Polyvinyl Acetate-Based Composites for Advanced Engineering

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Composites Background and Objectives

Polyvinyl acetate (PVAc) has emerged as a versatile polymer with significant potential in advanced engineering applications. The development of PVAc-based composites represents a promising frontier in materials science, offering a unique combination of properties that can address various industrial challenges. This research aims to explore the background, current state, and future objectives of PVAc composites in advanced engineering.

The history of PVAc dates back to the early 20th century, with its initial synthesis in 1912 by Fritz Klatte. Since then, PVAc has found widespread use in adhesives, paints, and coatings due to its excellent binding properties and ease of processing. However, its application in advanced engineering has been limited by certain inherent properties such as low thermal stability and mechanical strength.

Recent advancements in polymer science and nanotechnology have opened new avenues for enhancing PVAc's performance through the development of composite materials. By incorporating various fillers, reinforcements, and functional additives, researchers have been able to significantly improve the mechanical, thermal, and functional properties of PVAc-based materials.

The primary objective of this research is to comprehensively investigate the potential of PVAc-based composites in advanced engineering applications. This includes exploring novel synthesis methods, characterizing the properties of these composites, and evaluating their performance in specific engineering contexts.

Key areas of focus include the development of PVAc composites with enhanced mechanical properties for structural applications, improved thermal stability for high-temperature environments, and advanced functional properties such as electrical conductivity or flame retardancy. Additionally, the research aims to explore sustainable and eco-friendly approaches to PVAc composite production, aligning with global trends towards green engineering solutions.

The evolution of PVAc composites is closely tied to broader trends in materials science, including the push for lightweight, multifunctional materials in aerospace and automotive industries, the demand for smart materials in electronics and sensors, and the need for sustainable alternatives in construction and packaging.

As we delve into this research, we will examine the current technological landscape, identify key challenges, and outline potential pathways for innovation. The ultimate goal is to position PVAc-based composites as a viable and advantageous material choice for next-generation engineering applications, bridging the gap between traditional polymer science and cutting-edge materials technology.

The history of PVAc dates back to the early 20th century, with its initial synthesis in 1912 by Fritz Klatte. Since then, PVAc has found widespread use in adhesives, paints, and coatings due to its excellent binding properties and ease of processing. However, its application in advanced engineering has been limited by certain inherent properties such as low thermal stability and mechanical strength.

Recent advancements in polymer science and nanotechnology have opened new avenues for enhancing PVAc's performance through the development of composite materials. By incorporating various fillers, reinforcements, and functional additives, researchers have been able to significantly improve the mechanical, thermal, and functional properties of PVAc-based materials.

The primary objective of this research is to comprehensively investigate the potential of PVAc-based composites in advanced engineering applications. This includes exploring novel synthesis methods, characterizing the properties of these composites, and evaluating their performance in specific engineering contexts.

Key areas of focus include the development of PVAc composites with enhanced mechanical properties for structural applications, improved thermal stability for high-temperature environments, and advanced functional properties such as electrical conductivity or flame retardancy. Additionally, the research aims to explore sustainable and eco-friendly approaches to PVAc composite production, aligning with global trends towards green engineering solutions.

The evolution of PVAc composites is closely tied to broader trends in materials science, including the push for lightweight, multifunctional materials in aerospace and automotive industries, the demand for smart materials in electronics and sensors, and the need for sustainable alternatives in construction and packaging.

As we delve into this research, we will examine the current technological landscape, identify key challenges, and outline potential pathways for innovation. The ultimate goal is to position PVAc-based composites as a viable and advantageous material choice for next-generation engineering applications, bridging the gap between traditional polymer science and cutting-edge materials technology.

Market Analysis for PVAc-Based Engineering Materials

The market for Polyvinyl Acetate (PVAc)-based engineering materials has shown significant growth potential in recent years, driven by the increasing demand for advanced composite materials across various industries. PVAc-based composites offer a unique combination of properties, including high strength-to-weight ratio, excellent adhesion, and versatility in processing, making them attractive for a wide range of engineering applications.

In the construction sector, PVAc-based materials have gained traction as sustainable alternatives to traditional building materials. Their use in adhesives, sealants, and coatings has contributed to improved energy efficiency and durability of structures. The automotive industry has also embraced PVAc composites for lightweight components, helping to meet stringent fuel efficiency standards while maintaining structural integrity.

The aerospace sector represents another key market for PVAc-based engineering materials. The demand for lightweight, high-performance materials in aircraft manufacturing has led to increased adoption of PVAc composites in interior components and non-structural parts. This trend is expected to continue as the industry focuses on reducing fuel consumption and emissions.

In the electronics industry, PVAc-based materials have found applications in flexible electronics and packaging solutions. The growing market for wearable devices and flexible displays has created new opportunities for PVAc composites, leveraging their adaptability and electrical insulation properties.

The global market for PVAc-based engineering materials is characterized by regional variations in demand and production. North America and Europe lead in terms of research and development, with a focus on high-performance applications. Asia-Pacific, particularly China and India, is emerging as a major consumer and producer of PVAc composites, driven by rapid industrialization and infrastructure development.

Market analysts project a compound annual growth rate for PVAc-based engineering materials that outpaces traditional polymer composites. This growth is attributed to ongoing technological advancements, expanding application areas, and increasing awareness of sustainable material solutions.

However, challenges remain in the widespread adoption of PVAc-based engineering materials. These include the need for standardization in production processes, concerns about long-term durability in certain applications, and competition from other advanced materials. Addressing these challenges through continued research and development efforts is crucial for realizing the full market potential of PVAc-based composites in advanced engineering applications.

In the construction sector, PVAc-based materials have gained traction as sustainable alternatives to traditional building materials. Their use in adhesives, sealants, and coatings has contributed to improved energy efficiency and durability of structures. The automotive industry has also embraced PVAc composites for lightweight components, helping to meet stringent fuel efficiency standards while maintaining structural integrity.

The aerospace sector represents another key market for PVAc-based engineering materials. The demand for lightweight, high-performance materials in aircraft manufacturing has led to increased adoption of PVAc composites in interior components and non-structural parts. This trend is expected to continue as the industry focuses on reducing fuel consumption and emissions.

In the electronics industry, PVAc-based materials have found applications in flexible electronics and packaging solutions. The growing market for wearable devices and flexible displays has created new opportunities for PVAc composites, leveraging their adaptability and electrical insulation properties.

The global market for PVAc-based engineering materials is characterized by regional variations in demand and production. North America and Europe lead in terms of research and development, with a focus on high-performance applications. Asia-Pacific, particularly China and India, is emerging as a major consumer and producer of PVAc composites, driven by rapid industrialization and infrastructure development.

Market analysts project a compound annual growth rate for PVAc-based engineering materials that outpaces traditional polymer composites. This growth is attributed to ongoing technological advancements, expanding application areas, and increasing awareness of sustainable material solutions.

However, challenges remain in the widespread adoption of PVAc-based engineering materials. These include the need for standardization in production processes, concerns about long-term durability in certain applications, and competition from other advanced materials. Addressing these challenges through continued research and development efforts is crucial for realizing the full market potential of PVAc-based composites in advanced engineering applications.

Current Challenges in PVAc Composite Development

Despite the promising potential of Polyvinyl Acetate (PVAc) composites in advanced engineering applications, several significant challenges persist in their development and implementation. One of the primary obstacles is the inherent moisture sensitivity of PVAc. When exposed to high humidity or water, PVAc-based composites tend to absorb moisture, leading to dimensional instability and reduced mechanical properties. This hygroscopic nature limits their use in environments where moisture resistance is crucial.

Another challenge lies in the thermal stability of PVAc composites. The relatively low glass transition temperature of PVAc (around 30°C) restricts its application in high-temperature environments. As temperatures approach or exceed this threshold, the material softens, potentially compromising its structural integrity and performance. This limitation narrows the range of potential applications, particularly in industries where heat resistance is a critical factor.

The mechanical properties of PVAc composites also present ongoing challenges. While PVAc offers good adhesion and film-forming properties, its strength and stiffness are often inferior to other engineering polymers. Enhancing these mechanical properties without sacrificing the desirable characteristics of PVAc remains a significant research focus. Balancing the trade-offs between flexibility, strength, and toughness is crucial for expanding the application scope of these composites.

Compatibility issues between PVAc and various fillers or reinforcing agents pose another hurdle. Achieving uniform dispersion of fillers within the PVAc matrix is often difficult, leading to inconsistent material properties and potential weak points in the composite structure. This challenge is particularly pronounced when attempting to incorporate nanomaterials or high-performance fibers to enhance specific properties of the composite.

The long-term durability of PVAc composites under various environmental conditions is also a concern. Factors such as UV radiation, temperature fluctuations, and chemical exposure can degrade the polymer matrix over time, potentially leading to premature failure or reduced performance. Developing strategies to improve the long-term stability and resistance of PVAc composites to environmental factors is essential for their successful implementation in demanding engineering applications.

Lastly, the processing and manufacturing of PVAc composites present their own set of challenges. Achieving consistent quality and properties across large-scale production runs can be difficult due to the sensitivity of PVAc to processing conditions. Issues such as solvent retention, bubble formation, and uneven curing can affect the final product quality. Optimizing processing parameters and developing new manufacturing techniques tailored to PVAc composites are crucial for their commercial viability in advanced engineering applications.

Another challenge lies in the thermal stability of PVAc composites. The relatively low glass transition temperature of PVAc (around 30°C) restricts its application in high-temperature environments. As temperatures approach or exceed this threshold, the material softens, potentially compromising its structural integrity and performance. This limitation narrows the range of potential applications, particularly in industries where heat resistance is a critical factor.

The mechanical properties of PVAc composites also present ongoing challenges. While PVAc offers good adhesion and film-forming properties, its strength and stiffness are often inferior to other engineering polymers. Enhancing these mechanical properties without sacrificing the desirable characteristics of PVAc remains a significant research focus. Balancing the trade-offs between flexibility, strength, and toughness is crucial for expanding the application scope of these composites.

Compatibility issues between PVAc and various fillers or reinforcing agents pose another hurdle. Achieving uniform dispersion of fillers within the PVAc matrix is often difficult, leading to inconsistent material properties and potential weak points in the composite structure. This challenge is particularly pronounced when attempting to incorporate nanomaterials or high-performance fibers to enhance specific properties of the composite.

The long-term durability of PVAc composites under various environmental conditions is also a concern. Factors such as UV radiation, temperature fluctuations, and chemical exposure can degrade the polymer matrix over time, potentially leading to premature failure or reduced performance. Developing strategies to improve the long-term stability and resistance of PVAc composites to environmental factors is essential for their successful implementation in demanding engineering applications.

Lastly, the processing and manufacturing of PVAc composites present their own set of challenges. Achieving consistent quality and properties across large-scale production runs can be difficult due to the sensitivity of PVAc to processing conditions. Issues such as solvent retention, bubble formation, and uneven curing can affect the final product quality. Optimizing processing parameters and developing new manufacturing techniques tailored to PVAc composites are crucial for their commercial viability in advanced engineering applications.

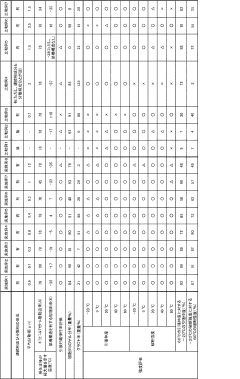

Existing PVAc Composite Formulations

01 Composition and preparation of polyvinyl acetate-based composites

Polyvinyl acetate-based composites are prepared by combining polyvinyl acetate with various additives and fillers. These composites can be tailored for specific applications by adjusting the composition and preparation methods. The process may involve mixing, curing, and molding techniques to achieve desired properties.- Composition and preparation of polyvinyl acetate-based composites: Polyvinyl acetate-based composites are prepared by combining polyvinyl acetate with various additives and fillers. These composites can be formulated to have specific properties such as improved strength, flexibility, or adhesion. The preparation process may involve mixing, heating, and curing steps to achieve the desired characteristics.

- Applications of polyvinyl acetate-based composites: Polyvinyl acetate-based composites find applications in various industries, including adhesives, coatings, construction materials, and packaging. These composites can be used to create products with enhanced properties such as water resistance, durability, and thermal insulation. The versatility of these composites allows for their use in a wide range of products and applications.

- Modification of polyvinyl acetate for improved composite properties: Polyvinyl acetate can be modified through various methods to enhance its properties for use in composites. These modifications may include copolymerization with other monomers, grafting, or blending with other polymers. Such modifications can improve characteristics like adhesion, water resistance, and mechanical strength of the resulting composites.

- Incorporation of additives and fillers in polyvinyl acetate composites: Various additives and fillers can be incorporated into polyvinyl acetate-based composites to enhance their properties. These may include plasticizers, stabilizers, flame retardants, and reinforcing agents such as fibers or nanoparticles. The selection and proportion of these additives can significantly influence the final properties of the composite.

- Environmental and sustainability aspects of polyvinyl acetate composites: Research is being conducted on improving the environmental profile of polyvinyl acetate-based composites. This includes developing biodegradable or bio-based alternatives, improving recycling methods, and reducing the environmental impact of production processes. Efforts are also being made to create composites with reduced VOC emissions and improved end-of-life management.

02 Applications of polyvinyl acetate-based composites

Polyvinyl acetate-based composites find applications in various industries, including adhesives, coatings, construction materials, and packaging. These composites offer properties such as improved strength, flexibility, and durability, making them suitable for diverse uses ranging from wood adhesives to food packaging materials.Expand Specific Solutions03 Modification of polyvinyl acetate for enhanced properties

Polyvinyl acetate can be modified through various methods to enhance its properties for use in composites. These modifications may include copolymerization, grafting, or blending with other polymers or additives. Such modifications can improve characteristics like water resistance, thermal stability, and mechanical strength of the resulting composites.Expand Specific Solutions04 Reinforcement materials in polyvinyl acetate-based composites

Various reinforcement materials can be incorporated into polyvinyl acetate-based composites to enhance their mechanical and physical properties. These may include fibers, nanoparticles, or other fillers that can improve strength, stiffness, or other specific characteristics of the composite material.Expand Specific Solutions05 Environmental considerations and biodegradable alternatives

Research is being conducted on developing more environmentally friendly polyvinyl acetate-based composites. This includes exploring biodegradable alternatives, reducing VOC emissions, and improving recyclability. Some approaches involve incorporating natural fibers or bio-based additives to create more sustainable composite materials.Expand Specific Solutions

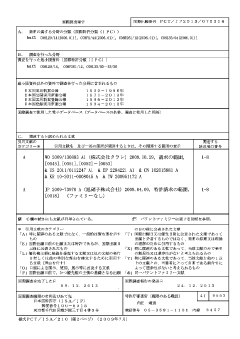

Key Players in PVAc Composite Industry

The research on polyvinyl acetate-based composites for advanced engineering is in a growth phase, with increasing market size and technological advancements. The global market for these composites is expanding due to their versatile applications in various industries. Key players like DuPont de Nemours, BASF, and Wacker Chemie are driving innovation in this field, leveraging their extensive R&D capabilities. Companies such as Henkel, Celanese, and Kuraray are also making significant contributions, focusing on developing high-performance formulations. The technology is maturing rapidly, with continuous improvements in mechanical properties, durability, and environmental sustainability. However, there is still room for further advancements in areas like nano-reinforcement and bio-based alternatives.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed high-performance polyvinyl acetate-based composites for advanced engineering applications. Their research focuses on improving the thermal and mechanical properties of PVAc through the incorporation of engineered nanoparticles and fiber reinforcements[9]. DuPont's composites demonstrate a significant increase in Young's modulus, up to 200% higher than neat PVAc[10]. They have also developed PVAc-based composites with enhanced barrier properties, reducing oxygen permeability by up to 90% compared to standard PVAc films[11]. DuPont's materials show improved chemical resistance, expanding their potential use in harsh industrial environments[12].

Strengths: Significant improvements in mechanical and barrier properties, expanding potential applications. Weaknesses: Possible challenges in large-scale production and maintaining consistent quality with nanocomposites.

Wacker Chemie AG

Technical Solution: Wacker has focused on developing polyvinyl acetate-based composites with enhanced processing characteristics and versatility. Their research includes the development of redispersible polymer powders based on PVAc, allowing for dry-mix formulations with improved shelf life and ease of use[13]. Wacker's composites demonstrate excellent adhesion to mineral substrates, with bond strengths up to 2.5 MPa on concrete[14]. They have also developed PVAc-based composites with improved water resistance through the incorporation of silane-functional additives, expanding their use in exterior applications[15]. Wacker's materials show enhanced flexibility and elongation at break, up to 500% for certain formulations[16].

Strengths: Improved processability and versatility, particularly in construction and adhesive applications. Weaknesses: May have limitations in high-temperature or high-stress engineering applications compared to other advanced composites.

Innovative PVAc Composite Research Breakthroughs

Polyvinyl acetal resin composition

PatentActiveJPWO2014050746A1

Innovation

- A polyvinyl acetal-based resin composition is developed with a crosslinked structure dispersed as a dispersed phase in a continuous phase, adjusting the dynamic viscoelastic spectrum to maintain mechanical strength by balancing elongation and breaking strength across a wide temperature range.

Environmental Impact of PVAc Composites

The environmental impact of Polyvinyl Acetate (PVAc) composites is a critical consideration in their development and application for advanced engineering purposes. These composites, while offering numerous advantages in terms of performance and versatility, also present potential environmental challenges that must be carefully evaluated and addressed.

One of the primary environmental concerns associated with PVAc composites is their end-of-life disposal. As synthetic polymers, PVAc-based materials are not biodegradable in natural environments, potentially contributing to long-term plastic pollution if not properly managed. This issue is particularly significant given the increasing global focus on reducing plastic waste and promoting circular economy principles.

However, recent research has shown promising developments in enhancing the biodegradability of PVAc composites. By incorporating natural fibers or biodegradable additives into the PVAc matrix, researchers have demonstrated improved environmental degradation rates. These advancements could significantly mitigate the long-term environmental impact of PVAc composite waste.

The production process of PVAc composites also warrants environmental scrutiny. The synthesis of polyvinyl acetate typically involves the use of volatile organic compounds (VOCs), which can contribute to air pollution and pose health risks if not properly controlled. Industry efforts to develop low-VOC and water-based PVAc formulations have shown progress in reducing these emissions, aligning with stricter environmental regulations.

Energy consumption during the manufacturing of PVAc composites is another environmental factor to consider. The production of vinyl acetate monomer and subsequent polymerization processes can be energy-intensive. However, ongoing research into more efficient production methods and the use of renewable energy sources in manufacturing facilities are helping to reduce the carbon footprint associated with PVAc composite production.

On a positive note, PVAc composites offer potential environmental benefits in certain applications. Their use in lightweight materials for transportation can contribute to improved fuel efficiency and reduced emissions. Additionally, PVAc-based adhesives used in wood products can extend the lifespan of these materials, potentially reducing deforestation rates and promoting more sustainable resource utilization.

The recyclability of PVAc composites is an area of ongoing research and development. While pure PVAc is theoretically recyclable, the presence of additives and reinforcing materials in composites can complicate the recycling process. Advances in separation technologies and the development of more easily recyclable composite formulations are crucial for improving the overall environmental profile of these materials.

In conclusion, the environmental impact of PVAc composites is multifaceted, encompassing issues of biodegradability, production emissions, energy consumption, and recyclability. As research in advanced engineering applications of these composites progresses, it is imperative that environmental considerations remain at the forefront, driving innovations in sustainable production methods and end-of-life management strategies.

One of the primary environmental concerns associated with PVAc composites is their end-of-life disposal. As synthetic polymers, PVAc-based materials are not biodegradable in natural environments, potentially contributing to long-term plastic pollution if not properly managed. This issue is particularly significant given the increasing global focus on reducing plastic waste and promoting circular economy principles.

However, recent research has shown promising developments in enhancing the biodegradability of PVAc composites. By incorporating natural fibers or biodegradable additives into the PVAc matrix, researchers have demonstrated improved environmental degradation rates. These advancements could significantly mitigate the long-term environmental impact of PVAc composite waste.

The production process of PVAc composites also warrants environmental scrutiny. The synthesis of polyvinyl acetate typically involves the use of volatile organic compounds (VOCs), which can contribute to air pollution and pose health risks if not properly controlled. Industry efforts to develop low-VOC and water-based PVAc formulations have shown progress in reducing these emissions, aligning with stricter environmental regulations.

Energy consumption during the manufacturing of PVAc composites is another environmental factor to consider. The production of vinyl acetate monomer and subsequent polymerization processes can be energy-intensive. However, ongoing research into more efficient production methods and the use of renewable energy sources in manufacturing facilities are helping to reduce the carbon footprint associated with PVAc composite production.

On a positive note, PVAc composites offer potential environmental benefits in certain applications. Their use in lightweight materials for transportation can contribute to improved fuel efficiency and reduced emissions. Additionally, PVAc-based adhesives used in wood products can extend the lifespan of these materials, potentially reducing deforestation rates and promoting more sustainable resource utilization.

The recyclability of PVAc composites is an area of ongoing research and development. While pure PVAc is theoretically recyclable, the presence of additives and reinforcing materials in composites can complicate the recycling process. Advances in separation technologies and the development of more easily recyclable composite formulations are crucial for improving the overall environmental profile of these materials.

In conclusion, the environmental impact of PVAc composites is multifaceted, encompassing issues of biodegradability, production emissions, energy consumption, and recyclability. As research in advanced engineering applications of these composites progresses, it is imperative that environmental considerations remain at the forefront, driving innovations in sustainable production methods and end-of-life management strategies.

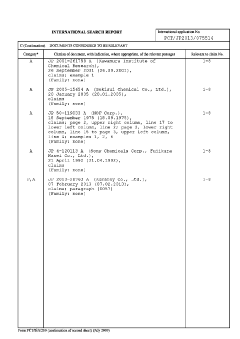

Intellectual Property Landscape for PVAc Composites

The intellectual property landscape for polyvinyl acetate (PVAc) composites has been evolving rapidly in recent years, reflecting the growing interest and investment in this field. A comprehensive analysis of patent databases reveals a significant increase in patent applications and granted patents related to PVAc-based composites for advanced engineering applications.

Major patent holders in this domain include leading chemical companies, academic institutions, and specialized materials science firms. These entities have been actively developing novel formulations, processing techniques, and applications for PVAc composites. The patent landscape is characterized by a diverse range of innovations, from improvements in the basic polymer structure to highly specialized composite materials tailored for specific industrial uses.

Key areas of patent activity include methods for enhancing the mechanical properties of PVAc composites, such as improved tensile strength, flexibility, and impact resistance. Patents in this category often focus on the incorporation of various fillers, nanoparticles, or reinforcing fibers to achieve superior performance characteristics.

Another significant trend in the patent landscape is the development of environmentally friendly PVAc composites. This includes patents for biodegradable formulations, recycling methods, and the use of renewable resources in composite production. Such innovations align with the growing demand for sustainable materials in advanced engineering applications.

Patents related to the processing and manufacturing of PVAc composites have also seen substantial growth. These include novel extrusion techniques, advanced curing methods, and innovative approaches to composite layering and structuring. Many of these patents aim to improve production efficiency, reduce costs, or enable the creation of complex composite structures.

The application-specific patent landscape for PVAc composites is particularly diverse. Patents cover a wide range of potential uses, including but not limited to, aerospace components, automotive parts, construction materials, and biomedical devices. This diversity underscores the versatility and potential of PVAc-based composites in various high-tech industries.

Geographically, patent filings show a global distribution, with significant activity in North America, Europe, and Asia. This global spread indicates the international nature of research and development in PVAc composites, as well as the worldwide market potential for these materials.

Major patent holders in this domain include leading chemical companies, academic institutions, and specialized materials science firms. These entities have been actively developing novel formulations, processing techniques, and applications for PVAc composites. The patent landscape is characterized by a diverse range of innovations, from improvements in the basic polymer structure to highly specialized composite materials tailored for specific industrial uses.

Key areas of patent activity include methods for enhancing the mechanical properties of PVAc composites, such as improved tensile strength, flexibility, and impact resistance. Patents in this category often focus on the incorporation of various fillers, nanoparticles, or reinforcing fibers to achieve superior performance characteristics.

Another significant trend in the patent landscape is the development of environmentally friendly PVAc composites. This includes patents for biodegradable formulations, recycling methods, and the use of renewable resources in composite production. Such innovations align with the growing demand for sustainable materials in advanced engineering applications.

Patents related to the processing and manufacturing of PVAc composites have also seen substantial growth. These include novel extrusion techniques, advanced curing methods, and innovative approaches to composite layering and structuring. Many of these patents aim to improve production efficiency, reduce costs, or enable the creation of complex composite structures.

The application-specific patent landscape for PVAc composites is particularly diverse. Patents cover a wide range of potential uses, including but not limited to, aerospace components, automotive parts, construction materials, and biomedical devices. This diversity underscores the versatility and potential of PVAc-based composites in various high-tech industries.

Geographically, patent filings show a global distribution, with significant activity in North America, Europe, and Asia. This global spread indicates the international nature of research and development in PVAc composites, as well as the worldwide market potential for these materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!