Thermite Technology in Infrastructure Development Projects

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Tech Evolution

Thermite technology in infrastructure development has undergone significant evolution since its inception. Initially developed for military applications, thermite reactions have found their way into civil engineering and construction projects due to their unique properties and capabilities.

In the early stages, thermite was primarily used for welding railway tracks. The exothermic reaction's ability to generate intense heat quickly made it ideal for joining large metal components in situ. This application laid the foundation for thermite's use in infrastructure development.

As research progressed, engineers discovered new applications for thermite in construction. The 1970s saw the introduction of thermite welding for repairing and joining large steel structures, such as bridges and high-rise buildings. This method proved particularly useful in situations where traditional welding techniques were impractical or impossible.

The 1980s and 1990s marked a period of refinement in thermite technology. Researchers focused on improving the composition of thermite mixtures to enhance their performance and safety. This led to the development of more stable and controllable thermite reactions, expanding their potential applications in infrastructure projects.

In the early 2000s, thermite technology found new applications in demolition and controlled destruction of structures. The ability to generate localized, intense heat made it an effective tool for cutting through steel beams and concrete reinforcements, facilitating more precise and controlled demolition processes.

Recent advancements have focused on enhancing the efficiency and environmental impact of thermite reactions. Researchers have explored ways to reduce emissions and improve the overall sustainability of thermite-based processes in construction and infrastructure development.

The integration of digital technologies has also played a crucial role in the evolution of thermite applications. Computer modeling and simulation tools now allow engineers to optimize thermite reactions for specific infrastructure projects, improving safety and efficiency.

Looking ahead, the future of thermite technology in infrastructure development is likely to involve further refinements in composition and application techniques. Researchers are exploring the potential of nano-thermites and other advanced materials to create even more powerful and controllable reactions. Additionally, there is growing interest in developing thermite-based solutions for rapid infrastructure repair and disaster response scenarios.

In the early stages, thermite was primarily used for welding railway tracks. The exothermic reaction's ability to generate intense heat quickly made it ideal for joining large metal components in situ. This application laid the foundation for thermite's use in infrastructure development.

As research progressed, engineers discovered new applications for thermite in construction. The 1970s saw the introduction of thermite welding for repairing and joining large steel structures, such as bridges and high-rise buildings. This method proved particularly useful in situations where traditional welding techniques were impractical or impossible.

The 1980s and 1990s marked a period of refinement in thermite technology. Researchers focused on improving the composition of thermite mixtures to enhance their performance and safety. This led to the development of more stable and controllable thermite reactions, expanding their potential applications in infrastructure projects.

In the early 2000s, thermite technology found new applications in demolition and controlled destruction of structures. The ability to generate localized, intense heat made it an effective tool for cutting through steel beams and concrete reinforcements, facilitating more precise and controlled demolition processes.

Recent advancements have focused on enhancing the efficiency and environmental impact of thermite reactions. Researchers have explored ways to reduce emissions and improve the overall sustainability of thermite-based processes in construction and infrastructure development.

The integration of digital technologies has also played a crucial role in the evolution of thermite applications. Computer modeling and simulation tools now allow engineers to optimize thermite reactions for specific infrastructure projects, improving safety and efficiency.

Looking ahead, the future of thermite technology in infrastructure development is likely to involve further refinements in composition and application techniques. Researchers are exploring the potential of nano-thermites and other advanced materials to create even more powerful and controllable reactions. Additionally, there is growing interest in developing thermite-based solutions for rapid infrastructure repair and disaster response scenarios.

Infrastructure Demand

The global infrastructure sector is experiencing a significant surge in demand, driven by rapid urbanization, population growth, and the need for sustainable development. This increasing demand for infrastructure projects presents a unique opportunity for innovative technologies like thermite to play a crucial role in enhancing construction processes and outcomes.

Urbanization is a key driver of infrastructure demand, with the United Nations projecting that 68% of the world's population will live in urban areas by 2050. This urban shift necessitates substantial investments in transportation networks, energy systems, water management, and public facilities. Developing countries, in particular, are facing immense pressure to expand their infrastructure to support economic growth and improve living standards.

Climate change and environmental concerns are also shaping infrastructure demand. There is a growing emphasis on resilient and sustainable infrastructure that can withstand extreme weather events and reduce carbon emissions. This trend is driving the adoption of green building practices and the integration of renewable energy systems into infrastructure projects.

The global infrastructure investment gap is substantial, with estimates suggesting that $94 trillion in infrastructure investments will be needed by 2040 to keep pace with projected economic and demographic changes. This gap is particularly pronounced in emerging markets and developing economies, where rapid industrialization and urbanization are outpacing infrastructure development.

In the context of these global trends, thermite technology offers several advantages that align with the evolving demands of the infrastructure sector. Its ability to generate high temperatures rapidly and efficiently makes it particularly suitable for welding and joining large metal components, which is crucial in the construction of bridges, railways, and pipelines. The exothermic nature of thermite reactions also presents opportunities for innovative applications in concrete curing and ground improvement techniques.

Moreover, the infrastructure sector's increasing focus on speed and efficiency in project delivery creates a favorable environment for thermite technology adoption. Its potential to reduce construction time and labor costs aligns well with the industry's push for more cost-effective and time-efficient building methods. This is especially relevant in urban environments where minimizing disruption during construction is a priority.

The demand for infrastructure resilience and longevity also positions thermite technology favorably. Its use in welding and metal joining can contribute to the creation of stronger, more durable structures capable of withstanding harsh environmental conditions and prolonged use. This aligns with the growing emphasis on life-cycle cost considerations in infrastructure planning and development.

Urbanization is a key driver of infrastructure demand, with the United Nations projecting that 68% of the world's population will live in urban areas by 2050. This urban shift necessitates substantial investments in transportation networks, energy systems, water management, and public facilities. Developing countries, in particular, are facing immense pressure to expand their infrastructure to support economic growth and improve living standards.

Climate change and environmental concerns are also shaping infrastructure demand. There is a growing emphasis on resilient and sustainable infrastructure that can withstand extreme weather events and reduce carbon emissions. This trend is driving the adoption of green building practices and the integration of renewable energy systems into infrastructure projects.

The global infrastructure investment gap is substantial, with estimates suggesting that $94 trillion in infrastructure investments will be needed by 2040 to keep pace with projected economic and demographic changes. This gap is particularly pronounced in emerging markets and developing economies, where rapid industrialization and urbanization are outpacing infrastructure development.

In the context of these global trends, thermite technology offers several advantages that align with the evolving demands of the infrastructure sector. Its ability to generate high temperatures rapidly and efficiently makes it particularly suitable for welding and joining large metal components, which is crucial in the construction of bridges, railways, and pipelines. The exothermic nature of thermite reactions also presents opportunities for innovative applications in concrete curing and ground improvement techniques.

Moreover, the infrastructure sector's increasing focus on speed and efficiency in project delivery creates a favorable environment for thermite technology adoption. Its potential to reduce construction time and labor costs aligns well with the industry's push for more cost-effective and time-efficient building methods. This is especially relevant in urban environments where minimizing disruption during construction is a priority.

The demand for infrastructure resilience and longevity also positions thermite technology favorably. Its use in welding and metal joining can contribute to the creation of stronger, more durable structures capable of withstanding harsh environmental conditions and prolonged use. This aligns with the growing emphasis on life-cycle cost considerations in infrastructure planning and development.

Current Challenges

Thermite technology in infrastructure development projects faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the safety concerns associated with the highly exothermic nature of thermite reactions. The intense heat generated during the process poses potential risks to workers and surrounding structures, necessitating stringent safety protocols and specialized handling procedures.

Environmental considerations also present a substantial challenge. The byproducts of thermite reactions, including metal oxides and slag, can have detrimental effects on local ecosystems if not properly managed. This necessitates the development of comprehensive waste management strategies and environmental impact assessments for each project.

The cost-effectiveness of thermite technology in infrastructure development remains a contentious issue. While it offers advantages in certain applications, such as rail welding and underwater repairs, the initial investment in equipment and training can be substantial. This economic barrier often leads to hesitation among project managers and investors, particularly in regions with limited budgets for infrastructure development.

Technical limitations pose another set of challenges. The precision required for successful thermite reactions can be difficult to achieve in field conditions, especially in adverse weather or underwater environments. This can lead to inconsistent results and potential structural weaknesses in the finished product, undermining the reliability of the technology.

Regulatory hurdles further complicate the implementation of thermite technology. Many jurisdictions lack specific guidelines for its use in infrastructure projects, leading to uncertainty and potential legal complications. The absence of standardized regulations also hampers the development of best practices and quality control measures across the industry.

The shortage of skilled personnel trained in thermite technology applications presents an ongoing challenge. The specialized nature of the process requires extensive training and experience, which is not widely available in many regions. This skills gap can lead to project delays and increased costs as organizations struggle to find or train qualified technicians.

Scalability issues also emerge when considering thermite technology for large-scale infrastructure projects. While effective for localized applications, scaling up the process for extensive structural work presents logistical and technical challenges that have yet to be fully resolved.

Lastly, the integration of thermite technology with existing infrastructure and construction methodologies remains a complex task. Compatibility issues with traditional materials and techniques can arise, necessitating careful planning and potentially extensive modifications to established project workflows.

Environmental considerations also present a substantial challenge. The byproducts of thermite reactions, including metal oxides and slag, can have detrimental effects on local ecosystems if not properly managed. This necessitates the development of comprehensive waste management strategies and environmental impact assessments for each project.

The cost-effectiveness of thermite technology in infrastructure development remains a contentious issue. While it offers advantages in certain applications, such as rail welding and underwater repairs, the initial investment in equipment and training can be substantial. This economic barrier often leads to hesitation among project managers and investors, particularly in regions with limited budgets for infrastructure development.

Technical limitations pose another set of challenges. The precision required for successful thermite reactions can be difficult to achieve in field conditions, especially in adverse weather or underwater environments. This can lead to inconsistent results and potential structural weaknesses in the finished product, undermining the reliability of the technology.

Regulatory hurdles further complicate the implementation of thermite technology. Many jurisdictions lack specific guidelines for its use in infrastructure projects, leading to uncertainty and potential legal complications. The absence of standardized regulations also hampers the development of best practices and quality control measures across the industry.

The shortage of skilled personnel trained in thermite technology applications presents an ongoing challenge. The specialized nature of the process requires extensive training and experience, which is not widely available in many regions. This skills gap can lead to project delays and increased costs as organizations struggle to find or train qualified technicians.

Scalability issues also emerge when considering thermite technology for large-scale infrastructure projects. While effective for localized applications, scaling up the process for extensive structural work presents logistical and technical challenges that have yet to be fully resolved.

Lastly, the integration of thermite technology with existing infrastructure and construction methodologies remains a complex task. Compatibility issues with traditional materials and techniques can arise, necessitating careful planning and potentially extensive modifications to established project workflows.

Existing Solutions

01 Thermite composition and ignition methods

Thermite technology involves the use of specific compositions and ignition methods to produce high-temperature reactions. These compositions typically include metal oxides and reactive metals. Various ignition techniques are employed to initiate the thermite reaction, such as electrical ignition or chemical initiators. The resulting exothermic reaction generates intense heat and molten metal, which can be used for various applications.- Thermite composition and ignition methods: Thermite technology involves specific compositions of metal oxides and reducing agents, typically aluminum. Various ignition methods are employed, including electrical, chemical, and mechanical means. The reaction produces intense heat and molten metal, useful for welding, incendiary devices, and metal purification.

- Applications in welding and metal joining: Thermite reactions are utilized in welding applications, particularly for joining railway tracks, pipes, and large metal structures. The process involves controlled ignition of the thermite mixture in a mold, resulting in molten metal that fuses the joint. This technique is valued for its portability and ability to create strong, seamless joints.

- Thermite in military and defense applications: Thermite technology finds use in military applications such as incendiary devices, armor-piercing munitions, and pyrotechnics. The high-temperature reaction and metal-cutting capabilities make it effective for disabling equipment or creating diversions. Specialized formulations and delivery systems are developed for various tactical scenarios.

- Safety and control mechanisms: Given the intense nature of thermite reactions, safety measures and control mechanisms are crucial. This includes specialized containment vessels, remote ignition systems, and precise mixture ratios. Innovations focus on improving stability, reducing unintended ignitions, and enhancing user safety in various applications.

- Novel thermite compositions and enhancements: Research in thermite technology explores new material combinations and additives to enhance performance. This includes nano-scale particles for increased reactivity, environmentally friendly compositions, and tailored thermite mixtures for specific applications like underwater welding or space-based operations.

02 Thermite welding and metal joining

Thermite technology is widely used in welding and metal joining processes. The high-temperature reaction of thermite mixtures can be harnessed to join metal components, particularly in railway track welding. This process involves carefully designed molds and ignition systems to control the flow of molten metal and ensure proper fusion of the joined parts. Innovations in this field focus on improving weld quality, reducing porosity, and enhancing overall efficiency.Expand Specific Solutions03 Thermite-based cutting and perforation tools

Thermite reactions are utilized in the development of cutting and perforation tools for various industries. These tools harness the intense heat and molten metal produced by thermite reactions to cut through or perforate materials such as metal structures, rock formations, or concrete. Applications include oil well perforation, demolition, and specialized cutting operations in challenging environments.Expand Specific Solutions04 Enhanced thermite formulations

Research in thermite technology focuses on developing enhanced formulations with improved performance characteristics. This includes the incorporation of nanomaterials, additives, or alternative fuel-oxidizer combinations to increase reaction rates, energy output, or specific properties. These advancements aim to tailor thermite reactions for specific applications, such as propulsion systems, pyrotechnics, or material synthesis.Expand Specific Solutions05 Safety and control mechanisms in thermite technology

Given the high-energy nature of thermite reactions, significant emphasis is placed on developing safety and control mechanisms. This includes the design of containment systems, precise ignition controls, and methods to manage reaction byproducts. Innovations in this area focus on minimizing risks associated with thermite use, improving handling procedures, and enhancing the overall safety profile of thermite-based technologies across various applications.Expand Specific Solutions

Key Industry Players

The thermite technology in infrastructure development projects is in a growth phase, with increasing market size and evolving applications. The global market for thermite welding is expanding, driven by infrastructure modernization and railway network expansion. Technologically, it's advancing from traditional applications to more sophisticated uses. Companies like China Petroleum & Chemical Corp. and Schlumberger Technologies, Inc. are pushing boundaries in oil and gas applications, while Holcim Technology Ltd. explores construction innovations. Universities such as Zhejiang University and Xi'an Jiaotong University contribute to research advancements. The technology's maturity varies across sectors, with established processes in rail welding but emerging applications in geotechnical engineering, as evidenced by Jiangsu Xintai Geotechnical Technology Co., Ltd.'s involvement.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. has developed a thermite-based technology for pipeline repair and maintenance in oil and gas infrastructure. Their approach involves using a controlled thermite reaction to generate localized heat, allowing for in-situ welding and sealing of pipeline defects. The company has also explored the use of thermite reactions for creating high-temperature resistant coatings on infrastructure components exposed to extreme conditions.

Strengths: Efficient and cost-effective pipeline repair, reduced downtime for maintenance. Weaknesses: Potential safety concerns due to high-temperature reactions, limited applicability in certain environments.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has pioneered the use of thermite technology in infrastructure development through their Advanced Materials division. They have developed a thermite-based concrete repair system that utilizes the heat generated from thermite reactions to rapidly cure and bond repair materials to existing concrete structures. This technology has been applied in bridge deck repairs, runway maintenance, and other critical infrastructure projects requiring quick turnaround times.

Strengths: Rapid repair and rehabilitation of concrete structures, improved durability of repairs. Weaknesses: Higher initial costs compared to traditional repair methods, specialized training required for application.

Core Thermite Innovations

Expanding Thermite Reactions for Downhole Applications

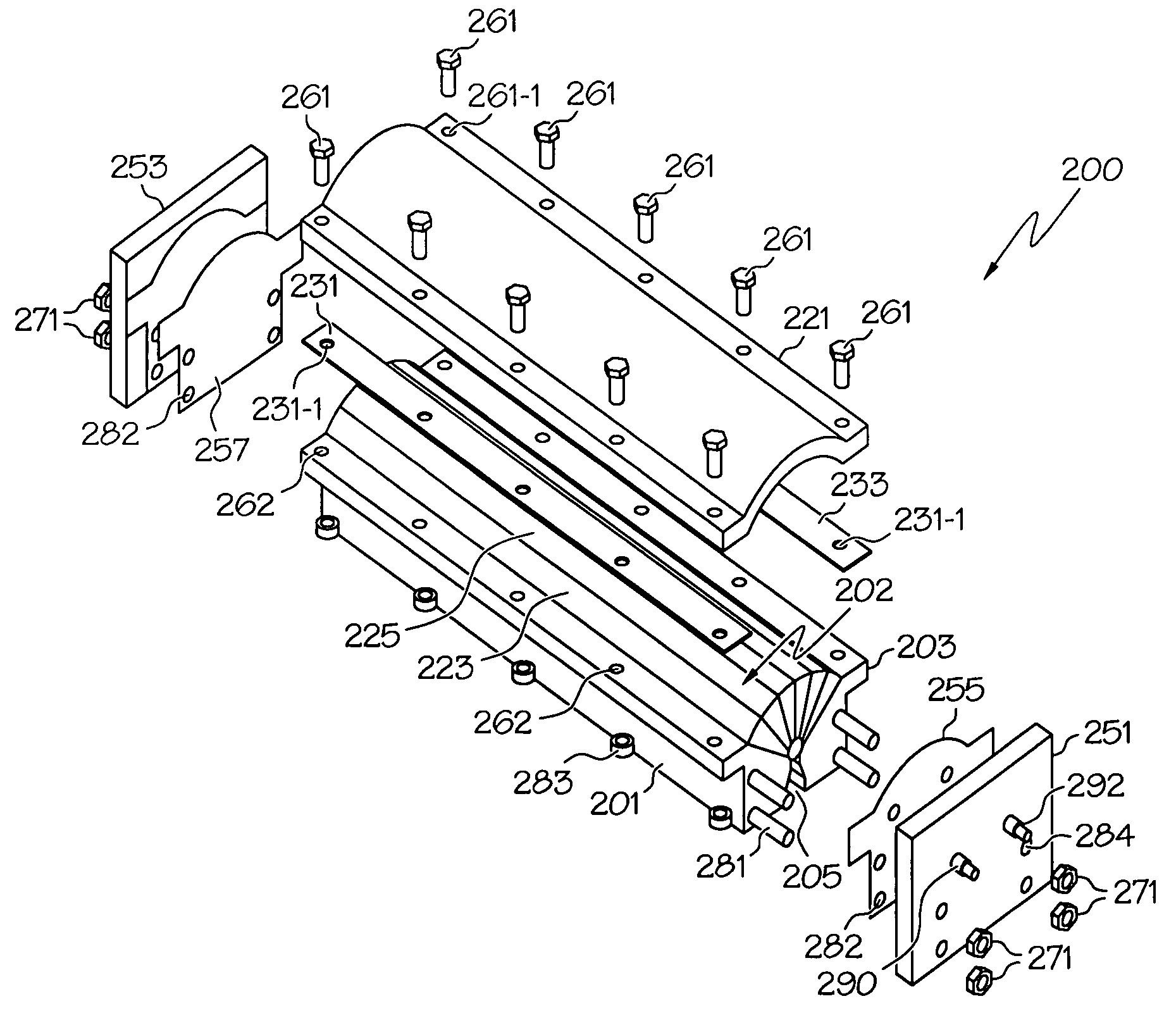

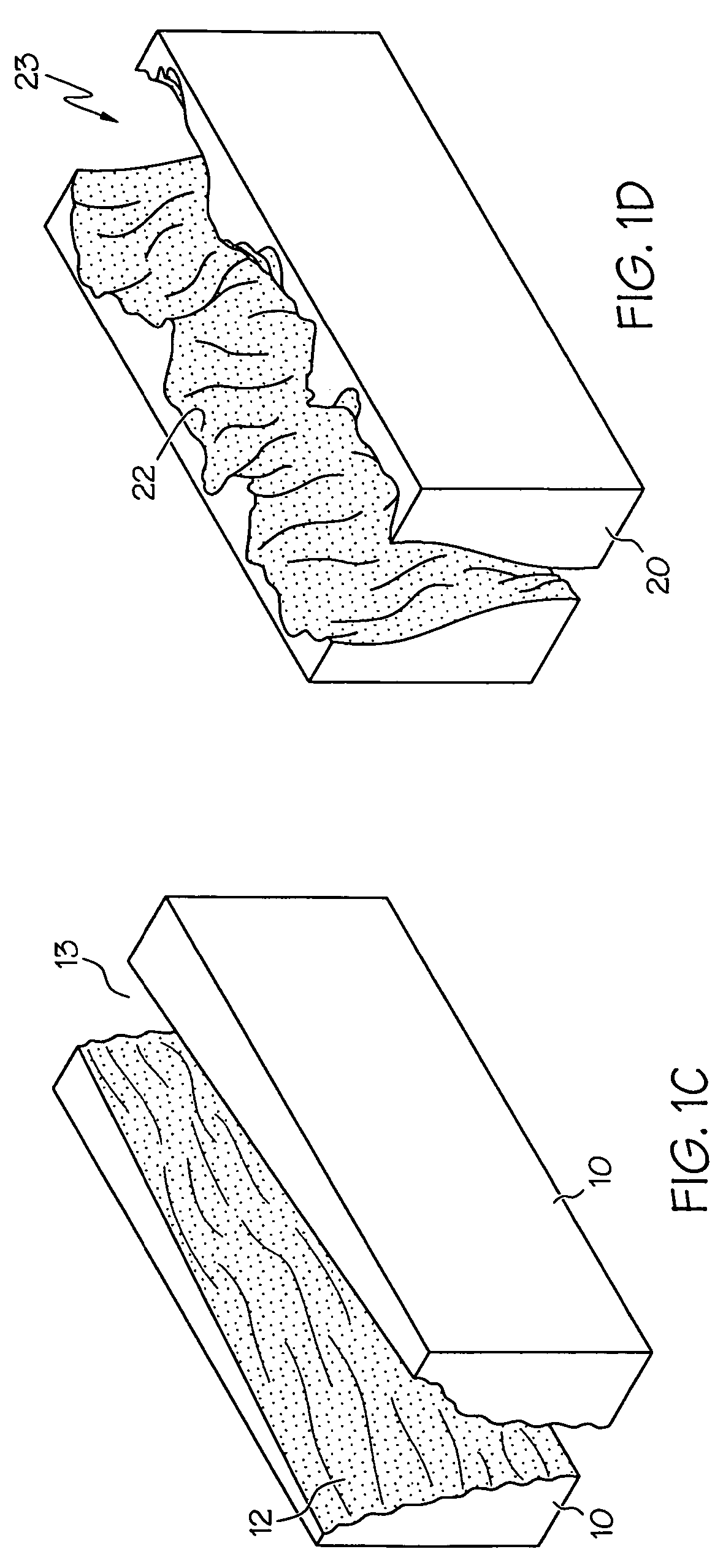

PatentActiveUS20200208494A1

Innovation

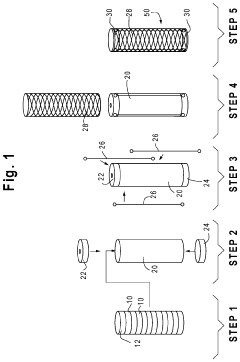

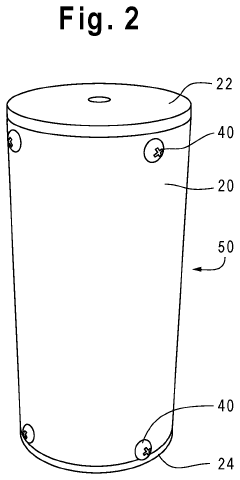

- A thermite reaction package with a cylindrical housing and ignition module, featuring gas-generating materials and additives like silicon carbide to control porosity and iron distribution, and a flexible or rigid structure to constrain longitudinal expansion and promote lateral expansion, forming a ceramic bridge plug or screen within the well.

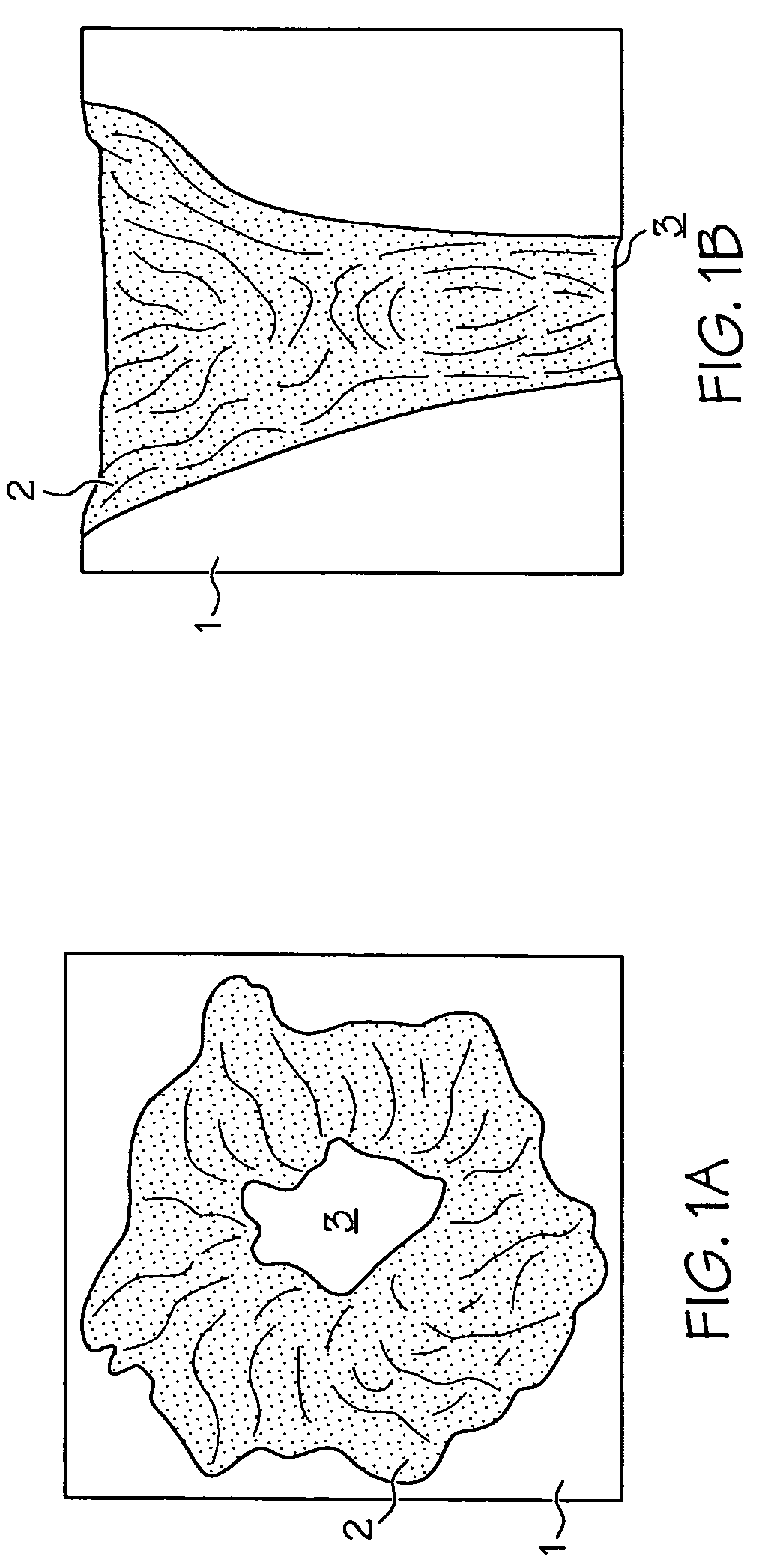

Thermite charge

PatentActiveUS7555986B2

Innovation

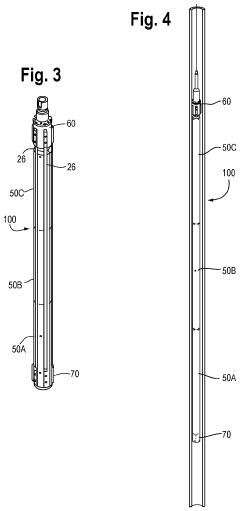

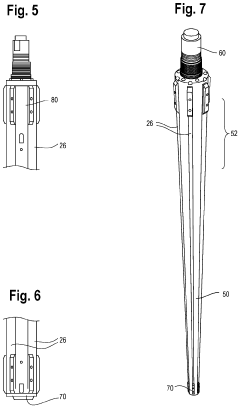

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

Safety and Regulations

The implementation of thermite technology in infrastructure development projects necessitates stringent safety measures and regulatory compliance. Given the high-temperature exothermic reactions involved in thermite processes, safety considerations are paramount to protect workers, the public, and the environment.

Regulatory bodies worldwide have established comprehensive guidelines for the use of thermite in construction and infrastructure projects. These regulations typically cover aspects such as storage, transportation, handling, and application of thermite materials. In the United States, the Occupational Safety and Health Administration (OSHA) provides specific standards for thermite welding operations, including requirements for personal protective equipment, fire prevention, and ventilation.

Safety protocols for thermite use in infrastructure projects often include mandatory training programs for personnel involved in handling and applying the material. These programs cover proper ignition techniques, containment procedures, and emergency response measures. Additionally, project managers must develop and implement site-specific safety plans that address potential hazards associated with thermite reactions, such as molten metal splatter and intense heat generation.

Environmental regulations also play a crucial role in the use of thermite technology. Many jurisdictions require environmental impact assessments before approving thermite-based infrastructure projects. These assessments evaluate potential effects on air quality, soil contamination, and water resources. Mitigation strategies, such as containment systems and proper waste disposal methods, are often mandated to minimize environmental risks.

The transportation of thermite materials is subject to strict regulations due to their classification as hazardous materials. In many countries, specialized permits and packaging requirements are necessary for the movement of thermite compounds. Compliance with these transportation regulations is essential to prevent accidents during transit and ensure the safe delivery of materials to project sites.

Quality control measures are another critical aspect of safety and regulatory compliance in thermite-based infrastructure projects. Regular inspections and testing of thermite materials, as well as the finished products of thermite reactions (such as welded joints), are typically required to ensure structural integrity and long-term safety of the infrastructure.

As thermite technology continues to evolve and find new applications in infrastructure development, regulatory frameworks are also adapting. Ongoing research and development efforts focus on improving the safety profile of thermite reactions and developing more environmentally friendly formulations. These advancements are likely to influence future regulations, potentially leading to more widespread adoption of thermite technology in infrastructure projects while maintaining the highest standards of safety and environmental protection.

Regulatory bodies worldwide have established comprehensive guidelines for the use of thermite in construction and infrastructure projects. These regulations typically cover aspects such as storage, transportation, handling, and application of thermite materials. In the United States, the Occupational Safety and Health Administration (OSHA) provides specific standards for thermite welding operations, including requirements for personal protective equipment, fire prevention, and ventilation.

Safety protocols for thermite use in infrastructure projects often include mandatory training programs for personnel involved in handling and applying the material. These programs cover proper ignition techniques, containment procedures, and emergency response measures. Additionally, project managers must develop and implement site-specific safety plans that address potential hazards associated with thermite reactions, such as molten metal splatter and intense heat generation.

Environmental regulations also play a crucial role in the use of thermite technology. Many jurisdictions require environmental impact assessments before approving thermite-based infrastructure projects. These assessments evaluate potential effects on air quality, soil contamination, and water resources. Mitigation strategies, such as containment systems and proper waste disposal methods, are often mandated to minimize environmental risks.

The transportation of thermite materials is subject to strict regulations due to their classification as hazardous materials. In many countries, specialized permits and packaging requirements are necessary for the movement of thermite compounds. Compliance with these transportation regulations is essential to prevent accidents during transit and ensure the safe delivery of materials to project sites.

Quality control measures are another critical aspect of safety and regulatory compliance in thermite-based infrastructure projects. Regular inspections and testing of thermite materials, as well as the finished products of thermite reactions (such as welded joints), are typically required to ensure structural integrity and long-term safety of the infrastructure.

As thermite technology continues to evolve and find new applications in infrastructure development, regulatory frameworks are also adapting. Ongoing research and development efforts focus on improving the safety profile of thermite reactions and developing more environmentally friendly formulations. These advancements are likely to influence future regulations, potentially leading to more widespread adoption of thermite technology in infrastructure projects while maintaining the highest standards of safety and environmental protection.

Environmental Impact

The environmental impact of thermite technology in infrastructure development projects is a critical consideration that requires thorough assessment. Thermite reactions, characterized by their high-temperature exothermic nature, can have both immediate and long-term effects on the surrounding ecosystem.

One of the primary environmental concerns associated with thermite technology is the release of particulate matter and gaseous emissions during the reaction process. These emissions may contain metal oxides and other potentially harmful substances, which can contribute to air pollution and pose risks to local flora and fauna. The intense heat generated by thermite reactions can also lead to localized soil sterilization, potentially disrupting microbial communities and affecting soil fertility in the immediate vicinity of the application site.

Water resources near infrastructure development projects utilizing thermite technology may be at risk of contamination. Runoff from reaction sites could introduce metal residues and other byproducts into nearby water bodies, potentially impacting aquatic ecosystems and water quality. This necessitates the implementation of robust containment and filtration systems to mitigate the risk of water pollution.

The use of thermite in infrastructure projects may also have implications for local biodiversity. The intense heat and light produced during thermite reactions can disturb wildlife, particularly nocturnal species, and may temporarily alter animal behavior patterns in the surrounding area. Additionally, the physical alterations to the landscape resulting from thermite-based construction techniques could lead to habitat fragmentation or loss, affecting local species populations.

On a broader scale, the production and transportation of thermite materials contribute to the project's overall carbon footprint. The energy-intensive processes involved in manufacturing thermite components and the logistics of transporting these materials to construction sites add to the cumulative environmental impact of infrastructure development.

However, it is important to note that thermite technology can also offer environmental benefits in certain applications. For instance, when used in rail welding, it can provide more durable and efficient rail connections, potentially reducing long-term maintenance requirements and associated environmental disturbances. Similarly, in demolition projects, the precise and controlled nature of thermite reactions can minimize collateral damage and reduce the overall environmental footprint of the demolition process.

To mitigate the environmental impact of thermite technology in infrastructure development, several strategies can be employed. These include the use of containment systems to capture emissions and residues, the implementation of site-specific environmental management plans, and the adoption of best practices for material handling and disposal. Additionally, ongoing research into more environmentally friendly thermite formulations and application techniques holds promise for further reducing the ecological footprint of this technology in future infrastructure projects.

One of the primary environmental concerns associated with thermite technology is the release of particulate matter and gaseous emissions during the reaction process. These emissions may contain metal oxides and other potentially harmful substances, which can contribute to air pollution and pose risks to local flora and fauna. The intense heat generated by thermite reactions can also lead to localized soil sterilization, potentially disrupting microbial communities and affecting soil fertility in the immediate vicinity of the application site.

Water resources near infrastructure development projects utilizing thermite technology may be at risk of contamination. Runoff from reaction sites could introduce metal residues and other byproducts into nearby water bodies, potentially impacting aquatic ecosystems and water quality. This necessitates the implementation of robust containment and filtration systems to mitigate the risk of water pollution.

The use of thermite in infrastructure projects may also have implications for local biodiversity. The intense heat and light produced during thermite reactions can disturb wildlife, particularly nocturnal species, and may temporarily alter animal behavior patterns in the surrounding area. Additionally, the physical alterations to the landscape resulting from thermite-based construction techniques could lead to habitat fragmentation or loss, affecting local species populations.

On a broader scale, the production and transportation of thermite materials contribute to the project's overall carbon footprint. The energy-intensive processes involved in manufacturing thermite components and the logistics of transporting these materials to construction sites add to the cumulative environmental impact of infrastructure development.

However, it is important to note that thermite technology can also offer environmental benefits in certain applications. For instance, when used in rail welding, it can provide more durable and efficient rail connections, potentially reducing long-term maintenance requirements and associated environmental disturbances. Similarly, in demolition projects, the precise and controlled nature of thermite reactions can minimize collateral damage and reduce the overall environmental footprint of the demolition process.

To mitigate the environmental impact of thermite technology in infrastructure development, several strategies can be employed. These include the use of containment systems to capture emissions and residues, the implementation of site-specific environmental management plans, and the adoption of best practices for material handling and disposal. Additionally, ongoing research into more environmentally friendly thermite formulations and application techniques holds promise for further reducing the ecological footprint of this technology in future infrastructure projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!