How to Harness Quasicrystal's Thermal Expansion Features?

Quasicrystal Thermal Expansion Background

Quasicrystals, discovered in 1982 by Dan Shechtman, represent a unique class of materials that exhibit long-range order but lack periodicity. This discovery challenged the conventional understanding of crystalline structures and opened up new avenues for materials science research. The thermal expansion properties of quasicrystals have since become a subject of significant interest due to their potential applications in various fields.

The thermal expansion of quasicrystals is characterized by its unusual behavior compared to traditional crystalline materials. Unlike conventional crystals, which typically expand uniformly when heated, quasicrystals can exhibit complex and often anisotropic thermal expansion patterns. This unique feature is attributed to their aperiodic structure and the presence of phason degrees of freedom, which are collective atomic rearrangements specific to quasicrystals.

One of the most intriguing aspects of quasicrystal thermal expansion is the occurrence of negative thermal expansion (NTE) in certain directions. This phenomenon, where the material contracts upon heating rather than expanding, has been observed in several quasicrystalline systems. The NTE behavior in quasicrystals is often associated with the presence of rigid unit modes and the complex interplay between different atomic clusters within the structure.

The study of thermal expansion in quasicrystals has been facilitated by advanced experimental techniques such as high-resolution X-ray diffraction, neutron scattering, and dilatometry. These methods have allowed researchers to probe the intricate structural changes that occur in quasicrystals over a wide range of temperatures, providing valuable insights into their thermal behavior.

The unique thermal expansion properties of quasicrystals have attracted attention for potential applications in various technological domains. For instance, the ability to tailor thermal expansion characteristics through composition and structure modification opens up possibilities for designing materials with near-zero or controlled thermal expansion. Such materials could find use in precision instruments, aerospace components, and thermal management systems where dimensional stability under varying temperatures is crucial.

Furthermore, the study of quasicrystal thermal expansion has contributed to the broader understanding of structure-property relationships in complex materials. It has challenged existing theories and models of thermal expansion, prompting the development of new theoretical frameworks to explain and predict the behavior of aperiodic structures under thermal stress.

As research in this field progresses, scientists and engineers are exploring ways to harness the unique thermal expansion features of quasicrystals for practical applications. This includes investigating composite materials that incorporate quasicrystalline phases to achieve specific thermal expansion characteristics, as well as developing novel manufacturing techniques to produce quasicrystalline materials with tailored properties.

Market Demand Analysis

The market demand for harnessing quasicrystal's thermal expansion features is driven by several key factors across various industries. In the aerospace sector, there is a growing need for materials that can withstand extreme temperature fluctuations while maintaining structural integrity. Quasicrystals, with their unique thermal expansion properties, offer potential solutions for developing high-performance components in aircraft engines and spacecraft.

The automotive industry is another significant market for quasicrystal applications. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, lightweight materials with superior thermal management capabilities are in high demand. Quasicrystals' thermal expansion features could be utilized in engine components, exhaust systems, and heat shields, potentially enhancing overall vehicle performance and durability.

In the electronics sector, the miniaturization trend and increasing power densities of devices have created a pressing need for advanced thermal management solutions. Quasicrystals' unique thermal properties could be leveraged to develop more efficient heat sinks and thermal interface materials, addressing the challenges of heat dissipation in compact electronic devices.

The energy industry, particularly in renewable energy systems, presents another potential market for quasicrystal applications. Solar panels and concentrated solar power systems require materials that can withstand high temperatures and thermal cycling. Quasicrystals' thermal expansion features could contribute to the development of more efficient and durable solar energy components.

The medical device industry is also showing interest in quasicrystal applications. Implantable devices and surgical instruments that require precise thermal management could benefit from the unique properties of quasicrystals, potentially improving patient outcomes and device longevity.

While the market potential for quasicrystal applications is significant, it is important to note that the technology is still in its early stages of commercialization. The current market size for quasicrystal-based products is relatively small, but it is expected to grow as research and development efforts intensify and new applications are discovered.

The global advanced materials market, which includes quasicrystals, is projected to experience substantial growth in the coming years. This growth is driven by increasing demand for high-performance materials across various industries and the ongoing push for technological advancements in material science.

Current Challenges in Quasicrystal Utilization

Despite the promising potential of quasicrystals, their widespread utilization faces several significant challenges. One of the primary obstacles is the difficulty in synthesizing large, high-quality quasicrystalline samples. The complex atomic structure of quasicrystals requires precise control over growth conditions, making it challenging to produce samples with consistent properties and minimal defects.

Another major hurdle is the limited understanding of quasicrystal formation mechanisms. The lack of periodicity in their structure complicates traditional crystallographic analysis techniques, hindering efforts to fully characterize and predict their behavior. This knowledge gap impedes the development of efficient manufacturing processes and the ability to tailor quasicrystal properties for specific applications.

The unique thermal expansion characteristics of quasicrystals, while potentially advantageous, also present challenges in terms of integration with other materials. The mismatch in thermal expansion coefficients between quasicrystals and conventional materials can lead to stress and potential failure at interfaces, limiting their use in composite structures or as coatings.

Furthermore, the mechanical properties of quasicrystals pose both opportunities and challenges. While they exhibit high hardness and wear resistance, they are often brittle, which restricts their use in applications requiring ductility or toughness. Developing methods to enhance the fracture toughness of quasicrystals without compromising their other desirable properties remains a significant challenge.

The cost-effective production of quasicrystals at industrial scales is another major obstacle. Current synthesis methods are often complex and energy-intensive, making large-scale production economically unfeasible for many potential applications. Developing more efficient and scalable production techniques is crucial for the widespread adoption of quasicrystal technology.

Additionally, the lack of standardized characterization and testing methods specific to quasicrystals hampers their integration into existing material systems and quality control processes. Establishing reliable and reproducible testing protocols is essential for ensuring consistent performance and facilitating the acceptance of quasicrystals in various industries.

Lastly, the limited availability of computational models and simulation tools tailored for quasicrystalline structures hinders the ability to predict and optimize their properties. Developing accurate and efficient computational methods for modeling quasicrystals is crucial for accelerating research and development efforts in this field.

Existing Thermal Expansion Applications

01 Thermal expansion properties of quasicrystals

Quasicrystals exhibit unique thermal expansion properties due to their aperiodic structure. They often display low or even negative thermal expansion coefficients, making them valuable for applications requiring dimensional stability over a wide temperature range. This characteristic is attributed to the complex atomic arrangements and long-range order in quasicrystalline materials.- Thermal expansion properties of quasicrystals: Quasicrystals exhibit unique thermal expansion properties due to their aperiodic structure. They often have low or even negative thermal expansion coefficients, making them valuable for applications requiring dimensional stability over a wide temperature range. This property is attributed to the complex atomic arrangements and bonding in quasicrystalline materials.

- Quasicrystal-based composites for thermal management: Composites incorporating quasicrystalline materials can be engineered to have tailored thermal expansion characteristics. These composites can combine the low thermal expansion of quasicrystals with other desirable properties of conventional materials, resulting in improved thermal management in various applications such as aerospace and electronics.

- Manufacturing methods for quasicrystalline materials with controlled thermal expansion: Specialized manufacturing techniques have been developed to produce quasicrystalline materials with specific thermal expansion properties. These methods may include rapid solidification, powder metallurgy, or thin film deposition techniques, allowing for precise control over the composition and structure of the quasicrystals to achieve desired thermal expansion characteristics.

- Applications of quasicrystals in thermal expansion-sensitive devices: The unique thermal expansion properties of quasicrystals make them suitable for use in devices that require high dimensional stability under varying temperature conditions. This includes precision instruments, optical systems, and microelectromechanical systems (MEMS) where thermal expansion mismatch can cause performance issues or device failure.

- Characterization and modeling of thermal expansion in quasicrystals: Advanced characterization techniques and theoretical modeling approaches have been developed to understand and predict the thermal expansion behavior of quasicrystals. These methods include high-resolution diffraction studies, in-situ thermal analysis, and computational simulations that account for the complex structure of quasicrystalline materials.

02 Quasicrystalline coatings for thermal management

Quasicrystalline materials can be used as coatings to manage thermal expansion in various applications. These coatings can help mitigate thermal stresses and improve the overall performance of components subjected to temperature fluctuations. The unique structure of quasicrystals allows for better thermal matching with substrates, enhancing durability and longevity of coated parts.Expand Specific Solutions03 Quasicrystal-based composites for thermal stability

Composites incorporating quasicrystalline materials can be engineered to achieve specific thermal expansion characteristics. By combining quasicrystals with other materials, it is possible to tailor the overall thermal expansion behavior of the composite. This approach is particularly useful in applications requiring precise control over thermal expansion, such as in aerospace and high-precision instruments.Expand Specific Solutions04 Thermal expansion measurement techniques for quasicrystals

Specialized techniques and instruments have been developed to accurately measure the thermal expansion of quasicrystalline materials. These methods often involve high-resolution dilatometry, X-ray diffraction, or optical interferometry to capture the subtle changes in dimensions over a range of temperatures. Understanding and quantifying the thermal expansion behavior is crucial for the effective application of quasicrystals in various fields.Expand Specific Solutions05 Applications exploiting quasicrystal thermal expansion

The unique thermal expansion properties of quasicrystals are being exploited in various applications. These include thermal barrier coatings, precision mechanical components, optical devices, and electronic packaging. The ability to control thermal expansion can lead to improved performance, reliability, and longevity in systems operating under varying temperature conditions.Expand Specific Solutions

Key Players in Quasicrystal Research

The competition landscape for harnessing quasicrystal's thermal expansion features is in an early development stage, with a growing market potential as industries seek advanced materials for thermal management. The technology's maturity is still evolving, with key players like Shin-Etsu Chemical Co., Ltd., SCHOTT AG, and Sumitomo Electric Industries Ltd. leading research efforts. Companies such as Panasonic Holdings Corp. and LG Electronics, Inc. are exploring applications in consumer electronics, while research institutions like the Institute of Metal Research Chinese Academy of Sciences and The University of Sydney are advancing fundamental understanding. The market size is expected to expand as quasicrystals' unique properties find applications in aerospace, electronics, and energy sectors.

Institute of Metal Research Chinese Academy of Sciences

The University of Sydney

Innovative Quasicrystal Structures

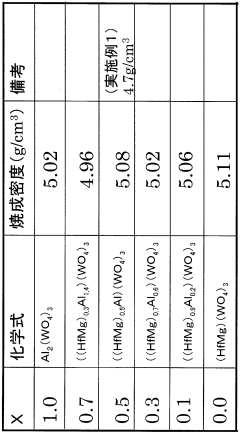

- A material with the chemical formula ((R4+ M2+) A3+) (QO) where R is Zr or Hf, M is Mg, Ca, Sr, or Ba, and Q is W or Mo, combined with A as Al, Sc, Y, Lu, or In, forming a single crystal system with orthorhombic structure, allowing for precise control of thermal expansion coefficients from negative to positive values.

- A particle group comprising crystals with specific properties, including a high differential lattice constant change with temperature, controlled porosity, and surface area ratios, is developed, which can be incorporated into compositions and molded articles to achieve excellent linear thermal expansion coefficient control.

Material Compatibility and Integration

Harnessing quasicrystals' thermal expansion features requires careful consideration of material compatibility and integration. The unique atomic structure of quasicrystals presents both challenges and opportunities when incorporating them into existing systems or developing new applications. One key aspect is the interface between quasicrystals and other materials, which must be carefully engineered to ensure proper adhesion and thermal conductivity.

Quasicrystals often exhibit low thermal expansion coefficients, making them potentially compatible with a wide range of materials. However, the mismatch in thermal expansion between quasicrystals and traditional crystalline materials can lead to stress accumulation at interfaces during temperature fluctuations. To address this issue, researchers have explored the use of gradient structures or intermediate layers to mitigate thermal stresses and improve overall system stability.

The integration of quasicrystals into composite materials has shown promise in leveraging their unique thermal properties. By dispersing quasicrystal particles within a matrix material, it is possible to create composites with tailored thermal expansion characteristics. This approach allows for fine-tuning of the overall thermal behavior while maintaining desirable mechanical properties of the matrix material.

Surface modification techniques play a crucial role in enhancing the compatibility of quasicrystals with other materials. Methods such as plasma treatment, chemical etching, or the application of coupling agents can improve the wettability and bonding strength at interfaces. These treatments can also help to optimize the thermal contact resistance between quasicrystals and adjacent materials, ensuring efficient heat transfer across boundaries.

In electronic applications, the integration of quasicrystals as thermal management materials requires careful consideration of their electrical properties. While many quasicrystals exhibit low electrical conductivity, which can be advantageous for certain applications, it may pose challenges in others. The development of conductive coatings or selective doping strategies can help overcome these limitations and enable the use of quasicrystals in a broader range of electronic systems.

The processing and manufacturing techniques used to incorporate quasicrystals into functional components must be carefully selected to preserve their unique structure and properties. Traditional high-temperature processing methods may not be suitable for all quasicrystal compositions, necessitating the development of novel fabrication approaches. Additive manufacturing techniques, such as 3D printing, have shown potential for creating complex quasicrystal-containing structures with precise control over material distribution and interface characteristics.

Environmental Impact Assessment

The environmental impact assessment of harnessing quasicrystal's thermal expansion features is a critical aspect that requires thorough examination. Quasicrystals, with their unique atomic structure and properties, offer potential advantages in various applications, including thermal management. However, their implementation may have both positive and negative effects on the environment.

One of the primary environmental benefits of utilizing quasicrystals' thermal expansion features is the potential for improved energy efficiency in various systems. By leveraging their low thermal expansion coefficients, quasicrystals can contribute to the development of more stable and durable components in high-temperature applications. This enhanced stability can lead to reduced material degradation and longer lifespans for equipment, ultimately decreasing the need for frequent replacements and minimizing waste generation.

Furthermore, the use of quasicrystals in thermal management systems may result in reduced energy consumption. Their unique thermal properties can enable more efficient heat dissipation and thermal regulation, potentially leading to lower power requirements in various industrial processes and consumer products. This reduction in energy consumption can contribute to decreased greenhouse gas emissions and a smaller carbon footprint.

However, it is essential to consider the potential negative environmental impacts associated with the production and processing of quasicrystals. The synthesis of quasicrystalline materials often involves energy-intensive processes and the use of rare or exotic elements. These production methods may contribute to increased energy consumption and greenhouse gas emissions during the manufacturing phase. Additionally, the extraction and processing of the raw materials required for quasicrystal production could lead to habitat disruption and resource depletion if not managed sustainably.

The disposal and recycling of quasicrystal-containing products at the end of their life cycle also warrant careful consideration. While quasicrystals themselves are generally stable and non-toxic, the composite materials or systems in which they are incorporated may pose challenges for recycling or safe disposal. Proper waste management strategies and recycling technologies need to be developed to mitigate potential environmental risks associated with quasicrystal-based products.

In terms of ecological impact, the introduction of quasicrystal-based materials into the environment should be thoroughly assessed. While quasicrystals are not known to pose significant direct threats to ecosystems, their long-term effects on soil, water, and living organisms require further study. Potential leaching of constituent elements or nanoparticle release from quasicrystal-containing products should be evaluated to ensure minimal impact on biodiversity and ecosystem health.

To fully harness the benefits of quasicrystals' thermal expansion features while minimizing environmental risks, a comprehensive life cycle assessment should be conducted. This assessment should encompass raw material extraction, production processes, product use, and end-of-life management. By identifying and addressing potential environmental hotspots throughout the quasicrystal life cycle, researchers and industry stakeholders can develop sustainable strategies for their implementation and maximize their positive environmental impact.