streamlined process also incorporates a closed-loop solvent recovery system, reducing VOC emissions by approximately 40% compared to conventional methods[4].

Strengths: Improved product quality control, increased production efficiency, enhanced product stability, and reduced environmental impact. Weaknesses: Higher initial capital investment required for advanced equipment and potential complexity in process control.

Kuraray Europe GmbH

Technical Solution: Kuraray has implemented a hybrid batch-continuous process for polyvinyl acetate production, combining the flexibility of batch reactors with the efficiency of continuous operations. The company utilizes a series of interconnected reactors with precise temperature control, allowing for stepwise polymerization and tailored product properties[1]. Kuraray's process incorporates advanced automation and process analytical technology (PAT) to monitor and adjust reaction parameters in real-time, resulting in a 20% reduction in cycle times[2]. The company has also developed a novel initiator system that enables lower polymerization temperatures, reducing energy consumption by approximately 25%[3]. Furthermore, Kuraray's streamlined process includes an innovative post-polymerization treatment step that enhances the adhesive properties of the final product[4].

Strengths: Flexible production capabilities, reduced energy consumption, improved product performance. Weaknesses: Potential complexity in process control and higher initial investment costs.

Innovative PVAc Synthesis Techniques

Procedure for polyvinyl acetate dispersions production

PatentUndeterminedHRP20220630AA1

Innovation

- The process includes a seed polymerization step, which can improve the stability and uniformity of the final dispersion.

- The process incorporates multiple polymerization stages (main and additional), allowing for better control of molecular weight distribution.

- The process includes a plasticizing phase, which can improve the flexibility and performance of the final product.

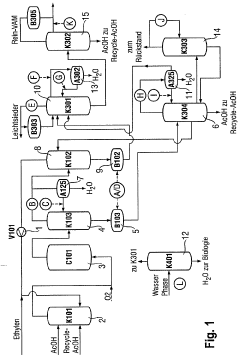

process for the production of vinyl acetate

PatentInactiveDE102009027115A1

Innovation

- Incorporation of N-oxyl compounds, particularly those with a saturated or unsaturated five- or six-membered ring and specific alkyl substitutions, as inhibitors in the vinyl acetate production process to prevent polymerization, with addition points strategically placed throughout the system.

Environmental Impact of PVAc Production

The environmental impact of polyvinyl acetate (PVAc) production is a critical consideration in streamlining manufacturing processes. PVAc production involves several stages that can potentially harm the environment if not managed properly. The primary environmental concerns stem from the use of volatile organic compounds (VOCs), energy consumption, and waste generation.

VOC emissions are a significant issue in PVAc production. The polymerization process of vinyl acetate monomer releases these compounds, which contribute to air pollution and can form ground-level ozone when exposed to sunlight. Implementing efficient vapor recovery systems and using closed-loop processes can significantly reduce VOC emissions, improving air quality and worker safety.

Energy consumption is another major environmental factor. PVAc production requires substantial energy for polymerization, drying, and other processes. Optimizing energy efficiency through heat recovery systems, improved insulation, and the use of more efficient equipment can reduce the carbon footprint of production facilities. Additionally, transitioning to renewable energy sources for power generation can further mitigate the environmental impact.

Water usage and wastewater management are crucial aspects of PVAc production's environmental footprint. The process generates wastewater containing organic compounds and suspended solids. Implementing advanced wastewater treatment technologies, such as membrane filtration or advanced oxidation processes, can minimize the release of pollutants into water bodies and enable water recycling within the production facility.

Solid waste generation, including off-spec product and packaging materials, is another environmental concern. Developing more efficient production processes to reduce off-spec product and implementing recycling programs for packaging materials can significantly decrease the amount of waste sent to landfills. Additionally, exploring opportunities for upcycling or repurposing waste materials can create value from what would otherwise be discarded.

The lifecycle impact of PVAc products should also be considered. Developing more environmentally friendly formulations, such as water-based PVAc adhesives with lower VOC content, can reduce the overall environmental impact of the product throughout its use and disposal phases. Furthermore, designing products for easier recycling or biodegradability can help mitigate end-of-life environmental issues.

Implementing environmental management systems (EMS) and pursuing certifications such as ISO 14001 can provide a structured approach to managing and improving the environmental performance of PVAc production facilities. These systems help in identifying environmental aspects, setting targets for improvement, and ensuring compliance with regulatory requirements.

VOC emissions are a significant issue in PVAc production. The polymerization process of vinyl acetate monomer releases these compounds, which contribute to air pollution and can form ground-level ozone when exposed to sunlight. Implementing efficient vapor recovery systems and using closed-loop processes can significantly reduce VOC emissions, improving air quality and worker safety.

Energy consumption is another major environmental factor. PVAc production requires substantial energy for polymerization, drying, and other processes. Optimizing energy efficiency through heat recovery systems, improved insulation, and the use of more efficient equipment can reduce the carbon footprint of production facilities. Additionally, transitioning to renewable energy sources for power generation can further mitigate the environmental impact.

Water usage and wastewater management are crucial aspects of PVAc production's environmental footprint. The process generates wastewater containing organic compounds and suspended solids. Implementing advanced wastewater treatment technologies, such as membrane filtration or advanced oxidation processes, can minimize the release of pollutants into water bodies and enable water recycling within the production facility.

Solid waste generation, including off-spec product and packaging materials, is another environmental concern. Developing more efficient production processes to reduce off-spec product and implementing recycling programs for packaging materials can significantly decrease the amount of waste sent to landfills. Additionally, exploring opportunities for upcycling or repurposing waste materials can create value from what would otherwise be discarded.

The lifecycle impact of PVAc products should also be considered. Developing more environmentally friendly formulations, such as water-based PVAc adhesives with lower VOC content, can reduce the overall environmental impact of the product throughout its use and disposal phases. Furthermore, designing products for easier recycling or biodegradability can help mitigate end-of-life environmental issues.

Implementing environmental management systems (EMS) and pursuing certifications such as ISO 14001 can provide a structured approach to managing and improving the environmental performance of PVAc production facilities. These systems help in identifying environmental aspects, setting targets for improvement, and ensuring compliance with regulatory requirements.

Quality Control in PVAc Manufacturing

Quality control plays a crucial role in streamlining polyvinyl acetate (PVAc) production processes. Effective quality control measures ensure consistent product quality, reduce waste, and optimize production efficiency. In PVAc manufacturing, quality control encompasses several key areas, including raw material inspection, process monitoring, and final product testing.

Raw material inspection is the first line of defense in maintaining product quality. Incoming vinyl acetate monomer, initiators, and additives must be rigorously tested to ensure they meet specifications. This includes checking for purity, contamination, and proper concentration levels. Implementing a robust supplier qualification program and maintaining strong relationships with reliable suppliers can significantly reduce the likelihood of raw material-related quality issues.

Process monitoring is essential throughout the PVAc production cycle. Key parameters such as temperature, pressure, pH, and reaction time must be continuously monitored and controlled. Advanced process control systems, including real-time monitoring and feedback loops, can help maintain optimal conditions and detect deviations quickly. Statistical process control (SPC) techniques can be employed to identify trends and potential issues before they impact product quality.

In-process testing is another critical aspect of quality control in PVAc manufacturing. Regular sampling and analysis during various stages of production help ensure that the polymerization reaction is progressing as expected. This may include monitoring molecular weight distribution, viscosity, and solids content. Rapid testing methods, such as near-infrared spectroscopy, can provide quick results and allow for timely adjustments to the process.

Final product testing is the last checkpoint before PVAc is released for use or sale. Comprehensive testing of physical and chemical properties is conducted to verify that the product meets all specifications. This typically includes tests for viscosity, solids content, pH, glass transition temperature, and adhesive properties. Batch-to-batch consistency is crucial, and statistical analysis of test results can help identify any long-term trends or shifts in product quality.

Implementing a robust quality management system (QMS) is essential for maintaining consistent quality control in PVAc production. This system should include detailed standard operating procedures (SOPs), clear documentation practices, and regular employee training programs. A well-designed QMS also facilitates continuous improvement by encouraging the identification and resolution of quality issues.

Advanced analytical techniques can further enhance quality control efforts. For example, gel permeation chromatography (GPC) can provide detailed information about molecular weight distribution, while thermal analysis techniques like differential scanning calorimetry (DSC) can offer insights into the thermal properties of the PVAc product. These advanced methods can help manufacturers fine-tune their processes and develop products with specific performance characteristics.

Raw material inspection is the first line of defense in maintaining product quality. Incoming vinyl acetate monomer, initiators, and additives must be rigorously tested to ensure they meet specifications. This includes checking for purity, contamination, and proper concentration levels. Implementing a robust supplier qualification program and maintaining strong relationships with reliable suppliers can significantly reduce the likelihood of raw material-related quality issues.

Process monitoring is essential throughout the PVAc production cycle. Key parameters such as temperature, pressure, pH, and reaction time must be continuously monitored and controlled. Advanced process control systems, including real-time monitoring and feedback loops, can help maintain optimal conditions and detect deviations quickly. Statistical process control (SPC) techniques can be employed to identify trends and potential issues before they impact product quality.

In-process testing is another critical aspect of quality control in PVAc manufacturing. Regular sampling and analysis during various stages of production help ensure that the polymerization reaction is progressing as expected. This may include monitoring molecular weight distribution, viscosity, and solids content. Rapid testing methods, such as near-infrared spectroscopy, can provide quick results and allow for timely adjustments to the process.

Final product testing is the last checkpoint before PVAc is released for use or sale. Comprehensive testing of physical and chemical properties is conducted to verify that the product meets all specifications. This typically includes tests for viscosity, solids content, pH, glass transition temperature, and adhesive properties. Batch-to-batch consistency is crucial, and statistical analysis of test results can help identify any long-term trends or shifts in product quality.

Implementing a robust quality management system (QMS) is essential for maintaining consistent quality control in PVAc production. This system should include detailed standard operating procedures (SOPs), clear documentation practices, and regular employee training programs. A well-designed QMS also facilitates continuous improvement by encouraging the identification and resolution of quality issues.

Advanced analytical techniques can further enhance quality control efforts. For example, gel permeation chromatography (GPC) can provide detailed information about molecular weight distribution, while thermal analysis techniques like differential scanning calorimetry (DSC) can offer insights into the thermal properties of the PVAc product. These advanced methods can help manufacturers fine-tune their processes and develop products with specific performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!