Quasicrystal: New Frontiers for Material Synthesis

Quasicrystal Evolution and Research Objectives

Quasicrystals, discovered in 1982 by Dan Shechtman, represent a revolutionary class of materials that challenge our traditional understanding of crystalline structures. These unique materials exhibit long-range order but lack periodicity, a characteristic that was once thought to be impossible in solid matter. The evolution of quasicrystal research has been marked by significant milestones, from initial skepticism to widespread acceptance and exploration of their potential applications.

The field of quasicrystal research has progressed through several key phases. Initially, the focus was on understanding the fundamental structure and formation mechanisms of these materials. This led to the development of new mathematical models and diffraction techniques to characterize their complex structures. As understanding grew, researchers began to explore the unique properties of quasicrystals, including their thermal, electrical, and mechanical characteristics.

In recent years, the emphasis has shifted towards the synthesis and application of quasicrystals in various technological domains. Researchers are now investigating the potential of quasicrystals in areas such as surface coatings, thermoelectric materials, and photonic devices. The ability to engineer quasicrystalline structures at the nanoscale has opened up new possibilities for material design and functionality.

The primary objectives of current quasicrystal research are multifaceted. One key goal is to develop more efficient and controllable methods for synthesizing quasicrystals, particularly in forms that are suitable for practical applications. This includes exploring new composition ranges and processing techniques to create stable quasicrystalline phases with tailored properties.

Another critical objective is to deepen our understanding of the relationship between the unique atomic structure of quasicrystals and their macroscopic properties. This knowledge is essential for designing quasicrystalline materials with specific functionalities for targeted applications. Researchers are also focusing on exploring the potential of quasicrystals in emerging fields such as quantum computing and advanced energy materials.

Furthermore, there is a growing interest in investigating the occurrence of quasicrystals in nature and their potential role in various natural phenomena. This includes studying quasicrystalline structures in meteorites and exploring their implications for our understanding of the early solar system and material formation under extreme conditions.

As the field progresses, interdisciplinary collaboration is becoming increasingly important. The complex nature of quasicrystals requires expertise from diverse areas including materials science, physics, chemistry, and mathematics. The ultimate aim is to bridge the gap between fundamental research and practical applications, paving the way for a new generation of advanced materials based on quasicrystalline structures.

Market Potential of Quasicrystal Materials

The market potential for quasicrystal materials is rapidly expanding as researchers and industries recognize their unique properties and diverse applications. Quasicrystals, with their non-periodic yet ordered atomic structures, offer a range of characteristics that set them apart from traditional crystalline and amorphous materials. This distinctive structure leads to exceptional properties such as low friction, high hardness, and unusual optical and electronic behaviors.

In the automotive and aerospace industries, quasicrystal coatings are gaining traction due to their superior wear resistance and low friction properties. These attributes can significantly enhance the lifespan and efficiency of engine components, potentially leading to fuel savings and reduced maintenance costs. The global market for advanced coatings in these sectors is projected to grow substantially, with quasicrystals poised to capture a significant share.

The electronics industry is another promising market for quasicrystal materials. Their unique electronic properties make them suitable for applications in semiconductors, thermoelectric devices, and photonic crystals. As the demand for more efficient and compact electronic devices continues to rise, quasicrystals could play a crucial role in next-generation technologies.

In the field of renewable energy, quasicrystals show potential in improving the efficiency of solar cells and thermoelectric generators. Their ability to manipulate light and heat in unconventional ways could lead to breakthroughs in energy harvesting and conversion technologies. This aligns well with the global push towards sustainable energy solutions, representing a substantial market opportunity.

The medical industry is also exploring the use of quasicrystals in various applications. Their biocompatibility and unique surface properties make them promising candidates for medical implants and drug delivery systems. As the healthcare sector continues to grow and innovate, the demand for advanced materials like quasicrystals is expected to increase.

However, the market potential of quasicrystal materials is not without challenges. The complexity of synthesizing quasicrystals on a large scale and the current high production costs are significant barriers to widespread adoption. Overcoming these challenges will be crucial for realizing the full market potential of these materials.

Despite these hurdles, the unique properties of quasicrystals and their potential applications across multiple industries suggest a promising future. As research advances and production techniques improve, the market for quasicrystal materials is expected to expand significantly. This growth will likely be driven by industries seeking innovative solutions to improve performance, efficiency, and sustainability in their products and processes.

Current Challenges in Quasicrystal Synthesis

The synthesis of quasicrystals remains a significant challenge in materials science, despite the considerable progress made since their discovery in 1982. One of the primary obstacles is the precise control of atomic arrangements required to form these aperiodic structures. Unlike conventional crystals, quasicrystals lack translational symmetry, making their formation process inherently complex and difficult to manipulate.

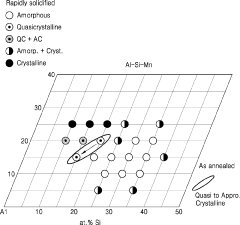

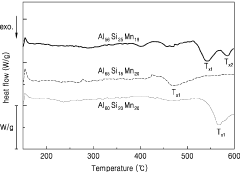

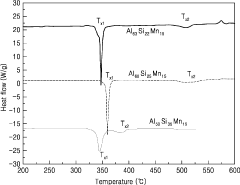

A major hurdle in quasicrystal synthesis is the narrow range of composition and processing conditions that allow for their formation. Many quasicrystalline phases are metastable, existing only within specific temperature and pressure ranges. This necessitates extremely precise control over synthesis parameters, which can be challenging to maintain consistently in large-scale production environments.

The kinetics of quasicrystal formation pose another significant challenge. The growth mechanisms of quasicrystals are not fully understood, and the transition from a disordered state to a quasicrystalline structure often involves complex intermediate phases. This makes it difficult to predict and control the nucleation and growth processes, leading to issues with reproducibility and scalability in synthesis methods.

Impurity control is another critical factor in quasicrystal synthesis. Even minute amounts of impurities can disrupt the delicate balance required for quasicrystal formation, leading to the crystallization of periodic phases instead. This necessitates the use of ultra-high purity starting materials and carefully controlled processing environments, which can significantly increase production costs.

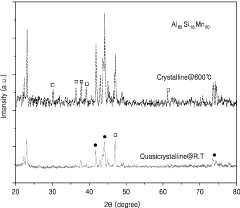

The characterization of quasicrystals presents its own set of challenges. Traditional crystallographic techniques are often inadequate for fully describing quasicrystalline structures, requiring the development of new analytical methods and mathematical frameworks. This complicates the process of verifying successful synthesis and assessing the quality of produced quasicrystals.

Furthermore, the limited availability of suitable precursor materials for certain quasicrystalline compositions restricts the exploration of new quasicrystal systems. Many potential quasicrystal-forming elements are rare or difficult to process, constraining the diversity of quasicrystals that can be synthesized and studied.

Lastly, the challenge of synthesizing bulk quasicrystals with consistent properties throughout the material remains significant. While thin films and small particles of quasicrystals can be produced with relative ease, scaling up to larger, three-dimensional structures while maintaining quasicrystalline order is an ongoing area of research that requires innovative approaches to overcome current limitations.

Existing Quasicrystal Synthesis Methods

01 Quasicrystal structure and composition

Quasicrystals are unique materials with aperiodic atomic structures that exhibit long-range order but lack translational symmetry. They often contain aluminum and transition metals, forming complex arrangements with unusual symmetries such as five-fold or ten-fold rotational symmetry. These structures result in unique properties, including high hardness, low friction, and thermal and electrical insulation.- Quasicrystal structure and composition: Quasicrystals are unique materials with aperiodic atomic structures that exhibit long-range order but lack translational symmetry. They are typically composed of metallic alloys and possess unusual physical properties. The structure and composition of quasicrystals are crucial for their formation and stability.

- Manufacturing methods for quasicrystals: Various techniques are employed to produce quasicrystals, including rapid solidification, melt spinning, and vapor deposition. These methods often involve precise control of cooling rates and composition to achieve the desired quasicrystalline structure. Advanced manufacturing processes can enhance the quality and yield of quasicrystals.

- Applications of quasicrystals: Quasicrystals find applications in diverse fields due to their unique properties. They are used in non-stick coatings, thermal barriers, and wear-resistant materials. Their low friction and high hardness make them suitable for mechanical components. Quasicrystals also show promise in electronic and optical applications.

- Characterization and analysis of quasicrystals: Advanced analytical techniques are employed to study the structure and properties of quasicrystals. These include X-ray diffraction, electron microscopy, and spectroscopic methods. Characterization is essential for understanding the unique features of quasicrystals and optimizing their performance in various applications.

- Quasicrystal-based composites and coatings: Quasicrystals are incorporated into composites and coatings to enhance material properties. These composites combine the unique characteristics of quasicrystals with other materials, resulting in improved mechanical, thermal, or electrical properties. Quasicrystal coatings can provide enhanced surface properties for various substrates.

02 Manufacturing methods for quasicrystals

Various techniques are employed to produce quasicrystals, including rapid solidification, physical vapor deposition, and mechanical alloying. These methods often involve precise control of composition, temperature, and cooling rates to achieve the desired quasicrystalline structure. Some processes use high-energy ball milling or plasma spraying to create quasicrystalline coatings or bulk materials.Expand Specific Solutions03 Applications of quasicrystals in coatings and surface treatments

Quasicrystals are utilized in various surface treatments and coatings due to their unique properties. They are applied to improve wear resistance, reduce friction, and enhance corrosion protection in tools, machinery parts, and automotive components. Quasicrystalline coatings can also be used to create non-stick surfaces or to improve the thermal management of electronic devices.Expand Specific Solutions04 Quasicrystals in composite materials

Quasicrystals are incorporated into composite materials to enhance their mechanical, thermal, and electrical properties. These composites can combine the unique characteristics of quasicrystals with those of traditional materials, resulting in improved strength, hardness, and thermal stability. Applications include aerospace components, cutting tools, and high-performance structural materials.Expand Specific Solutions05 Characterization and analysis of quasicrystals

Advanced techniques are employed to study and characterize quasicrystals, including electron microscopy, X-ray diffraction, and neutron scattering. These methods help researchers understand the complex atomic arrangements, phase transitions, and physical properties of quasicrystalline materials. Computer simulations and theoretical models are also used to predict and analyze quasicrystal structures and behaviors.Expand Specific Solutions

Key Institutions in Quasicrystal Research

The research on quasicrystals represents an emerging frontier in material synthesis, with the field currently in its growth phase. The market for quasicrystal applications is expanding, driven by their unique properties and potential uses in various industries. While the technology is still evolving, several key players are advancing its development. Universities like the University of California, Sichuan University, and Shanghai Jiao Tong University are at the forefront of academic research. Corporate entities such as Sony Group Corp., Samsung Electronics, and BASF are exploring commercial applications. Research institutions like the Council of Scientific & Industrial Research and government bodies are also contributing significantly, indicating a diverse and competitive landscape in quasicrystal research and development.

Council of Scientific & Industrial Research

The Regents of the University of California

Breakthrough Studies in Quasicrystal Formation

- A polyhedral quasicrystalline material with long-range translational order and rotational symmetry is used in the phase change layer, enabling phase transitions between quasi-crystalline and crystalline states with minimal energy change, allowing for fast phase transitions.

- The introduction of reversible click chemistry reactions allows for the formation, disruption, and reformation of nanostructured materials in response to specific stimuli, achieved through the careful selection and modification of chemical moieties that can serve as reversible 'clickable' sites, enabling controlled bond formation and cleavage.

Applications of Quasicrystals in Industry

Quasicrystals have emerged as a promising material with unique properties that offer a wide range of potential applications across various industries. Their distinctive atomic structure, characterized by long-range order without periodicity, gives rise to exceptional physical and chemical properties that can be harnessed for innovative industrial solutions.

In the aerospace industry, quasicrystals have shown great potential as thermal barrier coatings for jet engines. Their low thermal conductivity and high oxidation resistance make them ideal for protecting engine components from extreme temperatures, potentially increasing engine efficiency and lifespan. Additionally, the high hardness and low friction coefficients of quasicrystalline materials make them excellent candidates for wear-resistant coatings on aircraft components.

The automotive sector has also begun exploring the use of quasicrystals in various applications. Quasicrystalline alloys can be used to create lightweight, high-strength components that contribute to improved fuel efficiency and vehicle performance. Moreover, their unique surface properties make them suitable for non-stick, corrosion-resistant coatings on engine parts and exhaust systems.

In the energy industry, quasicrystals show promise in the development of more efficient thermoelectric materials. Their complex atomic structure can lead to reduced thermal conductivity while maintaining good electrical conductivity, potentially improving the conversion of waste heat into electricity in power plants and industrial processes.

The electronics industry is another sector that stands to benefit from quasicrystal applications. Their unusual electronic properties make them candidates for novel semiconductor materials, potentially leading to advancements in electronic devices and sensors. Additionally, quasicrystalline thin films have shown potential in creating selective solar absorbers for improved solar energy harvesting.

In the medical field, quasicrystals are being investigated for their potential in creating biocompatible materials for implants and prosthetics. Their unique surface properties can inhibit bacterial growth and promote better integration with living tissues, potentially reducing the risk of implant rejection and infection.

The manufacturing industry is exploring quasicrystals for their tribological properties. Their low friction and wear resistance make them excellent candidates for cutting tools, bearings, and other mechanical components subject to high wear and tear. This could lead to increased durability and efficiency in various manufacturing processes.

As research in quasicrystals continues to advance, it is likely that new applications will emerge across these and other industries. The unique properties of quasicrystals offer exciting possibilities for addressing current technological challenges and driving innovation in material science and engineering.

Environmental Impact of Quasicrystal Production

The production of quasicrystals, while offering promising advancements in material science, also raises important environmental considerations. The synthesis process of quasicrystals typically involves high-energy methods such as melt-spinning, vapor deposition, or plasma spraying, which can have significant energy consumption implications. These energy-intensive processes contribute to increased carbon emissions, particularly if the energy source is not renewable.

Furthermore, the production of quasicrystals often requires the use of rare earth elements and transition metals, such as aluminum, copper, iron, and manganese. The mining and extraction of these materials can lead to habitat destruction, soil erosion, and water pollution in the areas where they are sourced. Additionally, the refining processes for these metals often involve chemical treatments that may generate hazardous waste products.

The unique atomic structure of quasicrystals also presents challenges in terms of recyclability and end-of-life disposal. Unlike conventional crystalline materials, quasicrystals cannot be easily reprocessed or recycled using standard methods, potentially leading to increased waste accumulation over time. This aspect raises concerns about long-term environmental impact and resource efficiency.

However, it is important to note that the environmental impact of quasicrystal production must be balanced against their potential benefits. Quasicrystals exhibit exceptional properties such as low friction, high hardness, and thermal insulation, which could lead to more efficient and durable products in various applications. For instance, their use in coating technologies could extend the lifespan of machinery and reduce the need for frequent replacements, ultimately conserving resources.

Efforts are being made to develop more sustainable production methods for quasicrystals. Research is ongoing into lower-energy synthesis techniques, such as mechanochemical methods and sol-gel processes, which could significantly reduce the environmental footprint of production. Additionally, there is growing interest in exploring bio-inspired approaches to quasicrystal synthesis, mimicking natural processes that create complex structures under ambient conditions.

As the field of quasicrystal research advances, it is crucial to prioritize the development of environmentally friendly production techniques and to consider the full lifecycle impact of these materials. This includes exploring ways to improve recyclability, reduce reliance on rare earth elements, and minimize energy consumption in the synthesis process. By addressing these environmental challenges, the potential of quasicrystals can be harnessed while minimizing their ecological footprint.