Thermite Reaction Byproducts: Environmental and Practical Considerations

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Reaction Overview and Objectives

Thermite reactions, a class of highly exothermic redox processes, have been a subject of scientific interest and practical application for over a century. These reactions typically involve the reduction of a metal oxide by a more reactive metal, most commonly aluminum, resulting in the production of a more stable oxide and the corresponding reduced metal. The intense heat generated during these reactions, often exceeding 2500°C, has led to their widespread use in various industrial and military applications.

The primary objective of studying thermite reaction byproducts is to gain a comprehensive understanding of their environmental impact and practical implications. This investigation is crucial for developing safer and more sustainable applications of thermite reactions across different sectors. By examining the composition, quantity, and dispersion patterns of these byproducts, researchers aim to mitigate potential environmental hazards and optimize the efficiency of thermite-based processes.

Historically, thermite reactions were first discovered by German chemist Hans Goldschmidt in 1893. Initially developed for welding railway tracks, the technology quickly found applications in metallurgy, incendiary devices, and pyrotechnics. As the use of thermite reactions expanded, so did the need to understand and manage their byproducts. The evolution of environmental consciousness in recent decades has further intensified the focus on the ecological footprint of these reactions.

Current research in this field is driven by several key factors. First, there is a growing emphasis on environmental sustainability across all industries, necessitating a thorough assessment of the ecological impact of thermite reactions. Second, advancements in analytical techniques have enabled more precise characterization of reaction byproducts, allowing for better risk assessment and management. Lastly, the expanding applications of thermite reactions in fields such as materials science and nanotechnology have introduced new considerations regarding byproduct formation and control.

The technological trajectory in this domain is expected to focus on developing cleaner thermite formulations, improving byproduct containment methods, and exploring novel applications that minimize environmental risks. This may involve the use of alternative reactants, the implementation of advanced filtration systems, or the development of closed-loop processes that capture and recycle byproducts. Additionally, there is increasing interest in harnessing the unique properties of thermite reaction byproducts for beneficial applications, potentially transforming waste products into valuable resources.

The primary objective of studying thermite reaction byproducts is to gain a comprehensive understanding of their environmental impact and practical implications. This investigation is crucial for developing safer and more sustainable applications of thermite reactions across different sectors. By examining the composition, quantity, and dispersion patterns of these byproducts, researchers aim to mitigate potential environmental hazards and optimize the efficiency of thermite-based processes.

Historically, thermite reactions were first discovered by German chemist Hans Goldschmidt in 1893. Initially developed for welding railway tracks, the technology quickly found applications in metallurgy, incendiary devices, and pyrotechnics. As the use of thermite reactions expanded, so did the need to understand and manage their byproducts. The evolution of environmental consciousness in recent decades has further intensified the focus on the ecological footprint of these reactions.

Current research in this field is driven by several key factors. First, there is a growing emphasis on environmental sustainability across all industries, necessitating a thorough assessment of the ecological impact of thermite reactions. Second, advancements in analytical techniques have enabled more precise characterization of reaction byproducts, allowing for better risk assessment and management. Lastly, the expanding applications of thermite reactions in fields such as materials science and nanotechnology have introduced new considerations regarding byproduct formation and control.

The technological trajectory in this domain is expected to focus on developing cleaner thermite formulations, improving byproduct containment methods, and exploring novel applications that minimize environmental risks. This may involve the use of alternative reactants, the implementation of advanced filtration systems, or the development of closed-loop processes that capture and recycle byproducts. Additionally, there is increasing interest in harnessing the unique properties of thermite reaction byproducts for beneficial applications, potentially transforming waste products into valuable resources.

Market Analysis for Thermite Applications

The thermite reaction, known for its high-temperature exothermic properties, has found applications across various industries, creating a diverse and growing market. The global market for thermite applications is primarily driven by its use in metal purification, welding, and incendiary devices. In the metal production sector, thermite reactions are employed for purifying metals like chromium and manganese, contributing to the overall growth of the metallurgical industry.

The welding segment, particularly in railway track welding, represents a significant portion of the thermite market. As countries invest in expanding and upgrading their rail infrastructure, the demand for thermite welding continues to rise. This trend is especially prominent in developing economies where rapid urbanization and transportation development projects are underway.

In the defense sector, thermite finds applications in incendiary devices and pyrotechnics, although this market segment is more specialized and subject to strict regulations. The aerospace industry also utilizes thermite in certain niche applications, such as emergency destruction of sensitive equipment.

The market for thermite applications is geographically diverse, with significant demand in North America, Europe, and Asia-Pacific regions. The Asia-Pacific market, in particular, is expected to show robust growth due to increasing industrialization and infrastructure development in countries like China and India.

Environmental considerations are becoming increasingly important in the thermite market. As awareness of the environmental impact of industrial processes grows, there is a rising demand for cleaner and more sustainable thermite reaction processes. This trend is driving research and development efforts to minimize harmful byproducts and improve the overall environmental profile of thermite applications.

The market is characterized by a mix of large multinational corporations and specialized smaller companies. Key players are focusing on developing innovative thermite formulations that offer improved performance, safety, and environmental compatibility. These advancements are expected to open up new application areas and market opportunities.

Looking ahead, the thermite applications market is projected to experience steady growth. Factors such as ongoing infrastructure development, technological advancements in metal production, and the expansion of the aerospace and defense sectors are expected to drive this growth. However, the market also faces challenges, including environmental concerns and the need for stringent safety measures in handling and application.

The welding segment, particularly in railway track welding, represents a significant portion of the thermite market. As countries invest in expanding and upgrading their rail infrastructure, the demand for thermite welding continues to rise. This trend is especially prominent in developing economies where rapid urbanization and transportation development projects are underway.

In the defense sector, thermite finds applications in incendiary devices and pyrotechnics, although this market segment is more specialized and subject to strict regulations. The aerospace industry also utilizes thermite in certain niche applications, such as emergency destruction of sensitive equipment.

The market for thermite applications is geographically diverse, with significant demand in North America, Europe, and Asia-Pacific regions. The Asia-Pacific market, in particular, is expected to show robust growth due to increasing industrialization and infrastructure development in countries like China and India.

Environmental considerations are becoming increasingly important in the thermite market. As awareness of the environmental impact of industrial processes grows, there is a rising demand for cleaner and more sustainable thermite reaction processes. This trend is driving research and development efforts to minimize harmful byproducts and improve the overall environmental profile of thermite applications.

The market is characterized by a mix of large multinational corporations and specialized smaller companies. Key players are focusing on developing innovative thermite formulations that offer improved performance, safety, and environmental compatibility. These advancements are expected to open up new application areas and market opportunities.

Looking ahead, the thermite applications market is projected to experience steady growth. Factors such as ongoing infrastructure development, technological advancements in metal production, and the expansion of the aerospace and defense sectors are expected to drive this growth. However, the market also faces challenges, including environmental concerns and the need for stringent safety measures in handling and application.

Current Challenges in Thermite Byproduct Management

The management of thermite reaction byproducts presents several significant challenges in both environmental and practical aspects. One of the primary concerns is the high-temperature nature of thermite reactions, which can produce byproducts that are difficult to contain and control. These byproducts often include molten metal oxides and elemental metals, which can pose serious safety risks if not properly managed.

Environmental considerations are at the forefront of current challenges. The release of thermite byproducts into the environment can lead to soil and water contamination. Metal oxides, particularly those containing aluminum, iron, or other reactive metals, may persist in the environment and potentially impact local ecosystems. The leaching of these compounds into groundwater systems is a particular concern, as it can affect water quality and aquatic life over extended periods.

Another significant challenge is the disposal of thermite reaction residues. These materials often require specialized handling and disposal methods due to their reactive nature and potential toxicity. Traditional waste management facilities may not be equipped to handle these byproducts safely, necessitating the development of specialized disposal protocols and facilities.

The variability in thermite compositions further complicates byproduct management. Different thermite formulations can produce a wide range of byproducts, each with unique chemical and physical properties. This diversity makes it challenging to develop standardized handling and disposal procedures that are effective across all thermite applications.

Occupational health and safety represent another critical challenge. Workers involved in thermite reactions or byproduct handling may be exposed to high temperatures, toxic fumes, and reactive materials. Developing comprehensive safety protocols and protective equipment that can withstand the extreme conditions associated with thermite reactions is an ongoing challenge for industry professionals.

The potential for secondary reactions of thermite byproducts is also a significant concern. Some byproducts may remain reactive even after the initial reaction has concluded, posing risks of unexpected ignition or chemical reactions during storage or transport. This necessitates careful monitoring and specialized containment strategies to prevent accidents.

Lastly, the regulatory landscape surrounding thermite byproduct management is complex and evolving. Compliance with environmental regulations, waste management laws, and occupational safety standards requires constant vigilance and adaptation. As scientific understanding of the long-term impacts of these byproducts grows, regulations are likely to become more stringent, presenting ongoing challenges for industries utilizing thermite reactions.

Environmental considerations are at the forefront of current challenges. The release of thermite byproducts into the environment can lead to soil and water contamination. Metal oxides, particularly those containing aluminum, iron, or other reactive metals, may persist in the environment and potentially impact local ecosystems. The leaching of these compounds into groundwater systems is a particular concern, as it can affect water quality and aquatic life over extended periods.

Another significant challenge is the disposal of thermite reaction residues. These materials often require specialized handling and disposal methods due to their reactive nature and potential toxicity. Traditional waste management facilities may not be equipped to handle these byproducts safely, necessitating the development of specialized disposal protocols and facilities.

The variability in thermite compositions further complicates byproduct management. Different thermite formulations can produce a wide range of byproducts, each with unique chemical and physical properties. This diversity makes it challenging to develop standardized handling and disposal procedures that are effective across all thermite applications.

Occupational health and safety represent another critical challenge. Workers involved in thermite reactions or byproduct handling may be exposed to high temperatures, toxic fumes, and reactive materials. Developing comprehensive safety protocols and protective equipment that can withstand the extreme conditions associated with thermite reactions is an ongoing challenge for industry professionals.

The potential for secondary reactions of thermite byproducts is also a significant concern. Some byproducts may remain reactive even after the initial reaction has concluded, posing risks of unexpected ignition or chemical reactions during storage or transport. This necessitates careful monitoring and specialized containment strategies to prevent accidents.

Lastly, the regulatory landscape surrounding thermite byproduct management is complex and evolving. Compliance with environmental regulations, waste management laws, and occupational safety standards requires constant vigilance and adaptation. As scientific understanding of the long-term impacts of these byproducts grows, regulations are likely to become more stringent, presenting ongoing challenges for industries utilizing thermite reactions.

Existing Byproduct Mitigation Strategies

01 Environmental impact of thermite reaction byproducts

Thermite reactions produce various byproducts that can have significant environmental impacts. These may include metal oxides, slag, and gaseous emissions. The environmental effects can range from soil contamination to air pollution, depending on the specific reactants used and the scale of the reaction. Proper containment and disposal methods are crucial to mitigate these impacts.- Environmental impact of thermite reaction byproducts: Thermite reactions produce various byproducts that can have significant environmental impacts. These may include metal oxides, slag, and gaseous emissions. The environmental effects can range from soil contamination to air pollution, depending on the specific reactants used and the scale of the reaction. Proper containment and disposal methods are crucial to mitigate these impacts.

- Mitigation strategies for thermite reaction byproducts: Various strategies can be employed to mitigate the environmental impact of thermite reaction byproducts. These may include using containment systems, filtration technologies, and neutralization processes. Some approaches focus on recycling or repurposing the byproducts, while others aim to minimize the production of harmful substances through careful selection of reactants and reaction conditions.

- Monitoring and analysis of thermite reaction emissions: Monitoring and analyzing the emissions from thermite reactions is crucial for assessing their environmental impact. This involves the use of specialized sensors, sampling techniques, and analytical methods to identify and quantify the byproducts released. Real-time monitoring systems can help in early detection of potential environmental hazards and allow for prompt corrective actions.

- Eco-friendly alternatives to traditional thermite reactions: Research is ongoing to develop more environmentally friendly alternatives to traditional thermite reactions. These may include the use of green chemistry principles, such as employing less toxic reactants or catalysts that promote cleaner reactions. Some approaches focus on developing novel reaction systems that produce fewer harmful byproducts or enable easier containment and disposal of waste products.

- Regulatory considerations for thermite reaction byproducts: The environmental impact of thermite reaction byproducts is subject to various regulatory considerations. These may include guidelines for proper disposal, emissions standards, and requirements for environmental impact assessments. Compliance with these regulations is essential for industries and research institutions working with thermite reactions to ensure responsible management of byproducts and minimize potential harm to the environment.

02 Mitigation strategies for thermite reaction byproducts

Various strategies can be employed to mitigate the environmental impact of thermite reaction byproducts. These may include using containment systems, filtration technologies, and neutralization processes. Some approaches focus on recycling or repurposing the byproducts, while others aim to minimize the production of harmful substances through careful selection of reactants and reaction conditions.Expand Specific Solutions03 Monitoring and analysis of thermite reaction emissions

Monitoring and analyzing the emissions from thermite reactions is crucial for assessing their environmental impact. This involves the use of specialized sensors, sampling techniques, and analytical methods to identify and quantify the byproducts released during and after the reaction. Such data is essential for developing effective mitigation strategies and ensuring compliance with environmental regulations.Expand Specific Solutions04 Eco-friendly alternatives to traditional thermite reactions

Research is ongoing to develop more environmentally friendly alternatives to traditional thermite reactions. These may include modified formulations that produce less harmful byproducts, alternative reaction pathways that achieve similar results with reduced environmental impact, or entirely new technologies that can replace thermite reactions in certain applications while minimizing ecological consequences.Expand Specific Solutions05 Regulatory considerations for thermite reaction byproducts

The environmental impact of thermite reaction byproducts is subject to various regulatory considerations. These may include emission standards, waste disposal regulations, and environmental impact assessment requirements. Compliance with these regulations often necessitates the implementation of specific control measures, reporting procedures, and ongoing monitoring to ensure that the environmental impact of thermite reactions is minimized and managed appropriately.Expand Specific Solutions

Key Industry Players in Thermite Production

The thermite reaction byproducts market is in a growth phase, driven by increasing industrial applications and environmental concerns. The market size is expanding, with a focus on sustainable practices and waste management. Technologically, the field is advancing rapidly, with companies like Doosan Enerbility Co., Ltd. and Elkem ASA leading innovation in byproduct utilization. Research institutions such as Korea Institute of Geoscience & Mineral Resources and Zhejiang University are contributing to technological maturity through collaborative efforts. Companies like Tronox LLC and Zhejiang NHU Co. Ltd. are exploring novel applications, while established players like Alcoa, Inc. and BASF Corp. are refining existing processes for improved efficiency and environmental compatibility.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed proprietary thermite formulations for use in their aerospace and defense applications. Their research focuses on creating thermite reactions with minimal environmental impact and maximum energy output. They have explored the use of alternative metal fuels and oxidizers to reduce harmful byproducts while maintaining high reaction temperatures. Lockheed Martin's approach includes the development of containment systems to capture and neutralize potentially harmful reaction products, as well as the use of computer modeling to predict and optimize reaction outcomes.

Strengths: Extensive resources for research and development, integration capabilities with existing aerospace systems. Weaknesses: Potential focus on military applications may limit civilian use, proprietary nature of research may restrict information sharing.

BASF Corp.

Technical Solution: BASF has developed eco-friendly thermite formulations for industrial applications. Their research focuses on creating thermite mixtures that produce minimal harmful byproducts while maintaining high reaction efficiency. BASF's approach involves using alternative oxidizers and fuels derived from sustainable sources, as well as incorporating additives that can neutralize or capture potentially harmful reaction products. They have also explored the use of microencapsulation techniques to control the release of reaction products and improve overall safety.

Strengths: Extensive chemical expertise, global research network, focus on sustainability. Weaknesses: May face challenges in adapting thermite technology to their core business areas.

Innovative Approaches to Byproduct Reduction

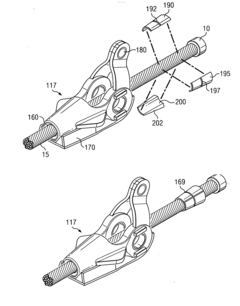

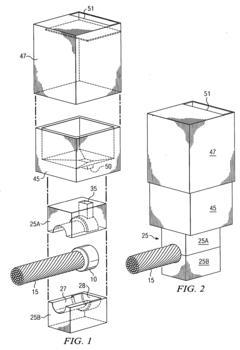

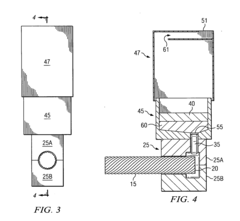

System and method for termination of a wire rope

PatentInactiveUS20070119562A1

Innovation

- A drag socket system utilizing an exothermic metallic reaction to fuse a wire rope termination, combined with a novel connector mechanism, allowing for easy and safe connection and disconnection of wire ropes, reducing weight and increasing strength while minimizing the need for high-force tools.

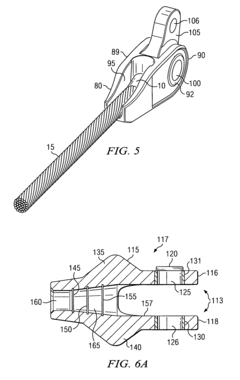

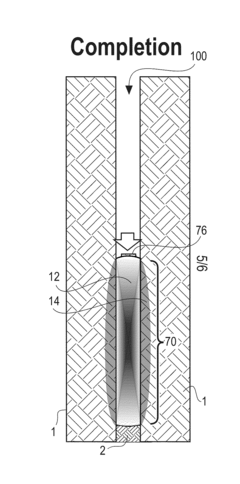

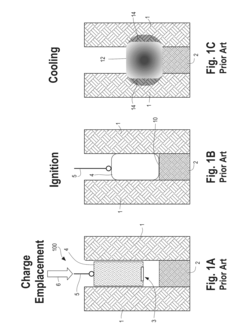

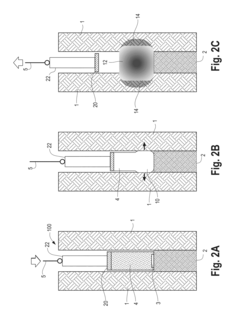

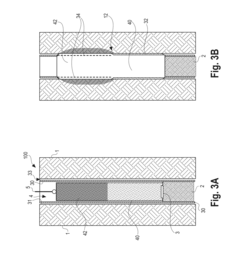

Well sealing via thermite reactions

PatentActiveUS20150211326A1

Innovation

- The method involves diluting thermite reactants to control reaction parameters, using layered thermite charges with varying temperatures, adding eutectic materials to alter melt properties, and applying compressive loads to reduce porosity, as well as optimizing ignition geometry for directional control of thermite expansion.

Environmental Impact Assessment

The environmental impact assessment of thermite reaction byproducts is a critical aspect of evaluating the overall sustainability and safety of thermite-based processes. Thermite reactions, known for their high-temperature exothermic nature, produce various byproducts that can have significant environmental implications.

One of the primary concerns is the release of metal oxides, particularly aluminum oxide, which is a common product of thermite reactions. While aluminum oxide itself is generally considered non-toxic, the fine particulate matter generated during the reaction can contribute to air pollution. These particles, when airborne, may pose respiratory risks to both humans and wildlife in the vicinity of thermite operations.

The high temperatures associated with thermite reactions can also lead to the formation of nitrogen oxides (NOx) when conducted in open-air environments. NOx emissions are known contributors to smog formation and acid rain, potentially impacting local air quality and ecosystems. Additionally, the intense heat can cause localized soil sterilization, affecting the microbial communities essential for soil health and nutrient cycling.

Water contamination is another potential environmental concern. If thermite reactions occur near water bodies or if byproducts are improperly disposed of, there is a risk of metal ions leaching into groundwater or surface water. This can lead to altered pH levels and increased metal concentrations in aquatic ecosystems, potentially harming flora and fauna.

The production of slag, a glassy byproduct of thermite reactions, presents both environmental challenges and opportunities. While slag disposal can be problematic due to its volume and potential for containing trace metals, it also has potential applications in construction materials, potentially reducing the environmental footprint through recycling.

Long-term environmental impacts of thermite byproducts include potential soil contamination and changes in local geochemistry. The accumulation of metal oxides in soil can alter its physical and chemical properties, potentially affecting plant growth and soil ecosystem functions. This is particularly relevant in areas where thermite reactions are frequently conducted or in industrial settings where thermite-based processes are common.

Mitigation strategies for these environmental impacts are crucial. These may include the implementation of advanced filtration systems to capture particulate matter, controlled reaction environments to minimize NOx formation, and proper disposal or recycling protocols for slag and other solid byproducts. Additionally, site-specific environmental monitoring programs can help track and manage the long-term effects of thermite reaction byproducts on local ecosystems.

One of the primary concerns is the release of metal oxides, particularly aluminum oxide, which is a common product of thermite reactions. While aluminum oxide itself is generally considered non-toxic, the fine particulate matter generated during the reaction can contribute to air pollution. These particles, when airborne, may pose respiratory risks to both humans and wildlife in the vicinity of thermite operations.

The high temperatures associated with thermite reactions can also lead to the formation of nitrogen oxides (NOx) when conducted in open-air environments. NOx emissions are known contributors to smog formation and acid rain, potentially impacting local air quality and ecosystems. Additionally, the intense heat can cause localized soil sterilization, affecting the microbial communities essential for soil health and nutrient cycling.

Water contamination is another potential environmental concern. If thermite reactions occur near water bodies or if byproducts are improperly disposed of, there is a risk of metal ions leaching into groundwater or surface water. This can lead to altered pH levels and increased metal concentrations in aquatic ecosystems, potentially harming flora and fauna.

The production of slag, a glassy byproduct of thermite reactions, presents both environmental challenges and opportunities. While slag disposal can be problematic due to its volume and potential for containing trace metals, it also has potential applications in construction materials, potentially reducing the environmental footprint through recycling.

Long-term environmental impacts of thermite byproducts include potential soil contamination and changes in local geochemistry. The accumulation of metal oxides in soil can alter its physical and chemical properties, potentially affecting plant growth and soil ecosystem functions. This is particularly relevant in areas where thermite reactions are frequently conducted or in industrial settings where thermite-based processes are common.

Mitigation strategies for these environmental impacts are crucial. These may include the implementation of advanced filtration systems to capture particulate matter, controlled reaction environments to minimize NOx formation, and proper disposal or recycling protocols for slag and other solid byproducts. Additionally, site-specific environmental monitoring programs can help track and manage the long-term effects of thermite reaction byproducts on local ecosystems.

Regulatory Framework for Thermite Use

The regulatory framework for thermite use is complex and multifaceted, reflecting the potential hazards associated with thermite reactions and their byproducts. At the federal level in the United States, the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) classifies thermite as an explosive material, subjecting it to strict controls under the Federal Explosives Law. This classification necessitates proper licensing, storage, and handling procedures for entities dealing with thermite.

The Occupational Safety and Health Administration (OSHA) has established guidelines for workplace safety when handling thermite, including requirements for personal protective equipment, proper ventilation, and emergency response protocols. These regulations aim to minimize the risks of burns, respiratory issues, and other potential health hazards associated with thermite use.

Environmental regulations concerning thermite reactions are primarily governed by the Environmental Protection Agency (EPA) under the Resource Conservation and Recovery Act (RCRA) and the Clean Air Act. The RCRA classifies certain thermite byproducts as hazardous waste, mandating specific disposal procedures to prevent soil and groundwater contamination. The Clean Air Act regulates emissions from thermite reactions, particularly focusing on particulate matter and metal oxide fumes.

At the state and local levels, additional regulations may apply, often more stringent than federal standards. For instance, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that can cause cancer, birth defects, or other reproductive harm, which may include certain thermite byproducts.

International regulations vary, but many countries follow guidelines set by the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This system provides a standardized approach to communicating chemical hazards, including those associated with thermite and its byproducts.

The transportation of thermite is regulated by the Department of Transportation (DOT) in the US and similar agencies internationally. These regulations dictate packaging, labeling, and shipping requirements to ensure safe transport and prevent accidental ignition or exposure.

Compliance with these regulations requires comprehensive record-keeping, regular inspections, and ongoing training for personnel involved in thermite handling and use. Companies must also develop and maintain detailed safety data sheets (SDS) that outline the potential hazards, proper handling procedures, and emergency response measures for thermite and its byproducts.

As research continues to reveal more about the environmental and health impacts of thermite reaction byproducts, regulatory frameworks are likely to evolve. This may lead to more stringent controls on emissions, disposal methods, and long-term environmental monitoring requirements for areas where thermite reactions have occurred.

The Occupational Safety and Health Administration (OSHA) has established guidelines for workplace safety when handling thermite, including requirements for personal protective equipment, proper ventilation, and emergency response protocols. These regulations aim to minimize the risks of burns, respiratory issues, and other potential health hazards associated with thermite use.

Environmental regulations concerning thermite reactions are primarily governed by the Environmental Protection Agency (EPA) under the Resource Conservation and Recovery Act (RCRA) and the Clean Air Act. The RCRA classifies certain thermite byproducts as hazardous waste, mandating specific disposal procedures to prevent soil and groundwater contamination. The Clean Air Act regulates emissions from thermite reactions, particularly focusing on particulate matter and metal oxide fumes.

At the state and local levels, additional regulations may apply, often more stringent than federal standards. For instance, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that can cause cancer, birth defects, or other reproductive harm, which may include certain thermite byproducts.

International regulations vary, but many countries follow guidelines set by the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This system provides a standardized approach to communicating chemical hazards, including those associated with thermite and its byproducts.

The transportation of thermite is regulated by the Department of Transportation (DOT) in the US and similar agencies internationally. These regulations dictate packaging, labeling, and shipping requirements to ensure safe transport and prevent accidental ignition or exposure.

Compliance with these regulations requires comprehensive record-keeping, regular inspections, and ongoing training for personnel involved in thermite handling and use. Companies must also develop and maintain detailed safety data sheets (SDS) that outline the potential hazards, proper handling procedures, and emergency response measures for thermite and its byproducts.

As research continues to reveal more about the environmental and health impacts of thermite reaction byproducts, regulatory frameworks are likely to evolve. This may lead to more stringent controls on emissions, disposal methods, and long-term environmental monitoring requirements for areas where thermite reactions have occurred.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!