How to Innovate with Quasicrystal Foams?

Quasicrystal Foam Background and Objectives

Quasicrystal foams represent a fascinating frontier in materials science, combining the unique properties of quasicrystals with the structural advantages of foam materials. The concept of quasicrystals, first discovered by Dan Shechtman in 1982, revolutionized our understanding of atomic arrangements in solids. These structures exhibit long-range order but lack periodicity, resulting in exceptional physical and chemical properties.

The development of quasicrystal foams aims to harness these unique characteristics in a porous, lightweight form. This innovative approach seeks to address various technological challenges across multiple industries, from aerospace to energy storage. The primary objective is to create materials that combine the strength, thermal stability, and low friction properties of quasicrystals with the low density and high surface area of foams.

Historically, the field of quasicrystal research has evolved from initial skepticism to widespread acceptance and exploration of practical applications. The progression from bulk quasicrystals to thin films and now to foam structures represents a natural evolution in the quest to optimize their properties for real-world use. This trajectory aligns with broader trends in materials science towards designing materials with tailored, multifunctional properties at various scales.

The current technological landscape presents both opportunities and challenges for quasicrystal foam innovation. Advances in manufacturing techniques, particularly in additive manufacturing and controlled solidification processes, have opened new avenues for creating complex quasicrystalline structures. Concurrently, the growing demand for high-performance materials in extreme environments, such as those encountered in space exploration or advanced energy systems, provides a compelling driving force for this research.

Key objectives in the development of quasicrystal foams include optimizing their mechanical properties, enhancing their thermal and electrical characteristics, and exploring their potential for catalysis and energy storage applications. Researchers aim to achieve a delicate balance between maintaining the unique quasicrystalline order at the atomic scale and controlling the macroscopic foam structure to tailor properties for specific applications.

As we look towards future innovations, the field of quasicrystal foams stands at the intersection of fundamental materials science and practical engineering challenges. The potential to create materials with unprecedented combinations of properties – such as ultra-low density coupled with high strength and thermal stability – promises to unlock new possibilities in fields ranging from aerospace to biomedical engineering. This research not only pushes the boundaries of our understanding of material structures but also offers tangible pathways to addressing some of the most pressing technological needs of our time.

Market Potential for Quasicrystal Foam Applications

Quasicrystal foams represent a novel class of materials with unique structural properties that offer significant potential across various industries. The market for these innovative materials is expected to grow substantially in the coming years, driven by their exceptional characteristics and diverse applications.

In the aerospace sector, quasicrystal foams show promise for lightweight structural components, thermal insulation, and impact absorption. Their high strength-to-weight ratio and thermal stability make them ideal candidates for next-generation aircraft and spacecraft designs. The global aerospace market, valued at over $300 billion, presents a substantial opportunity for quasicrystal foam integration.

The automotive industry is another key market for quasicrystal foam applications. As vehicle manufacturers strive for improved fuel efficiency and safety, these materials could be utilized in body panels, crash absorption systems, and noise reduction components. With the global automotive market projected to reach $9 trillion by 2030, even a small market share could translate to significant revenue potential.

In the construction sector, quasicrystal foams offer exciting possibilities for energy-efficient building materials. Their unique thermal and acoustic properties make them suitable for insulation, soundproofing, and structural reinforcement. The global construction market, expected to exceed $15 trillion by 2030, provides ample opportunities for quasicrystal foam integration in both residential and commercial applications.

The electronics industry could benefit from quasicrystal foams in thermal management solutions for high-performance computing and power electronics. As the demand for more powerful and compact electronic devices continues to grow, the need for advanced cooling solutions becomes increasingly critical. The global thermal management market, projected to reach $78 billion by 2025, represents a significant opportunity for quasicrystal foam technologies.

Medical applications of quasicrystal foams are also emerging, particularly in the field of orthopedic implants and tissue engineering scaffolds. Their biocompatibility and tailorable mechanical properties make them attractive for developing next-generation medical devices. The global orthopedic devices market, expected to reach $62 billion by 2027, offers substantial growth potential for quasicrystal foam-based innovations.

While the market potential for quasicrystal foam applications is promising, challenges such as high production costs and limited large-scale manufacturing capabilities need to be addressed. As research and development efforts continue to advance, and production processes become more refined, the commercial viability of quasicrystal foams is expected to improve significantly.

Current State and Challenges in Quasicrystal Foam Development

Quasicrystal foams represent a cutting-edge area of materials science that combines the unique properties of quasicrystals with the structural advantages of foam materials. The current state of quasicrystal foam development is characterized by significant progress in theoretical understanding and initial experimental successes, but also faces substantial challenges in practical implementation and large-scale production.

Recent advancements in quasicrystal research have provided a solid foundation for exploring their potential in foam structures. Quasicrystals, known for their aperiodic long-range order and forbidden symmetries, offer exceptional mechanical properties, low friction coefficients, and unique thermal and electrical characteristics. When integrated into foam structures, these properties could lead to materials with unprecedented combinations of strength, lightness, and functional capabilities.

However, the synthesis of quasicrystal foams remains a complex process. Current methods often involve rapid solidification techniques or complex alloying processes, which are difficult to control and scale up. The challenge lies in maintaining the quasicrystalline structure while achieving the desired foam morphology. Researchers are exploring various approaches, including powder metallurgy, melt infiltration, and additive manufacturing, to overcome these hurdles.

One of the primary obstacles in quasicrystal foam development is the inherent brittleness of many quasicrystalline materials. This characteristic limits their formability and makes it challenging to create stable foam structures without compromising the unique properties of the quasicrystals. Scientists are investigating ways to enhance the ductility of quasicrystalline materials or to develop composite systems that can mitigate this brittleness while preserving the desirable attributes of quasicrystals.

Another significant challenge is the control of foam cell size and distribution. The performance of quasicrystal foams heavily depends on their cellular structure, and achieving uniform, controllable pore sizes across large volumes remains difficult. This issue is compounded by the complex phase diagrams and narrow composition ranges required for quasicrystal formation.

The development of quasicrystal foams also faces economic challenges. The high cost of raw materials and complex processing requirements currently limit their commercial viability. Researchers are working on identifying more cost-effective quasicrystalline compositions and streamlining production methods to make these materials more accessible for industrial applications.

Despite these challenges, the potential applications of quasicrystal foams continue to drive research forward. Their unique combination of properties makes them promising candidates for aerospace components, thermal management systems, and high-performance structural materials. As research progresses, interdisciplinary collaboration between materials scientists, chemists, and engineers will be crucial in overcoming the current limitations and unlocking the full potential of quasicrystal foams.

Existing Quasicrystal Foam Fabrication Methods

01 Quasicrystalline structure in metal foams

Quasicrystalline structures can be incorporated into metal foams to enhance their properties. These structures, characterized by their non-periodic but ordered arrangement, can improve the foam's strength, thermal insulation, and wear resistance. The quasicrystalline phase can be introduced during the foam formation process or through post-processing treatments.- Quasicrystalline structure in metal foams: Quasicrystalline structures can be incorporated into metal foams to enhance their properties. These structures, characterized by their non-periodic but ordered arrangement, can improve the foam's strength, thermal insulation, and wear resistance. The quasicrystalline phase can be introduced during the foam formation process or through post-processing treatments.

- Manufacturing methods for quasicrystal foams: Various manufacturing techniques can be employed to produce quasicrystal foams. These may include powder metallurgy, melt infiltration, and gas injection methods. The choice of method depends on the desired foam properties and the specific quasicrystalline alloy composition. Control of processing parameters is crucial to achieve the desired quasicrystalline structure within the foam.

- Applications of quasicrystal foams: Quasicrystal foams find applications in various industries due to their unique properties. They can be used in lightweight structural components, thermal insulation materials, and energy absorption systems. The combination of low density and high strength makes them suitable for aerospace and automotive applications. Additionally, their unusual electronic properties may lead to novel uses in electronic devices.

- Composite materials incorporating quasicrystal foams: Quasicrystal foams can be integrated into composite materials to create hybrid structures with enhanced properties. These composites may combine the unique characteristics of quasicrystals with those of other materials, such as polymers or ceramics. The resulting materials can exhibit improved mechanical, thermal, and electrical properties, opening up new possibilities for advanced engineering applications.

- Surface modification of quasicrystal foams: The surface of quasicrystal foams can be modified to enhance specific properties or functionalities. Techniques such as coating, etching, or chemical treatment can be applied to alter the surface characteristics. These modifications can improve properties like corrosion resistance, wettability, or biocompatibility, expanding the potential applications of quasicrystal foams in various fields.

02 Manufacturing methods for quasicrystal foams

Various manufacturing techniques can be employed to produce quasicrystal foams. These may include powder metallurgy, melt infiltration, and gas injection methods. The choice of method depends on the desired foam properties and the specific quasicrystalline alloy composition. Control of processing parameters is crucial to achieve the desired quasicrystalline structure within the foam.Expand Specific Solutions03 Applications of quasicrystal foams

Quasicrystal foams find applications in various industries due to their unique properties. They can be used in lightweight structural components, thermal insulation materials, and energy absorption systems. The combination of low density and high strength makes them suitable for aerospace and automotive applications. Additionally, their thermal properties make them valuable in heat management systems.Expand Specific Solutions04 Composite materials incorporating quasicrystal foams

Quasicrystal foams can be integrated into composite materials to create hybrid structures with enhanced properties. These composites may combine the lightweight and thermal properties of quasicrystal foams with the strength and durability of other materials. Such composites can be tailored for specific applications, offering improved performance over traditional materials.Expand Specific Solutions05 Surface treatments and coatings for quasicrystal foams

Various surface treatments and coatings can be applied to quasicrystal foams to further enhance their properties or functionalities. These treatments may include oxidation resistance coatings, wear-resistant layers, or functionalized surfaces for specific applications. The coatings can be applied through methods such as physical vapor deposition, chemical vapor deposition, or electroplating.Expand Specific Solutions

Key Players in Quasicrystal Foam Research and Industry

The innovation landscape for quasicrystal foams is in its early stages, with the market still developing and showing potential for significant growth. The technology is at the intersection of materials science and nanotechnology, attracting interest from diverse industries. Companies like Dow Global Technologies LLC, BASF Corp., and Evonik Operations GmbH are leading research efforts, leveraging their expertise in advanced materials. The market size is expected to expand as applications in aerospace, automotive, and energy sectors emerge. While the technology is not yet fully mature, ongoing research by institutions like Shandong University and the Aerospace Materials and Technology Research Institute indicates rapid advancements. The competitive landscape is characterized by a mix of established chemical companies and specialized research institutions, each contributing to the evolving field of quasicrystal foam innovation.

Dow Global Technologies LLC

Evonik Operations GmbH

Core Innovations in Quasicrystal Foam Structures

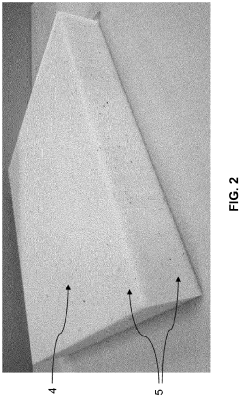

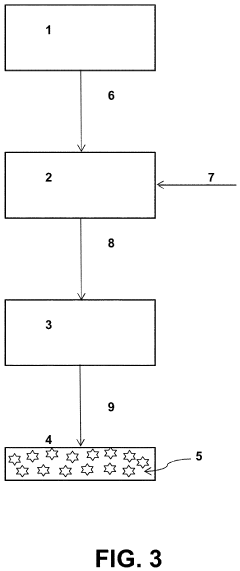

- A flexible foam made of expanded polymeric material, specifically polyurethane or latex, is developed to incorporate a mixture of bio-crystals like shungite, tourmaline, and quartz, which are dispersed within the foam's cellular structure to adhere to its walls, allowing the invigorating influence to be transmitted to the body.

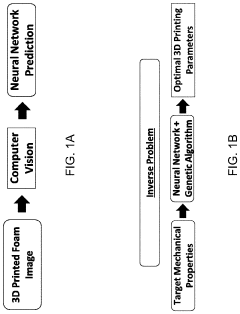

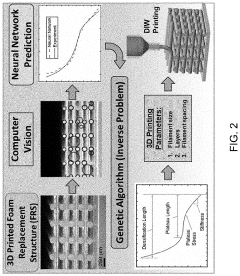

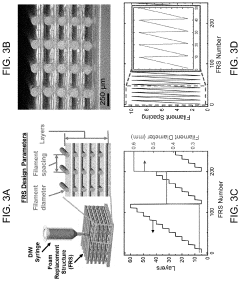

- A method using artificial neural networks (ANNs) and genetic algorithms (GAs) in conjunction with computer vision to predict and design the mechanical response of 3D printed foam replacement structures, allowing for rapid prediction of mechanical properties and optimization of printing parameters to achieve target mechanical responses.

Material Properties and Characterization Techniques

Quasicrystal foams represent a novel class of materials with unique structural and functional properties. These materials combine the aperiodic order of quasicrystals with the lightweight and porous nature of foams, resulting in a complex material system that requires specialized characterization techniques to fully understand and optimize their properties.

The mechanical properties of quasicrystal foams are of particular interest due to their potential applications in lightweight structural components. These foams exhibit a combination of high strength-to-weight ratio and enhanced energy absorption capabilities. The quasi-periodic arrangement of atoms in the foam structure contributes to their unique deformation behavior, which can be characterized through compression and tensile testing. Additionally, nanoindentation techniques can provide insights into the local mechanical properties and hardness distribution within the foam structure.

Thermal properties of quasicrystal foams are another critical area of investigation. These materials often display low thermal conductivity due to their complex atomic arrangement, making them potential candidates for thermal insulation applications. Thermal conductivity measurements, along with differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), can provide valuable information about the thermal stability and phase transitions in quasicrystal foams.

The surface properties of quasicrystal foams play a crucial role in their potential applications, such as catalysis and filtration. Surface area and porosity measurements using techniques like Brunauer-Emmett-Teller (BET) analysis and mercury porosimetry can reveal the intricate pore structure and surface characteristics of these materials. Additionally, X-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM) can provide insights into the surface chemistry and topography of quasicrystal foams.

Structural characterization of quasicrystal foams is essential for understanding their unique properties. X-ray diffraction (XRD) techniques, including both conventional and synchrotron-based methods, are crucial for analyzing the quasi-periodic atomic arrangement. Transmission electron microscopy (TEM) and scanning electron microscopy (SEM) can provide high-resolution imaging of the foam structure, revealing the intricate patterns and defects that contribute to their properties.

Advanced spectroscopic techniques, such as Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), can offer valuable information about the chemical bonding and local atomic environment in quasicrystal foams. These methods can help identify the presence of specific structural motifs and provide insights into the formation mechanisms of quasicrystalline phases within the foam structure.

Potential Applications across Industries

Quasicrystal foams represent a frontier in materials science with vast potential for innovation across various industries. In the aerospace sector, these unique structures offer promising applications in lightweight yet robust components for aircraft and spacecraft. Their exceptional strength-to-weight ratio and thermal insulation properties make them ideal candidates for heat shields and structural elements in extreme environments.

The automotive industry stands to benefit significantly from quasicrystal foams. These materials could revolutionize vehicle design by enabling the creation of lighter, more fuel-efficient cars without compromising safety. Their energy-absorbing capabilities make them excellent candidates for impact-resistant parts, potentially enhancing passenger protection in collisions.

In the field of energy, quasicrystal foams show promise for improving the efficiency of solar panels and fuel cells. Their unique atomic arrangements could lead to enhanced electron transport and catalytic properties, potentially boosting the performance of renewable energy technologies. Additionally, their thermal management capabilities could find applications in advanced battery systems and heat exchangers.

The construction industry could leverage quasicrystal foams to develop superior insulation materials for buildings. Their low thermal conductivity and fire-resistant properties make them attractive for creating energy-efficient and safer structures. Moreover, their acoustic damping characteristics could be utilized in noise reduction applications for urban environments.

In the biomedical field, quasicrystal foams offer intriguing possibilities for implant materials and drug delivery systems. Their biocompatibility and controllable porosity could enable the development of scaffolds for tissue engineering and customized drug release mechanisms. The unique surface properties of quasicrystals may also lead to innovations in antimicrobial coatings for medical devices.

The electronics industry could harness quasicrystal foams for next-generation cooling solutions in high-performance computing systems. Their thermal management capabilities and lightweight nature make them ideal for dissipating heat in compact electronic devices, potentially enabling further miniaturization and increased processing power.

Lastly, the sports and recreation sector could benefit from quasicrystal foams in the development of advanced protective gear and high-performance equipment. Their energy-absorbing properties could enhance the safety of helmets and body armor, while their lightweight nature could contribute to the creation of more efficient sports equipment, from bicycles to tennis rackets.