How to Engineer Safer Thermite Blends for Construction?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Safety Objectives

The primary objective of engineering safer thermite blends for construction is to mitigate the inherent risks associated with these highly exothermic reactions while maintaining their effectiveness in specific applications. Thermite reactions, known for their intense heat generation and ability to produce molten metal, pose significant safety challenges that must be addressed to ensure their responsible use in construction settings.

One key safety objective is to control the reaction rate and heat release. By modifying the composition and particle size of the thermite components, researchers aim to develop blends that react in a more controlled and predictable manner. This approach can help prevent sudden, explosive reactions that may lead to accidents or injuries on construction sites.

Another critical goal is to reduce the sensitivity of thermite mixtures to unintended ignition. This involves exploring additives or coating technologies that can increase the activation energy required for the reaction to initiate, thereby reducing the risk of accidental ignition due to static electricity, impact, or friction during handling and storage.

Minimizing the production of hazardous byproducts is also a paramount safety objective. Researchers are investigating alternative formulations that generate fewer toxic fumes or particulates, ensuring a safer working environment for construction personnel and reducing environmental impact.

Enhancing the stability of thermite blends during storage and transportation is another crucial aspect of safety engineering. This includes developing packaging solutions and stabilizing agents that can prevent degradation or premature reaction of the components, even under varying environmental conditions.

Furthermore, improving the precision and localization of thermite reactions is essential for their safe application in construction. Engineers are working on methods to confine the reaction to specific areas, preventing heat spread and potential damage to surrounding structures or materials.

Lastly, the development of robust safety protocols and handling procedures is an integral part of engineering safer thermite blends. This includes designing specialized equipment for mixing, applying, and igniting thermite materials, as well as establishing comprehensive training programs for workers who will be using these materials on construction sites.

One key safety objective is to control the reaction rate and heat release. By modifying the composition and particle size of the thermite components, researchers aim to develop blends that react in a more controlled and predictable manner. This approach can help prevent sudden, explosive reactions that may lead to accidents or injuries on construction sites.

Another critical goal is to reduce the sensitivity of thermite mixtures to unintended ignition. This involves exploring additives or coating technologies that can increase the activation energy required for the reaction to initiate, thereby reducing the risk of accidental ignition due to static electricity, impact, or friction during handling and storage.

Minimizing the production of hazardous byproducts is also a paramount safety objective. Researchers are investigating alternative formulations that generate fewer toxic fumes or particulates, ensuring a safer working environment for construction personnel and reducing environmental impact.

Enhancing the stability of thermite blends during storage and transportation is another crucial aspect of safety engineering. This includes developing packaging solutions and stabilizing agents that can prevent degradation or premature reaction of the components, even under varying environmental conditions.

Furthermore, improving the precision and localization of thermite reactions is essential for their safe application in construction. Engineers are working on methods to confine the reaction to specific areas, preventing heat spread and potential damage to surrounding structures or materials.

Lastly, the development of robust safety protocols and handling procedures is an integral part of engineering safer thermite blends. This includes designing specialized equipment for mixing, applying, and igniting thermite materials, as well as establishing comprehensive training programs for workers who will be using these materials on construction sites.

Construction Industry Demand

The construction industry has shown a growing demand for safer and more efficient demolition and welding techniques, particularly in urban environments where traditional explosive methods pose significant risks. Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has emerged as a potential solution due to its high heat generation and controlled reaction properties. The market for safer thermite blends in construction is driven by several factors, including stringent safety regulations, increasing urbanization, and the need for precision in demolition and welding processes.

Urban redevelopment projects have become a major driver for the demand of safer thermite blends. As cities expand and renovate, there is a pressing need for demolition techniques that minimize collateral damage to surrounding structures and reduce environmental impact. Thermite-based solutions offer a more controlled and localized approach compared to traditional explosives, making them particularly attractive for densely populated areas.

The global construction industry, valued at over $11 trillion in 2021, is projected to grow at a CAGR of 7.3% from 2022 to 2030. Within this market, the demolition segment is expected to see significant growth, with a particular emphasis on technologies that enhance safety and efficiency. The demand for safer thermite blends is anticipated to follow this trend, with an estimated market potential of several hundred million dollars annually.

Safety concerns in the construction industry have led to increased regulatory scrutiny and stricter guidelines for demolition and welding processes. This has created a substantial market opportunity for innovative thermite blends that can meet or exceed these safety standards. Construction companies are willing to invest in advanced materials that reduce the risk of accidents, minimize downtime, and improve overall project efficiency.

The infrastructure sector, including bridge repair and maintenance, presents another significant market for safer thermite blends. The ability of thermite to generate high temperatures in a controlled manner makes it ideal for welding large metal structures. As governments worldwide increase infrastructure spending, the demand for reliable and safe welding solutions is expected to rise proportionally.

Environmental considerations are also driving the demand for safer thermite blends. Traditional demolition methods often result in significant dust and debris, which can have negative impacts on air quality and surrounding ecosystems. Thermite-based solutions offer the potential for cleaner, more contained reactions, aligning with the construction industry's growing focus on sustainability and environmental responsibility.

Urban redevelopment projects have become a major driver for the demand of safer thermite blends. As cities expand and renovate, there is a pressing need for demolition techniques that minimize collateral damage to surrounding structures and reduce environmental impact. Thermite-based solutions offer a more controlled and localized approach compared to traditional explosives, making them particularly attractive for densely populated areas.

The global construction industry, valued at over $11 trillion in 2021, is projected to grow at a CAGR of 7.3% from 2022 to 2030. Within this market, the demolition segment is expected to see significant growth, with a particular emphasis on technologies that enhance safety and efficiency. The demand for safer thermite blends is anticipated to follow this trend, with an estimated market potential of several hundred million dollars annually.

Safety concerns in the construction industry have led to increased regulatory scrutiny and stricter guidelines for demolition and welding processes. This has created a substantial market opportunity for innovative thermite blends that can meet or exceed these safety standards. Construction companies are willing to invest in advanced materials that reduce the risk of accidents, minimize downtime, and improve overall project efficiency.

The infrastructure sector, including bridge repair and maintenance, presents another significant market for safer thermite blends. The ability of thermite to generate high temperatures in a controlled manner makes it ideal for welding large metal structures. As governments worldwide increase infrastructure spending, the demand for reliable and safe welding solutions is expected to rise proportionally.

Environmental considerations are also driving the demand for safer thermite blends. Traditional demolition methods often result in significant dust and debris, which can have negative impacts on air quality and surrounding ecosystems. Thermite-based solutions offer the potential for cleaner, more contained reactions, aligning with the construction industry's growing focus on sustainability and environmental responsibility.

Thermite Blend Challenges

Thermite blends, while highly effective for construction applications, present significant safety challenges that require careful engineering and handling. The primary concern lies in the highly exothermic nature of the thermite reaction, which can generate temperatures exceeding 2500°C. This extreme heat poses risks of uncontrolled ignition, rapid propagation, and potential structural damage if not properly managed.

One of the key challenges in engineering safer thermite blends is controlling the reaction rate. Traditional thermite mixtures tend to react rapidly, making them difficult to control once ignited. This rapid reaction can lead to unexpected heat distribution, potentially compromising the integrity of surrounding structures or endangering workers. Developing methods to moderate the reaction speed without sacrificing the desired thermal output is a critical area of research.

Another significant challenge is the sensitivity of thermite blends to environmental factors. Moisture, static electricity, and mechanical shock can all potentially trigger unwanted reactions. This sensitivity necessitates stringent storage, transportation, and handling protocols, which can be complex and costly to implement in construction settings. Enhancing the stability of thermite blends under various environmental conditions is crucial for improving overall safety.

The production of toxic fumes and particulates during the thermite reaction presents additional safety concerns. These byproducts can pose health risks to workers and potentially contaminate the surrounding area. Developing formulations that minimize harmful emissions while maintaining the desired thermal properties is a complex balancing act that requires innovative approaches in materials science.

Precision in mixture composition is another critical challenge. Even small variations in the ratio of fuel to oxidizer can significantly affect the reaction characteristics and safety profile of the thermite blend. Ensuring consistent and accurate mixing processes in field conditions can be difficult, necessitating the development of robust quality control measures and potentially new mixing technologies.

The potential for secondary reactions with surrounding materials adds another layer of complexity to thermite blend safety. In construction environments, the high temperatures generated by thermite reactions can interact with a variety of materials, potentially leading to unforeseen chemical reactions or structural weaknesses. Predicting and mitigating these secondary effects requires comprehensive understanding of material interactions under extreme conditions.

Addressing these challenges demands a multidisciplinary approach, combining expertise in chemistry, materials science, and engineering. Innovations in nano-scale particle engineering, smart ignition systems, and advanced containment technologies are among the promising avenues being explored to enhance the safety profile of thermite blends for construction applications.

One of the key challenges in engineering safer thermite blends is controlling the reaction rate. Traditional thermite mixtures tend to react rapidly, making them difficult to control once ignited. This rapid reaction can lead to unexpected heat distribution, potentially compromising the integrity of surrounding structures or endangering workers. Developing methods to moderate the reaction speed without sacrificing the desired thermal output is a critical area of research.

Another significant challenge is the sensitivity of thermite blends to environmental factors. Moisture, static electricity, and mechanical shock can all potentially trigger unwanted reactions. This sensitivity necessitates stringent storage, transportation, and handling protocols, which can be complex and costly to implement in construction settings. Enhancing the stability of thermite blends under various environmental conditions is crucial for improving overall safety.

The production of toxic fumes and particulates during the thermite reaction presents additional safety concerns. These byproducts can pose health risks to workers and potentially contaminate the surrounding area. Developing formulations that minimize harmful emissions while maintaining the desired thermal properties is a complex balancing act that requires innovative approaches in materials science.

Precision in mixture composition is another critical challenge. Even small variations in the ratio of fuel to oxidizer can significantly affect the reaction characteristics and safety profile of the thermite blend. Ensuring consistent and accurate mixing processes in field conditions can be difficult, necessitating the development of robust quality control measures and potentially new mixing technologies.

The potential for secondary reactions with surrounding materials adds another layer of complexity to thermite blend safety. In construction environments, the high temperatures generated by thermite reactions can interact with a variety of materials, potentially leading to unforeseen chemical reactions or structural weaknesses. Predicting and mitigating these secondary effects requires comprehensive understanding of material interactions under extreme conditions.

Addressing these challenges demands a multidisciplinary approach, combining expertise in chemistry, materials science, and engineering. Innovations in nano-scale particle engineering, smart ignition systems, and advanced containment technologies are among the promising avenues being explored to enhance the safety profile of thermite blends for construction applications.

Current Safety Solutions

01 Composition and handling of thermite blends

Thermite blends require careful composition and handling to ensure safety. This includes precise mixing of metal oxides and reducing agents, as well as proper storage and transportation methods. Safety measures such as using non-sparking tools and protective equipment are essential when working with these reactive materials.- Safety measures in thermite blend handling: Implementing proper safety protocols when handling thermite blends is crucial. This includes using appropriate personal protective equipment, ensuring proper ventilation, and following strict handling procedures to minimize risks associated with the highly reactive nature of thermite mixtures.

- Composition modifications for improved safety: Altering the composition of thermite blends can enhance safety. This may involve incorporating stabilizing agents, adjusting particle sizes, or using less reactive components to reduce the risk of unintended ignition or explosive reactions while maintaining desired performance characteristics.

- Containment and storage solutions: Developing specialized containment and storage solutions for thermite blends is essential for safety. This includes designing containers with appropriate materials, incorporating pressure relief mechanisms, and implementing temperature control systems to prevent accidental ignition or decomposition during storage and transport.

- Ignition control and reaction management: Implementing advanced ignition control and reaction management techniques can significantly improve the safety of thermite blends. This may involve developing precise ignition systems, controlling reaction rates, and incorporating quenching mechanisms to prevent uncontrolled propagation of the thermite reaction.

- Environmental and disposal considerations: Addressing environmental concerns and proper disposal methods for thermite blends and their byproducts is crucial for overall safety. This includes developing eco-friendly formulations, implementing safe cleanup procedures, and establishing protocols for the responsible disposal of unused materials and reaction residues.

02 Containment and ignition control systems

Specialized containment vessels and ignition control systems are crucial for safe use of thermite blends. These systems help prevent accidental ignition and contain the reaction, reducing the risk of uncontrolled fires or explosions. Advanced ignition mechanisms allow for precise control over the initiation of the thermite reaction.Expand Specific Solutions03 Safety additives and stabilizers

Incorporating safety additives and stabilizers into thermite blends can enhance their stability and reduce sensitivity to accidental ignition. These additives can include flame retardants, desensitizing agents, or materials that improve the overall safety profile of the blend without compromising its intended performance.Expand Specific Solutions04 Environmental and health considerations

Addressing environmental and health concerns is crucial when working with thermite blends. This includes developing formulations with reduced toxicity, implementing proper disposal methods for waste products, and establishing protocols for handling potential exposure to fumes or residues generated during thermite reactions.Expand Specific Solutions05 Training and safety protocols

Implementing comprehensive training programs and safety protocols is essential for personnel working with thermite blends. This includes educating workers on proper handling techniques, emergency procedures, and the use of personal protective equipment. Regular safety drills and updates to protocols based on new research or incidents are also important aspects of maintaining a safe working environment.Expand Specific Solutions

Key Thermite Manufacturers

The engineering of safer thermite blends for construction is in a developing stage, with a growing market driven by increasing safety concerns and infrastructure demands. The technology's maturity varies across applications, with some established uses and ongoing research for novel formulations. Key players like Xi'an Modern Chemistry Research Institute, Nanjing University of Science & Technology, and Beijing Institute of Technology are advancing fundamental research, while companies such as Lockheed Martin Corp. and Airbus Defence & Space SAS are exploring industrial applications. The competitive landscape is diverse, including academic institutions, defense contractors, and specialized materials companies, indicating a multifaceted approach to innovation in this field.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed a safer thermite blend for construction applications, focusing on controlled reactivity and reduced environmental impact. Their approach involves using nano-aluminum particles and metal oxide fuel components, which allows for precise control over the reaction rate and temperature. The company has also incorporated flame retardants and stabilizers to enhance safety during storage and handling. Additionally, they have implemented a unique encapsulation technique that isolates the thermite components until activation, further improving safety and shelf life.

Strengths: Precise control over reaction, enhanced safety features, and improved shelf life. Weaknesses: Potentially higher production costs and complexity in manufacturing process.

Airbus Defence & Space SAS

Technical Solution: Airbus Defence & Space has engineered a safer thermite blend specifically for aerospace and defense applications, which can be adapted for construction use. Their technology focuses on a multi-component system that separates the fuel and oxidizer until activation. The blend incorporates advanced ceramic materials as heat sinks to control the reaction temperature and reduce the risk of unintended ignition. They have also developed a proprietary binder system that improves the structural integrity of the thermite mixture, making it more resistant to accidental ignition due to impact or friction.

Strengths: High safety standards, controlled reaction, and improved structural integrity. Weaknesses: May be overengineered for some construction applications, potentially leading to higher costs.

Innovative Thermite Formulas

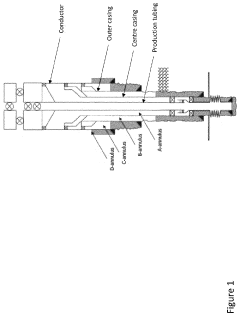

Nano-thermite Well Plug

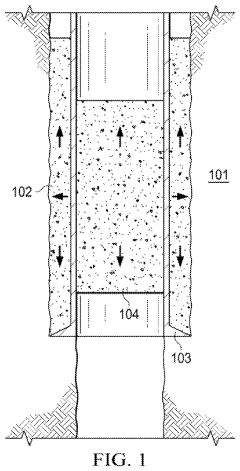

PatentActiveUS20210087904A1

Innovation

- The use of nano-thermite compositions, comprising aluminum and bismuth, which ignite at lower temperatures and react rapidly to form a seal across the wellbore, reducing the need for extensive rig use and complex ignition systems, and allowing for precise plug formation without the need for extensive milling or removal of tubing.

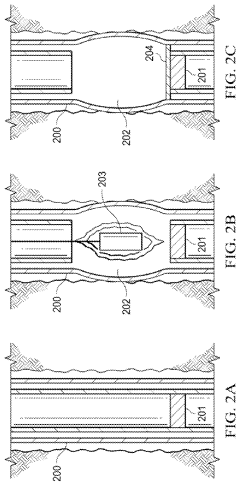

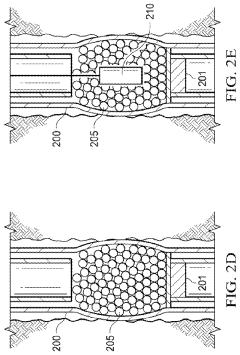

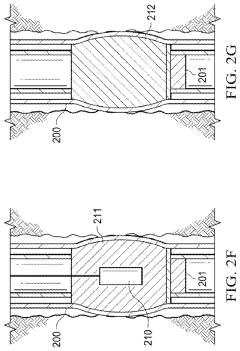

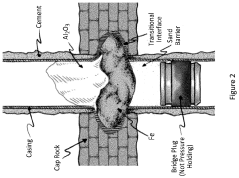

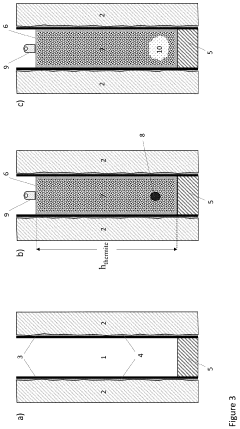

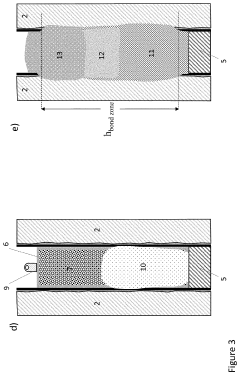

Thermite reaction charge, method for forming a threephased rock-to-rock well barrier, and a well barrier formed thereof

PatentActiveUS20230258052A1

Innovation

- A rigless method employing a bismuth oxide and fuel metal thermite reaction charge, adapted to produce sufficient heat and react slowly enough to melt downhole completion and form a three-phase rock-to-rock well barrier with bismuth, steel, and slag phases, providing a resilient bonding with the rock formation.

Regulatory Framework

The regulatory framework surrounding the use of thermite blends in construction is complex and multifaceted, involving various governmental agencies and industry standards. At the federal level in the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in setting and enforcing safety standards for the use of thermite in construction activities. OSHA's regulations cover aspects such as proper handling, storage, and application of thermite materials, as well as requirements for personal protective equipment (PPE) for workers.

The Environmental Protection Agency (EPA) also has jurisdiction over the use of thermite blends, particularly concerning their potential environmental impact. The EPA's regulations focus on the proper disposal of thermite waste and the prevention of harmful emissions during the thermite reaction process. Additionally, the Department of Transportation (DOT) regulates the transportation of thermite materials, classifying them as hazardous materials and imposing strict guidelines for their shipment.

At the state and local levels, regulations may vary, with some jurisdictions imposing additional requirements or restrictions on the use of thermite in construction. These local regulations often address specific concerns related to fire safety, noise pollution, and the protection of nearby structures and infrastructure.

Industry standards also play a significant role in shaping the regulatory landscape for thermite use in construction. Organizations such as the American Welding Society (AWS) and the National Fire Protection Association (NFPA) provide guidelines and best practices for the safe use of thermite in welding and other construction applications. These standards often become de facto regulations, as many construction contracts and insurance policies require adherence to them.

The regulatory framework also extends to the manufacturing and quality control of thermite blends. The American Society for Testing and Materials (ASTM) has developed specific standards for the composition and performance of thermite materials used in construction. These standards ensure consistency and reliability in thermite products across the industry.

As safety concerns continue to evolve, the regulatory framework for thermite use in construction is subject to ongoing review and updates. Recent trends indicate a move towards more stringent safety requirements, particularly in urban construction projects where the potential risks associated with thermite use are heightened. This dynamic regulatory environment necessitates constant vigilance and adaptation from construction companies and thermite manufacturers to ensure compliance and maintain safety standards.

The Environmental Protection Agency (EPA) also has jurisdiction over the use of thermite blends, particularly concerning their potential environmental impact. The EPA's regulations focus on the proper disposal of thermite waste and the prevention of harmful emissions during the thermite reaction process. Additionally, the Department of Transportation (DOT) regulates the transportation of thermite materials, classifying them as hazardous materials and imposing strict guidelines for their shipment.

At the state and local levels, regulations may vary, with some jurisdictions imposing additional requirements or restrictions on the use of thermite in construction. These local regulations often address specific concerns related to fire safety, noise pollution, and the protection of nearby structures and infrastructure.

Industry standards also play a significant role in shaping the regulatory landscape for thermite use in construction. Organizations such as the American Welding Society (AWS) and the National Fire Protection Association (NFPA) provide guidelines and best practices for the safe use of thermite in welding and other construction applications. These standards often become de facto regulations, as many construction contracts and insurance policies require adherence to them.

The regulatory framework also extends to the manufacturing and quality control of thermite blends. The American Society for Testing and Materials (ASTM) has developed specific standards for the composition and performance of thermite materials used in construction. These standards ensure consistency and reliability in thermite products across the industry.

As safety concerns continue to evolve, the regulatory framework for thermite use in construction is subject to ongoing review and updates. Recent trends indicate a move towards more stringent safety requirements, particularly in urban construction projects where the potential risks associated with thermite use are heightened. This dynamic regulatory environment necessitates constant vigilance and adaptation from construction companies and thermite manufacturers to ensure compliance and maintain safety standards.

Environmental Impact

The environmental impact of thermite blends in construction applications is a critical consideration that requires careful assessment and mitigation strategies. Thermite reactions, while highly effective for certain construction processes, can potentially lead to significant environmental concerns if not properly managed.

One of the primary environmental issues associated with thermite blends is the release of particulate matter during the reaction. These particles, often containing metal oxides and other byproducts, can contribute to air pollution and pose respiratory risks to both workers and nearby communities. The fine particulate matter can remain suspended in the air for extended periods, potentially affecting air quality over a wide area.

Soil contamination is another environmental concern related to thermite use in construction. Residual materials from the thermite reaction, including unreacted components and reaction products, can leach into the soil. This may lead to changes in soil chemistry, potentially affecting local flora and fauna. In some cases, these contaminants could migrate to groundwater sources, further extending their environmental impact.

The high temperatures generated during thermite reactions can also have localized effects on the immediate environment. This intense heat may cause damage to surrounding vegetation, alter soil microbial communities, and potentially create long-lasting changes to the local ecosystem. In urban environments, this thermal impact could affect nearby structures and infrastructure.

Water pollution is a potential risk, particularly in scenarios where thermite is used near water bodies or in areas with high water tables. The runoff from construction sites using thermite blends may contain dissolved metals and other chemical compounds that can adversely affect aquatic ecosystems and water quality.

To address these environmental concerns, several approaches can be considered in engineering safer thermite blends. Developing formulations that produce fewer airborne particles and less toxic byproducts is a key area of focus. This may involve altering the composition of the thermite mixture or incorporating additives that bind potential contaminants.

Implementing more efficient reaction processes that minimize waste and unused materials can significantly reduce the environmental footprint of thermite use. Additionally, designing containment systems to capture and treat emissions and residues from thermite reactions is crucial in minimizing environmental dispersal of potentially harmful substances.

Exploring alternative, more environmentally friendly materials that can achieve similar results to traditional thermite blends is an important avenue for research. This may include investigating bio-based or recyclable components that can reduce the overall environmental impact while maintaining the desired performance characteristics.

One of the primary environmental issues associated with thermite blends is the release of particulate matter during the reaction. These particles, often containing metal oxides and other byproducts, can contribute to air pollution and pose respiratory risks to both workers and nearby communities. The fine particulate matter can remain suspended in the air for extended periods, potentially affecting air quality over a wide area.

Soil contamination is another environmental concern related to thermite use in construction. Residual materials from the thermite reaction, including unreacted components and reaction products, can leach into the soil. This may lead to changes in soil chemistry, potentially affecting local flora and fauna. In some cases, these contaminants could migrate to groundwater sources, further extending their environmental impact.

The high temperatures generated during thermite reactions can also have localized effects on the immediate environment. This intense heat may cause damage to surrounding vegetation, alter soil microbial communities, and potentially create long-lasting changes to the local ecosystem. In urban environments, this thermal impact could affect nearby structures and infrastructure.

Water pollution is a potential risk, particularly in scenarios where thermite is used near water bodies or in areas with high water tables. The runoff from construction sites using thermite blends may contain dissolved metals and other chemical compounds that can adversely affect aquatic ecosystems and water quality.

To address these environmental concerns, several approaches can be considered in engineering safer thermite blends. Developing formulations that produce fewer airborne particles and less toxic byproducts is a key area of focus. This may involve altering the composition of the thermite mixture or incorporating additives that bind potential contaminants.

Implementing more efficient reaction processes that minimize waste and unused materials can significantly reduce the environmental footprint of thermite use. Additionally, designing containment systems to capture and treat emissions and residues from thermite reactions is crucial in minimizing environmental dispersal of potentially harmful substances.

Exploring alternative, more environmentally friendly materials that can achieve similar results to traditional thermite blends is an important avenue for research. This may include investigating bio-based or recyclable components that can reduce the overall environmental impact while maintaining the desired performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!