How to Implement Thermite Techniques in Field Operations?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Techniques Background and Objectives

Thermite techniques have a rich history dating back to their discovery in the late 19th century. Initially developed for welding and metal purification, these exothermic reactions have since found applications in various fields, including military operations, demolition, and emergency response. The evolution of thermite technology has been driven by the need for portable, high-energy heat sources capable of generating intense temperatures in field conditions.

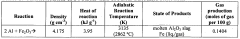

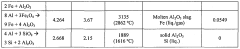

The primary objective of implementing thermite techniques in field operations is to harness the rapid, high-temperature reaction between a metal oxide and a more reactive metal. This reaction produces molten metal and slag, generating temperatures exceeding 2500°C. Such extreme heat can be utilized for cutting, welding, or breaching materials that are otherwise difficult to process in remote or challenging environments.

Recent technological advancements have focused on enhancing the safety, efficiency, and controllability of thermite reactions. Researchers have explored various compositions and ignition methods to tailor the reaction characteristics for specific field applications. The development of nano-thermites, for instance, has opened new possibilities for increased reactivity and energy output, potentially revolutionizing the implementation of thermite techniques in field operations.

One of the key trends in thermite technology is the pursuit of more environmentally friendly and less hazardous formulations. This includes efforts to reduce toxic byproducts and improve the overall safety profile of thermite reactions, making them more suitable for a wider range of field applications. Additionally, there is a growing interest in developing thermite compositions that can be easily transported and stored, addressing logistical challenges often encountered in field operations.

The implementation of thermite techniques in field operations also aims to overcome limitations in traditional heat sources. Unlike conventional fuel-based systems, thermite reactions do not require external oxygen supply, making them ideal for use in oxygen-deficient environments or underwater applications. This unique characteristic has led to increased research into specialized thermite formulations for extreme conditions, such as deep-sea welding or space-based manufacturing.

As the field continues to evolve, the objectives for implementing thermite techniques in field operations extend beyond mere heat generation. Researchers are exploring ways to harness the byproducts of thermite reactions, such as using the molten metal for in-situ repairs or leveraging the intense light emission for signaling purposes. These multifaceted applications underscore the versatility and potential of thermite technology in addressing complex operational challenges.

The primary objective of implementing thermite techniques in field operations is to harness the rapid, high-temperature reaction between a metal oxide and a more reactive metal. This reaction produces molten metal and slag, generating temperatures exceeding 2500°C. Such extreme heat can be utilized for cutting, welding, or breaching materials that are otherwise difficult to process in remote or challenging environments.

Recent technological advancements have focused on enhancing the safety, efficiency, and controllability of thermite reactions. Researchers have explored various compositions and ignition methods to tailor the reaction characteristics for specific field applications. The development of nano-thermites, for instance, has opened new possibilities for increased reactivity and energy output, potentially revolutionizing the implementation of thermite techniques in field operations.

One of the key trends in thermite technology is the pursuit of more environmentally friendly and less hazardous formulations. This includes efforts to reduce toxic byproducts and improve the overall safety profile of thermite reactions, making them more suitable for a wider range of field applications. Additionally, there is a growing interest in developing thermite compositions that can be easily transported and stored, addressing logistical challenges often encountered in field operations.

The implementation of thermite techniques in field operations also aims to overcome limitations in traditional heat sources. Unlike conventional fuel-based systems, thermite reactions do not require external oxygen supply, making them ideal for use in oxygen-deficient environments or underwater applications. This unique characteristic has led to increased research into specialized thermite formulations for extreme conditions, such as deep-sea welding or space-based manufacturing.

As the field continues to evolve, the objectives for implementing thermite techniques in field operations extend beyond mere heat generation. Researchers are exploring ways to harness the byproducts of thermite reactions, such as using the molten metal for in-situ repairs or leveraging the intense light emission for signaling purposes. These multifaceted applications underscore the versatility and potential of thermite technology in addressing complex operational challenges.

Field Operation Demand Analysis

The implementation of thermite techniques in field operations has seen a significant rise in demand across various sectors, particularly in military, construction, and emergency response fields. This growing interest stems from the unique properties of thermite reactions, which produce intense heat and molten metal, making them valuable for specific applications in challenging environments.

In the military sector, there is an increasing need for portable and efficient methods to disable or destroy sensitive equipment quickly in the field. Thermite techniques offer a compact and reliable solution for this purpose, allowing for rapid and thorough destruction of electronic devices, weapons systems, or classified materials when faced with the risk of capture or compromise.

The construction industry has also shown a rising interest in thermite techniques for specialized welding and cutting operations. In remote locations or underwater environments where traditional welding methods are impractical, thermite reactions provide a self-contained heat source capable of joining or cutting thick metal structures. This demand is particularly evident in pipeline construction and repair, as well as in offshore installations.

Emergency response teams are increasingly exploring thermite applications for scenarios involving hazardous material containment or neutralization. The ability of thermite reactions to generate extreme temperatures rapidly and in a controlled manner makes them valuable for breaching contaminated containers or neutralizing dangerous substances in situ.

Market analysis indicates a steady growth in the demand for thermite-based tools and equipment, with an estimated annual increase of 5-7% in the specialized field operations sector. This growth is driven by the technique's versatility, reliability, and effectiveness in extreme conditions where conventional methods fall short.

However, the implementation of thermite techniques in field operations faces several challenges that influence market demand. Safety concerns and the need for specialized training are primary factors limiting widespread adoption. Regulatory restrictions on the transportation and use of thermite materials also impact accessibility and deployment in certain regions.

To address these challenges and meet the growing demand, there is an increasing focus on developing safer, more user-friendly thermite systems. Innovations in packaging, ignition mechanisms, and containment systems are aimed at enhancing the safety profile and ease of use in field conditions. These advancements are expected to expand the potential applications and market reach of thermite techniques in various field operations.

In the military sector, there is an increasing need for portable and efficient methods to disable or destroy sensitive equipment quickly in the field. Thermite techniques offer a compact and reliable solution for this purpose, allowing for rapid and thorough destruction of electronic devices, weapons systems, or classified materials when faced with the risk of capture or compromise.

The construction industry has also shown a rising interest in thermite techniques for specialized welding and cutting operations. In remote locations or underwater environments where traditional welding methods are impractical, thermite reactions provide a self-contained heat source capable of joining or cutting thick metal structures. This demand is particularly evident in pipeline construction and repair, as well as in offshore installations.

Emergency response teams are increasingly exploring thermite applications for scenarios involving hazardous material containment or neutralization. The ability of thermite reactions to generate extreme temperatures rapidly and in a controlled manner makes them valuable for breaching contaminated containers or neutralizing dangerous substances in situ.

Market analysis indicates a steady growth in the demand for thermite-based tools and equipment, with an estimated annual increase of 5-7% in the specialized field operations sector. This growth is driven by the technique's versatility, reliability, and effectiveness in extreme conditions where conventional methods fall short.

However, the implementation of thermite techniques in field operations faces several challenges that influence market demand. Safety concerns and the need for specialized training are primary factors limiting widespread adoption. Regulatory restrictions on the transportation and use of thermite materials also impact accessibility and deployment in certain regions.

To address these challenges and meet the growing demand, there is an increasing focus on developing safer, more user-friendly thermite systems. Innovations in packaging, ignition mechanisms, and containment systems are aimed at enhancing the safety profile and ease of use in field conditions. These advancements are expected to expand the potential applications and market reach of thermite techniques in various field operations.

Current Challenges in Thermite Implementation

The implementation of thermite techniques in field operations faces several significant challenges that hinder widespread adoption and effective utilization. One of the primary obstacles is the inherent safety risks associated with thermite reactions. The high temperatures and intense exothermic nature of these reactions pose potential hazards to operators and surrounding environments, necessitating stringent safety protocols and specialized handling procedures.

Another major challenge lies in the precise control and initiation of thermite reactions in field conditions. Achieving consistent and reliable ignition, especially in adverse weather or challenging terrain, remains a complex task. The sensitivity of thermite mixtures to environmental factors such as humidity and temperature fluctuations can impact their performance and reliability, making it difficult to ensure predictable outcomes in diverse operational settings.

The transportation and storage of thermite materials present additional logistical hurdles. Due to their reactive nature, these materials often require special packaging, handling, and storage conditions to maintain their efficacy and prevent accidental ignition. This complexity increases the overall cost and complexity of field operations involving thermite techniques.

Furthermore, the environmental impact of thermite reactions is a growing concern. The byproducts of these reactions, including metal oxides and other residues, can have long-lasting effects on soil and water systems. Developing eco-friendly thermite formulations and implementing effective clean-up procedures are ongoing challenges that need to be addressed for sustainable field applications.

The scalability of thermite techniques for various field operation sizes presents another significant challenge. While thermite reactions can be highly effective for certain applications, adapting these techniques to different scales of operation, from small-scale precision tasks to large-scale industrial applications, requires considerable research and development efforts.

Lastly, the regulatory landscape surrounding the use of thermite materials in field operations is complex and often restrictive. Navigating the various legal and regulatory requirements across different jurisdictions can be a daunting task for organizations looking to implement these techniques. This regulatory complexity can significantly impede the adoption and development of innovative thermite applications in field operations.

Another major challenge lies in the precise control and initiation of thermite reactions in field conditions. Achieving consistent and reliable ignition, especially in adverse weather or challenging terrain, remains a complex task. The sensitivity of thermite mixtures to environmental factors such as humidity and temperature fluctuations can impact their performance and reliability, making it difficult to ensure predictable outcomes in diverse operational settings.

The transportation and storage of thermite materials present additional logistical hurdles. Due to their reactive nature, these materials often require special packaging, handling, and storage conditions to maintain their efficacy and prevent accidental ignition. This complexity increases the overall cost and complexity of field operations involving thermite techniques.

Furthermore, the environmental impact of thermite reactions is a growing concern. The byproducts of these reactions, including metal oxides and other residues, can have long-lasting effects on soil and water systems. Developing eco-friendly thermite formulations and implementing effective clean-up procedures are ongoing challenges that need to be addressed for sustainable field applications.

The scalability of thermite techniques for various field operation sizes presents another significant challenge. While thermite reactions can be highly effective for certain applications, adapting these techniques to different scales of operation, from small-scale precision tasks to large-scale industrial applications, requires considerable research and development efforts.

Lastly, the regulatory landscape surrounding the use of thermite materials in field operations is complex and often restrictive. Navigating the various legal and regulatory requirements across different jurisdictions can be a daunting task for organizations looking to implement these techniques. This regulatory complexity can significantly impede the adoption and development of innovative thermite applications in field operations.

Existing Thermite Field Operation Solutions

01 Thermite welding techniques

Thermite welding is a technique used to join metal components, particularly in railway track welding. It involves the exothermic reaction of aluminum powder and iron oxide to produce molten iron and aluminum oxide. This process generates high temperatures, allowing for the fusion of metal parts. The technique includes preparation of the joint, ignition of the thermite mixture, and controlled cooling for a strong weld.- Thermite welding techniques: Thermite welding is a technique used for joining metal components, particularly in railway track welding. It involves the exothermic reaction of aluminum powder and metal oxide to produce intense heat for melting and fusing metals. This method is widely used for its efficiency and ability to create strong, durable joints in various industrial applications.

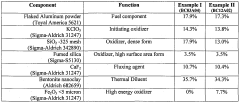

- Thermite compositions and formulations: Various thermite compositions and formulations have been developed to enhance performance and safety. These may include additives to control reaction rates, improve ignition properties, or modify the resulting slag. Specialized formulations can be tailored for specific applications, such as underwater welding or high-temperature metal cutting.

- Ignition systems for thermite reactions: Advanced ignition systems have been developed to initiate thermite reactions safely and reliably. These may include electronic ignition devices, remote activation mechanisms, or specialized primers. Such systems aim to improve control over the reaction start time and enhance overall safety in thermite applications.

- Thermite-based cutting and perforation tools: Thermite reactions are utilized in specialized cutting and perforation tools, particularly in the oil and gas industry. These tools can create precise holes or cuts in metal structures, even in challenging environments such as underwater or in high-pressure situations. The intense heat generated by the thermite reaction allows for efficient material removal.

- Safety measures and containment systems: Given the high temperatures and intense reactions involved in thermite processes, various safety measures and containment systems have been developed. These include specialized reaction vessels, heat-resistant materials, and protective equipment. Such measures aim to prevent accidents, contain molten metal splatter, and ensure safe handling of thermite materials in industrial settings.

02 Thermite compositions and additives

Various thermite compositions and additives are used to enhance performance or tailor properties for specific applications. These may include different metal oxides, fuel materials, or additives to control reaction rates or temperatures. Innovations in thermite mixtures can improve ignition sensitivity, energy output, or reduce unwanted byproducts.Expand Specific Solutions03 Thermite reaction initiation methods

Different methods are employed to initiate thermite reactions, including electrical ignition, chemical starters, and laser ignition. These techniques aim to provide reliable and controlled ignition of the thermite mixture. Some methods focus on remote or delayed ignition for safety or specific application requirements.Expand Specific Solutions04 Thermite applications in material processing

Thermite reactions are utilized in various material processing applications beyond welding. These include metal purification, alloy production, and synthesis of advanced materials. The high temperatures and reducing conditions of thermite reactions enable unique material transformations and syntheses.Expand Specific Solutions05 Safety and control measures in thermite techniques

Given the high temperatures and reactivity of thermite mixtures, various safety and control measures are implemented. These include specialized containment vessels, reaction moderators, and precise mixture ratios. Advanced monitoring and control systems may be used to manage the reaction process and ensure safe operation.Expand Specific Solutions

Key Players in Thermite Industry

The implementation of thermite techniques in field operations is currently in a growth phase, with increasing market size and technological advancements. The global market for thermite-based applications is expanding, driven by demand in sectors such as defense, construction, and industrial manufacturing. Technological maturity varies across different applications, with companies like Robertson Intellectual Properties LLC, Beijing Institute of Technology, and BiSN Oil Tools Ltd leading innovation. Research institutions such as the Chemical Materials Research Institute of China Academy of Engineering Physics and PLA Army Engineering University are contributing to advancements in thermite technology. The competitive landscape is diverse, with both established players and emerging startups vying for market share, indicating a dynamic and evolving field with significant potential for further development and application.

Battelle Memorial Institute

Technical Solution: Battelle has developed advanced thermite techniques for field operations, focusing on controlled exothermic reactions. Their approach involves precise mixing of metal oxides and aluminum powder to create a stable, yet highly reactive compound. The institute has engineered a remote ignition system that allows for safe distance activation, crucial for hazardous environments. Additionally, they've implemented a modular design that enables customization of the thermite mixture based on specific operational requirements, such as penetration depth or heat duration.

Strengths: Highly customizable for various field applications, remote activation for enhanced safety, and precise control over the reaction. Weaknesses: Potentially high cost due to specialized materials and limited reusability of components.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed a proprietary thermite-based system for field operations, particularly focused on military applications. Their technology incorporates a nano-engineered thermite mixture that provides enhanced energy density and controlled burn rates. The system features a smart ignition mechanism that can be integrated with existing field communication networks for synchronized operations. Lockheed Martin has also developed a containment system that allows for directional control of the thermite reaction, enabling precise application in various scenarios such as breaching operations or emergency destruction of sensitive equipment.

Strengths: High energy density, network-integrated ignition system, and directional control capabilities. Weaknesses: Potentially complex deployment process and higher production costs due to advanced materials used.

Core Thermite Reaction Innovations

Solid-state thermite composition based heating device

PatentWO2010117857A2

Innovation

- A solid-state thermite reaction composition comprising a fuel component, primary oxidizer, initiating oxidizers, thermal diluent, and fluxing agents, integrated with a heating device featuring a reaction chamber and actuable trigger mechanism, allowing controlled thermite reactions for precise heat generation, with activation mechanisms like piezoelectric spark ignitors or exothermic couples to initiate the reaction safely.

Metal/metal oxide fueled engine

PatentUndeterminedNZ546023A

Innovation

- A method involving the ignition of a thermite mixture in a chamber, where water or steam is introduced to control the reaction temperature, produce hydrogen, and sustain the thermite reaction, allowing the conversion of heat and pressure into mechanical energy through the use of a heat engine.

Safety Protocols for Thermite Handling

Safety protocols for thermite handling are paramount in field operations due to the highly reactive nature of thermite mixtures. These protocols encompass a comprehensive set of guidelines and procedures designed to minimize risks associated with the storage, transportation, and use of thermite in various applications.

Personal protective equipment (PPE) forms the first line of defense for personnel working with thermite. This includes fire-resistant clothing, heat-resistant gloves, safety goggles, and respiratory protection. The specific PPE requirements may vary depending on the scale of the operation and the environmental conditions.

Proper storage of thermite components is crucial to prevent accidental ignition. Aluminum powder and iron oxide should be stored separately in sealed, moisture-proof containers. These containers must be clearly labeled and kept in a cool, dry area away from potential ignition sources. Access to storage areas should be restricted to authorized personnel only.

Transportation of thermite materials requires special considerations. Vehicles used for transport must be equipped with appropriate fire suppression systems and have proper ventilation. The materials should be secured to prevent shifting during transit, and transportation routes should be carefully planned to avoid populated areas when possible.

Before initiating any thermite reaction, a thorough site assessment must be conducted. This includes identifying potential hazards, establishing a safety perimeter, and ensuring the availability of fire suppression equipment. Emergency response plans should be in place, and all personnel must be briefed on evacuation procedures.

The mixing and preparation of thermite should only be performed by trained professionals in a controlled environment. Precise measurements and proper mixing techniques are essential to ensure the desired reaction characteristics. Any unused mixture should be disposed of according to established hazardous waste protocols.

During the ignition and reaction phase, strict adherence to safety procedures is critical. Remote ignition methods should be employed whenever possible to maintain a safe distance from the reaction. Thermal imaging cameras can be used to monitor the reaction temperature and ensure it remains within expected parameters.

Post-reaction safety measures are equally important. The reaction site must be secured and allowed to cool completely before any inspection or clean-up activities begin. Proper disposal of reaction byproducts and any contaminated materials must follow environmental regulations and industry best practices.

Regular training and drills should be conducted to ensure all personnel are familiar with safety protocols and can respond effectively in emergency situations. This includes simulations of potential accidents and practice in the use of safety equipment.

Personal protective equipment (PPE) forms the first line of defense for personnel working with thermite. This includes fire-resistant clothing, heat-resistant gloves, safety goggles, and respiratory protection. The specific PPE requirements may vary depending on the scale of the operation and the environmental conditions.

Proper storage of thermite components is crucial to prevent accidental ignition. Aluminum powder and iron oxide should be stored separately in sealed, moisture-proof containers. These containers must be clearly labeled and kept in a cool, dry area away from potential ignition sources. Access to storage areas should be restricted to authorized personnel only.

Transportation of thermite materials requires special considerations. Vehicles used for transport must be equipped with appropriate fire suppression systems and have proper ventilation. The materials should be secured to prevent shifting during transit, and transportation routes should be carefully planned to avoid populated areas when possible.

Before initiating any thermite reaction, a thorough site assessment must be conducted. This includes identifying potential hazards, establishing a safety perimeter, and ensuring the availability of fire suppression equipment. Emergency response plans should be in place, and all personnel must be briefed on evacuation procedures.

The mixing and preparation of thermite should only be performed by trained professionals in a controlled environment. Precise measurements and proper mixing techniques are essential to ensure the desired reaction characteristics. Any unused mixture should be disposed of according to established hazardous waste protocols.

During the ignition and reaction phase, strict adherence to safety procedures is critical. Remote ignition methods should be employed whenever possible to maintain a safe distance from the reaction. Thermal imaging cameras can be used to monitor the reaction temperature and ensure it remains within expected parameters.

Post-reaction safety measures are equally important. The reaction site must be secured and allowed to cool completely before any inspection or clean-up activities begin. Proper disposal of reaction byproducts and any contaminated materials must follow environmental regulations and industry best practices.

Regular training and drills should be conducted to ensure all personnel are familiar with safety protocols and can respond effectively in emergency situations. This includes simulations of potential accidents and practice in the use of safety equipment.

Environmental Impact Assessment

The implementation of thermite techniques in field operations necessitates a comprehensive environmental impact assessment to ensure responsible and sustainable practices. Thermite reactions, characterized by their high-temperature exothermic nature, can potentially have significant effects on the surrounding ecosystem and environmental conditions.

One primary concern is the release of heat and particulate matter during thermite reactions. The intense heat generated can cause localized temperature increases in soil and nearby water bodies, potentially disrupting microbial communities and aquatic ecosystems. Additionally, the dispersion of fine metal oxide particles produced as byproducts of the reaction may lead to air quality issues and soil contamination if not properly managed.

The use of thermite techniques may also impact local flora and fauna. The sudden release of heat and light can disturb wildlife habitats and disrupt natural behavioral patterns. In sensitive ecosystems, such as forests or wetlands, the risk of unintended fires or habitat destruction must be carefully evaluated and mitigated.

Water resources are another critical consideration in the environmental impact assessment. Thermite reactions near water sources could potentially lead to thermal pollution or the introduction of metal oxides into aquatic systems. This may affect water quality, aquatic life, and downstream ecosystems, necessitating thorough monitoring and preventive measures.

Soil quality is also a key factor to assess. The high temperatures and chemical reactions associated with thermite techniques can alter soil composition and structure. This may impact soil fertility, microbial activity, and the ability of the area to support vegetation post-operation. Long-term effects on soil health and potential remediation strategies should be thoroughly examined.

The assessment should also consider the cumulative effects of repeated thermite operations in a given area. While individual operations may have limited impact, frequent use could lead to more significant environmental changes over time. This includes potential alterations to local climate patterns, soil chemistry, and ecosystem dynamics.

Mitigation strategies play a crucial role in minimizing environmental impact. These may include the use of containment systems to control particle dispersion, cooling mechanisms to manage heat dissipation, and careful site selection to avoid sensitive ecological areas. Post-operation site restoration and monitoring protocols should also be developed to ensure long-term environmental recovery.

In conclusion, a thorough environmental impact assessment for thermite techniques in field operations must address a wide range of potential effects on air, water, soil, and ecosystems. By identifying and mitigating these impacts, organizations can ensure more sustainable and environmentally responsible implementation of thermite technologies.

One primary concern is the release of heat and particulate matter during thermite reactions. The intense heat generated can cause localized temperature increases in soil and nearby water bodies, potentially disrupting microbial communities and aquatic ecosystems. Additionally, the dispersion of fine metal oxide particles produced as byproducts of the reaction may lead to air quality issues and soil contamination if not properly managed.

The use of thermite techniques may also impact local flora and fauna. The sudden release of heat and light can disturb wildlife habitats and disrupt natural behavioral patterns. In sensitive ecosystems, such as forests or wetlands, the risk of unintended fires or habitat destruction must be carefully evaluated and mitigated.

Water resources are another critical consideration in the environmental impact assessment. Thermite reactions near water sources could potentially lead to thermal pollution or the introduction of metal oxides into aquatic systems. This may affect water quality, aquatic life, and downstream ecosystems, necessitating thorough monitoring and preventive measures.

Soil quality is also a key factor to assess. The high temperatures and chemical reactions associated with thermite techniques can alter soil composition and structure. This may impact soil fertility, microbial activity, and the ability of the area to support vegetation post-operation. Long-term effects on soil health and potential remediation strategies should be thoroughly examined.

The assessment should also consider the cumulative effects of repeated thermite operations in a given area. While individual operations may have limited impact, frequent use could lead to more significant environmental changes over time. This includes potential alterations to local climate patterns, soil chemistry, and ecosystem dynamics.

Mitigation strategies play a crucial role in minimizing environmental impact. These may include the use of containment systems to control particle dispersion, cooling mechanisms to manage heat dissipation, and careful site selection to avoid sensitive ecological areas. Post-operation site restoration and monitoring protocols should also be developed to ensure long-term environmental recovery.

In conclusion, a thorough environmental impact assessment for thermite techniques in field operations must address a wide range of potential effects on air, water, soil, and ecosystems. By identifying and mitigating these impacts, organizations can ensure more sustainable and environmentally responsible implementation of thermite technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!