Quasicrystal: Enabling Breakthroughs in Electronic Devices

Quasicrystal Evolution and Research Objectives

Quasicrystals, discovered in 1982 by Dan Shechtman, represent a revolutionary class of materials that challenge traditional crystallography. These structures exhibit long-range order but lack periodicity, a property once thought impossible in solid matter. The evolution of quasicrystal research has been marked by significant milestones, from initial skepticism to widespread acceptance and exploration of their unique properties.

The field has progressed through several key phases. Initially, researchers focused on understanding the fundamental structure and formation mechanisms of quasicrystals. This was followed by the discovery of various types of quasicrystals, including icosahedral, decagonal, and dodecagonal symmetries. As understanding deepened, attention shifted to exploring the physical and chemical properties of these materials.

Recent years have seen a surge in interest in the potential applications of quasicrystals, particularly in electronic devices. Their unique electronic structure, resulting from their aperiodic arrangement of atoms, offers intriguing possibilities for novel electronic properties. This has led to research objectives aimed at harnessing these properties for technological advancements.

One primary research goal is to develop quasicrystalline materials with enhanced electronic characteristics. This includes exploring their potential as semiconductors with unique band structures, which could lead to more efficient electronic components. Another objective is to investigate the use of quasicrystals in photonic devices, leveraging their distinctive light interaction properties.

Researchers are also focusing on the integration of quasicrystals into existing electronic technologies. This involves studying methods to grow high-quality quasicrystalline thin films and developing techniques to incorporate these materials into conventional device architectures. The aim is to create hybrid systems that combine the advantages of quasicrystals with traditional electronic materials.

A significant research direction is the exploration of quantum effects in quasicrystalline structures. The unique electron behavior in these materials could potentially be exploited for quantum computing applications, presenting an exciting frontier in quasicrystal research.

As the field progresses, there is a growing emphasis on computational modeling and simulation of quasicrystalline structures. These tools are crucial for predicting and understanding the behavior of quasicrystals at the atomic level, guiding experimental research, and accelerating the development of practical applications.

The overarching goal of current quasicrystal research is to bridge the gap between fundamental understanding and practical implementation. By focusing on these research objectives, scientists and engineers aim to unlock the full potential of quasicrystals, potentially revolutionizing electronic device technology and opening new avenues in materials science and engineering.

Electronic Device Market Demand Analysis

The electronic device market has witnessed significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. The potential application of quasicrystals in electronic devices presents a promising avenue for further market expansion and innovation.

The global electronic devices market is projected to continue its upward trajectory, with a particular focus on smartphones, tablets, wearables, and IoT devices. Consumer demand for faster, more efficient, and multifunctional devices is a key driver of market growth. The integration of quasicrystal technology could potentially address these demands by enhancing device performance and capabilities.

In the smartphone segment, which dominates the electronic device market, consumers are increasingly seeking devices with improved processing power, longer battery life, and enhanced display quality. Quasicrystals' unique electronic properties could potentially contribute to the development of more energy-efficient processors and improved display technologies, aligning with these market demands.

The wearable technology sector, including smartwatches and fitness trackers, is experiencing rapid growth. These devices require compact, energy-efficient components that can perform multiple functions. Quasicrystals' potential to improve electronic conductivity and thermal management could be particularly beneficial in this segment, potentially leading to smaller, more powerful wearable devices.

The Internet of Things (IoT) market is another area where quasicrystal technology could have a significant impact. As the number of connected devices continues to grow, there is an increasing need for components that can handle complex data processing while maintaining energy efficiency. Quasicrystals' unique electronic properties could potentially address these requirements, driving further growth in the IoT sector.

In the consumer electronics market, there is a growing demand for devices with improved durability and resistance to environmental factors. Quasicrystals' potential applications in creating more robust and corrosion-resistant materials could meet this market need, particularly in devices designed for outdoor or harsh environments.

The automotive industry, which is increasingly integrating advanced electronic systems, represents another potential market for quasicrystal-based technologies. As vehicles become more connected and autonomous, there is a growing demand for sophisticated sensors and processing units. Quasicrystals could potentially contribute to the development of more efficient and reliable automotive electronic systems.

However, it's important to note that the market demand for quasicrystal-based electronic devices is still speculative. The technology is in its early stages of research and development, and its practical applications in consumer electronics are yet to be fully realized. The market's receptiveness to quasicrystal-based devices will depend on the technology's ability to deliver tangible benefits in terms of performance, cost-effectiveness, and reliability compared to existing solutions.

Quasicrystal Technology Status and Challenges

Quasicrystals, discovered in 1982 by Dan Shechtman, have revolutionized our understanding of solid-state physics and crystallography. These unique structures exhibit long-range order but lack periodicity, challenging conventional crystallographic principles. Over the past four decades, significant progress has been made in understanding quasicrystals, yet numerous challenges persist in their application to electronic devices.

The current state of quasicrystal technology is characterized by a growing body of theoretical knowledge and experimental techniques. Researchers have successfully synthesized various quasicrystalline materials, including alloys of aluminum, copper, and iron. Advanced imaging techniques, such as high-resolution transmission electron microscopy and atomic force microscopy, have enabled detailed structural analysis of these materials.

One of the primary challenges in quasicrystal research is the controlled synthesis of large, high-quality samples. While small quasicrystals can be produced reliably, scaling up production for practical applications remains difficult. This limitation hinders the integration of quasicrystals into electronic devices on a commercial scale.

Another significant challenge lies in understanding and manipulating the electronic properties of quasicrystals. Their unique atomic arrangements result in complex electronic structures that are not fully understood. This lack of comprehensive knowledge impedes the development of quasicrystal-based electronic components with predictable and controllable properties.

The potential of quasicrystals in electronic devices is further constrained by difficulties in interfacing them with conventional materials. Creating stable and efficient interfaces between quasicrystalline and periodic structures is crucial for device fabrication but remains a significant technical hurdle.

Geographically, quasicrystal research is distributed across several countries, with notable contributions from the United States, Japan, Germany, and China. Each region focuses on different aspects of quasicrystal technology, from fundamental physics to potential applications in electronics and materials science.

Despite these challenges, recent advancements have shown promise. Researchers have made progress in understanding the formation mechanisms of quasicrystals, which could lead to improved synthesis methods. Additionally, novel applications in areas such as thermoelectric materials and surface coatings have emerged, demonstrating the versatility of quasicrystalline structures.

The field of quasicrystal research is at a critical juncture. While significant progress has been made in understanding these materials, translating this knowledge into practical electronic applications remains a formidable challenge. Overcoming these obstacles will require interdisciplinary collaboration and continued investment in both fundamental research and applied technology development.

Current Quasicrystal Integration Methods

01 Quasicrystal structure and composition

Quasicrystals are unique materials with aperiodic atomic structures that exhibit long-range order but lack translational symmetry. They are typically composed of metallic alloys and possess unusual physical properties. The composition and structure of quasicrystals are crucial for their formation and stability.- Quasicrystal structure and composition: Quasicrystals are unique materials with aperiodic atomic structures that exhibit long-range order but lack translational symmetry. They often contain aluminum and transition metals, forming complex alloys with unusual properties. The composition and structure of quasicrystals are crucial for their unique characteristics and potential applications.

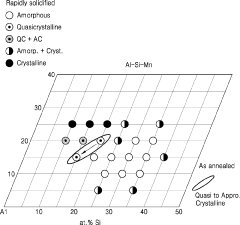

- Manufacturing methods for quasicrystals: Various techniques are employed to produce quasicrystals, including rapid solidification, melt spinning, and vapor deposition. These methods aim to create the specific conditions necessary for quasicrystal formation, often involving precise control of cooling rates and composition. Advanced manufacturing processes can lead to improved quality and larger-scale production of quasicrystalline materials.

- Applications of quasicrystals in coatings and surface treatments: Quasicrystals find applications in coatings and surface treatments due to their unique properties such as low friction, high hardness, and corrosion resistance. They can be used to enhance the performance of various materials and components in industries such as automotive, aerospace, and manufacturing.

- Quasicrystal-based composites and alloys: Researchers are developing new composites and alloys incorporating quasicrystalline phases to create materials with enhanced properties. These materials can combine the unique characteristics of quasicrystals with those of traditional crystalline materials, leading to improved mechanical, thermal, and electrical properties for various applications.

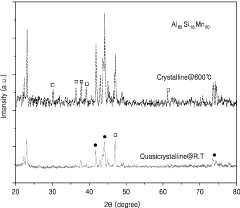

- Characterization and analysis techniques for quasicrystals: Advanced characterization and analysis techniques are essential for studying the complex structure and properties of quasicrystals. These methods include electron microscopy, X-ray diffraction, and spectroscopic techniques, which help researchers understand the unique atomic arrangements and physical properties of quasicrystalline materials.

02 Manufacturing methods for quasicrystals

Various techniques are employed to produce quasicrystals, including rapid solidification, melt spinning, and vapor deposition. These methods often involve precise control of cooling rates and composition to achieve the desired quasicrystalline structure. Advanced manufacturing processes can enhance the quality and yield of quasicrystals.Expand Specific Solutions03 Applications of quasicrystals

Quasicrystals find applications in diverse fields due to their unique properties. They are used in non-stick coatings, thermal barriers, and hydrogen storage materials. Their low friction and wear resistance make them suitable for mechanical components. Quasicrystals also show promise in electronic and optical applications.Expand Specific Solutions04 Characterization and analysis of quasicrystals

Advanced analytical techniques are employed to study the structure and properties of quasicrystals. These include electron microscopy, X-ray diffraction, and neutron scattering. Computational methods and simulations are also used to understand the complex arrangements of atoms in quasicrystals and predict their behavior.Expand Specific Solutions05 Novel quasicrystal compositions and alloys

Research continues to explore new compositions and alloys that can form quasicrystals. This includes the development of multi-component systems and the incorporation of rare earth elements. Novel quasicrystalline materials with enhanced properties or stability are being investigated for potential industrial applications.Expand Specific Solutions

Key Players in Quasicrystal Research and Applications

The research on quasicrystals for electronic devices is in an emerging stage, with significant potential for market growth. The technology is still in its early phases of development, indicating a relatively low maturity level. However, the involvement of major players like Samsung Electronics Co., Ltd. and LG Electronics, Inc. suggests growing industry interest. Academic institutions such as Massachusetts Institute of Technology and the University of California are driving fundamental research, while companies like Universal Display Corp. and Nanoco Technologies Ltd. are exploring practical applications. The market size is currently limited but expected to expand as the technology matures. Collaboration between academia and industry is crucial for advancing quasicrystal applications in electronic devices, with potential breakthroughs on the horizon.

Samsung Electronics Co., Ltd.

Massachusetts Institute of Technology

Breakthrough Quasicrystal Patents and Publications

- A polyhedral quasicrystalline material with long-range translational order and rotational symmetry is used in the phase change layer, enabling phase transitions between quasi-crystalline and crystalline states with minimal energy change, allowing for fast phase transitions.

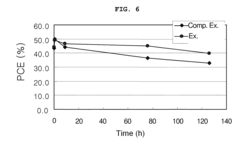

- A nanocrystal composite is developed, incorporating semiconductor nanocrystals, a matrix material, and a radical scavenger positioned between the nanocrystals and the matrix, which can be either surrounding or coating the nanocrystals, selected from compounds like piperidine, hydroxylamine, lactone, benzophenone, and benzotriazole, to neutralize or inhibit radical reactions.

Material Properties and Characterization Techniques

Quasicrystals represent a unique class of materials with aperiodic long-range order, exhibiting remarkable properties that set them apart from traditional crystalline and amorphous structures. The material properties of quasicrystals are intrinsically linked to their complex atomic arrangements, which give rise to a range of unusual physical, chemical, and electronic characteristics.

One of the most distinctive features of quasicrystals is their high electrical resistivity, which can be several orders of magnitude greater than that of their crystalline counterparts. This property is attributed to the presence of localized electronic states and the absence of extended Bloch waves typically found in periodic crystals. The unique electronic structure of quasicrystals also leads to interesting thermoelectric properties, making them potential candidates for thermoelectric applications.

Quasicrystals exhibit exceptional hardness and low friction coefficients, often surpassing those of many conventional alloys. These mechanical properties are attributed to their complex atomic structure, which inhibits dislocation movement and plastic deformation. Additionally, quasicrystals demonstrate low thermal conductivity, high oxidation resistance, and unique surface properties, such as non-stick behavior and low wettability.

Characterization of quasicrystals requires a combination of advanced techniques due to their complex structure. X-ray diffraction (XRD) and electron diffraction are essential for identifying the quasicrystalline nature of these materials, revealing their characteristic non-crystallographic rotational symmetries. High-resolution transmission electron microscopy (HRTEM) provides direct imaging of the quasiperiodic atomic arrangements, allowing for detailed structural analysis.

Scanning tunneling microscopy (STM) and atomic force microscopy (AFM) are valuable tools for investigating the surface structure and local electronic properties of quasicrystals. These techniques can reveal the presence of unique surface features, such as pseudo-Mackay clusters, and provide insights into the local density of states.

Spectroscopic methods, including X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy, are employed to study the electronic structure and vibrational properties of quasicrystals. These techniques can provide information on the chemical bonding and local atomic environments within the quasicrystalline structure.

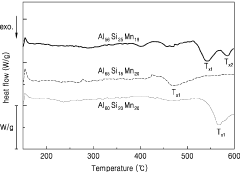

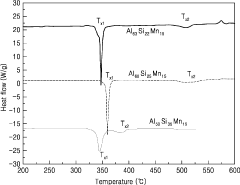

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are crucial for investigating the thermal stability and phase transitions of quasicrystals. These methods can reveal important information about the formation and decomposition of quasicrystalline phases, as well as their behavior under different temperature conditions.

As research on quasicrystals continues to advance, new characterization techniques are being developed and refined to better understand their unique properties and structure. These include advanced synchrotron-based methods, such as resonant X-ray scattering and X-ray absorption spectroscopy, which offer unprecedented insights into the electronic and magnetic properties of quasicrystals at the atomic scale.

Quasicrystal Manufacturing Processes and Scalability

The manufacturing processes and scalability of quasicrystals present unique challenges and opportunities in the field of electronic devices. Traditional crystal growth methods, such as Czochralski or Bridgman techniques, are not directly applicable to quasicrystals due to their aperiodic structure. Instead, researchers have developed specialized techniques to produce high-quality quasicrystalline materials.

One of the primary methods for quasicrystal synthesis is rapid solidification, which involves quickly cooling a molten alloy to form the desired quasicrystalline phase. This technique can be implemented through melt spinning or gas atomization processes. Melt spinning, in particular, has shown promise in producing thin ribbons of quasicrystalline materials with consistent properties.

Another approach is the flux growth method, where quasicrystals are grown from a molten metal solution. This technique allows for the formation of larger, more perfect quasicrystals, albeit at a slower rate compared to rapid solidification. Flux growth has been successfully used to produce icosahedral quasicrystals of various compositions, including Al-Cu-Fe and Zn-Mg-Ho systems.

Physical vapor deposition (PVD) techniques, such as molecular beam epitaxy (MBE) and sputtering, have also been employed to create thin films of quasicrystalline materials. These methods offer precise control over composition and thickness, making them particularly suitable for electronic device applications. However, scaling up PVD processes for large-area production remains a challenge.

Scalability of quasicrystal manufacturing is a critical factor in their potential adoption for electronic devices. While laboratory-scale production has been demonstrated, industrial-scale manufacturing processes are still in development. The complexity of quasicrystalline structures and the need for precise compositional control pose significant challenges to large-scale production.

Efforts to improve scalability focus on optimizing existing techniques and developing new approaches. For instance, continuous casting methods are being explored to produce larger volumes of quasicrystalline materials. Additionally, researchers are investigating the use of additive manufacturing techniques, such as 3D printing, to create complex quasicrystalline structures with greater precision and scalability.

As the field progresses, advancements in manufacturing processes and scalability will play a crucial role in enabling the widespread adoption of quasicrystals in electronic devices. Overcoming these challenges will be essential for realizing the full potential of quasicrystals in next-generation electronic applications.