How to Minimize Quasicrystal Development Costs?

Quasicrystal Cost Reduction Objectives

The primary objective of minimizing quasicrystal development costs is to enhance the economic viability and commercial potential of these unique materials. This goal encompasses several key aspects, including optimizing production processes, improving material quality, and expanding potential applications.

One of the main cost reduction objectives is to streamline the manufacturing process of quasicrystals. This involves developing more efficient synthesis methods that require less energy input and fewer raw materials. By refining the production techniques, we aim to reduce the overall cost per unit of quasicrystal material produced, making it more competitive with traditional crystalline materials.

Another crucial objective is to improve the yield and quality of quasicrystals. Higher-quality materials with fewer defects and impurities can lead to better performance in various applications, potentially offsetting the higher production costs. Additionally, increasing the yield of usable quasicrystal material from each production batch can significantly reduce waste and overall costs.

Scaling up production is also a key objective in minimizing development costs. As production volumes increase, economies of scale can be achieved, leading to lower per-unit costs. This objective requires investment in larger-scale production facilities and equipment, but can result in substantial long-term cost savings.

Research and development efforts aimed at finding new applications for quasicrystals are another important aspect of cost reduction. By expanding the potential market for these materials, development costs can be spread across a larger customer base, making the overall investment more economically viable. This includes exploring applications in fields such as electronics, energy storage, and advanced materials.

Collaboration between academic institutions and industry partners is a critical objective in reducing quasicrystal development costs. By pooling resources, knowledge, and expertise, research efforts can be more focused and efficient, potentially leading to faster breakthroughs and cost reductions. Such collaborations can also help in sharing the financial burden of expensive equipment and facilities.

Lastly, an important objective is to optimize the characterization and testing processes for quasicrystals. Developing more efficient and cost-effective methods for analyzing and validating the properties of quasicrystals can significantly reduce the overall development costs. This includes investing in advanced analytical tools and techniques that can provide more accurate and rapid results, reducing the time and resources required for material evaluation.

Market Analysis for Quasicrystal Applications

The market for quasicrystal applications is experiencing a gradual expansion, driven by the unique properties these materials offer. Quasicrystals, with their non-periodic atomic structure, exhibit characteristics that make them attractive for various industrial and technological applications. The global market for quasicrystal-based products is currently in its nascent stage but shows promising growth potential.

One of the primary sectors driving demand for quasicrystals is the aerospace industry. The material's high strength-to-weight ratio and thermal stability make it ideal for developing advanced aircraft components and thermal barrier coatings. This application alone is expected to contribute significantly to market growth in the coming years as aerospace manufacturers seek innovative materials to enhance performance and fuel efficiency.

The automotive industry is another key market for quasicrystal applications. The material's low friction coefficient and wear resistance properties make it suitable for developing more efficient engine components and surface coatings. As automakers strive to meet stringent emissions standards and improve fuel economy, the demand for quasicrystal-based solutions is likely to increase.

In the field of electronics, quasicrystals are gaining attention for their potential use in developing novel semiconductors and photonic devices. Their unique electronic properties could lead to breakthroughs in computing and telecommunications technologies. However, this segment of the market is still largely in the research and development phase, with commercial applications expected to materialize in the medium to long term.

The medical industry is also exploring the use of quasicrystals, particularly in the development of advanced surgical instruments and implants. The material's biocompatibility and resistance to wear make it an attractive option for long-lasting medical devices. While this application is still in its early stages, it represents a promising avenue for future market growth.

Despite the potential, the market for quasicrystal applications faces several challenges. The high production costs associated with synthesizing quasicrystals remain a significant barrier to widespread adoption. Additionally, the complexity of manufacturing processes and the need for specialized equipment limit the number of suppliers capable of producing high-quality quasicrystals at scale.

To address these challenges and minimize development costs, industry players are focusing on improving production techniques and exploring new synthesis methods. Collaborative research efforts between academic institutions and industrial partners are also playing a crucial role in advancing quasicrystal technology and identifying cost-effective manufacturing processes.

As the technology matures and production costs decrease, the market for quasicrystal applications is expected to expand. However, the rate of adoption will largely depend on the industry's ability to overcome current technical and economic hurdles. Continued investment in research and development, along with strategic partnerships across the value chain, will be essential for realizing the full market potential of quasicrystal applications.

Current Challenges in Quasicrystal Production

The production of quasicrystals presents several significant challenges that impact development costs. One of the primary obstacles is the complexity of their atomic structure. Unlike conventional crystals, quasicrystals exhibit long-range order without periodicity, making their formation and control exceptionally difficult. This structural intricacy necessitates highly precise manufacturing processes, which often translate to increased production expenses.

Material purity is another critical challenge in quasicrystal production. The unique properties of quasicrystals are highly sensitive to impurities, requiring ultra-high-purity raw materials. Sourcing and maintaining such high-grade materials significantly elevate production costs. Moreover, even minute contaminations during the manufacturing process can lead to defects, resulting in reduced yield rates and increased waste.

The synthesis of quasicrystals often demands extreme conditions, such as rapid cooling rates or high pressures. Achieving and maintaining these conditions on an industrial scale is technologically demanding and energy-intensive. The specialized equipment required for these processes, including advanced furnaces and precision cooling systems, represents a substantial capital investment and ongoing operational expense.

Quality control and characterization of quasicrystals pose additional challenges. Traditional crystallographic techniques are often inadequate for analyzing quasicrystalline structures, necessitating the development and use of advanced analytical methods. These may include high-resolution electron microscopy, sophisticated X-ray diffraction techniques, and complex computational modeling. The cost of acquiring and operating such advanced analytical equipment adds significantly to the overall development expenses.

Scalability remains a persistent issue in quasicrystal production. Many synthesis methods that work well in laboratory settings prove difficult to scale up for industrial production. This scaling challenge often requires extensive research and development efforts to adapt processes for larger-scale manufacturing, further increasing development costs.

The limited commercial applications of quasicrystals also contribute to their high development costs. With a relatively small market demand, the economies of scale that typically help reduce production costs in other industries are not readily achievable. This limited market size makes it challenging to justify large investments in process optimization and automation, which could otherwise help reduce long-term production expenses.

Lastly, the interdisciplinary nature of quasicrystal research and development adds another layer of complexity and cost. Effective development often requires collaboration between materials scientists, physicists, chemists, and engineers. Coordinating such diverse expertise and integrating their insights into practical manufacturing processes can be both time-consuming and expensive, further contributing to the overall development costs of quasicrystals.

Cost-Effective Quasicrystal Synthesis Methods

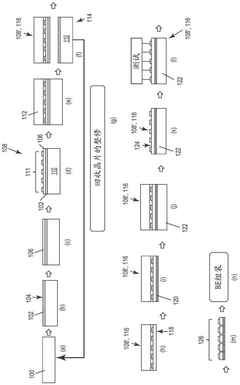

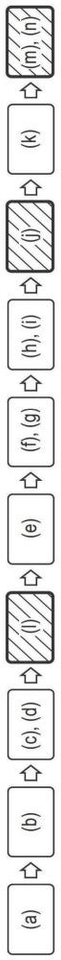

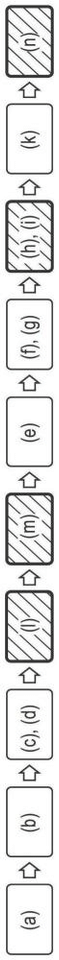

01 Cost estimation and management for quasicrystal development

Developing cost estimation and management strategies specific to quasicrystal research and production. This includes budgeting for specialized equipment, materials, and personnel required for quasicrystal synthesis and characterization. Implementing cost-effective methods for scaling up production while maintaining quality control.- Cost estimation and management for quasicrystal development: Developing cost estimation and management strategies specific to quasicrystal research and production. This includes budgeting for specialized equipment, materials, and personnel required for quasicrystal synthesis and characterization. Effective cost management is crucial due to the complex nature of quasicrystal development and the need for advanced technologies.

- Advanced manufacturing techniques for quasicrystals: Implementing cutting-edge manufacturing processes to optimize quasicrystal production and reduce associated costs. This may involve developing new synthesis methods, improving existing techniques, or adapting technologies from other fields to enhance efficiency and reduce resource consumption in quasicrystal fabrication.

- Material selection and optimization for cost-effective quasicrystal production: Researching and selecting optimal materials for quasicrystal synthesis to balance performance and cost. This includes exploring alternative precursors, catalysts, or substrates that can reduce overall production expenses while maintaining or improving the quality of the resulting quasicrystals.

- Scaling up quasicrystal production for commercial viability: Developing strategies to scale up quasicrystal production from laboratory to industrial levels while managing costs. This involves optimizing processes, improving yield, and reducing waste to make quasicrystal production economically viable for commercial applications.

- Collaborative research and development to share quasicrystal development costs: Establishing partnerships between academic institutions, research centers, and industry to share the financial burden of quasicrystal development. This collaborative approach can help distribute costs associated with expensive equipment, facilities, and expertise, making quasicrystal research more accessible and cost-effective.

02 Advanced manufacturing techniques for quasicrystals

Exploring and implementing advanced manufacturing techniques to reduce production costs of quasicrystals. This may include novel synthesis methods, improved processing techniques, and automation of certain production steps to increase efficiency and reduce labor costs.Expand Specific Solutions03 Material optimization for cost-effective quasicrystal production

Researching and developing alternative materials or precursors for quasicrystal synthesis that are more cost-effective without compromising the unique properties of quasicrystals. This includes exploring new alloy compositions and optimizing material ratios to reduce raw material costs.Expand Specific Solutions04 Energy-efficient processes for quasicrystal development

Developing energy-efficient processes for quasicrystal synthesis and processing to reduce overall production costs. This may involve optimizing heating and cooling cycles, implementing energy recovery systems, and exploring low-temperature synthesis methods.Expand Specific Solutions05 Computational modeling for cost reduction in quasicrystal research

Utilizing advanced computational modeling and simulation techniques to predict quasicrystal structures, properties, and behavior. This approach can significantly reduce experimental costs by minimizing trial-and-error processes in material development and optimizing experimental design.Expand Specific Solutions

Key Players in Quasicrystal Research

The quasicrystal development market is in its early stages, characterized by limited commercial applications and a focus on research and development. The market size remains relatively small, with potential for growth as new applications emerge. Technologically, quasicrystals are still in the experimental phase, with companies like Shin-Etsu Handotai, Infineon Technologies, and Sumitomo Electric Industries leading research efforts. The Institute of Microelectronics of Chinese Academy of Sciences and Semiconductor Energy Laboratory are also contributing to advancements. To minimize development costs, collaboration between academic institutions and industry players is crucial, as seen with partnerships involving Nanjing University of Aeronautics & Astronautics and Tongji University. Leveraging existing semiconductor manufacturing expertise from companies like Taiwan Semiconductor Manufacturing Co., Ltd. could also help reduce costs and accelerate progress in quasicrystal development.

Shin-Etsu Handotai Co., Ltd.

Infineon Technologies AG

Innovative Approaches to Quasicrystal Formation

- By forming a porous layer on the first main surface of the semiconductor wafer and forming a doped region in the epitaxial layer, the wafer is separated from the substrate along the porous layer, the semiconductor wafer is reused, and material loss and production costs are reduced.

- The process of growing LYSO scintillation crystals using molybdenum crucibles is accomplished by evacuating the vacuum furnace to ≤10Pa, using a weakly reducing protective gas (a mixture of Ar and H2) for heating and ventilation to prevent oxidation of the molybdenum crucible and use it at high temperatures. The carbon felt protects the crucible and crystal and ensures corrosion resistance in the molten state.

Material Sourcing Strategies

Minimizing quasicrystal development costs through effective material sourcing strategies is crucial for advancing research and commercial applications in this field. The unique atomic structure of quasicrystals demands specialized materials, often rare and expensive, making strategic sourcing essential for cost reduction.

One key approach is to establish long-term partnerships with reliable suppliers. By fostering these relationships, researchers and manufacturers can secure more favorable pricing and ensure a steady supply of high-quality materials. This stability allows for better budget planning and reduces the risk of production delays due to material shortages.

Diversifying the supplier base is another critical strategy. Relying on multiple sources for key materials can help mitigate supply chain risks and create competition among suppliers, potentially leading to better pricing. However, it's important to balance this diversification with the need for consistent quality across different suppliers.

Exploring alternative materials that can substitute for more expensive components without compromising the quasicrystal's properties is a promising avenue for cost reduction. This may involve collaborating with materials scientists to identify or develop new alloys or compounds that exhibit similar characteristics at a lower cost.

Implementing just-in-time inventory management can significantly reduce storage costs and minimize waste of expensive materials. This approach requires precise coordination with suppliers and a deep understanding of the production process to ensure materials are available when needed without excess stockpiling.

Investing in recycling and reclamation processes for rare or expensive materials used in quasicrystal production can lead to substantial cost savings over time. Developing efficient methods to recover and reuse materials from production waste or end-of-life products can create a more sustainable and economical material sourcing cycle.

Leveraging bulk purchasing power through consortiums or industry collaborations can help smaller research groups or companies access materials at more competitive prices. By pooling resources and orders, participants can negotiate better terms with suppliers and potentially access materials that would be prohibitively expensive individually.

Lastly, staying informed about global market trends and geopolitical factors affecting material availability and pricing is crucial. This knowledge can inform strategic decisions about when to purchase materials in bulk or seek alternatives, helping to navigate price fluctuations and supply chain disruptions effectively.

Scaling Quasicrystal Production

Scaling quasicrystal production presents unique challenges due to the complex nature of these materials. To minimize development costs, it is crucial to focus on optimizing production processes and leveraging economies of scale. One key approach is to refine the growth techniques for quasicrystals, such as flux growth or melt spinning methods. By improving these processes, manufacturers can increase yield rates and reduce material waste, thereby lowering overall production costs.

Automation plays a significant role in scaling production efficiently. Implementing advanced robotics and AI-driven systems in the manufacturing process can help maintain precise control over growth conditions, ensuring consistency and quality while reducing labor costs. These automated systems can monitor and adjust parameters such as temperature, pressure, and composition in real-time, maximizing the likelihood of successful quasicrystal formation.

Developing standardized production protocols is another essential step in scaling quasicrystal production. By establishing clear guidelines and procedures for each stage of the manufacturing process, companies can streamline operations and minimize errors. This standardization also facilitates knowledge transfer and training of new personnel, reducing long-term costs associated with skill development and retention.

Material optimization is a critical factor in cost reduction. Research into alternative precursor materials or more efficient ways to utilize existing materials can lead to significant savings. Additionally, exploring methods to recycle or repurpose byproducts from the quasicrystal production process can further reduce raw material costs and improve sustainability.

Collaboration with academic institutions and research centers can provide access to cutting-edge technologies and expertise without the need for extensive in-house research and development. These partnerships can accelerate innovation in production methods and help identify novel applications for quasicrystals, potentially opening new market opportunities and justifying increased production scales.

Investing in advanced characterization techniques is essential for quality control and process optimization. High-resolution electron microscopy, X-ray diffraction, and other analytical tools can help identify defects and inconsistencies in quasicrystal structures, allowing for rapid adjustments to production parameters. While these technologies may require initial capital investment, they can significantly reduce long-term costs by improving product quality and reducing waste.

Finally, exploring modular production systems can offer flexibility and cost-effectiveness in scaling operations. These systems allow for incremental capacity increases as demand grows, reducing the risk of overinvestment in production capabilities. Modular designs also facilitate easier maintenance and upgrades, potentially extending the lifespan of production equipment and reducing long-term capital expenditures.