How to Develop Impactful Quasicrystal-Based Prototypes?

Quasicrystal Evolution

The evolution of quasicrystals represents a fascinating journey in materials science, marked by groundbreaking discoveries and paradigm shifts in our understanding of atomic structures. Initially discovered by Dan Shechtman in 1982, quasicrystals challenged the long-held belief that all crystals must have periodic structures. This discovery, which earned Shechtman the Nobel Prize in Chemistry in 2011, opened up new avenues for research and potential applications.

The early stages of quasicrystal research focused primarily on understanding their unique structural properties. Scientists discovered that these materials possess long-range order but lack periodicity, exhibiting symmetries that were previously thought impossible in crystals, such as five-fold rotational symmetry. This period was characterized by intense theoretical work to explain the formation and stability of quasicrystals.

As research progressed, the focus shifted towards exploring the physical and chemical properties of quasicrystals. Scientists discovered that these materials exhibit unusual combinations of properties, including low friction, high hardness, and poor thermal and electrical conductivity. These findings sparked interest in potential applications across various industries.

The late 1990s and early 2000s saw a surge in efforts to synthesize new types of quasicrystals and to develop methods for growing large, high-quality samples. This phase was crucial for enabling more detailed studies of quasicrystal properties and for exploring practical applications. Researchers successfully created quasicrystals in various alloy systems, expanding beyond the initial aluminum-based compositions.

Recent years have witnessed a renewed interest in quasicrystals, driven by advancements in characterization techniques and computational modeling. High-resolution electron microscopy and advanced X-ray diffraction methods have allowed for more precise structural analysis, while powerful computational tools have enabled simulations of quasicrystal formation and properties at atomic scales.

The evolution of quasicrystal research has also seen a broadening of the field beyond metallic alloys. Discoveries of quasicrystalline structures in soft matter systems, such as polymers and colloids, have opened up new possibilities for applications in fields like photonics and self-assembly. Additionally, the observation of natural quasicrystals in meteorite samples has raised intriguing questions about their formation in extraterrestrial environments.

As we look towards developing impactful quasicrystal-based prototypes, this evolutionary journey provides crucial insights. The progression from fundamental discovery to potential applications highlights the importance of continued basic research alongside applied development. The unique properties of quasicrystals, refined and better understood through decades of study, now offer promising avenues for innovation in areas such as surface coatings, thermal barriers, and novel electronic materials.

Market Potential Analysis

The market potential for quasicrystal-based prototypes is significant and multifaceted, spanning various industries and applications. As these unique materials continue to garner attention from researchers and innovators, their commercial viability is becoming increasingly apparent.

In the aerospace sector, quasicrystals show promise for developing lightweight, high-strength materials that could revolutionize aircraft and spacecraft design. The unique structural properties of quasicrystals, particularly their high hardness and low friction coefficients, make them ideal candidates for advanced coatings and components in aerospace applications. This could lead to improved fuel efficiency and enhanced performance of aircraft engines and structural elements.

The automotive industry also stands to benefit from quasicrystal-based innovations. As manufacturers seek to improve fuel economy and reduce emissions, the development of lighter, stronger materials becomes crucial. Quasicrystal-based alloys could be used in engine components, reducing wear and improving efficiency. Additionally, their potential as catalytic converters could lead to more effective emission control systems.

In the field of electronics, quasicrystals offer exciting possibilities for next-generation devices. Their unique electronic properties, including high electrical resistivity and low thermal conductivity, make them potential candidates for thermoelectric materials. This could open up new markets in energy harvesting and cooling technologies, particularly in applications where traditional semiconductors fall short.

The medical device industry is another sector where quasicrystal-based prototypes could make a significant impact. Their biocompatibility and resistance to wear make them attractive for use in implants and prosthetics. The development of quasicrystal-coated surgical instruments could also lead to improved performance and longevity in medical tools.

The energy sector, particularly in the realm of renewable energy, presents another promising market for quasicrystal-based innovations. Their potential use in solar cells and hydrogen storage materials could contribute to advancements in clean energy technologies. This aligns with the growing global focus on sustainable energy solutions and could drive significant investment in quasicrystal research and development.

As nanotechnology continues to advance, the unique properties of quasicrystals at the nanoscale could lead to breakthroughs in areas such as quantum computing, advanced sensors, and novel optical devices. This opens up potential markets in cutting-edge technology sectors that are still in their infancy but show immense promise for future growth.

While the market potential for quasicrystal-based prototypes is substantial, it's important to note that many applications are still in the early stages of development. The transition from laboratory research to commercial products will require significant investment in scaling up production processes and overcoming manufacturing challenges. However, the diverse range of potential applications and the unique properties of quasicrystals suggest that successful prototypes could disrupt multiple industries and create new market opportunities.

Technical Hurdles

The development of impactful quasicrystal-based prototypes faces several significant technical hurdles that researchers and engineers must overcome. One of the primary challenges lies in the precise control and manipulation of quasicrystalline structures at the atomic level. Unlike conventional crystals, quasicrystals lack periodicity, making it difficult to predict and control their formation and growth processes accurately.

Another major obstacle is the limited availability of suitable materials for quasicrystal formation. While quasicrystals have been discovered in various alloy systems, finding compositions that exhibit desirable properties for specific applications remains a complex task. This challenge is compounded by the fact that many quasicrystalline materials are metastable, requiring careful control of processing conditions to maintain their unique structure.

The characterization and analysis of quasicrystals pose additional technical difficulties. Traditional crystallographic techniques are often inadequate for fully describing the complex, aperiodic structures of quasicrystals. Advanced imaging and diffraction methods, such as high-resolution transmission electron microscopy and synchrotron X-ray diffraction, are necessary but can be costly and time-consuming.

Scaling up the production of quasicrystal-based prototypes from laboratory samples to industrially viable quantities presents another significant hurdle. The delicate balance of processing parameters required to form and maintain quasicrystalline structures can be challenging to replicate consistently at larger scales. This scaling issue affects both the quality and cost-effectiveness of potential quasicrystal-based products.

Furthermore, integrating quasicrystals into functional devices and systems introduces additional complexities. The unique properties of quasicrystals, such as their low friction coefficients and unusual electronic behaviors, often require novel design approaches and manufacturing techniques that are not yet well-established in industry. Developing reliable methods for incorporating quasicrystals into composite materials or as coatings on conventional substrates remains an active area of research.

The long-term stability and performance of quasicrystal-based prototypes under various environmental conditions also present technical challenges. Understanding and mitigating potential degradation mechanisms, such as phase transformations or surface oxidation, is crucial for ensuring the durability and reliability of quasicrystal-based products in real-world applications.

Lastly, the interdisciplinary nature of quasicrystal research and development necessitates collaboration between experts in materials science, physics, chemistry, and engineering. Bridging the gaps between fundamental scientific understanding and practical engineering applications requires overcoming communication barriers and aligning research objectives across different fields.

Current Prototyping Methods

01 Structural properties and applications of quasicrystals

Quasicrystals exhibit unique structural properties that impact their applications in various fields. Their aperiodic atomic arrangement leads to unusual physical and chemical characteristics, making them suitable for use in materials science, engineering, and nanotechnology. These properties include high hardness, low friction, and thermal insulation, which can be exploited in the development of novel materials and coatings.- Structural properties and applications of quasicrystals: Quasicrystals exhibit unique structural properties that impact their applications in various fields. Their aperiodic atomic arrangement leads to unusual physical and chemical characteristics, making them suitable for use in materials science, engineering, and nanotechnology. These properties include high hardness, low friction, and thermal insulation, which can be exploited in coatings, composites, and thermal barriers.

- Quasicrystals in energy absorption and dissipation: The unique structure of quasicrystals contributes to their ability to absorb and dissipate energy effectively. This property makes them valuable in applications such as impact protection, vibration damping, and shock absorption. Quasicrystalline materials can be incorporated into protective gear, automotive components, and aerospace structures to enhance safety and performance.

- Quasicrystals in surface coatings and tribology: Quasicrystals have a significant impact on surface coatings and tribological applications. Their low friction and wear resistance properties make them ideal for use in protective coatings, reducing wear and extending the lifespan of mechanical components. These materials can be applied to cutting tools, engine parts, and other high-wear surfaces to improve performance and efficiency.

- Quasicrystals in electromagnetic applications: The unique electronic properties of quasicrystals impact their use in electromagnetic applications. Their unusual band structure and electron transport characteristics make them suitable for use in antennas, electromagnetic shielding, and photonic devices. Quasicrystalline materials can be engineered to manipulate electromagnetic waves in novel ways, leading to advancements in communication technologies and electronic systems.

- Quasicrystals in thermal management: Quasicrystals have a significant impact on thermal management applications due to their unique thermal properties. Their low thermal conductivity and high thermal stability make them excellent candidates for thermal barrier coatings and heat management systems. These materials can be used in aerospace, automotive, and industrial applications to improve energy efficiency and protect components from extreme temperatures.

02 Quasicrystals in energy absorption and dissipation

The unique structure of quasicrystals contributes to their ability to absorb and dissipate energy effectively. This property makes them valuable in applications such as impact protection, vibration damping, and shock absorption. Quasicrystalline materials can be incorporated into composite structures or used as coatings to enhance the energy-absorbing capabilities of various products and systems.Expand Specific Solutions03 Quasicrystals in surface engineering and tribology

The impact of quasicrystals on surface engineering and tribology is significant due to their low friction and wear-resistant properties. These characteristics make them suitable for use in coatings and surface treatments to improve the performance and durability of mechanical components. Quasicrystalline materials can enhance the tribological properties of various surfaces, leading to reduced friction and increased wear resistance in industrial applications.Expand Specific Solutions04 Quasicrystals in electromagnetic applications

Quasicrystals have unique electromagnetic properties that impact their use in various applications. Their aperiodic structure can lead to interesting interactions with electromagnetic waves, making them potentially useful in antenna design, electromagnetic shielding, and photonic devices. The impact of quasicrystals in this field extends to the development of novel electromagnetic materials and components with enhanced performance characteristics.Expand Specific Solutions05 Quasicrystals in thermal management

The impact of quasicrystals on thermal management is notable due to their unique thermal properties. Their aperiodic structure can lead to low thermal conductivity, making them useful for thermal insulation applications. Additionally, quasicrystalline materials can exhibit interesting thermoelectric properties, potentially impacting the development of more efficient thermoelectric devices for energy harvesting and cooling applications.Expand Specific Solutions

Industry Leaders

The development of impactful quasicrystal-based prototypes is currently in an emerging phase, with the market size still relatively small but showing potential for growth. The technology is in its early stages of maturity, with research institutions like the National Institute for Materials Science IAI and universities such as Osaka University and Nanjing University leading the way. Companies like Toyoda Gosei Co., Ltd. and NGK Insulators, Ltd. are also exploring applications, indicating growing industrial interest. The competitive landscape is diverse, with a mix of academic, governmental, and corporate players collaborating and competing to advance the field. As the technology matures, we can expect increased commercialization efforts and potential breakthroughs in various applications.

National Institute for Materials Science IAI

Shanghai Institute of Microsystem & Information Technology

Key Quasicrystal Patents

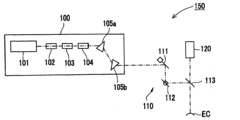

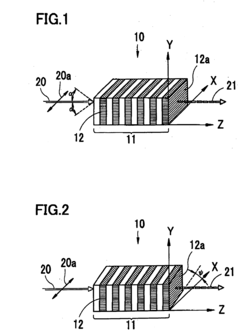

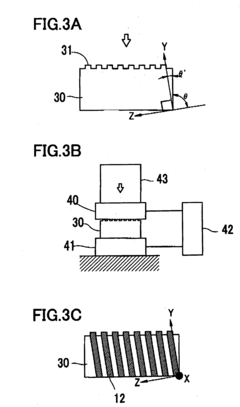

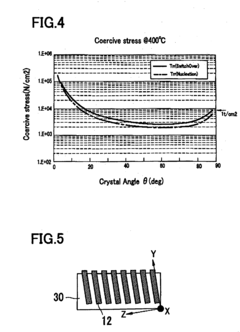

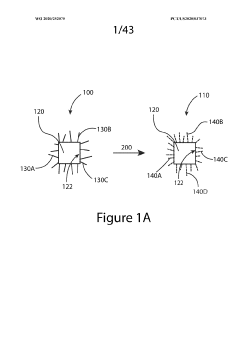

- A manufacturing method involving stress application to crystal quartz substrates at an angle of 60°<θ<90° relative to the Z axis, combined with temperature control between planes orthogonal to the stress direction, to induce periodic twins with interfaces in a plane containing the Y axis, allowing for high aspect ratio growth and improved control.

- The development of ligand-exchangeable Janus nanoparticles, where a nanocrystal core is coordinated with a first and second ligand, including functionalized aromatic molecules, allowing for the replacement of starting ligands with exchange ligands that have a ligand-ligand coupling energy less than -0.44 keT, enabling the modification of nanocrystal surfaces and properties.

Material Characterization

Material characterization is a crucial aspect of developing impactful quasicrystal-based prototypes. The unique atomic structure of quasicrystals necessitates specialized techniques to analyze their properties and behavior. X-ray diffraction (XRD) is a primary method used to confirm the quasicrystalline nature of a material, revealing the characteristic non-periodic but ordered patterns that distinguish quasicrystals from conventional crystals.

Transmission electron microscopy (TEM) plays a vital role in visualizing the atomic arrangement of quasicrystals. High-resolution TEM images can reveal the intricate patterns and symmetries that are hallmarks of quasicrystalline structures. This technique is particularly useful for identifying defects and grain boundaries, which can significantly impact the material's properties.

Scanning electron microscopy (SEM) is employed to examine the surface morphology and microstructure of quasicrystal samples. When coupled with energy-dispersive X-ray spectroscopy (EDS), it provides valuable information about the elemental composition and distribution within the material. This is essential for understanding the chemical homogeneity and potential impurities in quasicrystal prototypes.

Atomic force microscopy (AFM) offers insights into the surface topography of quasicrystals at the nanoscale. This technique is particularly useful for studying the growth mechanisms and surface properties of thin-film quasicrystal prototypes. AFM can also be used to investigate the mechanical properties of quasicrystals through nanoindentation experiments.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are employed to study the thermal stability and phase transitions of quasicrystals. These methods are crucial for determining the temperature ranges in which quasicrystal prototypes maintain their unique structure and properties.

Spectroscopic techniques, including Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), provide information about the vibrational modes and bonding characteristics of quasicrystals. These methods can offer insights into the local atomic environment and help identify any structural changes or impurities in the material.

Mechanical testing is essential for evaluating the performance of quasicrystal-based prototypes in potential applications. Hardness tests, tensile strength measurements, and wear resistance assessments are commonly performed to characterize the mechanical properties of quasicrystals. These tests are particularly important for developing quasicrystal coatings and bulk materials for structural applications.

Electrical and thermal conductivity measurements are crucial for understanding the transport properties of quasicrystals. These characteristics are often unique in quasicrystals, with some exhibiting low thermal conductivity combined with moderate electrical conductivity, making them potential candidates for thermoelectric applications.

Scalability Challenges

Scaling up quasicrystal-based prototypes presents significant challenges due to the unique structural properties of these materials. The aperiodic nature of quasicrystals, while offering novel properties, complicates traditional manufacturing processes. One primary obstacle is maintaining the quasicrystalline structure over larger scales without introducing defects or phase transitions. As the size of the prototype increases, the likelihood of structural imperfections also rises, potentially compromising the desired properties that make quasicrystals attractive for applications.

Another scalability challenge lies in the precise control of growth conditions required for quasicrystal formation. The delicate balance of temperature, pressure, and composition necessary for quasicrystal nucleation and growth becomes increasingly difficult to maintain uniformly across larger volumes. This can lead to inconsistencies in the final product, affecting performance and reliability.

The cost-effectiveness of scaling up quasicrystal production is also a significant concern. Many quasicrystals require rare or expensive elements, and the complex processing techniques needed for their synthesis can be resource-intensive. As production scales increase, optimizing material usage and streamlining manufacturing processes become crucial for economic viability.

Furthermore, the integration of quasicrystal-based components into larger systems poses its own set of challenges. The unique properties of quasicrystals, such as their unusual electronic and thermal behaviors, may not always align seamlessly with conventional materials used in surrounding structures. This mismatch can lead to interface issues and complicate the design of larger, more complex prototypes.

Quality control and characterization of large-scale quasicrystal prototypes present additional hurdles. Traditional analytical techniques may need to be adapted or entirely new methods developed to accurately assess the structure and properties of scaled-up quasicrystalline materials. Ensuring consistency and reproducibility across batches becomes increasingly challenging as production volumes grow.

Addressing these scalability challenges requires a multidisciplinary approach, combining advances in materials science, engineering, and manufacturing technologies. Innovations in growth techniques, such as improved flux methods or controlled solidification processes, may help overcome some of the structural limitations. Additionally, the development of novel composite materials that incorporate quasicrystalline phases could offer a pathway to scalable production while maintaining desirable properties.