How to Optimize Quasicrystal Performance in Electronics?

Quasicrystal Evolution and Objectives

Quasicrystals, discovered in 1982 by Dan Shechtman, have revolutionized our understanding of solid-state physics and materials science. These unique structures, characterized by their long-range order but lack of periodicity, have evolved from a scientific curiosity to a promising field with potential applications in electronics. The evolution of quasicrystals in electronics has been marked by significant milestones and ongoing research efforts to harness their unique properties.

The primary objective in optimizing quasicrystal performance in electronics is to leverage their distinctive electronic and thermal properties. Quasicrystals exhibit low electrical conductivity coupled with high thermal conductivity, making them potential candidates for thermoelectric applications. Additionally, their unique atomic arrangements lead to interesting electronic band structures, which could be exploited for novel electronic devices.

One of the key goals in quasicrystal research is to develop methods for synthesizing high-quality, large-scale quasicrystalline materials suitable for electronic applications. This involves refining growth techniques, such as melt-spinning and flux-growth methods, to produce quasicrystals with minimal defects and optimal electronic properties. Researchers are also exploring ways to create thin films and nanostructures of quasicrystals, which could be integrated into existing semiconductor technologies.

Another important objective is to understand and manipulate the electronic properties of quasicrystals at the quantum level. This includes investigating phenomena such as electron localization, pseudogap formation, and unusual magnetoresistance behaviors. By gaining a deeper understanding of these properties, researchers aim to design quasicrystal-based electronic components with superior performance characteristics.

The development of quasicrystal-based devices is a crucial aspect of their evolution in electronics. This includes exploring their potential in areas such as photonic crystals, where the unique symmetry of quasicrystals could lead to novel optical properties and applications in telecommunications and computing. Additionally, researchers are investigating the use of quasicrystals in quantum computing, where their non-periodic structure might offer advantages in qubit design and error correction.

As the field progresses, a significant objective is to bridge the gap between theoretical predictions and practical applications. This involves developing accurate models to predict the behavior of quasicrystals in various electronic environments and validating these models through experimental studies. Such efforts are crucial for realizing the full potential of quasicrystals in next-generation electronic devices.

Electronic Market Demand Analysis

The demand for quasicrystals in the electronics market has been steadily growing due to their unique properties and potential applications. Quasicrystals, with their aperiodic yet ordered structure, offer a combination of characteristics that make them particularly attractive for various electronic components and devices.

In the semiconductor industry, quasicrystals are being explored for their potential to enhance the performance of transistors and other microelectronic devices. Their unusual electronic properties, including low electrical conductivity and high thermal conductivity, make them promising candidates for heat dissipation in high-power electronic systems. This is particularly relevant as the miniaturization of electronic components continues to push the limits of thermal management.

The telecommunications sector has shown increasing interest in quasicrystals for their potential in antenna design. The unique symmetry of quasicrystals can lead to improved electromagnetic wave propagation and reception, potentially enhancing the efficiency and range of wireless communication devices. This could have significant implications for the development of next-generation 5G and future 6G technologies.

In the field of optoelectronics, quasicrystals are being investigated for their photonic properties. Their ability to manipulate light in novel ways could lead to advancements in LED technology, optical sensors, and photovoltaic cells. The market for these applications is expected to grow substantially as energy efficiency and advanced sensing capabilities become increasingly important in consumer electronics and industrial applications.

The automotive industry is another sector driving demand for quasicrystals in electronics. As vehicles become more electrified and autonomous, there is a growing need for advanced electronic systems that can operate reliably under harsh conditions. Quasicrystals' unique combination of properties makes them potential candidates for use in sensors, actuators, and other electronic components in automotive applications.

Despite the promising potential, the market for quasicrystals in electronics is still in its early stages. Challenges in large-scale production and integration into existing manufacturing processes have limited widespread adoption. However, as research progresses and manufacturing techniques improve, the demand is expected to accelerate.

Market analysts predict that the global market for quasicrystal-based electronic components could reach significant value in the coming years, driven by advancements in nanotechnology and materials science. The increasing focus on sustainable and energy-efficient technologies is likely to further boost the demand for quasicrystals in electronics, as their unique properties align well with these goals.

Quasicrystal Tech Status and Hurdles

Quasicrystals, discovered in the 1980s, have been the subject of intense research due to their unique structural properties. In electronics, these materials offer promising potential for enhancing device performance. However, the current state of quasicrystal technology in electronics faces several challenges that hinder widespread adoption.

One of the primary hurdles is the difficulty in synthesizing high-quality quasicrystals with consistent properties. The complex atomic arrangements that give quasicrystals their unique characteristics also make them challenging to produce reliably at scale. This inconsistency in production affects the reproducibility of electronic properties, a critical factor for commercial applications.

Another significant challenge lies in integrating quasicrystals into existing electronic manufacturing processes. Traditional semiconductor fabrication techniques are not always compatible with quasicrystal materials, necessitating the development of new processing methods. This integration challenge slows down the adoption of quasicrystals in mainstream electronic devices.

The electronic properties of quasicrystals, while promising, are not yet fully understood or optimized. Their unusual electronic structure, characterized by pseudogaps and localized states, presents both opportunities and challenges. Researchers are still working to fully exploit these properties for practical applications in electronics, such as improved conductivity or novel quantum effects.

Thermal management is another area of concern. While some quasicrystals exhibit excellent thermal properties, others may face issues with heat dissipation in high-performance electronic applications. This variability in thermal behavior needs to be addressed to ensure reliable operation in diverse electronic environments.

From a geographical perspective, research on quasicrystals in electronics is concentrated in a few key regions. Japan, the United States, and several European countries lead in this field, with emerging contributions from China and South Korea. This concentration of expertise can limit global progress and adoption of quasicrystal technology in electronics.

Despite these challenges, recent advancements show promise. Improved synthesis techniques, such as molecular beam epitaxy and advanced rapid solidification methods, are enhancing the quality and consistency of quasicrystals. Additionally, progress in theoretical modeling and characterization techniques is providing deeper insights into quasicrystal properties, paving the way for more targeted optimization strategies.

In conclusion, while quasicrystals hold significant potential for optimizing electronic performance, several technical hurdles must be overcome. Addressing these challenges requires a multidisciplinary approach, combining materials science, electronic engineering, and advanced manufacturing techniques. As research progresses, the unique properties of quasicrystals may lead to breakthroughs in electronic device performance and functionality.

Current Quasicrystal Optimization Methods

01 Structural properties of quasicrystals

Quasicrystals exhibit unique structural properties that contribute to their performance. These materials possess long-range order but lack periodicity, resulting in unusual symmetries and physical characteristics. The atomic arrangement in quasicrystals leads to distinctive electronic, thermal, and mechanical properties that differ from conventional crystalline materials.- Structural properties of quasicrystals: Quasicrystals exhibit unique structural properties that contribute to their performance. These materials possess long-range order but lack periodicity, resulting in unusual symmetries and physical characteristics. The atomic arrangement in quasicrystals leads to distinctive electronic, thermal, and mechanical properties that can be exploited in various applications.

- Thermal and electrical conductivity: Quasicrystals demonstrate interesting thermal and electrical conductivity properties. Their unique atomic structure often results in low thermal conductivity and electrical resistivity, making them potential candidates for thermoelectric materials and thermal barrier coatings. These properties can be tuned by adjusting the composition and processing of the quasicrystalline materials.

- Mechanical properties and wear resistance: Quasicrystals exhibit exceptional mechanical properties, including high hardness and wear resistance. These characteristics make them suitable for applications in cutting tools, coatings, and reinforcement in composite materials. The unique atomic structure of quasicrystals contributes to their ability to maintain strength and hardness at elevated temperatures.

- Surface properties and catalytic activity: The surface properties of quasicrystals are of particular interest due to their potential in catalysis and surface engineering. Quasicrystalline surfaces can exhibit low friction, high oxidation resistance, and unique adsorption properties. These characteristics make them promising materials for catalytic applications and the development of non-stick coatings.

- Optical and photonic properties: Quasicrystals possess intriguing optical and photonic properties due to their aperiodic structure. These materials can exhibit unique light transmission and reflection characteristics, making them potential candidates for photonic devices and optical coatings. The quasiperiodic arrangement of atoms in these materials can lead to the formation of photonic band gaps and unusual light propagation behaviors.

02 Mechanical performance of quasicrystal-based materials

Quasicrystals and their composites demonstrate exceptional mechanical properties. They often exhibit high hardness, low friction coefficients, and improved wear resistance compared to traditional crystalline materials. These characteristics make quasicrystals suitable for applications in coatings, cutting tools, and other high-wear environments.Expand Specific Solutions03 Thermal and electrical properties of quasicrystals

Quasicrystals possess unique thermal and electrical properties that influence their performance. They often demonstrate low thermal and electrical conductivity, which can be advantageous in certain applications. These properties are attributed to the complex atomic structure and electron behavior in quasicrystalline materials.Expand Specific Solutions04 Optical and photonic applications of quasicrystals

Quasicrystals exhibit interesting optical properties due to their unique structural arrangements. They can display photonic band gaps and unusual light transmission characteristics, making them potentially useful in optical devices, sensors, and photonic applications. The non-periodic nature of quasicrystals allows for the manipulation of electromagnetic waves in ways not possible with conventional crystals.Expand Specific Solutions05 Quasicrystal-based coatings and surface treatments

Quasicrystalline materials are being explored for use in coatings and surface treatments. Their unique properties, such as low surface energy, high hardness, and corrosion resistance, make them attractive for protective coatings in various industries. These coatings can enhance the performance and durability of underlying materials in demanding environments.Expand Specific Solutions

Key Players in Quasicrystal Electronics

The optimization of quasicrystal performance in electronics is an emerging field in the semiconductor industry, currently in its early development stage. The market size is relatively small but growing, driven by potential applications in advanced electronic devices. The technology maturity is still low, with significant research and development ongoing. Key players like Samsung Electronics, LG Electronics, and Sony Group are investing in this area, leveraging their expertise in semiconductor manufacturing. Companies such as TSMC and IBM are also exploring quasicrystal applications, while research institutions like Fudan University and Northwestern Polytechnical University are contributing to fundamental advancements. The competitive landscape is characterized by a mix of established electronics giants and specialized research entities, all aiming to unlock the unique properties of quasicrystals for enhanced electronic performance.

Samsung Electronics Co., Ltd.

Taiwan Semiconductor Manufacturing Co., Ltd.

Breakthrough Quasicrystal Research

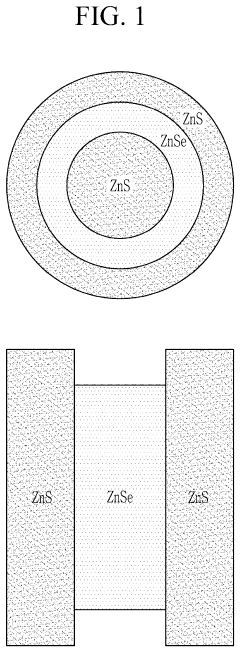

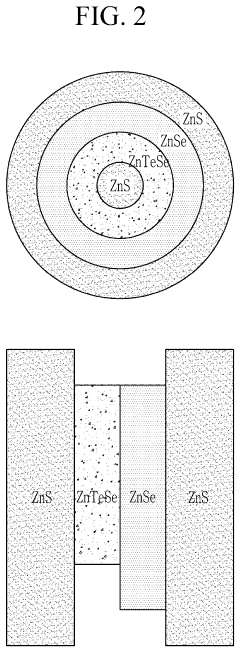

- A cadmium-free semiconductor nanocrystal particle with a core-shell structure, where the core and shells are composed of different Group II-VI compounds, specifically including zinc and sulfur, with a bandgap configuration that allows for efficient light emission in the blue spectrum, and a method for producing these particles involving a multi-layered shell structure to enhance quantum efficiency and stability.

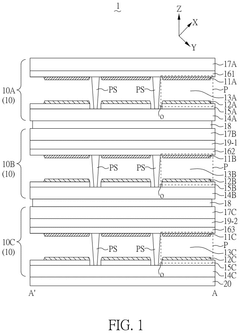

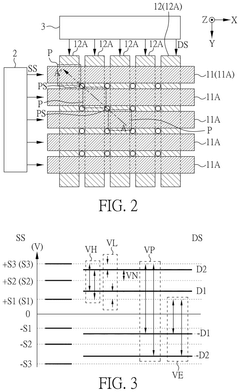

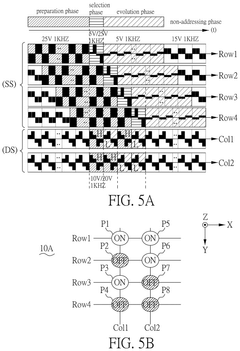

- The proposed method involves an electronic device with a cholesteric liquid crystal layer between intersecting first and second electrodes, where specific voltage waveforms are applied during different operation phases (preparation, selection, and evolution) to optimize the liquid crystal's state and reduce energy consumption.

Quasicrystal Manufacturing Processes

The manufacturing processes for quasicrystals play a crucial role in optimizing their performance in electronic applications. These processes typically involve rapid solidification techniques to create the unique aperiodic structures characteristic of quasicrystals. One common method is melt-spinning, where molten alloy is rapidly cooled on a rotating copper wheel, resulting in thin ribbons of quasicrystalline material. This process allows for precise control over cooling rates and composition, which are critical factors in quasicrystal formation.

Another important manufacturing technique is gas atomization, where a stream of molten alloy is dispersed into fine droplets by high-pressure gas jets. These droplets solidify rapidly in flight, forming quasicrystalline powder particles. This method is particularly useful for producing large quantities of quasicrystalline material for subsequent processing or direct application in electronic components.

For more controlled growth of quasicrystals, flux growth methods are often employed. In this process, the quasicrystal-forming elements are dissolved in a metallic flux at high temperatures. As the solution is slowly cooled, quasicrystals nucleate and grow within the flux. This technique allows for the production of larger, higher-quality quasicrystals, which can be particularly beneficial for certain electronic applications requiring precise structural properties.

Post-processing steps are often necessary to optimize quasicrystal performance in electronics. These may include heat treatments to improve structural stability and reduce defects, as well as surface treatments to enhance specific properties such as electrical conductivity or thermal management capabilities. Precision cutting and polishing techniques are also employed to prepare quasicrystals for integration into electronic devices, ensuring optimal interface quality and performance.

Advanced manufacturing processes are continually being developed to improve quasicrystal quality and scalability. These include additive manufacturing techniques, such as selective laser melting, which allow for the creation of complex quasicrystalline structures with tailored properties. Additionally, thin film deposition methods, like sputtering or pulsed laser deposition, are being explored to create quasicrystalline coatings or layers for electronic applications.

The optimization of quasicrystal performance in electronics heavily relies on the precise control and refinement of these manufacturing processes. Ongoing research focuses on understanding the relationship between processing parameters and the resulting quasicrystal structure and properties, aiming to develop more efficient and reliable production methods for electronic-grade quasicrystalline materials.

Quasicrystal Environmental Impact

The environmental impact of quasicrystals in electronics is a complex and multifaceted issue that requires careful consideration. As these unique materials gain prominence in electronic applications, their potential effects on the environment throughout their lifecycle become increasingly important to assess.

Quasicrystals, with their aperiodic atomic structure, offer unique properties that can enhance electronic performance. However, their production and use may have environmental implications. The manufacturing process of quasicrystals often involves energy-intensive methods and the use of rare or potentially toxic elements. This raises concerns about resource depletion and energy consumption during production.

In electronic devices, quasicrystals can contribute to improved efficiency and reduced power consumption. This positive aspect may lead to decreased energy use and associated environmental benefits over the lifetime of the devices. However, the integration of quasicrystals into complex electronic systems may complicate recycling and disposal processes.

The end-of-life management of quasicrystal-containing electronics presents both challenges and opportunities. On one hand, the unique composition of quasicrystals may require specialized recycling techniques to recover valuable materials effectively. On the other hand, their durability and resistance to wear could potentially extend the lifespan of electronic components, reducing overall electronic waste.

Water and soil contamination risks associated with quasicrystal production and disposal need thorough evaluation. While quasicrystals themselves may be relatively inert, the chemicals and processes involved in their manufacture and integration into electronics could pose environmental hazards if not properly managed.

The potential for quasicrystals to enable more efficient and compact electronic designs may indirectly benefit the environment by reducing material usage and device size. This could lead to smaller environmental footprints for electronic products throughout their lifecycle.

As research into quasicrystals progresses, there is a growing focus on developing more environmentally friendly production methods and exploring bio-inspired quasicrystalline structures. These advancements may mitigate some of the current environmental concerns associated with quasicrystal use in electronics.

In conclusion, while quasicrystals offer promising benefits for electronic performance optimization, their environmental impact requires ongoing assessment and mitigation strategies. Balancing the potential advantages with responsible production, use, and disposal practices will be crucial for ensuring the sustainable integration of quasicrystals in future electronic technologies.