Polyvinyl Acetate in Advanced Coatings: Opportunities & Limitations

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Coating Evolution

Polyvinyl acetate (PVAc) coatings have undergone significant evolution since their introduction in the mid-20th century. Initially developed as a simple, water-based alternative to solvent-borne coatings, PVAc has transformed into a versatile material with advanced applications in various industries.

The early stages of PVAc coating development focused on improving basic properties such as adhesion, durability, and water resistance. Researchers experimented with different molecular weights and copolymerization techniques to enhance these characteristics. By the 1970s, PVAc coatings had established themselves as cost-effective solutions for interior paints and wood adhesives.

The 1980s and 1990s saw a shift towards environmental concerns, driving the development of low-VOC and zero-VOC PVAc formulations. This period also marked the beginning of PVAc's integration with other polymers to create hybrid systems, expanding its performance capabilities and application range.

In the early 2000s, nanotechnology began to influence PVAc coating evolution. The incorporation of nanoparticles, such as silica and titanium dioxide, led to significant improvements in scratch resistance, UV protection, and self-cleaning properties. This opened up new opportunities for PVAc in exterior and high-performance coating applications.

Recent advancements have focused on smart and functional PVAc coatings. Researchers have explored the integration of stimuli-responsive materials, allowing PVAc coatings to change properties in response to environmental factors like temperature or pH. Additionally, the development of antimicrobial and self-healing PVAc coatings has gained traction, particularly in healthcare and automotive industries.

The latest frontier in PVAc coating evolution involves sustainability and bio-based alternatives. Efforts are underway to develop PVAc formulations using renewable resources and to improve the biodegradability of coating systems. This aligns with the growing demand for environmentally friendly materials across various sectors.

Throughout its evolution, PVAc coatings have consistently adapted to meet changing market demands and technological advancements. From simple emulsion paints to sophisticated, multi-functional coating systems, PVAc has demonstrated remarkable versatility and potential for continued innovation in the field of advanced coatings.

The early stages of PVAc coating development focused on improving basic properties such as adhesion, durability, and water resistance. Researchers experimented with different molecular weights and copolymerization techniques to enhance these characteristics. By the 1970s, PVAc coatings had established themselves as cost-effective solutions for interior paints and wood adhesives.

The 1980s and 1990s saw a shift towards environmental concerns, driving the development of low-VOC and zero-VOC PVAc formulations. This period also marked the beginning of PVAc's integration with other polymers to create hybrid systems, expanding its performance capabilities and application range.

In the early 2000s, nanotechnology began to influence PVAc coating evolution. The incorporation of nanoparticles, such as silica and titanium dioxide, led to significant improvements in scratch resistance, UV protection, and self-cleaning properties. This opened up new opportunities for PVAc in exterior and high-performance coating applications.

Recent advancements have focused on smart and functional PVAc coatings. Researchers have explored the integration of stimuli-responsive materials, allowing PVAc coatings to change properties in response to environmental factors like temperature or pH. Additionally, the development of antimicrobial and self-healing PVAc coatings has gained traction, particularly in healthcare and automotive industries.

The latest frontier in PVAc coating evolution involves sustainability and bio-based alternatives. Efforts are underway to develop PVAc formulations using renewable resources and to improve the biodegradability of coating systems. This aligns with the growing demand for environmentally friendly materials across various sectors.

Throughout its evolution, PVAc coatings have consistently adapted to meet changing market demands and technological advancements. From simple emulsion paints to sophisticated, multi-functional coating systems, PVAc has demonstrated remarkable versatility and potential for continued innovation in the field of advanced coatings.

Market Demand Analysis

The market demand for polyvinyl acetate (PVA) in advanced coatings has been experiencing significant growth, driven by the increasing need for high-performance, environmentally friendly coating solutions across various industries. The global PVA market, including its applications in coatings, is projected to expand at a steady rate in the coming years, with the Asia-Pacific region leading the growth.

In the construction sector, there is a rising demand for PVA-based coatings due to their excellent adhesion properties, durability, and resistance to weathering. These coatings are widely used in both interior and exterior applications, including wall paints, primers, and sealants. The growing construction activities in emerging economies, coupled with the renovation and maintenance projects in developed countries, are fueling the demand for PVA-based coatings.

The automotive industry represents another significant market for PVA in advanced coatings. As automakers strive to improve vehicle aesthetics and durability while reducing environmental impact, PVA-based coatings are gaining traction. These coatings offer excellent gloss retention, chemical resistance, and UV protection, making them suitable for both interior and exterior automotive applications.

In the packaging industry, PVA-based coatings are increasingly being used for food packaging materials due to their non-toxic nature and barrier properties. The growing emphasis on sustainable packaging solutions is driving the adoption of PVA coatings as an alternative to traditional petroleum-based materials.

The textile industry is also contributing to the market demand for PVA in advanced coatings. PVA-based coatings are used to improve the durability, water resistance, and appearance of textiles, particularly in technical textiles and high-performance fabrics.

However, the market demand for PVA in advanced coatings faces some limitations. The volatility in raw material prices, particularly vinyl acetate monomer, can impact the overall cost of PVA-based coatings. Additionally, the availability of alternative coating materials, such as acrylic and epoxy-based coatings, poses a challenge to market growth.

Despite these challenges, the overall market outlook for PVA in advanced coatings remains positive. The increasing focus on sustainable and eco-friendly coating solutions, coupled with ongoing research and development efforts to enhance the performance of PVA-based coatings, is expected to drive market growth in the coming years.

In the construction sector, there is a rising demand for PVA-based coatings due to their excellent adhesion properties, durability, and resistance to weathering. These coatings are widely used in both interior and exterior applications, including wall paints, primers, and sealants. The growing construction activities in emerging economies, coupled with the renovation and maintenance projects in developed countries, are fueling the demand for PVA-based coatings.

The automotive industry represents another significant market for PVA in advanced coatings. As automakers strive to improve vehicle aesthetics and durability while reducing environmental impact, PVA-based coatings are gaining traction. These coatings offer excellent gloss retention, chemical resistance, and UV protection, making them suitable for both interior and exterior automotive applications.

In the packaging industry, PVA-based coatings are increasingly being used for food packaging materials due to their non-toxic nature and barrier properties. The growing emphasis on sustainable packaging solutions is driving the adoption of PVA coatings as an alternative to traditional petroleum-based materials.

The textile industry is also contributing to the market demand for PVA in advanced coatings. PVA-based coatings are used to improve the durability, water resistance, and appearance of textiles, particularly in technical textiles and high-performance fabrics.

However, the market demand for PVA in advanced coatings faces some limitations. The volatility in raw material prices, particularly vinyl acetate monomer, can impact the overall cost of PVA-based coatings. Additionally, the availability of alternative coating materials, such as acrylic and epoxy-based coatings, poses a challenge to market growth.

Despite these challenges, the overall market outlook for PVA in advanced coatings remains positive. The increasing focus on sustainable and eco-friendly coating solutions, coupled with ongoing research and development efforts to enhance the performance of PVA-based coatings, is expected to drive market growth in the coming years.

Technical Challenges

Polyvinyl acetate (PVA) faces several technical challenges in its application to advanced coatings, despite its widespread use and numerous advantages. One of the primary issues is its limited water resistance. When exposed to moisture, PVA-based coatings can soften, swell, and even dissolve, compromising their protective properties and durability. This characteristic significantly restricts its use in exterior applications or environments with high humidity.

Another challenge lies in the thermal stability of PVA coatings. At elevated temperatures, PVA tends to degrade, leading to discoloration, loss of adhesion, and reduced mechanical properties. This thermal sensitivity limits its application in high-temperature environments or in coatings that may be exposed to heat during their lifecycle.

The relatively low glass transition temperature of PVA presents additional difficulties. This property results in soft, tacky coatings at room temperature, which can easily attract dust and dirt, reducing the aesthetic appeal and potentially affecting the coating's functionality. It also makes PVA coatings susceptible to mechanical damage, such as scratching or denting.

Chemical resistance is another area where PVA coatings face limitations. They exhibit poor resistance to many organic solvents, oils, and certain chemicals, which can cause swelling, dissolution, or degradation of the coating. This restricts their use in industrial or automotive applications where exposure to such substances is common.

The inherent brittleness of PVA films poses challenges in achieving flexible coatings that can withstand mechanical stress without cracking or peeling. This property limits the use of PVA in applications requiring high flexibility or elongation, such as coatings for flexible substrates or areas subject to frequent movement or vibration.

Adhesion to certain substrates, particularly non-porous or low-energy surfaces, can be problematic for PVA-based coatings. This limitation necessitates the use of additional surface treatments or primers, adding complexity and cost to the coating process.

Lastly, the biodegradability of PVA, while often considered an environmental advantage, can be a drawback in applications requiring long-term durability. The susceptibility to microbial attack can lead to premature degradation of the coating in certain environments, potentially compromising its protective function over time.

Addressing these technical challenges is crucial for expanding the application of PVA in advanced coatings. Research efforts are ongoing to develop modified PVA formulations, blends, or composites that can overcome these limitations while retaining the beneficial properties of PVA, such as its excellent film-forming ability and environmental friendliness.

Another challenge lies in the thermal stability of PVA coatings. At elevated temperatures, PVA tends to degrade, leading to discoloration, loss of adhesion, and reduced mechanical properties. This thermal sensitivity limits its application in high-temperature environments or in coatings that may be exposed to heat during their lifecycle.

The relatively low glass transition temperature of PVA presents additional difficulties. This property results in soft, tacky coatings at room temperature, which can easily attract dust and dirt, reducing the aesthetic appeal and potentially affecting the coating's functionality. It also makes PVA coatings susceptible to mechanical damage, such as scratching or denting.

Chemical resistance is another area where PVA coatings face limitations. They exhibit poor resistance to many organic solvents, oils, and certain chemicals, which can cause swelling, dissolution, or degradation of the coating. This restricts their use in industrial or automotive applications where exposure to such substances is common.

The inherent brittleness of PVA films poses challenges in achieving flexible coatings that can withstand mechanical stress without cracking or peeling. This property limits the use of PVA in applications requiring high flexibility or elongation, such as coatings for flexible substrates or areas subject to frequent movement or vibration.

Adhesion to certain substrates, particularly non-porous or low-energy surfaces, can be problematic for PVA-based coatings. This limitation necessitates the use of additional surface treatments or primers, adding complexity and cost to the coating process.

Lastly, the biodegradability of PVA, while often considered an environmental advantage, can be a drawback in applications requiring long-term durability. The susceptibility to microbial attack can lead to premature degradation of the coating in certain environments, potentially compromising its protective function over time.

Addressing these technical challenges is crucial for expanding the application of PVA in advanced coatings. Research efforts are ongoing to develop modified PVA formulations, blends, or composites that can overcome these limitations while retaining the beneficial properties of PVA, such as its excellent film-forming ability and environmental friendliness.

Current PVAc Solutions

01 Synthesis and polymerization of polyvinyl acetate

Various methods and processes for synthesizing and polymerizing polyvinyl acetate, including different catalysts, reaction conditions, and techniques to control molecular weight and properties of the resulting polymer.- Synthesis and polymerization of polyvinyl acetate: Various methods and processes for synthesizing and polymerizing polyvinyl acetate, including different catalysts, reaction conditions, and techniques to control molecular weight and properties of the resulting polymer.

- Polyvinyl acetate copolymers and blends: Development of copolymers and blends incorporating polyvinyl acetate to enhance specific properties such as adhesion, flexibility, or durability for various applications in coatings, adhesives, and materials science.

- Emulsion and dispersion techniques: Methods for creating stable emulsions and dispersions of polyvinyl acetate in aqueous or non-aqueous media, including surfactant selection, particle size control, and stabilization techniques for improved product performance.

- Modifications and functionalization of polyvinyl acetate: Techniques for modifying polyvinyl acetate through chemical reactions, grafting, or incorporation of functional groups to tailor its properties for specific applications such as improved adhesion or compatibility with other materials.

- Applications of polyvinyl acetate in various industries: Utilization of polyvinyl acetate in diverse fields such as adhesives, coatings, textiles, construction materials, and packaging, highlighting its versatility and adaptability to different industrial needs.

02 Polyvinyl acetate copolymers and blends

Development of copolymers and blends incorporating polyvinyl acetate to enhance specific properties such as adhesion, flexibility, or durability for various applications in coatings, adhesives, and materials science.Expand Specific Solutions03 Emulsion and dispersion techniques

Methods for creating stable emulsions and dispersions of polyvinyl acetate for use in water-based formulations, including techniques to control particle size and improve stability in various environmental conditions.Expand Specific Solutions04 Modifications and functionalization of polyvinyl acetate

Processes for modifying polyvinyl acetate through chemical reactions or physical treatments to introduce new functional groups or alter its properties for specific applications in industries such as construction, textiles, and packaging.Expand Specific Solutions05 Applications and formulations of polyvinyl acetate

Various applications and formulations of polyvinyl acetate in diverse industries, including adhesives, coatings, films, and composite materials, with focus on optimizing performance for specific end-use requirements.Expand Specific Solutions

Industry Leaders

The polyvinyl acetate (PVA) market in advanced coatings is experiencing steady growth, driven by increasing demand in construction, automotive, and packaging industries. The market is in a mature stage but continues to evolve with technological advancements. Key players like Kuraray Co., Ltd., DuPont de Nemours, Inc., and BASF Corp. are investing in R&D to improve PVA properties and expand applications. The technology's maturity is evident in the diverse product offerings from companies such as Sekisui Chemical Co., Ltd. and Dow Global Technologies LLC. However, challenges remain in enhancing PVA's moisture resistance and adhesion properties, presenting opportunities for innovation and market differentiation among competitors.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed advanced polyvinyl acetate (PVA) formulations for high-performance coatings. Their POVAL™ and MOWIFLEX™ product lines incorporate modified PVA resins with enhanced water resistance and adhesion properties[1]. These formulations utilize cross-linking agents and nanoparticle additives to improve film formation and durability. Kuraray's PVA-based coatings offer excellent barrier properties against oxygen and solvents, making them suitable for packaging and industrial applications[2]. The company has also introduced bio-based PVA variants, aligning with sustainability trends in the coatings industry[3].

Strengths: Superior barrier properties, eco-friendly options, and versatility in applications. Limitations: Higher cost compared to conventional coatings and potential moisture sensitivity in certain environments.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered the development of hybrid PVA-based coatings that combine the benefits of polyvinyl acetate with other polymer systems. Their Elvanol™ PVA resins are engineered for enhanced compatibility with acrylic and epoxy systems, resulting in coatings with improved chemical resistance and durability[4]. DuPont's technology focuses on optimizing the molecular weight distribution and degree of hydrolysis of PVA to tailor performance for specific applications. They have also developed water-based PVA emulsions that offer low VOC content while maintaining high performance in architectural and industrial coatings[5].

Strengths: Excellent chemical resistance, low VOC formulations, and broad application range. Limitations: Relatively high production costs and potential for yellowing in UV-exposed applications.

Key PVAc Innovations

Vinyl acetate binders in above-critical pigment volume concentration coatings composition

PatentWO2016015236A1

Innovation

- A coating composition comprising an aqueous dispersion of polymer particles with 35 to 79.9 weight percent vinyl acetate and 0.1 to 6 weight percent phosphorus acid monomer units, combined with pigment and extender particles, where the polymer particles adsorb to pigment surfaces, achieving an above-critical PVC concentration and optimizing hiding performance.

Bioactive agent release coating and controlled humidity method

PatentInactiveEP1517714B1

Innovation

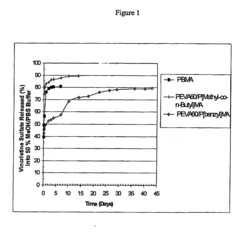

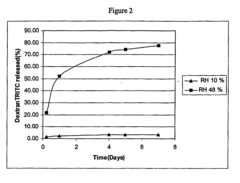

- A coating composition comprising polyalkyl(meth)acrylate and poly(ethylene-co-vinyl acetate) is applied under controlled humidity conditions to ensure uniform bioactive agent release, allowing for adjustable release profiles and enhanced biocompatibility, durability, and flexibility, even during device flexion or expansion.

Environmental Impact

The environmental impact of polyvinyl acetate (PVAc) in advanced coatings is a critical consideration for manufacturers, regulators, and consumers alike. PVAc, while offering numerous benefits in coating applications, also presents certain environmental challenges that must be carefully evaluated and addressed.

One of the primary environmental concerns associated with PVAc coatings is their potential for volatile organic compound (VOC) emissions. During the application and curing process, PVAc-based coatings can release VOCs into the atmosphere, contributing to air pollution and potentially harmful effects on human health and the environment. However, it is worth noting that advancements in PVAc formulations have led to the development of low-VOC and zero-VOC options, significantly mitigating this issue.

The production of PVAc itself also has environmental implications. The manufacturing process involves the polymerization of vinyl acetate monomer, which requires energy and resources. Additionally, the use of petrochemical-based raw materials in PVAc production raises concerns about the depletion of non-renewable resources and the carbon footprint associated with its lifecycle.

On the positive side, PVAc coatings offer several environmental advantages. Their durability and long-lasting nature mean that surfaces coated with PVAc-based products require less frequent repainting or replacement, potentially reducing overall material consumption and waste generation. Furthermore, PVAc is generally considered non-toxic and does not pose significant risks to aquatic life when properly disposed of.

End-of-life considerations for PVAc coatings are an important aspect of their environmental impact. While PVAc is not biodegradable, it can be recycled in some instances. However, the recycling process for PVAc-coated materials can be challenging due to the need for separation from other materials. Improper disposal of PVAc coatings can lead to microplastic pollution, as the polymer may break down into smaller particles over time.

Recent research has focused on developing more environmentally friendly alternatives to traditional PVAc coatings. Bio-based PVAc formulations, derived from renewable resources such as plant-based materials, show promise in reducing the environmental footprint of these coatings. Additionally, water-based PVAc emulsions are gaining popularity as they offer reduced VOC emissions and easier clean-up compared to solvent-based systems.

In conclusion, while PVAc coatings present certain environmental challenges, ongoing innovations in formulation and production techniques are addressing many of these concerns. The balance between the performance benefits of PVAc in advanced coatings and its environmental impact continues to drive research and development in this field, with a clear trend towards more sustainable and eco-friendly solutions.

One of the primary environmental concerns associated with PVAc coatings is their potential for volatile organic compound (VOC) emissions. During the application and curing process, PVAc-based coatings can release VOCs into the atmosphere, contributing to air pollution and potentially harmful effects on human health and the environment. However, it is worth noting that advancements in PVAc formulations have led to the development of low-VOC and zero-VOC options, significantly mitigating this issue.

The production of PVAc itself also has environmental implications. The manufacturing process involves the polymerization of vinyl acetate monomer, which requires energy and resources. Additionally, the use of petrochemical-based raw materials in PVAc production raises concerns about the depletion of non-renewable resources and the carbon footprint associated with its lifecycle.

On the positive side, PVAc coatings offer several environmental advantages. Their durability and long-lasting nature mean that surfaces coated with PVAc-based products require less frequent repainting or replacement, potentially reducing overall material consumption and waste generation. Furthermore, PVAc is generally considered non-toxic and does not pose significant risks to aquatic life when properly disposed of.

End-of-life considerations for PVAc coatings are an important aspect of their environmental impact. While PVAc is not biodegradable, it can be recycled in some instances. However, the recycling process for PVAc-coated materials can be challenging due to the need for separation from other materials. Improper disposal of PVAc coatings can lead to microplastic pollution, as the polymer may break down into smaller particles over time.

Recent research has focused on developing more environmentally friendly alternatives to traditional PVAc coatings. Bio-based PVAc formulations, derived from renewable resources such as plant-based materials, show promise in reducing the environmental footprint of these coatings. Additionally, water-based PVAc emulsions are gaining popularity as they offer reduced VOC emissions and easier clean-up compared to solvent-based systems.

In conclusion, while PVAc coatings present certain environmental challenges, ongoing innovations in formulation and production techniques are addressing many of these concerns. The balance between the performance benefits of PVAc in advanced coatings and its environmental impact continues to drive research and development in this field, with a clear trend towards more sustainable and eco-friendly solutions.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of polyvinyl acetate (PVA) in advanced coatings. As the industry continues to evolve, manufacturers and end-users must navigate an increasingly complex landscape of regulations and standards to ensure the safety, quality, and environmental sustainability of their products.

In the United States, the Environmental Protection Agency (EPA) regulates the use of PVA in coatings under the Toxic Substances Control Act (TSCA). The agency has established specific guidelines for the production, handling, and disposal of PVA-based materials. Manufacturers must comply with reporting requirements and adhere to strict safety protocols to minimize potential environmental and health risks associated with PVA use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of PVA in advanced coatings. Under REACH, companies must register PVA and provide detailed information on its properties, potential hazards, and safe use guidelines. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

In addition to regional regulations, international standards such as ISO 9001 for quality management and ISO 14001 for environmental management systems are increasingly important for companies working with PVA in advanced coatings. These standards help ensure consistent product quality and demonstrate a commitment to sustainable practices, which can be a significant competitive advantage in the global market.

The food packaging industry, a major application area for PVA-based coatings, is subject to particularly stringent regulations. In the United States, the Food and Drug Administration (FDA) regulates the use of PVA in food contact materials under the Federal Food, Drug, and Cosmetic Act. Similarly, the European Food Safety Authority (EFSA) has established specific migration limits and other requirements for PVA used in food packaging applications.

As environmental concerns continue to grow, regulations addressing volatile organic compound (VOC) emissions have become increasingly important. Many jurisdictions have implemented strict limits on VOC content in coatings, driving the development of low-VOC and zero-VOC formulations. PVA-based coatings, which typically have low VOC emissions, are well-positioned to meet these regulatory requirements.

Compliance with these regulations presents both challenges and opportunities for the PVA coatings industry. While meeting regulatory requirements can be costly and time-consuming, it also drives innovation and promotes the development of safer, more sustainable products. Companies that successfully navigate the regulatory landscape can gain a competitive edge and build trust with consumers and stakeholders.

Looking ahead, regulatory trends suggest a continued focus on environmental sustainability and human health protection. This may lead to further restrictions on certain chemicals and increased demand for bio-based and recyclable materials. As a result, the PVA coatings industry must remain proactive in addressing regulatory challenges and adapting to evolving compliance requirements to ensure long-term success in the market.

In the United States, the Environmental Protection Agency (EPA) regulates the use of PVA in coatings under the Toxic Substances Control Act (TSCA). The agency has established specific guidelines for the production, handling, and disposal of PVA-based materials. Manufacturers must comply with reporting requirements and adhere to strict safety protocols to minimize potential environmental and health risks associated with PVA use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of PVA in advanced coatings. Under REACH, companies must register PVA and provide detailed information on its properties, potential hazards, and safe use guidelines. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

In addition to regional regulations, international standards such as ISO 9001 for quality management and ISO 14001 for environmental management systems are increasingly important for companies working with PVA in advanced coatings. These standards help ensure consistent product quality and demonstrate a commitment to sustainable practices, which can be a significant competitive advantage in the global market.

The food packaging industry, a major application area for PVA-based coatings, is subject to particularly stringent regulations. In the United States, the Food and Drug Administration (FDA) regulates the use of PVA in food contact materials under the Federal Food, Drug, and Cosmetic Act. Similarly, the European Food Safety Authority (EFSA) has established specific migration limits and other requirements for PVA used in food packaging applications.

As environmental concerns continue to grow, regulations addressing volatile organic compound (VOC) emissions have become increasingly important. Many jurisdictions have implemented strict limits on VOC content in coatings, driving the development of low-VOC and zero-VOC formulations. PVA-based coatings, which typically have low VOC emissions, are well-positioned to meet these regulatory requirements.

Compliance with these regulations presents both challenges and opportunities for the PVA coatings industry. While meeting regulatory requirements can be costly and time-consuming, it also drives innovation and promotes the development of safer, more sustainable products. Companies that successfully navigate the regulatory landscape can gain a competitive edge and build trust with consumers and stakeholders.

Looking ahead, regulatory trends suggest a continued focus on environmental sustainability and human health protection. This may lead to further restrictions on certain chemicals and increased demand for bio-based and recyclable materials. As a result, the PVA coatings industry must remain proactive in addressing regulatory challenges and adapting to evolving compliance requirements to ensure long-term success in the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!