Quasicrystal Innovations in Wear-Resistant Materials

Quasicrystal Evolution

The evolution of quasicrystals in wear-resistant materials represents a fascinating journey of scientific discovery and technological innovation. This unique class of materials, first discovered in 1982 by Dan Shechtman, has undergone significant development over the past four decades.

In the early stages, quasicrystals were primarily a subject of theoretical interest, challenging the conventional understanding of crystalline structures. The initial focus was on understanding their atomic arrangements and unique properties. As research progressed, scientists began to recognize the potential of quasicrystals for practical applications, particularly in wear-resistant materials.

The 1990s marked a turning point in quasicrystal research, with increased efforts to synthesize and characterize these materials. Researchers explored various alloy systems, including Al-Cu-Fe and Ti-Zr-Ni, to create stable quasicrystalline structures. This period saw the development of bulk quasicrystals and quasicrystal-reinforced composites, laying the groundwork for their application in wear-resistant coatings.

By the early 2000s, the focus shifted towards optimizing the production processes and enhancing the mechanical properties of quasicrystalline materials. Advances in rapid solidification techniques and powder metallurgy enabled the creation of more uniform and stable quasicrystalline structures. This led to improved wear resistance and hardness, making quasicrystals increasingly attractive for industrial applications.

The past decade has witnessed a surge in research on quasicrystal-based coatings for wear-resistant applications. Scientists have developed novel deposition techniques, such as thermal spraying and physical vapor deposition, to create thin films of quasicrystalline materials on various substrates. These coatings have shown exceptional wear resistance, low friction coefficients, and high hardness, outperforming many traditional wear-resistant materials.

Recent innovations have focused on creating hybrid materials that combine quasicrystals with other advanced materials. For instance, quasicrystal-reinforced metal matrix composites have shown promise in applications requiring both wear resistance and structural integrity. Additionally, researchers have explored the potential of quasicrystalline materials in additive manufacturing, opening new avenues for creating complex, wear-resistant components.

Looking ahead, the evolution of quasicrystals in wear-resistant materials is likely to continue along several promising paths. These include the development of new quasicrystalline alloys with enhanced properties, the optimization of coating technologies for large-scale industrial applications, and the exploration of quasicrystal-based nanomaterials for advanced wear-resistant solutions. As our understanding of these unique materials deepens, their role in wear-resistant applications is expected to expand, potentially revolutionizing industries ranging from automotive to aerospace.

Market for Wear-Resistant Materials

The market for wear-resistant materials has been experiencing significant growth due to increasing demand across various industries. These materials are crucial in applications where surfaces are subjected to high levels of friction, abrasion, and wear, such as in automotive, aerospace, manufacturing, and mining sectors. The global wear-resistant materials market is projected to expand at a compound annual growth rate (CAGR) of over 6% in the coming years, driven by the need for improved durability and performance in industrial equipment and components.

Quasicrystals, with their unique atomic structure and properties, are emerging as a promising innovation in the field of wear-resistant materials. Their potential to enhance wear resistance while maintaining other desirable properties has attracted considerable attention from both researchers and industry players. The market for quasicrystal-based wear-resistant materials is still in its nascent stage but shows promising growth prospects as more applications are discovered and developed.

Key market segments for wear-resistant materials include coatings, bulk materials, and composite materials. Coatings represent the largest segment, with applications in cutting tools, engine components, and industrial machinery. The bulk materials segment is growing rapidly, particularly in the mining and construction industries, where heavy-duty equipment requires exceptional wear resistance. Composite materials, incorporating quasicrystalline structures, are gaining traction in aerospace and automotive applications due to their lightweight nature combined with superior wear resistance.

Geographically, Asia-Pacific dominates the wear-resistant materials market, followed by North America and Europe. The rapid industrialization and infrastructure development in countries like China and India are driving the demand for wear-resistant materials in the Asia-Pacific region. North America and Europe, with their established manufacturing and automotive industries, continue to be significant markets for advanced wear-resistant solutions, including those based on quasicrystal innovations.

The market is characterized by intense competition among key players, including multinational corporations and specialized materials companies. These companies are investing heavily in research and development to create novel wear-resistant materials that can outperform traditional options. The introduction of quasicrystal-based materials is expected to disrupt the market, potentially leading to new product categories and applications.

Customer demand in the wear-resistant materials market is increasingly focused on materials that can withstand extreme conditions while offering additional benefits such as reduced weight, improved thermal stability, and enhanced corrosion resistance. This trend aligns well with the properties offered by quasicrystal-based materials, positioning them as a promising solution to meet evolving market needs.

Quasicrystal Challenges

Despite the promising potential of quasicrystals in wear-resistant materials, several significant challenges hinder their widespread adoption and practical implementation. One of the primary obstacles is the difficulty in synthesizing large-scale, high-quality quasicrystalline materials. The complex atomic structure of quasicrystals requires precise control over composition and processing conditions, making mass production challenging and cost-prohibitive.

Another major hurdle is the inherent brittleness of many quasicrystalline materials. While they exhibit excellent hardness and wear resistance, their lack of ductility limits their application in scenarios where impact resistance or flexibility is required. This brittleness also complicates the manufacturing process, as traditional forming and shaping techniques may lead to fractures or defects in the material.

The stability of quasicrystals under various environmental conditions poses another challenge. Some quasicrystalline structures may undergo phase transformations or decomposition at elevated temperatures or under certain chemical environments, potentially compromising their wear-resistant properties. This instability limits their use in high-temperature applications or corrosive environments.

Furthermore, the integration of quasicrystals into existing material systems and manufacturing processes presents significant technical difficulties. Developing effective methods for bonding quasicrystalline coatings to substrates or incorporating quasicrystalline phases into composite materials requires extensive research and development.

The lack of comprehensive understanding of the structure-property relationships in quasicrystals also impedes their optimization for specific wear-resistant applications. The unique atomic arrangements in quasicrystals lead to complex and often counterintuitive material behaviors, making it challenging to predict and tailor their properties for specific use cases.

Lastly, the economic viability of quasicrystal-based wear-resistant materials remains a significant challenge. The high production costs, coupled with the technical difficulties in processing and application, currently limit their competitiveness against more conventional wear-resistant materials. Overcoming these economic barriers requires not only technological advancements but also the development of cost-effective production methods and the identification of high-value applications where the unique properties of quasicrystals can justify their premium cost.

Current Quasicrystal Solutions

01 Quasicrystalline coatings for wear resistance

Quasicrystalline materials can be applied as coatings to enhance wear resistance of various surfaces. These coatings exhibit unique structural properties that contribute to improved hardness and reduced friction, making them ideal for applications requiring high wear resistance.- Quasicrystalline coatings for wear resistance: Quasicrystalline materials can be applied as coatings to enhance wear resistance of various substrates. These coatings exhibit unique structural properties that contribute to improved hardness and reduced friction, making them ideal for applications requiring high wear resistance.

- Quasicrystal-reinforced composite materials: Incorporating quasicrystalline particles or phases into composite materials can significantly improve their wear resistance. These composites combine the unique properties of quasicrystals with the benefits of matrix materials, resulting in enhanced durability and performance in high-wear applications.

- Surface modification techniques for quasicrystals: Various surface modification techniques can be applied to quasicrystalline materials to further enhance their wear resistance. These may include heat treatments, ion implantation, or surface alloying, which can alter the surface properties and microstructure to optimize wear performance.

- Quasicrystalline alloys for wear-resistant applications: Specific alloy compositions can be designed to form quasicrystalline structures with superior wear resistance. These alloys often contain elements such as aluminum, copper, and transition metals, and can be tailored for various applications requiring high wear resistance and low friction.

- Manufacturing processes for wear-resistant quasicrystalline materials: Advanced manufacturing processes, such as rapid solidification, powder metallurgy, or additive manufacturing, can be employed to produce quasicrystalline materials with enhanced wear resistance. These processes allow for precise control over the material's structure and properties, optimizing their performance in wear-resistant applications.

02 Quasicrystal-reinforced composite materials

Composite materials incorporating quasicrystalline particles or phases can significantly improve wear resistance. These composites combine the unique properties of quasicrystals with other materials to create robust, wear-resistant structures suitable for various industrial applications.Expand Specific Solutions03 Surface treatment techniques for quasicrystals

Various surface treatment methods can be applied to quasicrystalline materials to further enhance their wear resistance. These techniques may include heat treatments, ion implantation, or surface alloying, which can modify the surface properties of quasicrystals to optimize their wear performance.Expand Specific Solutions04 Quasicrystalline alloys for wear-resistant applications

Specific alloy compositions can be designed to form quasicrystalline structures with enhanced wear resistance. These alloys often include elements such as aluminum, copper, and transition metals, and can be tailored for particular wear-resistant applications in industries like aerospace and automotive.Expand Specific Solutions05 Nanostructured quasicrystals for improved wear resistance

Nanostructured quasicrystalline materials can offer superior wear resistance compared to their bulk counterparts. The nanoscale features of these materials can lead to enhanced hardness, toughness, and wear resistance, making them suitable for demanding tribological applications.Expand Specific Solutions

Key Quasicrystal Innovators

The field of quasicrystal innovations in wear-resistant materials is in a nascent stage of development, with significant potential for growth. The market size is expanding as industries recognize the unique properties of quasicrystals for enhancing material durability. While the technology is still evolving, several key players are making strides in research and application. Companies like Sumitomo Electric Industries, Baker Hughes, and Kennametal are at the forefront, leveraging their expertise in materials science. Academic institutions such as Xi'an University of Technology and Sichuan University are contributing to fundamental research. The technology's maturity varies across applications, with some sectors seeing early commercial adoption while others remain in the experimental phase.

Baker Hughes Co.

Sumitomo Electric Industries Ltd.

Breakthrough Quasicrystal Patents

- A thermally sprayed coating with a quasicrystal-containing alloy composition of 10-45 Cu, 7-22 Fe, 0-30 Cr, 0-30 Co, 0-20 Ni, 0-7.5 W, and balance aluminum, with less than 30% ψ phase and at least 65% δ phase, applied subsonically to achieve reduced macrohardness and enhanced bond strength, incorporating chromium or cobalt for corrosion resistance.

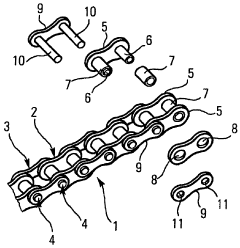

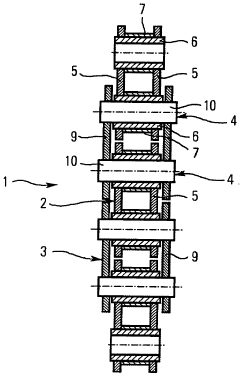

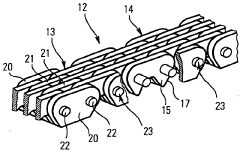

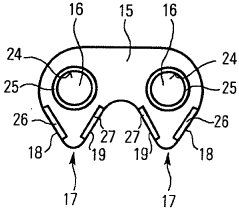

- A wear-resistant chain with at least partially nanocrystalline anti-wear coatings applied to chain joints and links, featuring nanocrystals embedded in an amorphous matrix, providing increased hardness and reduced friction, and comprising materials like ta-C, Si-doped DLC, nitridic nano-coatings, and metal matrices, which enhance wear resistance and thermal stability.

Manufacturing Processes

The manufacturing processes for quasicrystal-based wear-resistant materials involve several sophisticated techniques that leverage the unique properties of these materials. One primary method is rapid solidification, which is essential for creating the metastable quasicrystalline structure. This process typically involves melt spinning or gas atomization, where molten alloys are rapidly cooled at rates exceeding 10^6 K/s. The resulting quasicrystalline powders or ribbons serve as the base material for further processing.

Powder metallurgy techniques are commonly employed to consolidate quasicrystalline powders into bulk materials. This involves hot isostatic pressing (HIP) or spark plasma sintering (SPS), which allow for the preservation of the quasicrystalline structure while achieving near-full density. These methods are particularly advantageous as they minimize grain growth and maintain the material's wear-resistant properties.

Surface coating applications often utilize thermal spraying techniques, such as plasma spraying or high-velocity oxy-fuel (HVOF) spraying. These methods enable the deposition of quasicrystalline coatings on various substrates, enhancing their wear resistance. The process parameters, including particle size, spray distance, and temperature, are carefully controlled to ensure optimal coating adhesion and microstructure.

For bulk quasicrystalline materials, innovative forming techniques have been developed to overcome their inherent brittleness at room temperature. These include hot extrusion and equal channel angular pressing (ECAP), which can improve ductility while maintaining the quasicrystalline structure. Additionally, selective laser melting (SLM) has emerged as a promising additive manufacturing technique for producing complex quasicrystalline components with tailored properties.

Post-processing treatments play a crucial role in optimizing the performance of quasicrystalline wear-resistant materials. Heat treatments are often employed to relieve internal stresses and promote phase stability. Surface finishing techniques, such as polishing or shot peening, can further enhance wear resistance by improving surface roughness and inducing beneficial residual stresses.

The manufacturing of quasicrystal-based composites represents another frontier in wear-resistant materials. These composites typically combine quasicrystalline phases with conventional crystalline matrices, leveraging the strengths of both materials. In-situ synthesis methods, where quasicrystalline phases are formed during the solidification of a melt, have shown promise in producing homogeneous composites with enhanced wear resistance.

Environmental Impact

The environmental impact of quasicrystal innovations in wear-resistant materials is a critical aspect to consider as these materials gain prominence in various industries. Quasicrystals, with their unique atomic structure and properties, offer potential benefits in terms of sustainability and reduced environmental footprint compared to traditional wear-resistant materials.

One of the primary environmental advantages of quasicrystal-based wear-resistant materials is their potential to extend the lifespan of components and machinery. By providing superior wear resistance, these materials can significantly reduce the frequency of replacements and repairs, thereby minimizing waste generation and resource consumption. This longevity factor contributes to a more sustainable approach in manufacturing and industrial applications.

The production processes for quasicrystal materials often require less energy compared to conventional wear-resistant materials. This energy efficiency translates to reduced carbon emissions and a lower overall environmental impact during the manufacturing phase. Additionally, the unique properties of quasicrystals allow for the development of thinner and lighter components, potentially leading to weight reduction in various applications, such as automotive and aerospace industries. This weight reduction can contribute to improved fuel efficiency and decreased emissions in transportation sectors.

Quasicrystal-based materials also show promise in reducing the use of harmful substances commonly found in traditional wear-resistant coatings. Many conventional coatings contain toxic elements or compounds that can pose environmental risks during production, use, and disposal. Quasicrystals offer an alternative that may be less harmful to ecosystems and human health, aligning with global efforts to reduce the use of hazardous materials in industrial processes.

The recyclability of quasicrystal materials is another important environmental consideration. While research in this area is ongoing, early indications suggest that these materials may be more easily recyclable than some traditional wear-resistant materials. This potential for improved recyclability could lead to a more circular economy approach in material usage, reducing the demand for raw materials and minimizing waste sent to landfills.

However, it is important to note that the environmental impact of quasicrystal innovations is not entirely positive. The production of these materials may involve rare or specialized elements, which could have their own environmental implications in terms of mining and processing. Additionally, as a relatively new technology, the long-term environmental effects of widespread quasicrystal use are not yet fully understood and require further study.

In conclusion, while quasicrystal innovations in wear-resistant materials show promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand their ecological footprint. As research and development in this field progress, it will be crucial to balance the potential environmental advantages with any unforeseen impacts to ensure a truly sustainable technological advancement.