How to Develop Advanced Quasicrystal Filters?

Quasicrystal Filter Background and Objectives

Quasicrystals, discovered in 1982 by Dan Shechtman, represent a unique class of materials that exhibit long-range order but lack periodicity. This groundbreaking discovery challenged the conventional understanding of crystalline structures and opened up new possibilities in materials science. Quasicrystal filters, derived from this novel material class, have emerged as a promising technology for advanced signal processing and electromagnetic wave manipulation.

The development of quasicrystal filters aims to leverage the distinctive properties of quasicrystalline structures to achieve superior filtering performance compared to traditional periodic filters. These filters exploit the complex symmetries and long-range order of quasicrystals to create unique band structures and photonic properties. The primary objective is to design and fabricate filters that offer enhanced selectivity, broader stopbands, and reduced sensitivity to manufacturing tolerances.

The evolution of quasicrystal filter technology has been driven by the increasing demand for high-performance electromagnetic and acoustic filtering solutions in various applications. These include telecommunications, radar systems, wireless networks, and quantum computing. As the complexity and density of electromagnetic environments continue to grow, the need for more sophisticated filtering mechanisms becomes paramount.

Recent advancements in nanofabrication techniques and computational modeling have significantly accelerated the development of quasicrystal filters. The ability to precisely control material composition and structure at the nanoscale has enabled researchers to explore a wide range of quasicrystalline designs and optimize their filtering characteristics. Concurrently, powerful simulation tools have facilitated the prediction and analysis of complex wave interactions within quasicrystalline structures.

The objectives of developing advanced quasicrystal filters encompass several key areas. Firstly, researchers aim to expand the frequency range of operation, pushing the boundaries into higher frequency domains such as terahertz and optical regimes. Secondly, there is a focus on improving the filter's quality factor and insertion loss, crucial parameters for enhancing overall system performance. Additionally, efforts are directed towards miniaturization and integration, making quasicrystal filters compatible with modern compact electronic devices and integrated circuits.

Another important goal is to develop tunable and reconfigurable quasicrystal filters. This involves creating structures that can dynamically adjust their filtering properties in response to external stimuli, such as electric fields or mechanical stress. Such adaptability would greatly enhance the versatility of quasicrystal filters in dynamic operating environments.

Market Analysis for Quasicrystal Filter Applications

The market for quasicrystal filters is experiencing significant growth driven by the increasing demand for advanced signal processing and filtering technologies across various industries. Quasicrystal filters, with their unique structural properties and superior performance characteristics, are finding applications in telecommunications, aerospace, defense, and consumer electronics sectors.

In the telecommunications industry, quasicrystal filters are gaining traction due to their ability to provide high selectivity and low insertion loss in radio frequency (RF) and microwave applications. As 5G networks continue to expand globally, the need for efficient signal filtering solutions is escalating, creating a substantial market opportunity for quasicrystal filters.

The aerospace and defense sectors are also key drivers of the quasicrystal filter market. These industries require high-performance filtering solutions for radar systems, satellite communications, and electronic warfare applications. Quasicrystal filters offer improved signal-to-noise ratios and enhanced frequency selectivity, making them ideal for these demanding environments.

Consumer electronics represent another significant market segment for quasicrystal filters. With the proliferation of wireless devices and the increasing complexity of communication protocols, there is a growing need for advanced filtering solutions to ensure signal integrity and minimize interference. Quasicrystal filters are well-positioned to address these challenges in smartphones, tablets, and other portable devices.

The automotive industry is emerging as a promising market for quasicrystal filters, particularly in the context of autonomous vehicles and advanced driver assistance systems (ADAS). These applications require robust and reliable signal processing capabilities, where quasicrystal filters can play a crucial role in enhancing performance and safety.

Market analysts project substantial growth for the quasicrystal filter market in the coming years. The increasing adoption of 5G technology, the expansion of IoT devices, and the ongoing advancements in wireless communication systems are expected to be the primary growth drivers. Additionally, the rising investments in defense modernization programs and the growing emphasis on space exploration are likely to further boost the demand for quasicrystal filters.

However, the market faces challenges such as the complexity of manufacturing processes and the relatively high costs associated with quasicrystal filter production. Overcoming these obstacles will be crucial for wider market adoption and sustained growth. As research and development efforts continue to improve manufacturing techniques and reduce costs, the market potential for quasicrystal filters is expected to expand significantly across various industries.

Current Challenges in Quasicrystal Filter Development

The development of advanced quasicrystal filters faces several significant challenges that hinder their widespread adoption and optimization. One of the primary obstacles is the complexity of quasicrystal structures themselves. Unlike traditional crystals with periodic lattices, quasicrystals exhibit long-range order without periodicity, making their design and fabrication considerably more intricate.

Manufacturing precision poses another major hurdle. The unique properties of quasicrystals stem from their precise atomic arrangements, which require extremely accurate fabrication techniques. Current manufacturing processes often struggle to achieve the necessary level of precision consistently, leading to variations in filter performance and reliability issues.

Material selection and compatibility present additional challenges. While quasicrystals have been discovered in various alloy systems, finding materials that can form stable quasicrystalline structures suitable for filter applications remains difficult. Moreover, ensuring these materials are compatible with existing manufacturing processes and can withstand operational conditions adds another layer of complexity.

The optimization of filter design is also a significant challenge. Traditional filter design methodologies often rely on periodic structures and well-established mathematical models. However, the aperiodic nature of quasicrystals requires new design approaches and computational tools. Developing accurate simulation models that can predict the behavior of quasicrystal filters across a wide range of frequencies and conditions is an ongoing challenge.

Scalability and cost-effectiveness represent further obstacles. While quasicrystal filters show promise in laboratory settings, scaling up production for commercial applications while maintaining performance and keeping costs competitive is proving difficult. The specialized equipment and expertise required for quasicrystal filter production contribute to higher manufacturing costs compared to conventional filter technologies.

Integration with existing systems and technologies also presents challenges. Quasicrystal filters may require modifications to surrounding components or entirely new system architectures to fully leverage their unique properties. This can lead to compatibility issues and increased complexity in overall system design.

Lastly, the lack of standardization in quasicrystal filter development and characterization methods hampers progress. Without established industry standards, comparing different quasicrystal filter designs and performances becomes challenging, slowing down innovation and adoption across the field. Overcoming these multifaceted challenges will be crucial for advancing quasicrystal filter technology and realizing its full potential in various applications.

Existing Quasicrystal Filter Design Approaches

01 Advanced quasicrystal filter structures

Quasicrystal filters with advanced structures are developed to enhance filtering performance. These structures may include multi-layered designs, specific geometric patterns, or novel material combinations to improve selectivity and efficiency in various applications.- Advanced quasicrystal filter structures: Quasicrystal filters with advanced structures are developed to enhance filtering performance. These structures may include multi-layered designs, specific geometric patterns, or novel material combinations that exploit the unique properties of quasicrystals for improved filtration efficiency.

- Fabrication methods for quasicrystal filters: Various advanced manufacturing techniques are employed to produce quasicrystal filters. These may include precision etching, 3D printing, or specialized deposition methods to create complex quasicrystalline structures with desired filtering properties.

- Applications of quasicrystal filters in advanced technologies: Quasicrystal filters find applications in cutting-edge technologies such as electromagnetic shielding, optical devices, and advanced sensing systems. Their unique structural properties make them suitable for specialized filtering requirements in various high-tech fields.

- Optimization of quasicrystal filter performance: Research focuses on optimizing the performance of quasicrystal filters through various means, including tuning the quasicrystalline structure, incorporating additional materials, or developing hybrid designs that combine quasicrystals with other filtering mechanisms.

- Characterization and analysis of quasicrystal filters: Advanced techniques for characterizing and analyzing quasicrystal filters are developed to better understand their properties and performance. This includes methods for measuring filtration efficiency, studying the interaction of quasicrystals with various substances, and modeling their behavior under different conditions.

02 Fabrication methods for quasicrystal filters

Innovative manufacturing techniques are employed to produce advanced quasicrystal filters. These methods may involve precision deposition, etching processes, or additive manufacturing to create complex quasicrystalline structures with desired properties for filtering applications.Expand Specific Solutions03 Applications of quasicrystal filters in optics

Quasicrystal filters find advanced applications in optical systems. They can be used for light manipulation, wavelength selection, or enhancing the performance of optical devices by leveraging the unique properties of quasicrystalline structures.Expand Specific Solutions04 Quasicrystal filters for electromagnetic shielding

Advanced quasicrystal filters are developed for electromagnetic shielding applications. These filters can effectively block or attenuate specific electromagnetic frequencies, providing protection for sensitive electronic equipment or enhancing signal quality in communication systems.Expand Specific Solutions05 Integration of quasicrystal filters in advanced materials

Quasicrystal filters are incorporated into advanced materials to create multifunctional composites. These integrated structures can combine filtering capabilities with other desirable properties such as mechanical strength, thermal management, or self-cleaning features.Expand Specific Solutions

Key Players in Quasicrystal Research and Industry

The development of advanced quasicrystal filters is in an emerging phase, with growing market potential due to their unique properties. The global market for these filters is expanding, driven by applications in telecommunications, aerospace, and electronics. Technologically, the field is still maturing, with ongoing research and development efforts. Companies like LG Electronics, NGK Insulators, and Toshiba Corp. are at the forefront, leveraging their expertise in materials science and electronics. Academic institutions such as Zhejiang University and Massachusetts Institute of Technology are contributing significant research. The collaboration between industry leaders and research institutions is accelerating progress, indicating a competitive landscape poised for rapid advancements in quasicrystal filter technology.

Toshiba Corp.

Samsung Electronics Co., Ltd.

Breakthrough Innovations in Quasicrystal Structures

- Incorporation of quaternary ammonium compound (QAC)-modified metal-organic framework (MOF) particles into electrospun polymer nanofibers, which are grafted via atomic transfer radical polymerization and electrospun to form a self-decontaminating filter that effectively kills bacteria while maintaining high particulate matter filtration efficiency.

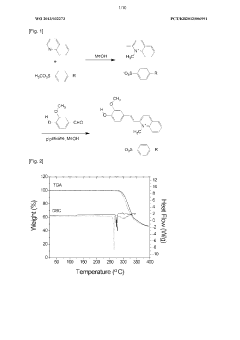

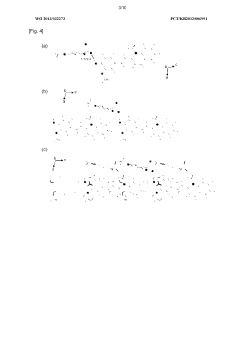

- Development of an ionic electro-optical quinolinium single crystal, specifically HMQ-T and HMQ-MBS, with optimized molecular structure and synthesis methods to enhance macroscopic optical nonlinearity and terahertz wave generation efficiency, utilizing condensation reactions for crystal growth and metathesis to achieve superior properties compared to conventional crystals like OH1 and inorganic ZnTe.

Materials Science Advancements for Quasicrystals

Recent advancements in materials science have significantly contributed to the development of quasicrystals, opening new avenues for their application in advanced filters. The discovery of quasicrystals in the 1980s revolutionized our understanding of crystalline structures, challenging the conventional notion of periodic lattices. Since then, researchers have made substantial progress in synthesizing and characterizing these unique materials.

One of the key breakthroughs in quasicrystal research has been the development of more precise fabrication techniques. Advanced methods such as molecular beam epitaxy and rapid quenching have enabled the creation of high-quality quasicrystalline samples with fewer defects and impurities. These improvements have led to a better understanding of the intrinsic properties of quasicrystals, paving the way for their utilization in filter applications.

The unique structural properties of quasicrystals, particularly their long-range order without periodicity, have been found to offer exceptional filtering capabilities. Recent studies have shown that quasicrystalline structures can effectively filter electromagnetic waves across a wide range of frequencies, making them promising candidates for advanced filter designs. This property stems from the presence of forbidden symmetries and the resulting photonic band gaps in quasicrystals.

Materials scientists have also made significant progress in tailoring the composition of quasicrystals to enhance their filtering properties. By carefully controlling the elemental ratios and introducing dopants, researchers have been able to fine-tune the electronic and optical characteristics of quasicrystalline materials. This level of control has enabled the development of quasicrystal filters with improved selectivity and efficiency.

Furthermore, advancements in computational modeling and simulation techniques have greatly accelerated the design process for quasicrystal-based filters. Sophisticated algorithms now allow researchers to predict the behavior of quasicrystalline structures under various conditions, optimizing their performance before physical prototyping. This approach has significantly reduced development time and costs associated with creating advanced quasicrystal filters.

The integration of quasicrystals with other advanced materials has also shown promising results. For instance, combining quasicrystalline structures with metamaterials has led to the creation of hybrid filters with enhanced functionality and tunability. These composite materials offer unprecedented control over wave propagation and filtering characteristics, opening up new possibilities for next-generation communication and sensing technologies.

Fabrication Techniques for Quasicrystal Filters

The fabrication of quasicrystal filters requires advanced techniques to achieve the desired structural and functional properties. One of the primary methods used is thin film deposition, which allows for precise control over the thickness and composition of the quasicrystalline layers. Techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) are commonly employed to create high-quality quasicrystal thin films. These methods enable the formation of complex quasiperiodic structures with long-range order but no translational symmetry.

Electron beam lithography is another crucial technique in the fabrication of quasicrystal filters. This high-resolution patterning method allows for the creation of intricate quasiperiodic patterns on the nanoscale. By using electron beams to expose resist materials, researchers can achieve feature sizes down to a few nanometers, which is essential for creating the precise structural arrangements required in quasicrystal filters.

Etching processes play a vital role in shaping the quasicrystalline structures. Both wet and dry etching techniques are utilized, depending on the specific requirements of the filter design. Reactive ion etching (RIE) is particularly useful for creating high-aspect-ratio structures with vertical sidewalls, which can enhance the performance of quasicrystal filters in certain applications.

Self-assembly techniques have gained attention in recent years as a potential method for fabricating quasicrystal filters. This approach leverages the natural tendency of certain materials to form quasiperiodic structures under specific conditions. By carefully controlling parameters such as temperature, pressure, and composition, researchers can induce the spontaneous formation of quasicrystalline patterns.

Advanced characterization techniques are essential throughout the fabrication process to ensure the quality and performance of quasicrystal filters. High-resolution transmission electron microscopy (HRTEM) and scanning tunneling microscopy (STM) are used to examine the atomic-scale structure of the quasicrystalline materials. X-ray diffraction (XRD) and electron diffraction techniques provide information about the long-range order and symmetry of the quasicrystalline patterns.

Post-processing steps, such as annealing and surface treatments, are often employed to optimize the properties of quasicrystal filters. These processes can improve the structural stability, reduce defects, and enhance the overall performance of the filters. Additionally, the integration of quasicrystal filters with other components and systems requires careful consideration of packaging and interconnection techniques to preserve the unique properties of the quasicrystalline structures.