Quasicrystal Applications in Precision Measurement

Quasicrystal Evolution and Measurement Goals

Quasicrystals, discovered in 1982 by Dan Shechtman, represent a revolutionary class of materials that challenge traditional crystallography. These structures exhibit long-range order but lack periodicity, a property once thought impossible in solid matter. The evolution of quasicrystal research has been marked by significant milestones, from initial skepticism to widespread acceptance and exploration of their unique properties.

The field has progressed through several key phases. Initially, research focused on understanding the fundamental structure and formation of quasicrystals. This was followed by the discovery of various types of quasicrystals, including icosahedral, decagonal, and octagonal symmetries. As understanding deepened, attention shifted to exploring the physical and chemical properties of these materials, revealing characteristics such as low friction, high hardness, and unusual electronic behavior.

In recent years, the potential applications of quasicrystals have become a primary focus, particularly in the realm of precision measurement. The aperiodic nature of quasicrystals offers unique advantages in this field. Their complex, yet ordered structure provides a basis for creating highly accurate measurement scales and reference standards that are not limited by the periodic constraints of traditional crystals.

The goals of quasicrystal research in precision measurement are multifaceted. One primary objective is to develop ultra-precise optical and electronic measurement devices. Quasicrystals' unique diffraction patterns and electronic properties could enable the creation of sensors with unprecedented accuracy and resolution. Another aim is to utilize quasicrystals in metrology, potentially redefining measurement standards at the atomic scale.

Researchers are also exploring the use of quasicrystals in quantum sensing applications. The non-periodic structure of quasicrystals may offer novel ways to manipulate and measure quantum states, potentially leading to breakthroughs in quantum metrology and sensing technologies. Additionally, there is growing interest in leveraging quasicrystals for nanoscale measurements, where their unique structural properties could provide advantages over conventional materials.

As the field progresses, the integration of quasicrystals with other advanced technologies, such as artificial intelligence and nanotechnology, is expected to open new frontiers in precision measurement. The ultimate goal is to push the boundaries of measurement accuracy and precision across various scientific and industrial domains, from materials science to quantum computing.

Market Analysis for Precision Measurement Technologies

The precision measurement technology market has been experiencing significant growth in recent years, driven by increasing demand for high-accuracy measurements across various industries. This market encompasses a wide range of technologies, including optical, electromagnetic, and quantum-based measurement systems. The global precision measurement market was valued at approximately $26 billion in 2020 and is projected to reach $36 billion by 2025, with a compound annual growth rate (CAGR) of 6.7%.

Key factors contributing to market growth include the rising adoption of automation in manufacturing processes, stringent quality control requirements in industries such as aerospace and healthcare, and the continuous miniaturization of electronic components. The automotive sector, in particular, has emerged as a major driver for precision measurement technologies, with the increasing complexity of vehicle systems demanding more accurate and reliable measurement solutions.

Geographically, North America and Europe currently dominate the precision measurement market, owing to their advanced industrial infrastructure and high investment in research and development. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, primarily due to rapid industrialization in countries like China and India.

The market for quasicrystal applications in precision measurement, while still nascent, shows promising potential. Quasicrystals, with their unique structural properties, offer novel opportunities for enhancing measurement accuracy and stability. The market for quasicrystal-based precision measurement technologies is estimated to be in its early stages, with a current market size of approximately $50 million. However, it is projected to grow at a CAGR of 12% over the next five years, reaching $88 million by 2026.

Key application areas for quasicrystal-based precision measurement technologies include semiconductor manufacturing, materials science research, and advanced metrology systems. The semiconductor industry, in particular, is showing keen interest in quasicrystal applications for improving the accuracy of lithography processes and enhancing the precision of chip manufacturing.

Despite the promising outlook, the market for quasicrystal applications in precision measurement faces several challenges. These include the high cost of quasicrystal production, limited understanding of their properties among potential end-users, and the need for extensive research to fully exploit their potential in measurement applications. Overcoming these barriers will be crucial for the widespread adoption of quasicrystal-based precision measurement technologies.

Current Quasicrystal Research Challenges

Quasicrystals, discovered in 1982, have presented unique challenges in materials science and precision measurement. Despite their potential, several significant obstacles hinder their widespread application in precision measurement technologies.

One of the primary challenges is the difficulty in synthesizing large, high-quality quasicrystals. The complex, aperiodic structure of quasicrystals makes their growth process highly sensitive to environmental conditions. Researchers struggle to produce samples with consistent properties and minimal defects, which is crucial for precision measurement applications.

Another major hurdle is the limited understanding of quasicrystal properties at the quantum level. While their unusual electronic and phononic structures offer promising avenues for quantum sensing, the lack of comprehensive theoretical models hampers the development of practical applications. This gap in knowledge affects the ability to predict and optimize quasicrystal behavior in measurement devices.

The integration of quasicrystals into existing measurement systems poses significant technical challenges. Their unique properties often require specialized interfaces and readout mechanisms, which are not readily compatible with conventional measurement apparatus. This incompatibility necessitates the development of new measurement protocols and equipment, a process that is both time-consuming and resource-intensive.

Stability and reproducibility issues also plague quasicrystal research. The complex structure of quasicrystals can lead to subtle variations in properties between samples, making it difficult to achieve consistent results in precision measurements. This variability complicates the calibration and standardization processes essential for high-precision applications.

Furthermore, the multidisciplinary nature of quasicrystal research presents collaborative challenges. Effective progress requires the integration of expertise from materials science, physics, chemistry, and engineering. However, the specialized knowledge required often leads to communication barriers between different research groups, slowing down overall progress in the field.

Lastly, the cost and complexity of quasicrystal research pose significant barriers to entry for many institutions. The specialized equipment and expertise required for synthesis and characterization of quasicrystals are often prohibitively expensive, limiting the number of research groups that can actively contribute to advancing the field.

These challenges collectively represent the current frontiers in quasicrystal research for precision measurement applications. Overcoming them will require concerted efforts in fundamental research, technological innovation, and interdisciplinary collaboration.

Existing Quasicrystal Measurement Solutions

01 Quasicrystal structure and formation

Quasicrystals are unique structures with long-range order but no periodicity. They exhibit symmetries that are not possible in conventional crystals. Research focuses on understanding their formation, properties, and potential applications in various fields.- Quasicrystal structure and formation: Quasicrystals are unique structures with long-range order but no periodicity. They exhibit unusual symmetries and properties. Research focuses on understanding their formation, atomic arrangements, and potential applications in various fields.

- Precision manufacturing of quasicrystalline materials: Advanced manufacturing techniques are developed to produce quasicrystalline materials with high precision. These methods aim to control the composition, structure, and properties of quasicrystals for specific applications in industries such as aerospace and electronics.

- Computational modeling of quasicrystals: Sophisticated computational models and algorithms are employed to simulate and predict the behavior of quasicrystals. These tools help researchers understand the complex structures and properties of quasicrystals, aiding in their design and optimization.

- Applications of quasicrystals in precision engineering: Quasicrystals find applications in precision engineering due to their unique properties. They are used in coatings, sensors, and high-performance materials where precise control of structure and properties is crucial for optimal performance.

- Characterization and analysis of quasicrystalline structures: Advanced characterization techniques are developed to analyze the complex structures of quasicrystals with high precision. These methods include electron microscopy, X-ray diffraction, and spectroscopic techniques, enabling researchers to study the atomic arrangements and properties of quasicrystals in detail.

02 Precision manufacturing of quasicrystalline materials

Advanced manufacturing techniques are developed to produce quasicrystalline materials with high precision. These methods aim to control the composition, structure, and properties of quasicrystals for specific applications in industries such as aerospace and electronics.Expand Specific Solutions03 Computational modeling of quasicrystals

Sophisticated computational models and algorithms are developed to simulate and predict the behavior of quasicrystals. These models help in understanding the complex structure and properties of quasicrystals, aiding in their design and optimization for various applications.Expand Specific Solutions04 Quasicrystal-based devices and applications

Researchers explore the unique properties of quasicrystals to develop novel devices and applications. These include electronic components, optical devices, and materials with enhanced mechanical properties, leveraging the distinctive characteristics of quasicrystalline structures.Expand Specific Solutions05 Precision measurement and characterization of quasicrystals

Advanced techniques and instruments are developed for precise measurement and characterization of quasicrystalline structures. These methods enable researchers to analyze the complex atomic arrangements and properties of quasicrystals with high accuracy and resolution.Expand Specific Solutions

Key Players in Quasicrystal Research

The research on quasicrystal applications in precision measurement is in an emerging stage, with growing market potential. The technology is still developing, as evidenced by the diverse range of institutions involved, including universities like Syracuse University and Massachusetts Institute of Technology, as well as corporations such as Seiko Epson Corp. and ULVAC, Inc. The field's interdisciplinary nature is reflected in the participation of both academic and industrial players, suggesting a moderate level of technological maturity. Companies like Robert Bosch GmbH and Micron Technology, Inc. indicate potential commercial applications, while research institutions continue to explore fundamental aspects, pointing to a competitive landscape that balances basic research with practical implementations.

Seiko Epson Corp.

The Georgia Tech Research Corp.

Breakthrough Quasicrystal Properties for Metrology

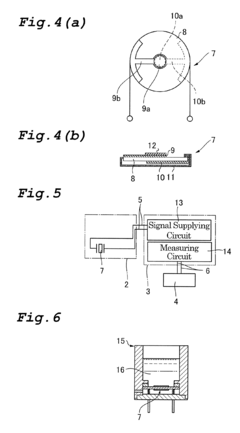

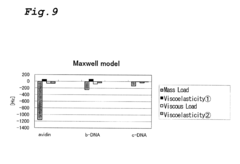

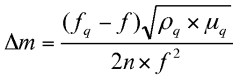

- The method involves using the differences in resonance frequencies between the fundamental mode and overtone modes to separate mass load, viscous load, and viscoelasticity load by applying formulas derived from Martin's transmission theory, specifically using the changes in frequencies F1 and F2 to determine the viscoelasticity and mass load terms, and applying models like the Voight model to quantify these loads.

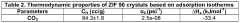

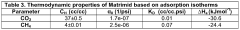

- A high-pressure quartz crystal microbalance (QCM) system with dual sensors (reference and sample) and additional sensors for temperature and pressure control, allowing for precise measurement of gas adsorption and desorption in thin films and coatings under varying conditions, using a high-pressure cell with a gas inlet and outlet for controlled gas influx and identification.

Quasicrystal Manufacturing Processes

The manufacturing processes for quasicrystals are complex and require precise control over various parameters. One of the primary methods for producing quasicrystals is rapid solidification, which involves cooling molten alloys at extremely high rates, typically exceeding 106 K/s. This process prevents the formation of periodic crystal structures and allows for the creation of quasicrystalline phases. Melt spinning is a commonly used technique for rapid solidification, where a thin stream of molten alloy is ejected onto a rapidly rotating copper wheel, resulting in the formation of thin ribbons or flakes of quasicrystalline material.

Another important manufacturing process is physical vapor deposition (PVD), which can produce high-quality quasicrystalline thin films. In this method, the constituent elements are vaporized in a vacuum chamber and deposited onto a substrate. Various PVD techniques, such as sputtering, electron beam evaporation, and pulsed laser deposition, can be employed to create quasicrystalline coatings with controlled composition and thickness.

Mechanical alloying is also utilized for quasicrystal production, particularly for bulk samples. This solid-state process involves high-energy ball milling of elemental powders or pre-alloyed materials, leading to the formation of quasicrystalline phases through repeated fracturing and cold welding of particles. The resulting powders can be consolidated using techniques like hot pressing or spark plasma sintering to create bulk quasicrystalline materials.

For precision measurement applications, the manufacturing of quasicrystal-based devices often requires additional processing steps. These may include microfabrication techniques such as photolithography, etching, and thin film deposition to create specific structures or patterns. The integration of quasicrystals into measurement devices may also involve bonding or joining processes to combine them with other materials or components.

Quality control is crucial in quasicrystal manufacturing, especially for precision measurement applications. Advanced characterization techniques like X-ray diffraction, transmission electron microscopy, and atomic force microscopy are employed to verify the quasicrystalline structure and assess the material's quality. Surface finishing processes, such as polishing or ion beam milling, may be necessary to achieve the required surface quality for high-precision measurements.

The optimization of quasicrystal manufacturing processes for precision measurement applications is an ongoing area of research. Efforts are focused on improving the reproducibility and scalability of production methods, as well as developing techniques to create quasicrystals with specific compositions and structures tailored for particular measurement applications. As the understanding of quasicrystal formation and properties continues to advance, new manufacturing processes and refinements to existing methods are likely to emerge, further enhancing the potential of quasicrystals in precision measurement technologies.

Standardization of Quasicrystal Metrology

The standardization of quasicrystal metrology is a critical step in advancing the application of quasicrystals in precision measurement. As the field of quasicrystal research continues to expand, establishing uniform methods and protocols for measuring and characterizing these unique structures becomes increasingly important.

One of the primary challenges in quasicrystal metrology is the development of standardized techniques for analyzing the complex, aperiodic patterns that define these materials. Traditional crystallographic methods are often insufficient for accurately describing quasicrystalline structures, necessitating the creation of new analytical approaches.

To address this issue, researchers are working to establish standardized diffraction techniques specifically tailored to quasicrystals. These methods aim to provide consistent and reliable data on the long-range order and local atomic arrangements within quasicrystalline samples. By developing standardized protocols for X-ray and electron diffraction analyses, scientists can ensure that results from different laboratories are directly comparable.

Another key aspect of quasicrystal metrology standardization is the development of reference materials. These carefully characterized samples serve as benchmarks for calibrating instruments and validating measurement techniques. The creation of certified quasicrystal reference materials is essential for ensuring the accuracy and reproducibility of measurements across different research institutions and industrial applications.

Standardization efforts also extend to the nomenclature and classification of quasicrystals. As new quasicrystalline structures are discovered, it is crucial to establish a unified system for describing and categorizing these materials. This includes standardizing terminology related to quasicrystal symmetry, composition, and structural characteristics.

The development of standardized imaging and surface analysis techniques is another important aspect of quasicrystal metrology. Advanced microscopy methods, such as atomic force microscopy (AFM) and scanning tunneling microscopy (STM), require specific protocols for accurately capturing the unique surface features of quasicrystals. Standardizing these techniques ensures that researchers can reliably compare and interpret surface data from different quasicrystalline samples.

As quasicrystals find increasing applications in precision measurement devices, the standardization of performance metrics becomes crucial. This includes establishing uniform methods for assessing the stability, accuracy, and resolution of quasicrystal-based sensors and measurement tools. By developing standardized testing procedures, manufacturers and researchers can objectively evaluate and compare the performance of different quasicrystal-based precision measurement devices.