Quasicrystal as a Pivotal Material in 3D Printing

Quasicrystal 3D Printing Background and Objectives

Quasicrystals, discovered in 1982 by Dan Shechtman, represent a unique class of materials that exhibit long-range order but lack periodicity. This groundbreaking discovery challenged the conventional understanding of crystalline structures and opened up new avenues for materials science research. In recent years, the potential application of quasicrystals in 3D printing has garnered significant attention from both academia and industry.

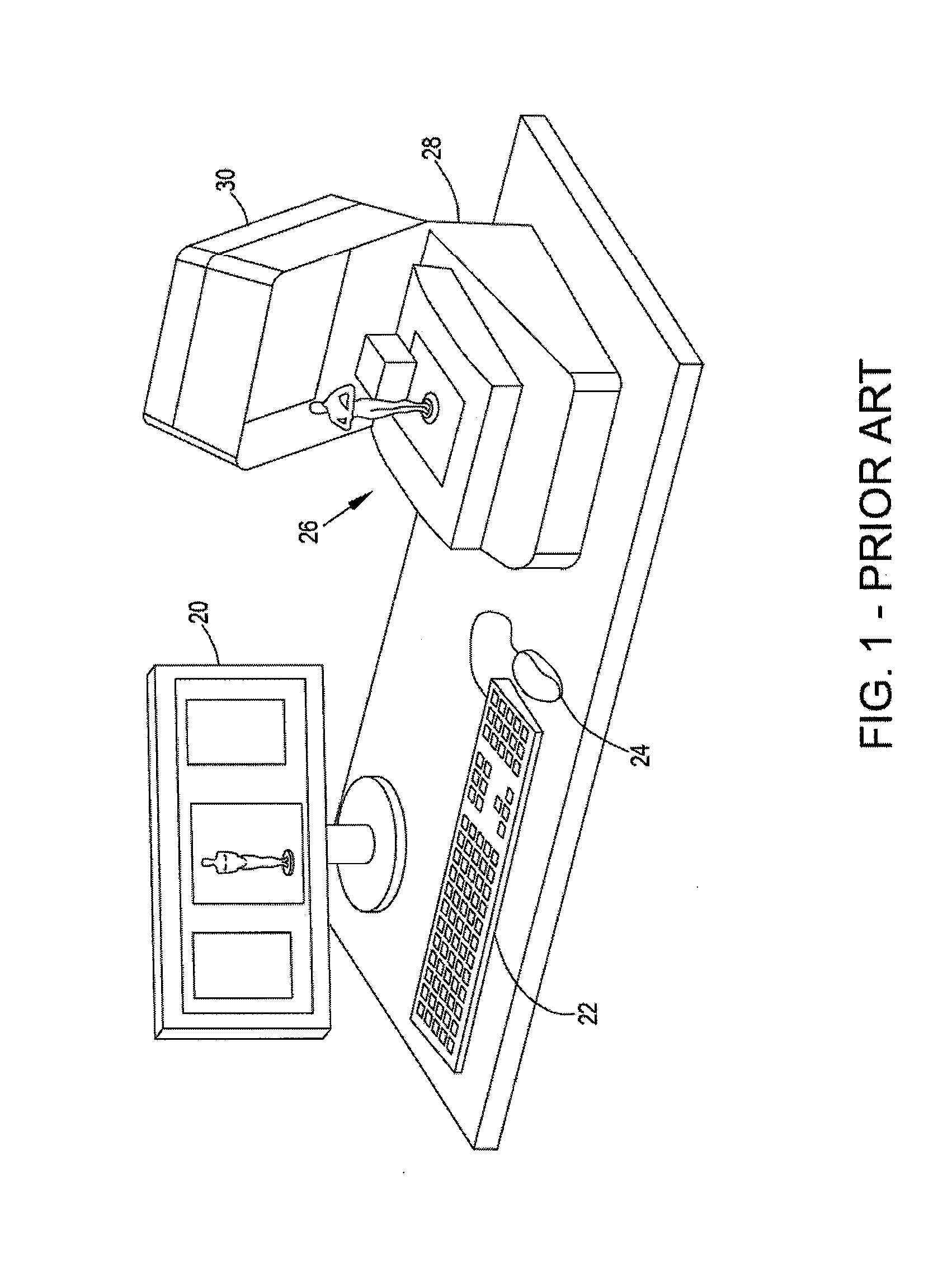

The evolution of 3D printing technology has been marked by continuous innovation in materials and processes. As the demand for advanced manufacturing techniques grows, researchers are exploring novel materials that can enhance the capabilities and applications of 3D printing. Quasicrystals, with their distinctive structural properties, have emerged as a promising candidate for revolutionizing the field of additive manufacturing.

The unique atomic arrangement of quasicrystals results in a combination of properties that are rarely found in conventional crystalline materials. These include high hardness, low friction coefficients, and excellent thermal and electrical insulation. Such characteristics make quasicrystals particularly attractive for use in 3D printing, where they could potentially address some of the limitations of current materials and expand the range of printable objects.

The primary objective of research into quasicrystals as a pivotal material in 3D printing is to harness their exceptional properties to create novel structures and components with enhanced performance. This includes exploring ways to incorporate quasicrystalline phases into printable materials, developing new printing techniques that can leverage the unique structure of quasicrystals, and investigating the potential applications of quasicrystal-based 3D printed objects across various industries.

Another key goal is to overcome the challenges associated with processing quasicrystals, which have traditionally been difficult to manufacture and shape using conventional methods. 3D printing offers a potential solution to these challenges by enabling precise control over material deposition and structure formation at the microscale.

Furthermore, researchers aim to understand the relationship between the quasicrystalline structure and the macroscopic properties of 3D printed objects. This knowledge is crucial for optimizing printing parameters and predicting the performance of quasicrystal-based components in real-world applications.

As the field progresses, there is also a focus on developing multifunctional materials that combine the properties of quasicrystals with other advanced materials, such as high-performance polymers or metal alloys. This approach could lead to the creation of hybrid materials with unprecedented combinations of strength, lightness, and functionality, opening up new possibilities in aerospace, automotive, and biomedical industries.

Market Analysis for Quasicrystal 3D Printing Applications

The market for quasicrystal applications in 3D printing is emerging as a promising frontier in advanced manufacturing. As quasicrystals exhibit unique structural properties, including high hardness, low friction, and thermal stability, they present significant potential for enhancing 3D printed products across various industries. The aerospace sector shows particular interest in quasicrystal-based 3D printing for developing lightweight yet durable components, potentially revolutionizing aircraft design and fuel efficiency.

In the automotive industry, quasicrystal 3D printing applications are being explored for creating high-performance engine parts and structural components that can withstand extreme temperatures and mechanical stress. This could lead to improved fuel efficiency and longer-lasting vehicles. The medical field is another area where quasicrystal 3D printing holds promise, especially in the production of biocompatible implants with enhanced wear resistance and reduced friction, potentially improving patient outcomes and implant longevity.

The electronics industry is investigating quasicrystal 3D printing for developing novel semiconductor materials and heat-dissipating components, which could lead to more efficient and compact electronic devices. In the energy sector, quasicrystal-based 3D printed materials are being researched for their potential in improving the efficiency of solar cells and thermoelectric devices, contributing to advancements in renewable energy technologies.

While the market for quasicrystal 3D printing applications is still in its early stages, it is expected to grow significantly in the coming years. The global 3D printing market is projected to expand rapidly, and quasicrystal applications are likely to capture a growing share of this market. However, challenges such as high production costs and the need for specialized equipment may initially limit widespread adoption.

As research and development in this field progress, we can anticipate a gradual increase in market demand for quasicrystal 3D printing applications. This growth will likely be driven by industries requiring materials with exceptional mechanical and thermal properties. The market potential is further enhanced by the ongoing trend towards customization and on-demand manufacturing, where quasicrystal 3D printing could offer unique solutions for producing complex, high-performance components.

Current Challenges in Quasicrystal 3D Printing Technology

The integration of quasicrystals into 3D printing technology presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is the complex atomic structure of quasicrystals, which exhibits long-range order but lacks periodicity. This unique arrangement makes it difficult to predict and control the material's behavior during the 3D printing process, particularly in terms of maintaining the quasicrystalline structure throughout the printed object.

Another major challenge lies in the development of suitable quasicrystal-based feedstock materials for 3D printing. Traditional 3D printing methods often rely on materials in powder or filament form, but creating quasicrystal powders or filaments with consistent properties and suitable flow characteristics for 3D printing is a complex task. The high melting points and brittleness of many quasicrystalline alloys further complicate their use in additive manufacturing processes.

The thermal management during the 3D printing of quasicrystals poses another significant hurdle. Quasicrystals are known for their low thermal conductivity, which can lead to uneven heating and cooling during the printing process. This thermal gradient can result in internal stresses, deformations, and potential loss of the quasicrystalline structure in the final product. Developing precise temperature control mechanisms and optimizing heat distribution within the printing environment are crucial challenges that need to be addressed.

Furthermore, the anisotropic properties of quasicrystals present challenges in achieving uniform mechanical and physical properties in 3D printed objects. The orientation-dependent characteristics of quasicrystals can lead to variations in strength, hardness, and other properties across different directions within the printed structure. Overcoming this anisotropy to produce parts with consistent and predictable properties is a key area of ongoing research.

The limited availability and high cost of quasicrystalline materials also pose significant barriers to their widespread adoption in 3D printing. Developing cost-effective methods for producing quasicrystal feedstock materials in sufficient quantities for large-scale 3D printing applications remains a challenge. Additionally, the need for specialized equipment and expertise to handle and process quasicrystals adds to the overall complexity and cost of implementing quasicrystal-based 3D printing technologies.

Lastly, there is a lack of comprehensive understanding of the relationship between processing parameters, microstructure, and final properties of 3D printed quasicrystalline materials. This knowledge gap hinders the development of optimized printing strategies and limits the ability to tailor the properties of printed quasicrystal objects for specific applications. Extensive research is needed to establish robust process-structure-property relationships for quasicrystal 3D printing.

Existing Quasicrystal 3D Printing Methodologies

01 Quasicrystal structure and composition

Quasicrystals are unique materials with aperiodic atomic structures that exhibit long-range order but lack translational symmetry. They are typically composed of metallic alloys and possess unusual physical properties. The structure and composition of quasicrystals are crucial for their unique characteristics and potential applications.- Quasicrystal structure and composition: Quasicrystals are unique materials with aperiodic atomic structures that exhibit long-range order but lack translational symmetry. They are typically composed of metallic alloys and possess unusual physical properties. The composition and structure of quasicrystals are crucial for their formation and stability.

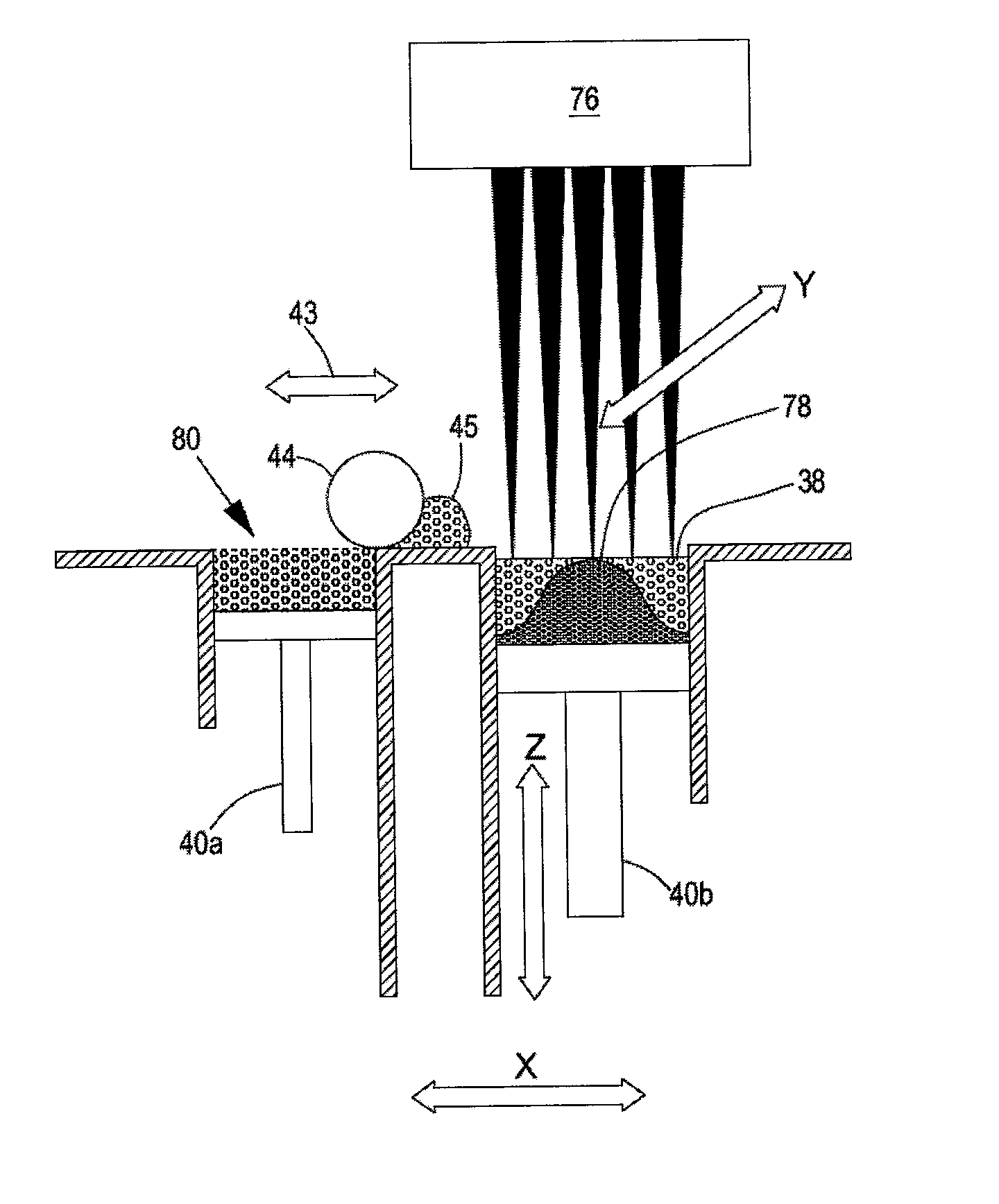

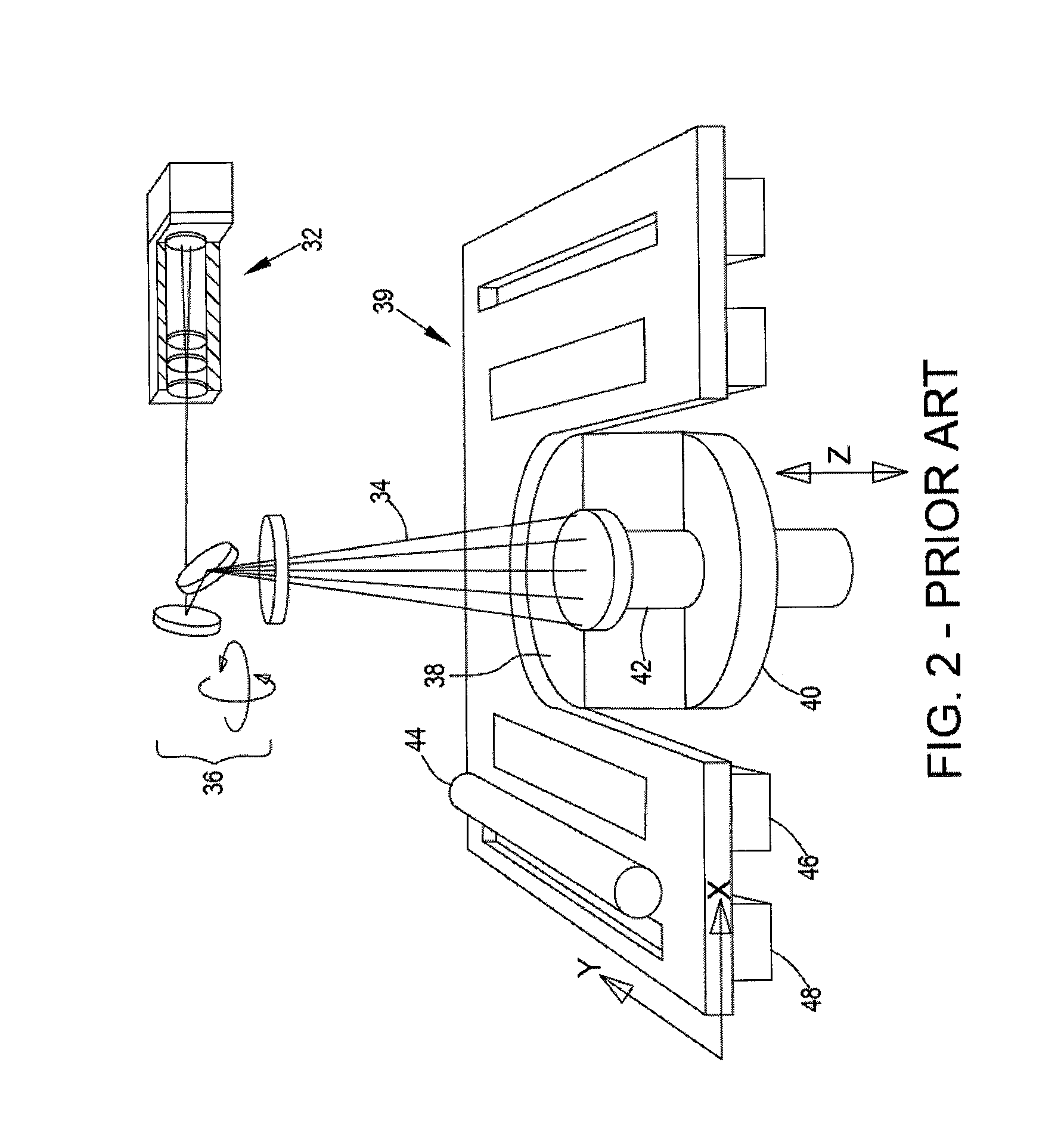

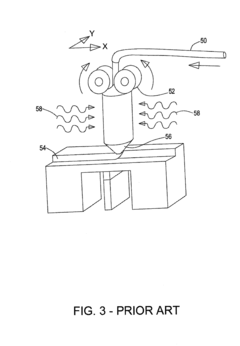

- Manufacturing methods for quasicrystals: Various techniques are employed to produce quasicrystals, including rapid solidification, melt spinning, and vapor deposition. These methods often involve precise control of cooling rates and composition to achieve the desired quasicrystalline structure. Advanced manufacturing processes can enhance the quality and yield of quasicrystals.

- Applications of quasicrystals: Quasicrystals find applications in diverse fields due to their unique properties. They are used in non-stick coatings, thermal barriers, and wear-resistant materials. Quasicrystals also show potential in catalysis, hydrogen storage, and as reinforcement in composite materials. Their unusual electronic properties make them candidates for thermoelectric devices.

- Characterization and analysis of quasicrystals: Advanced analytical techniques are essential for studying the structure and properties of quasicrystals. These include electron microscopy, X-ray diffraction, and neutron scattering. Computational methods and modeling are also employed to understand the complex arrangements of atoms in quasicrystalline structures and predict their properties.

- Novel quasicrystal compositions and alloys: Research continues to explore new compositions and alloys that can form quasicrystals. This includes investigating multi-component systems, rare earth elements, and unconventional combinations of metals. The discovery of new quasicrystalline materials can lead to improved properties and expanded applications in various technological fields.

02 Manufacturing methods for quasicrystals

Various techniques are employed to produce quasicrystals, including rapid solidification, vapor deposition, and electrodeposition. These methods aim to create the specific conditions necessary for quasicrystal formation, such as precise composition control and rapid cooling rates. Optimization of manufacturing processes is essential for producing high-quality quasicrystals with desired properties.Expand Specific Solutions03 Applications of quasicrystals

Quasicrystals have found applications in various fields due to their unique properties. They are used in non-stick coatings, thermal barriers, and hydrogen storage materials. Their low friction and wear resistance make them suitable for mechanical components. Quasicrystals also show promise in electronic and optical applications, as well as in the development of novel catalysts.Expand Specific Solutions04 Characterization and analysis of quasicrystals

Advanced techniques are employed to study the structure and properties of quasicrystals. These include electron microscopy, X-ray diffraction, and neutron scattering. Computational methods and simulations are also used to model and predict quasicrystal behavior. Accurate characterization is crucial for understanding the unique features of quasicrystals and developing new applications.Expand Specific Solutions05 Quasicrystal-based composites and coatings

Quasicrystals are incorporated into composites and coatings to enhance material properties. These composites combine the unique characteristics of quasicrystals with those of traditional materials, resulting in improved mechanical, thermal, and chemical properties. Quasicrystal-based coatings are developed for applications requiring high wear resistance, low friction, and thermal insulation.Expand Specific Solutions

Key Players in Quasicrystal and 3D Printing Industries

The research on quasicrystals as a pivotal material in 3D printing is in its early developmental stage, with significant potential for growth. The market size is currently limited but expected to expand as applications in advanced manufacturing emerge. Technologically, it's still in the experimental phase, with varying levels of maturity across different institutions. Key players like the Chinese Academy of Science Institute of Chemistry, IBM, and Stratasys are at the forefront, conducting fundamental research and exploring practical applications. Universities such as Dalian University of Technology and Southeast University are contributing to the knowledge base, while companies like China Petroleum & Chemical Corp. are investigating industrial applications. The field is characterized by a mix of academic and industrial efforts, indicating a collaborative approach to advancing this complex technology.

Chinese Academy of Science Institute of Chemistry

International Business Machines Corp.

Breakthrough Innovations in Quasicrystal 3D Printing

- The use of Quantum Cascade Lasers (QCLs) with focused wavelengths matching plastic absorption properties, combined with Pulse Width Modulation, to enhance the 3D printing process by providing high-resolution, rapid building speeds, and the ability to use engineering plastics, while maintaining a compact printer design.

- The use of polyhemiaminals (PHA), polyhexahydrotriazines (PHT), and polyoctatriazacanes (POTA) polymers, formed by reacting primary diamines with formaldehyde-type reagents and optionally formic acid, which can be processed through 3D printing apparatus to create objects with enhanced mechanical properties and the ability to be modified after printing.

Material Properties and Characterization of 3D Printed Quasicrystals

The material properties and characterization of 3D printed quasicrystals present a unique set of challenges and opportunities in the field of additive manufacturing. Quasicrystals, with their aperiodic yet ordered structure, exhibit exceptional mechanical, thermal, and electromagnetic properties that set them apart from traditional crystalline materials.

One of the most notable characteristics of 3D printed quasicrystals is their high hardness and low friction coefficient. This combination makes them particularly suitable for applications requiring wear-resistant surfaces. The aperiodic structure of quasicrystals contributes to their superior hardness, often surpassing that of many conventional alloys and ceramics.

Thermal properties of 3D printed quasicrystals are equally remarkable. They demonstrate low thermal conductivity while maintaining good thermal stability at elevated temperatures. This unique combination allows for the creation of thermal barrier coatings and heat-resistant components through additive manufacturing processes.

The electrical properties of quasicrystals produced via 3D printing are of significant interest. These materials often exhibit high electrical resistivity, which can be advantageous in certain electronic applications. Additionally, some quasicrystalline structures show promising thermoelectric properties, opening up possibilities for energy harvesting devices.

Characterization of 3D printed quasicrystals involves a range of advanced analytical techniques. X-ray diffraction (XRD) is crucial for confirming the quasicrystalline structure and identifying any potential crystalline phases. Transmission electron microscopy (TEM) provides detailed insights into the local atomic arrangements and defects within the printed structures.

Mechanical testing of 3D printed quasicrystals typically includes nanoindentation to assess hardness and elastic modulus at the microscale. Tribological studies are essential to quantify the low friction properties, while thermal analysis techniques such as differential scanning calorimetry (DSC) help in understanding phase transitions and thermal stability.

The surface properties of 3D printed quasicrystals are of particular interest. Atomic force microscopy (AFM) and scanning electron microscopy (SEM) are employed to examine surface topography and roughness, which can significantly influence the material's performance in various applications.

As research in this field progresses, there is a growing focus on tailoring the properties of 3D printed quasicrystals through composition control and process optimization. This includes exploring different alloy systems and refining printing parameters to achieve desired microstructures and properties.

Environmental Impact of Quasicrystal 3D Printing Processes

The environmental impact of quasicrystal 3D printing processes is a crucial aspect to consider as this technology advances. Quasicrystals, with their unique atomic structure and properties, offer potential benefits in terms of material efficiency and performance. However, their production and use in 3D printing also raise important environmental concerns.

One of the primary environmental advantages of quasicrystal 3D printing is the potential for reduced material waste. Traditional manufacturing methods often result in significant material loss, whereas 3D printing allows for more precise material deposition. Quasicrystals, with their complex structures, can be printed with high accuracy, potentially minimizing excess material usage and reducing overall waste.

Energy consumption is another critical factor to consider. The production of quasicrystals typically requires high temperatures and precise control, which can be energy-intensive. However, when used in 3D printing, quasicrystals may offer opportunities for energy savings in the long term. Their unique properties, such as low friction and high wear resistance, could lead to the production of more durable and efficient components, potentially reducing the need for frequent replacements and associated energy costs.

The lifecycle impact of quasicrystal-based 3D printed products is an area that requires further investigation. While these materials may offer enhanced durability and performance, their end-of-life disposal and recyclability need to be carefully assessed. The complex atomic structure of quasicrystals may present challenges in traditional recycling processes, necessitating the development of specialized recycling techniques to ensure sustainable material management.

Water usage and potential contamination are additional environmental concerns associated with quasicrystal 3D printing. The production and processing of quasicrystals may involve the use of various chemicals and solvents, which could pose risks to water resources if not properly managed. Implementing closed-loop systems and efficient water treatment processes will be essential to mitigate these potential impacts.

Air quality is another important consideration. The fine particles generated during the 3D printing process, particularly when working with metal-based quasicrystals, may pose respiratory risks if not adequately controlled. Proper ventilation systems and filtration technologies will be crucial to ensure worker safety and minimize environmental emissions.

As the technology evolves, there is a growing need for comprehensive life cycle assessments (LCAs) of quasicrystal 3D printing processes. These assessments should consider raw material extraction, processing, printing, use phase, and end-of-life management to provide a holistic understanding of the environmental footprint. Such studies will be instrumental in guiding the development of more sustainable practices and identifying areas for improvement in the quasicrystal 3D printing industry.