How to Diagnose Common 5.4 Triton Engine Issues?

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Overview

The 5.4 Triton engine, developed by Ford Motor Company, is a V8 gasoline engine that has been widely used in various Ford vehicles since its introduction in 1997. This engine has undergone several iterations and improvements over the years, with the most recent version being the 5.4L 3-valve Triton engine.

The Triton engine family is known for its reliability, power output, and versatility. It has been utilized in a range of Ford vehicles, including the popular F-150 pickup truck, Expedition SUV, and E-Series vans. The 5.4L displacement offers a good balance between power and fuel efficiency, making it suitable for both work and recreational purposes.

One of the key features of the 5.4 Triton engine is its modular design, which allows for easier manufacturing and maintenance. This design also enables the engine to be adapted for various applications, from light-duty trucks to high-performance vehicles.

Throughout its production run, the 5.4 Triton engine has been offered in different configurations, including 2-valve, 3-valve, and 4-valve versions. Each iteration brought improvements in power output, fuel efficiency, and emissions control. The 3-valve version, introduced in 2004, was particularly notable for its enhanced performance and reduced fuel consumption compared to its predecessors.

Despite its overall reliability, the 5.4 Triton engine has experienced some common issues over the years. These include spark plug problems, particularly in earlier models, where spark plugs could break or become difficult to remove. Other potential issues include oil leaks, timing chain tensioner failures, and exhaust manifold bolt failures.

Understanding these common problems is crucial for diagnosing and maintaining 5.4 Triton engines. Regular maintenance, including timely oil changes, proper spark plug replacement, and attention to cooling system health, can significantly extend the engine's lifespan and prevent many of these issues.

The 5.4 Triton engine's performance characteristics vary depending on the specific version and application. Generally, it produces between 230 to 320 horsepower and 330 to 390 lb-ft of torque, making it capable of handling heavy loads and providing strong acceleration when needed.

In recent years, Ford has phased out the 5.4 Triton engine in favor of more modern and efficient powertrains, such as the EcoBoost engine family. However, due to its long production run and widespread use, many 5.4 Triton engines remain in service today, making it important for mechanics and vehicle owners to be familiar with its characteristics and common diagnostic procedures.

The Triton engine family is known for its reliability, power output, and versatility. It has been utilized in a range of Ford vehicles, including the popular F-150 pickup truck, Expedition SUV, and E-Series vans. The 5.4L displacement offers a good balance between power and fuel efficiency, making it suitable for both work and recreational purposes.

One of the key features of the 5.4 Triton engine is its modular design, which allows for easier manufacturing and maintenance. This design also enables the engine to be adapted for various applications, from light-duty trucks to high-performance vehicles.

Throughout its production run, the 5.4 Triton engine has been offered in different configurations, including 2-valve, 3-valve, and 4-valve versions. Each iteration brought improvements in power output, fuel efficiency, and emissions control. The 3-valve version, introduced in 2004, was particularly notable for its enhanced performance and reduced fuel consumption compared to its predecessors.

Despite its overall reliability, the 5.4 Triton engine has experienced some common issues over the years. These include spark plug problems, particularly in earlier models, where spark plugs could break or become difficult to remove. Other potential issues include oil leaks, timing chain tensioner failures, and exhaust manifold bolt failures.

Understanding these common problems is crucial for diagnosing and maintaining 5.4 Triton engines. Regular maintenance, including timely oil changes, proper spark plug replacement, and attention to cooling system health, can significantly extend the engine's lifespan and prevent many of these issues.

The 5.4 Triton engine's performance characteristics vary depending on the specific version and application. Generally, it produces between 230 to 320 horsepower and 330 to 390 lb-ft of torque, making it capable of handling heavy loads and providing strong acceleration when needed.

In recent years, Ford has phased out the 5.4 Triton engine in favor of more modern and efficient powertrains, such as the EcoBoost engine family. However, due to its long production run and widespread use, many 5.4 Triton engines remain in service today, making it important for mechanics and vehicle owners to be familiar with its characteristics and common diagnostic procedures.

Market Analysis

The market for 5.4 Triton engine diagnostics and repair services has shown steady growth in recent years, driven by the large installed base of Ford vehicles equipped with this engine. As these vehicles age, the demand for diagnostic tools, repair services, and replacement parts continues to increase. The 5.4 Triton engine was widely used in popular Ford models like the F-150, Expedition, and E-Series vans from the late 1990s through the early 2010s, creating a substantial market for aftermarket support.

Independent repair shops and DIY enthusiasts represent a significant portion of this market, as many vehicle owners seek cost-effective alternatives to dealer services for out-of-warranty repairs. This has led to a growing market for diagnostic scanners, repair manuals, and online resources specifically tailored to addressing common 5.4 Triton engine issues.

The most frequent problems associated with the 5.4 Triton engine include spark plug and ignition coil failures, timing chain tensioner wear, and oil leaks. These issues have created niche markets for specialized tools and parts designed to address these specific problems. For example, there is a robust market for improved spark plug designs and installation tools to prevent the notorious issue of spark plugs breaking during removal.

Environmental regulations and increasing fuel efficiency standards have also influenced the market, driving demand for diagnostic and repair solutions that can help maintain optimal engine performance and reduce emissions. This trend has led to the development of more advanced diagnostic tools capable of pinpointing issues that affect fuel economy and emissions control systems.

The rise of online auto parts retailers and e-commerce platforms has significantly impacted the distribution channels for 5.4 Triton engine diagnostic tools and replacement parts. These platforms have made it easier for consumers to access a wide range of products and compare prices, leading to increased competition among suppliers and potentially lower costs for end-users.

Looking ahead, the market for 5.4 Triton engine diagnostics is expected to evolve as the vehicle population ages. While the demand for traditional repair services may gradually decline as older vehicles are retired, there is likely to be a growing market for remanufactured engines and long-term maintenance solutions for enthusiasts and collectors who wish to keep these vehicles on the road.

Independent repair shops and DIY enthusiasts represent a significant portion of this market, as many vehicle owners seek cost-effective alternatives to dealer services for out-of-warranty repairs. This has led to a growing market for diagnostic scanners, repair manuals, and online resources specifically tailored to addressing common 5.4 Triton engine issues.

The most frequent problems associated with the 5.4 Triton engine include spark plug and ignition coil failures, timing chain tensioner wear, and oil leaks. These issues have created niche markets for specialized tools and parts designed to address these specific problems. For example, there is a robust market for improved spark plug designs and installation tools to prevent the notorious issue of spark plugs breaking during removal.

Environmental regulations and increasing fuel efficiency standards have also influenced the market, driving demand for diagnostic and repair solutions that can help maintain optimal engine performance and reduce emissions. This trend has led to the development of more advanced diagnostic tools capable of pinpointing issues that affect fuel economy and emissions control systems.

The rise of online auto parts retailers and e-commerce platforms has significantly impacted the distribution channels for 5.4 Triton engine diagnostic tools and replacement parts. These platforms have made it easier for consumers to access a wide range of products and compare prices, leading to increased competition among suppliers and potentially lower costs for end-users.

Looking ahead, the market for 5.4 Triton engine diagnostics is expected to evolve as the vehicle population ages. While the demand for traditional repair services may gradually decline as older vehicles are retired, there is likely to be a growing market for remanufactured engines and long-term maintenance solutions for enthusiasts and collectors who wish to keep these vehicles on the road.

Common Issues Identified

The 5.4 Triton engine, widely used in Ford vehicles, is known for its reliability. However, like any mechanical system, it can experience issues over time. Several common problems have been identified in this engine model, requiring careful diagnosis and attention.

One of the most frequently reported issues is spark plug ejection. This problem typically occurs in 2004-2008 models and is characterized by spark plugs suddenly ejecting from the cylinder head. The root cause is often attributed to inadequate thread length in the cylinder head, which can lead to stripped threads and eventual ejection. Symptoms may include a sudden loss of power, misfiring, and a loud popping sound from the engine bay.

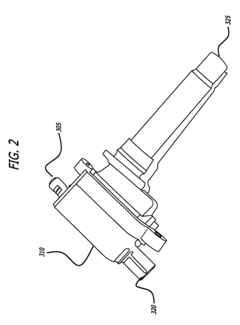

Another common issue is the failure of ignition coils. The 5.4 Triton engine uses a coil-on-plug ignition system, where each spark plug has its own ignition coil. These coils can deteriorate over time, leading to misfires, rough idling, and decreased fuel efficiency. Drivers may notice a check engine light or experience a loss of power, especially during acceleration.

Timing chain problems are also prevalent in some 5.4 Triton engines, particularly in earlier models. The timing chain can stretch or break, causing the engine to run poorly or fail to start. Symptoms often include a rattling noise from the front of the engine, especially during cold starts, and can progress to more severe issues if left unaddressed.

Oil leaks are another issue that 5.4 Triton engine owners may encounter. These leaks can occur from various locations, including the valve cover gaskets, oil pan gaskets, and front cover. Signs of oil leaks include oil spots on the ground beneath the vehicle, burning oil smell, and potentially low oil levels if the leak is significant.

The exhaust manifold is another component prone to problems in the 5.4 Triton engine. Cracks can develop in the manifold, leading to exhaust leaks. This issue is often accompanied by a ticking noise that increases with engine speed and can result in decreased performance and fuel efficiency.

Lastly, fuel injector failures have been reported in some 5.4 Triton engines. Faulty injectors can cause rough idling, poor acceleration, and decreased fuel economy. In some cases, drivers may notice a check engine light or experience difficulty starting the engine.

Recognizing these common issues is crucial for effective diagnosis and timely repair of 5.4 Triton engine problems. By understanding these potential trouble spots, owners and technicians can more quickly identify and address issues, potentially preventing more severe damage and extending the engine's lifespan.

One of the most frequently reported issues is spark plug ejection. This problem typically occurs in 2004-2008 models and is characterized by spark plugs suddenly ejecting from the cylinder head. The root cause is often attributed to inadequate thread length in the cylinder head, which can lead to stripped threads and eventual ejection. Symptoms may include a sudden loss of power, misfiring, and a loud popping sound from the engine bay.

Another common issue is the failure of ignition coils. The 5.4 Triton engine uses a coil-on-plug ignition system, where each spark plug has its own ignition coil. These coils can deteriorate over time, leading to misfires, rough idling, and decreased fuel efficiency. Drivers may notice a check engine light or experience a loss of power, especially during acceleration.

Timing chain problems are also prevalent in some 5.4 Triton engines, particularly in earlier models. The timing chain can stretch or break, causing the engine to run poorly or fail to start. Symptoms often include a rattling noise from the front of the engine, especially during cold starts, and can progress to more severe issues if left unaddressed.

Oil leaks are another issue that 5.4 Triton engine owners may encounter. These leaks can occur from various locations, including the valve cover gaskets, oil pan gaskets, and front cover. Signs of oil leaks include oil spots on the ground beneath the vehicle, burning oil smell, and potentially low oil levels if the leak is significant.

The exhaust manifold is another component prone to problems in the 5.4 Triton engine. Cracks can develop in the manifold, leading to exhaust leaks. This issue is often accompanied by a ticking noise that increases with engine speed and can result in decreased performance and fuel efficiency.

Lastly, fuel injector failures have been reported in some 5.4 Triton engines. Faulty injectors can cause rough idling, poor acceleration, and decreased fuel economy. In some cases, drivers may notice a check engine light or experience difficulty starting the engine.

Recognizing these common issues is crucial for effective diagnosis and timely repair of 5.4 Triton engine problems. By understanding these potential trouble spots, owners and technicians can more quickly identify and address issues, potentially preventing more severe damage and extending the engine's lifespan.

Current Diagnostic Methods

01 Engine design and configuration

The 5.4 Triton Engine is a V8 engine design used in various Ford vehicles. It features a modular architecture, allowing for flexibility in manufacturing and application across different vehicle platforms. The engine's configuration includes advanced technologies for improved performance and efficiency.- Engine design and configuration: The 5.4 Triton Engine is a V8 engine design used in various Ford vehicles. It features a modular architecture, allowing for different displacements and configurations. The engine incorporates advanced technologies for improved performance, fuel efficiency, and emissions control.

- Fuel injection and combustion systems: Innovations in fuel injection and combustion systems for the 5.4 Triton Engine focus on optimizing fuel delivery, enhancing combustion efficiency, and reducing emissions. These improvements may include direct injection technology, variable valve timing, and advanced engine control modules.

- Cooling and lubrication systems: Enhancements to the cooling and lubrication systems of the 5.4 Triton Engine aim to improve thermal management, reduce friction, and increase overall engine reliability. These may include advanced coolant formulations, oil pump designs, and innovative heat exchanger technologies.

- Exhaust and emissions control: Developments in exhaust and emissions control systems for the 5.4 Triton Engine focus on meeting stringent environmental regulations while maintaining performance. This may involve catalytic converter designs, exhaust gas recirculation systems, and particulate filters.

- Engine management and diagnostics: Advancements in engine management and diagnostic systems for the 5.4 Triton Engine aim to improve performance, fuel efficiency, and maintenance. These may include sophisticated engine control units, onboard diagnostic systems, and predictive maintenance technologies.

02 Fuel system and combustion optimization

Innovations in the fuel system and combustion process of the 5.4 Triton Engine focus on enhancing fuel efficiency and reducing emissions. This includes advancements in fuel injection technology, air-fuel mixture control, and combustion chamber design to optimize engine performance.Expand Specific Solutions03 Cooling and thermal management

The 5.4 Triton Engine incorporates advanced cooling and thermal management systems to maintain optimal operating temperatures. This includes innovative coolant flow designs, improved heat dissipation methods, and temperature-controlled components to enhance engine longevity and performance.Expand Specific Solutions04 Valve train and timing mechanisms

Advancements in the valve train and timing mechanisms of the 5.4 Triton Engine focus on improving engine breathing and overall efficiency. This includes variable valve timing systems, innovative camshaft designs, and precision-engineered valve components for enhanced performance across various operating conditions.Expand Specific Solutions05 Engine control and diagnostics

The 5.4 Triton Engine features sophisticated engine control and diagnostic systems. These include advanced electronic control units, sensor networks, and diagnostic algorithms to optimize engine performance, monitor critical parameters, and facilitate efficient maintenance and troubleshooting procedures.Expand Specific Solutions

Key Industry Players

The competitive landscape for diagnosing common 5.4 Triton engine issues is characterized by a mature market with established players and evolving technological solutions. The automotive diagnostics industry is in a growth phase, driven by increasing vehicle complexity and demand for efficient repair services. Major companies like Snap-On, Ford Global Technologies, and Honeywell International are at the forefront, leveraging advanced diagnostic tools and software. The market size is substantial, reflecting the widespread use of 5.4 Triton engines in Ford vehicles. Technological maturity varies, with traditional diagnostic methods coexisting alongside emerging AI-driven solutions from companies like Vitesco Technologies and United Automotive Electronic Systems, indicating a dynamic and competitive environment.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a comprehensive diagnostic approach for engines like the 5.4 Triton, focusing on turbocharger and related systems. Their solution integrates advanced sensors and control systems to monitor turbocharger performance, boost pressure, and exhaust gas flow. Honeywell's diagnostic system employs predictive analytics to identify potential issues before they lead to major failures. They utilize a combination of pressure, temperature, and speed sensors to create a detailed performance profile of the engine and turbocharger system[6]. Honeywell's approach also includes vibration analysis to detect early signs of mechanical wear or imbalance. For data interpretation, they have developed an AI-driven diagnostic algorithm that can differentiate between normal wear patterns and potential failure modes[8].

Strengths: Specialized expertise in turbocharger systems, predictive maintenance capabilities, and AI-enhanced diagnostics. Weaknesses: Primary focus on turbocharger-related issues may limit comprehensive engine diagnostics.

Snap-On, Inc.

Technical Solution: Snap-On has developed a range of diagnostic tools and software specifically designed for engines like the 5.4 Triton. Their approach focuses on providing comprehensive, user-friendly diagnostic solutions for both professional mechanics and DIY enthusiasts. Snap-On's diagnostic systems include handheld scanners with extensive vehicle coverage, including detailed parameter lists for the 5.4 Triton engine. These tools offer real-time data streaming, graphing capabilities, and bi-directional controls for component testing[7]. Snap-On's software includes a vast database of known issues and repair procedures, updated regularly to include the latest technical service bulletins. They have also implemented a community-driven troubleshooting database, allowing technicians to share insights on complex or unusual problems[9]. Additionally, Snap-On offers remote diagnostic capabilities, enabling expert support for difficult cases.

Strengths: User-friendly tools, extensive vehicle coverage, and community-driven knowledge base. Weaknesses: Reliance on regular software updates to maintain effectiveness.

Advanced Diagnostic Tools

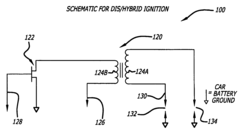

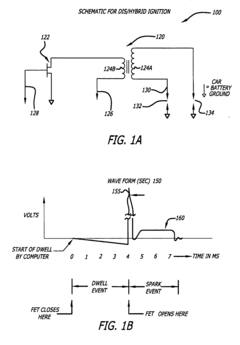

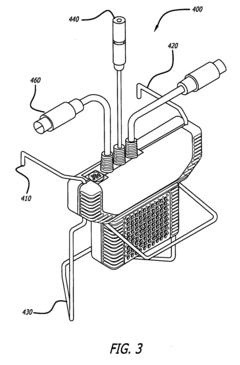

Efficient diagnosis of faulty distributorless and hybrid ignition systems

PatentInactiveUS20050068037A1

Innovation

- A method involving the sequential disconnection and reconnection of primary connectors in distributorless or hybrid ignition systems to identify faulty cylinder pairs by observing changes in misfiring or roughness, followed by measuring firing line voltage to pinpoint the faulty cylinder using devices like the SNAP ON VANTAGE MT2400 or SNAP ON DIS TESTER MT2700.

Environmental Regulations

Environmental regulations play a significant role in shaping the automotive industry, including the diagnosis and maintenance of engines like the 5.4 Triton. These regulations, primarily aimed at reducing emissions and improving fuel efficiency, have led to the development of more sophisticated engine management systems and diagnostic tools.

The Environmental Protection Agency (EPA) in the United States has established stringent emissions standards for vehicles, which directly impact the 5.4 Triton engine. These standards have necessitated the implementation of advanced onboard diagnostic (OBD) systems, which continuously monitor engine performance and emissions-related components. When diagnosing common issues in the 5.4 Triton engine, technicians must be aware of these OBD systems and their role in identifying potential problems.

One of the key aspects of environmental regulations affecting engine diagnostics is the requirement for vehicles to meet specific emissions targets. This has led to the integration of various sensors and control modules in the 5.4 Triton engine, such as oxygen sensors, mass airflow sensors, and catalytic converters. When diagnosing engine issues, technicians must consider the potential impact of these components on overall engine performance and emissions compliance.

The California Air Resources Board (CARB) has implemented even stricter emissions standards than the federal EPA regulations. Vehicles equipped with the 5.4 Triton engine sold in California and states following CARB standards must meet these more stringent requirements. This has resulted in additional diagnostic challenges, as technicians need to be familiar with both EPA and CARB regulations when troubleshooting engine issues.

Environmental regulations have also influenced the development of diagnostic tools and procedures. Manufacturers are required to provide standardized diagnostic trouble codes (DTCs) and access to onboard diagnostic information. This standardization has led to the creation of more sophisticated scan tools and diagnostic software, which are essential for accurately identifying and resolving issues in the 5.4 Triton engine.

The push for improved fuel efficiency, driven by environmental concerns and regulations, has resulted in the implementation of technologies such as variable valve timing and direct fuel injection in newer versions of the 5.4 Triton engine. These advancements, while beneficial for fuel economy and emissions reduction, can introduce additional complexities when diagnosing engine problems. Technicians must be well-versed in these technologies and their potential failure modes to effectively diagnose and repair issues.

As environmental regulations continue to evolve, the diagnostic process for engines like the 5.4 Triton will likely become increasingly complex. Future regulations may require even more advanced emissions control systems and diagnostic capabilities, further emphasizing the need for ongoing training and education for automotive technicians specializing in engine diagnostics and repair.

The Environmental Protection Agency (EPA) in the United States has established stringent emissions standards for vehicles, which directly impact the 5.4 Triton engine. These standards have necessitated the implementation of advanced onboard diagnostic (OBD) systems, which continuously monitor engine performance and emissions-related components. When diagnosing common issues in the 5.4 Triton engine, technicians must be aware of these OBD systems and their role in identifying potential problems.

One of the key aspects of environmental regulations affecting engine diagnostics is the requirement for vehicles to meet specific emissions targets. This has led to the integration of various sensors and control modules in the 5.4 Triton engine, such as oxygen sensors, mass airflow sensors, and catalytic converters. When diagnosing engine issues, technicians must consider the potential impact of these components on overall engine performance and emissions compliance.

The California Air Resources Board (CARB) has implemented even stricter emissions standards than the federal EPA regulations. Vehicles equipped with the 5.4 Triton engine sold in California and states following CARB standards must meet these more stringent requirements. This has resulted in additional diagnostic challenges, as technicians need to be familiar with both EPA and CARB regulations when troubleshooting engine issues.

Environmental regulations have also influenced the development of diagnostic tools and procedures. Manufacturers are required to provide standardized diagnostic trouble codes (DTCs) and access to onboard diagnostic information. This standardization has led to the creation of more sophisticated scan tools and diagnostic software, which are essential for accurately identifying and resolving issues in the 5.4 Triton engine.

The push for improved fuel efficiency, driven by environmental concerns and regulations, has resulted in the implementation of technologies such as variable valve timing and direct fuel injection in newer versions of the 5.4 Triton engine. These advancements, while beneficial for fuel economy and emissions reduction, can introduce additional complexities when diagnosing engine problems. Technicians must be well-versed in these technologies and their potential failure modes to effectively diagnose and repair issues.

As environmental regulations continue to evolve, the diagnostic process for engines like the 5.4 Triton will likely become increasingly complex. Future regulations may require even more advanced emissions control systems and diagnostic capabilities, further emphasizing the need for ongoing training and education for automotive technicians specializing in engine diagnostics and repair.

Cost-Benefit Analysis

When considering the diagnosis of common 5.4 Triton engine issues, a cost-benefit analysis is crucial for both vehicle owners and mechanics. This analysis helps determine the most efficient and economical approach to identifying and resolving engine problems.

One of the primary benefits of proper diagnosis is the potential for significant cost savings in the long run. By accurately identifying the root cause of an issue, unnecessary parts replacements and labor costs can be avoided. For instance, a misdiagnosed problem might lead to replacing an expensive component when a simple sensor calibration could have resolved the issue.

Time efficiency is another crucial factor in the cost-benefit equation. Advanced diagnostic tools and techniques can dramatically reduce the time required to pinpoint problems, translating to lower labor costs and faster vehicle turnaround times. This is particularly beneficial for commercial fleet operators who rely on minimal vehicle downtime.

However, the initial investment in diagnostic equipment and training must be considered. High-quality scanners, specialized tools, and ongoing education for mechanics represent significant upfront costs. These expenses need to be weighed against the long-term benefits of accurate and efficient diagnoses.

For vehicle owners, the cost of professional diagnosis services should be evaluated against the risks of DIY troubleshooting. While some basic checks can be performed at home, complex engine issues in the 5.4 Triton often require specialized knowledge and equipment. Attempting DIY fixes without proper diagnosis can lead to more severe damage and higher repair costs.

Preventive diagnostics also play a role in the cost-benefit analysis. Regular check-ups and early problem detection can prevent minor issues from escalating into major failures, potentially saving thousands in repair costs and extending the engine's lifespan.

Environmental considerations add another dimension to the analysis. Proper diagnosis and timely repairs can improve fuel efficiency and reduce emissions, contributing to long-term cost savings on fuel and compliance with environmental regulations.

In conclusion, while there are upfront costs associated with thorough diagnostic procedures for 5.4 Triton engine issues, the long-term benefits in terms of accurate repairs, reduced downtime, and prevention of secondary damage often outweigh these initial expenses. A comprehensive cost-benefit analysis should consider not only immediate financial implications but also long-term reliability, vehicle performance, and environmental impact.

One of the primary benefits of proper diagnosis is the potential for significant cost savings in the long run. By accurately identifying the root cause of an issue, unnecessary parts replacements and labor costs can be avoided. For instance, a misdiagnosed problem might lead to replacing an expensive component when a simple sensor calibration could have resolved the issue.

Time efficiency is another crucial factor in the cost-benefit equation. Advanced diagnostic tools and techniques can dramatically reduce the time required to pinpoint problems, translating to lower labor costs and faster vehicle turnaround times. This is particularly beneficial for commercial fleet operators who rely on minimal vehicle downtime.

However, the initial investment in diagnostic equipment and training must be considered. High-quality scanners, specialized tools, and ongoing education for mechanics represent significant upfront costs. These expenses need to be weighed against the long-term benefits of accurate and efficient diagnoses.

For vehicle owners, the cost of professional diagnosis services should be evaluated against the risks of DIY troubleshooting. While some basic checks can be performed at home, complex engine issues in the 5.4 Triton often require specialized knowledge and equipment. Attempting DIY fixes without proper diagnosis can lead to more severe damage and higher repair costs.

Preventive diagnostics also play a role in the cost-benefit analysis. Regular check-ups and early problem detection can prevent minor issues from escalating into major failures, potentially saving thousands in repair costs and extending the engine's lifespan.

Environmental considerations add another dimension to the analysis. Proper diagnosis and timely repairs can improve fuel efficiency and reduce emissions, contributing to long-term cost savings on fuel and compliance with environmental regulations.

In conclusion, while there are upfront costs associated with thorough diagnostic procedures for 5.4 Triton engine issues, the long-term benefits in terms of accurate repairs, reduced downtime, and prevention of secondary damage often outweigh these initial expenses. A comprehensive cost-benefit analysis should consider not only immediate financial implications but also long-term reliability, vehicle performance, and environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!