Thermite as an Alternative Energy Source: Future Possibilities

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Energy Evolution

The evolution of thermite as an energy source has been marked by significant milestones and technological advancements. Initially discovered in the late 19th century, thermite reactions were primarily used in welding and incendiary devices. However, the potential for harnessing thermite's intense exothermic reaction for energy production has gained traction in recent decades.

In the early stages of thermite energy research, focus was placed on understanding the fundamental chemical reactions and optimizing the composition of thermite mixtures. Scientists experimented with various metal oxide and metal fuel combinations to achieve higher energy outputs and more controlled reactions. This phase laid the groundwork for future applications in energy generation.

The mid-20th century saw increased interest in thermite's potential as an alternative energy source. Researchers began exploring ways to capture and convert the heat generated by thermite reactions into usable forms of energy. Early concepts included using thermite reactions to power steam turbines or directly heat working fluids in closed-loop systems.

As environmental concerns grew in the late 20th and early 21st centuries, thermite energy research shifted towards developing cleaner and more sustainable processes. Scientists investigated methods to reduce harmful emissions and increase the overall efficiency of thermite-based energy systems. This period also saw the emergence of novel concepts such as thermite-based batteries and energy storage solutions.

Recent advancements in nanotechnology have opened new avenues for thermite energy evolution. Nano-sized particles of metal oxides and fuels have demonstrated enhanced reactivity and energy release, potentially leading to more efficient and controllable thermite reactions. This breakthrough has reignited interest in thermite as a viable alternative energy source.

The current focus of thermite energy research lies in addressing key challenges such as reaction control, energy conversion efficiency, and scalability. Scientists are exploring innovative reactor designs, advanced materials, and hybrid systems that combine thermite reactions with other energy technologies. These efforts aim to overcome the limitations that have historically hindered the widespread adoption of thermite-based energy solutions.

Looking ahead, the future of thermite energy evolution appears promising. Ongoing research into novel thermite compositions, advanced ignition methods, and improved energy harvesting techniques may lead to breakthrough applications in various sectors. From portable power sources to large-scale industrial energy systems, thermite has the potential to play a significant role in the diversification of the global energy landscape.

In the early stages of thermite energy research, focus was placed on understanding the fundamental chemical reactions and optimizing the composition of thermite mixtures. Scientists experimented with various metal oxide and metal fuel combinations to achieve higher energy outputs and more controlled reactions. This phase laid the groundwork for future applications in energy generation.

The mid-20th century saw increased interest in thermite's potential as an alternative energy source. Researchers began exploring ways to capture and convert the heat generated by thermite reactions into usable forms of energy. Early concepts included using thermite reactions to power steam turbines or directly heat working fluids in closed-loop systems.

As environmental concerns grew in the late 20th and early 21st centuries, thermite energy research shifted towards developing cleaner and more sustainable processes. Scientists investigated methods to reduce harmful emissions and increase the overall efficiency of thermite-based energy systems. This period also saw the emergence of novel concepts such as thermite-based batteries and energy storage solutions.

Recent advancements in nanotechnology have opened new avenues for thermite energy evolution. Nano-sized particles of metal oxides and fuels have demonstrated enhanced reactivity and energy release, potentially leading to more efficient and controllable thermite reactions. This breakthrough has reignited interest in thermite as a viable alternative energy source.

The current focus of thermite energy research lies in addressing key challenges such as reaction control, energy conversion efficiency, and scalability. Scientists are exploring innovative reactor designs, advanced materials, and hybrid systems that combine thermite reactions with other energy technologies. These efforts aim to overcome the limitations that have historically hindered the widespread adoption of thermite-based energy solutions.

Looking ahead, the future of thermite energy evolution appears promising. Ongoing research into novel thermite compositions, advanced ignition methods, and improved energy harvesting techniques may lead to breakthrough applications in various sectors. From portable power sources to large-scale industrial energy systems, thermite has the potential to play a significant role in the diversification of the global energy landscape.

Market Demand Analysis

The market demand for alternative energy sources has been steadily increasing in recent years, driven by growing environmental concerns, energy security issues, and the need for sustainable development. Thermite, a mixture of metal powder fuel and metal oxide, presents an intriguing possibility as a potential alternative energy source. While traditionally used in welding and incendiary devices, its high energy density and rapid reaction rate make it an attractive candidate for energy generation.

The global alternative energy market is projected to experience significant growth in the coming years. Factors such as government initiatives, technological advancements, and increasing investments in renewable energy projects are contributing to this trend. As the world moves towards cleaner and more sustainable energy solutions, there is a growing interest in exploring unconventional energy sources like thermite.

One of the key advantages of thermite as an energy source is its high energy density. This characteristic makes it particularly appealing for applications where space and weight are critical factors, such as in portable power systems or emergency energy supplies. The potential market for such applications spans various sectors, including military, disaster relief, remote industrial operations, and off-grid residential use.

The transportation sector, which is actively seeking alternatives to fossil fuels, could potentially benefit from thermite-based energy systems. The automotive industry, in particular, is exploring various energy storage and generation technologies to improve the range and performance of electric vehicles. Thermite's high energy density could potentially address some of the current limitations in battery technology.

In the industrial sector, there is a growing demand for reliable and efficient energy sources for high-temperature processes. Thermite reactions generate extremely high temperatures, making them suitable for applications in metallurgy, materials processing, and waste treatment. This opens up potential markets in manufacturing, recycling, and environmental remediation industries.

However, it is important to note that the market adoption of thermite as an alternative energy source faces several challenges. Safety concerns related to the handling and storage of reactive materials, as well as the need for specialized equipment and expertise, may limit its widespread use in consumer applications. Additionally, the current regulatory framework for energy production and storage may need to be adapted to accommodate this novel technology.

Despite these challenges, the potential market for thermite-based energy solutions is significant. As research and development in this field progress, new applications and market opportunities are likely to emerge. The growing emphasis on energy diversification and the search for innovative solutions to meet global energy demands create a favorable environment for the exploration and development of thermite as an alternative energy source.

The global alternative energy market is projected to experience significant growth in the coming years. Factors such as government initiatives, technological advancements, and increasing investments in renewable energy projects are contributing to this trend. As the world moves towards cleaner and more sustainable energy solutions, there is a growing interest in exploring unconventional energy sources like thermite.

One of the key advantages of thermite as an energy source is its high energy density. This characteristic makes it particularly appealing for applications where space and weight are critical factors, such as in portable power systems or emergency energy supplies. The potential market for such applications spans various sectors, including military, disaster relief, remote industrial operations, and off-grid residential use.

The transportation sector, which is actively seeking alternatives to fossil fuels, could potentially benefit from thermite-based energy systems. The automotive industry, in particular, is exploring various energy storage and generation technologies to improve the range and performance of electric vehicles. Thermite's high energy density could potentially address some of the current limitations in battery technology.

In the industrial sector, there is a growing demand for reliable and efficient energy sources for high-temperature processes. Thermite reactions generate extremely high temperatures, making them suitable for applications in metallurgy, materials processing, and waste treatment. This opens up potential markets in manufacturing, recycling, and environmental remediation industries.

However, it is important to note that the market adoption of thermite as an alternative energy source faces several challenges. Safety concerns related to the handling and storage of reactive materials, as well as the need for specialized equipment and expertise, may limit its widespread use in consumer applications. Additionally, the current regulatory framework for energy production and storage may need to be adapted to accommodate this novel technology.

Despite these challenges, the potential market for thermite-based energy solutions is significant. As research and development in this field progress, new applications and market opportunities are likely to emerge. The growing emphasis on energy diversification and the search for innovative solutions to meet global energy demands create a favorable environment for the exploration and development of thermite as an alternative energy source.

Technical Challenges

The development of thermite as an alternative energy source faces several significant technical challenges that need to be addressed before widespread adoption can be considered. One of the primary obstacles is the control and containment of the thermite reaction. The exothermic nature of the reaction produces extremely high temperatures, often exceeding 2500°C, which poses safety risks and material constraints for any potential energy generation system.

Another major challenge lies in the efficient conversion of the thermal energy produced by thermite reactions into usable forms of energy, such as electricity. Current technologies for thermal-to-electric conversion, such as thermoelectric generators or steam turbines, may not be optimized for the rapid, high-temperature reactions characteristic of thermite. This inefficiency could significantly reduce the overall energy yield and economic viability of thermite-based energy systems.

The storage and handling of thermite materials present additional technical hurdles. Thermite mixtures are typically composed of metal powders and metal oxides, which can be sensitive to environmental conditions and may degrade over time. Developing stable, long-term storage solutions that maintain the reactivity of the thermite while ensuring safety is crucial for practical applications.

Scaling up thermite reactions for industrial-scale energy production introduces further complexities. The rapid nature of the reaction makes it challenging to design systems that can sustain continuous energy output. Intermittent energy generation may require sophisticated energy storage solutions to provide a stable power supply, adding to the overall system complexity and cost.

Environmental concerns also present technical challenges. While thermite reactions primarily produce metal oxides as byproducts, which are generally considered less harmful than carbon emissions, the large-scale production and disposal of these byproducts need careful consideration. Developing efficient recycling processes for the reaction products and minimizing any potential environmental impact are essential for the sustainability of thermite-based energy systems.

The ignition and control mechanisms for thermite reactions in an energy production context require significant refinement. Current ignition methods may not be suitable for repeated, controlled reactions in an energy generation setting. Developing precise, reliable, and safe ignition systems that can be integrated into a larger energy production framework is a critical technical challenge.

Lastly, the material science aspects of thermite energy systems pose substantial challenges. The extreme temperatures and rapid reaction rates place severe stress on containment materials and energy conversion components. Developing new materials or improving existing ones to withstand these conditions while maintaining efficiency and longevity is crucial for the feasibility of thermite-based energy technologies.

Another major challenge lies in the efficient conversion of the thermal energy produced by thermite reactions into usable forms of energy, such as electricity. Current technologies for thermal-to-electric conversion, such as thermoelectric generators or steam turbines, may not be optimized for the rapid, high-temperature reactions characteristic of thermite. This inefficiency could significantly reduce the overall energy yield and economic viability of thermite-based energy systems.

The storage and handling of thermite materials present additional technical hurdles. Thermite mixtures are typically composed of metal powders and metal oxides, which can be sensitive to environmental conditions and may degrade over time. Developing stable, long-term storage solutions that maintain the reactivity of the thermite while ensuring safety is crucial for practical applications.

Scaling up thermite reactions for industrial-scale energy production introduces further complexities. The rapid nature of the reaction makes it challenging to design systems that can sustain continuous energy output. Intermittent energy generation may require sophisticated energy storage solutions to provide a stable power supply, adding to the overall system complexity and cost.

Environmental concerns also present technical challenges. While thermite reactions primarily produce metal oxides as byproducts, which are generally considered less harmful than carbon emissions, the large-scale production and disposal of these byproducts need careful consideration. Developing efficient recycling processes for the reaction products and minimizing any potential environmental impact are essential for the sustainability of thermite-based energy systems.

The ignition and control mechanisms for thermite reactions in an energy production context require significant refinement. Current ignition methods may not be suitable for repeated, controlled reactions in an energy generation setting. Developing precise, reliable, and safe ignition systems that can be integrated into a larger energy production framework is a critical technical challenge.

Lastly, the material science aspects of thermite energy systems pose substantial challenges. The extreme temperatures and rapid reaction rates place severe stress on containment materials and energy conversion components. Developing new materials or improving existing ones to withstand these conditions while maintaining efficiency and longevity is crucial for the feasibility of thermite-based energy technologies.

Current Thermite Apps

01 Thermite composition and applications

Thermite is a pyrotechnic composition of metal powder fuel and metal oxide. It is used in various applications including welding, incendiary devices, and metal purification. The reaction produces intense heat and molten metal, making it suitable for specialized industrial and military uses.- Thermite composition and applications: Thermite is a pyrotechnic composition of metal powder fuel and metal oxide. It is used in various applications including welding, incendiary devices, and metal purification. The reaction produces intense heat and molten metal, making it suitable for specialized industrial and military uses.

- Thermite-based cutting and welding tools: Thermite reactions are utilized in cutting and welding tools for various applications, including underwater operations and pipeline maintenance. These tools leverage the high-temperature reaction of thermite to cut or join metal components efficiently, even in challenging environments.

- Enhanced thermite formulations: Research focuses on improving thermite formulations by incorporating additives or modifying particle sizes to enhance reactivity, control burn rates, or achieve specific performance characteristics. These advancements aim to optimize thermite for various applications and increase its efficiency.

- Thermite in oil and gas industry: Thermite reactions are employed in the oil and gas industry for various purposes, including well perforation, sealing, and abandonment operations. The controlled use of thermite allows for efficient and effective interventions in wellbores and pipelines.

- Safety and control mechanisms for thermite reactions: Given the intense nature of thermite reactions, safety measures and control mechanisms are crucial. This includes developing ignition systems, containment methods, and reaction moderation techniques to ensure safe and controlled use of thermite in various applications.

02 Thermite-based cutting and welding tools

Thermite reactions are utilized in cutting and welding tools for various applications, including underwater operations and emergency rescue situations. These tools can quickly cut through metal structures using the high-temperature reaction of thermite mixtures.Expand Specific Solutions03 Enhanced thermite formulations

Research focuses on improving thermite formulations by incorporating additives or modifying particle sizes to enhance reactivity, control burn rates, or improve specific properties. These advancements aim to optimize performance for various applications while maintaining safety.Expand Specific Solutions04 Thermite in oil and gas well operations

Thermite reactions are employed in oil and gas well operations for tasks such as perforating casings, initiating fractures, or sealing wells. The controlled use of thermite in these applications allows for efficient and targeted operations in challenging downhole environments.Expand Specific Solutions05 Safety and control mechanisms for thermite reactions

Given the intense nature of thermite reactions, safety and control mechanisms are crucial. This includes methods for initiating reactions remotely, containing the reaction products, and ensuring safe handling and storage of thermite materials. Innovations in this area focus on improving reliability and minimizing risks associated with thermite use.Expand Specific Solutions

Key Industry Players

The exploration of thermite as an alternative energy source is in its early stages, with the market still emerging and relatively small. The technology's maturity varies across different applications, ranging from experimental to early commercial stages. Companies like Rondo Energy, Inc. and Magaldi Power SpA are pioneering thermal energy storage solutions utilizing thermite-like reactions. Research institutions such as Nanjing University of Science & Technology and Xi'an Jiaotong University are advancing the fundamental understanding of thermite reactions. The Naval Research Laboratory and Massachusetts Institute of Technology are exploring novel applications in energy generation and storage. While promising, challenges in scalability, safety, and efficiency need to be addressed before widespread adoption can occur.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has been exploring thermite as an alternative energy source, focusing on its potential for underwater welding and cutting applications. Their research involves developing specialized thermite compositions that can react underwater, producing high temperatures for metal joining and separation. The lab has also investigated the use of thermite reactions for generating hydrogen gas, which could be used as a clean fuel source. Their approach includes optimizing particle sizes and additives to enhance reaction efficiency and control.

Strengths: Expertise in specialized thermite compositions for underwater use; potential for clean hydrogen production. Weaknesses: Limited to specific military applications; challenges in scaling up for broader energy production.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have been investigating thermite reactions for energy storage and release. Their approach involves developing nanostructured thermite materials that can store and release energy more efficiently than traditional thermite compositions. By manipulating the size and arrangement of reactant particles at the nanoscale, they aim to create thermite-based materials with controlled energy release rates and improved safety profiles. MIT's research also explores the potential of thermite reactions for space propulsion systems, where the high energy density of thermite could provide significant advantages for spacecraft thrusters.

Strengths: Cutting-edge research in nanostructured thermite materials; potential applications in energy storage and space propulsion. Weaknesses: Early-stage research with uncertain commercial viability; safety concerns associated with highly reactive materials.

Thermite Patents Review

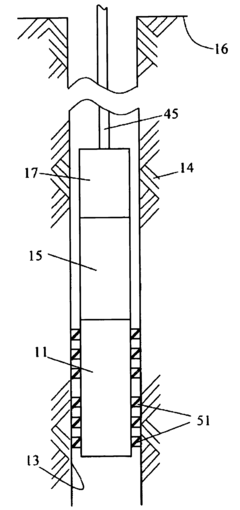

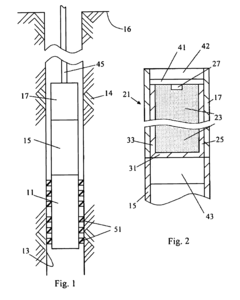

Non-explosive power source for actuating a subsurface tool

PatentActiveUS8196515B2

Innovation

- A non-explosive power source using thermite and a polymer that produces gas upon reaction, providing continuous pressure over an extended period to actuate subsurface tools without the hazards and regulatory burdens of explosive devices, and controlling heat transfer to prevent tool degradation.

Metal/metal oxide fueled engine

PatentUndeterminedNZ546023A

Innovation

- A method involving the ignition of a thermite mixture in a chamber, where water or steam is introduced to control the reaction temperature, produce hydrogen, and sustain the thermite reaction, allowing the conversion of heat and pressure into mechanical energy through the use of a heat engine.

Safety Regulations

The development of thermite as an alternative energy source necessitates stringent safety regulations to mitigate potential risks associated with its highly exothermic nature. Current safety standards for handling and storing thermite mixtures must be significantly enhanced to accommodate its use as a large-scale energy source. Regulatory bodies will need to establish comprehensive guidelines covering the entire lifecycle of thermite-based energy systems, from production and transportation to operational use and disposal.

Key areas of focus for safety regulations include thermal management, reaction control, and containment measures. Given the intense heat generated by thermite reactions, regulations must mandate advanced cooling systems and heat-resistant materials in all thermite-based energy facilities. Strict protocols for initiating and terminating reactions will be crucial to prevent uncontrolled ignitions or prolonged burning.

Environmental safety will be a primary concern, requiring regulations to address potential impacts on air quality, soil contamination, and water resources. Emission control standards must be developed to manage the release of reaction byproducts, particularly metal oxides and other particulates. Waste management regulations will need to outline proper disposal methods for spent thermite materials and reaction residues.

Worker safety in thermite energy facilities will demand specialized training programs and personal protective equipment. Regulations should specify minimum qualifications for personnel involved in handling thermite materials and operating related equipment. Emergency response plans and evacuation procedures must be standardized across the industry to address potential accidents or malfunctions.

Transportation of thermite materials will require new regulations to ensure safe handling during transit. This may include specifications for specialized containers, vehicle modifications, and route restrictions to minimize risks associated with accidents or unauthorized access.

Regulatory frameworks must also address the security aspects of thermite-based energy systems. Given the potential dual-use nature of thermite, strict controls on production, distribution, and access to thermite materials will be necessary to prevent misuse or diversion for non-energy purposes.

As the technology evolves, safety regulations will need to adapt continuously. This will require ongoing collaboration between industry stakeholders, research institutions, and regulatory bodies to identify emerging risks and develop appropriate mitigation strategies. Regular safety audits and compliance checks should be mandated to ensure adherence to established regulations and to identify areas for improvement in safety protocols.

Key areas of focus for safety regulations include thermal management, reaction control, and containment measures. Given the intense heat generated by thermite reactions, regulations must mandate advanced cooling systems and heat-resistant materials in all thermite-based energy facilities. Strict protocols for initiating and terminating reactions will be crucial to prevent uncontrolled ignitions or prolonged burning.

Environmental safety will be a primary concern, requiring regulations to address potential impacts on air quality, soil contamination, and water resources. Emission control standards must be developed to manage the release of reaction byproducts, particularly metal oxides and other particulates. Waste management regulations will need to outline proper disposal methods for spent thermite materials and reaction residues.

Worker safety in thermite energy facilities will demand specialized training programs and personal protective equipment. Regulations should specify minimum qualifications for personnel involved in handling thermite materials and operating related equipment. Emergency response plans and evacuation procedures must be standardized across the industry to address potential accidents or malfunctions.

Transportation of thermite materials will require new regulations to ensure safe handling during transit. This may include specifications for specialized containers, vehicle modifications, and route restrictions to minimize risks associated with accidents or unauthorized access.

Regulatory frameworks must also address the security aspects of thermite-based energy systems. Given the potential dual-use nature of thermite, strict controls on production, distribution, and access to thermite materials will be necessary to prevent misuse or diversion for non-energy purposes.

As the technology evolves, safety regulations will need to adapt continuously. This will require ongoing collaboration between industry stakeholders, research institutions, and regulatory bodies to identify emerging risks and develop appropriate mitigation strategies. Regular safety audits and compliance checks should be mandated to ensure adherence to established regulations and to identify areas for improvement in safety protocols.

Environmental Impact

The environmental impact of thermite as an alternative energy source is a critical consideration in assessing its future possibilities. Thermite reactions, while highly exothermic and capable of producing significant energy, present several environmental challenges that must be carefully evaluated.

One of the primary environmental concerns associated with thermite reactions is the production of metal oxide byproducts. These reactions typically involve the oxidation of aluminum, resulting in the formation of aluminum oxide (Al2O3). While aluminum oxide itself is generally considered inert and non-toxic, the large-scale production and disposal of this byproduct could potentially lead to environmental issues if not managed properly.

The high temperatures generated during thermite reactions also pose potential environmental risks. These extreme temperatures can cause localized thermal pollution, potentially affecting surrounding ecosystems and altering soil composition. Additionally, the intense heat may lead to the release of volatile organic compounds (VOCs) and other harmful emissions, contributing to air pollution and potentially impacting local air quality.

Another environmental consideration is the sourcing of raw materials for thermite reactions. The production of aluminum, a key component in thermite, is energy-intensive and often associated with significant environmental impacts, including greenhouse gas emissions and habitat disruption from mining activities. Sustainable sourcing and production methods would need to be developed to mitigate these upstream environmental effects.

Water consumption and potential contamination are also important factors to consider. While thermite reactions themselves do not require water, cooling systems and waste management processes associated with large-scale energy production could potentially impact local water resources. Proper water management strategies would be essential to minimize environmental impact and ensure sustainable operation.

The potential for accidental releases or uncontrolled reactions presents another environmental risk. Thermite is highly reactive and can ignite spontaneously under certain conditions. Stringent safety measures and containment protocols would be necessary to prevent environmental contamination and ecological damage in the event of accidents or spills.

On a positive note, thermite reactions produce minimal greenhouse gas emissions compared to traditional fossil fuel combustion. This aspect could potentially contribute to reducing overall carbon footprint if thermite-based energy systems were to replace more carbon-intensive energy sources. However, a comprehensive life cycle assessment would be required to fully quantify the net environmental impact of thermite as an alternative energy source.

One of the primary environmental concerns associated with thermite reactions is the production of metal oxide byproducts. These reactions typically involve the oxidation of aluminum, resulting in the formation of aluminum oxide (Al2O3). While aluminum oxide itself is generally considered inert and non-toxic, the large-scale production and disposal of this byproduct could potentially lead to environmental issues if not managed properly.

The high temperatures generated during thermite reactions also pose potential environmental risks. These extreme temperatures can cause localized thermal pollution, potentially affecting surrounding ecosystems and altering soil composition. Additionally, the intense heat may lead to the release of volatile organic compounds (VOCs) and other harmful emissions, contributing to air pollution and potentially impacting local air quality.

Another environmental consideration is the sourcing of raw materials for thermite reactions. The production of aluminum, a key component in thermite, is energy-intensive and often associated with significant environmental impacts, including greenhouse gas emissions and habitat disruption from mining activities. Sustainable sourcing and production methods would need to be developed to mitigate these upstream environmental effects.

Water consumption and potential contamination are also important factors to consider. While thermite reactions themselves do not require water, cooling systems and waste management processes associated with large-scale energy production could potentially impact local water resources. Proper water management strategies would be essential to minimize environmental impact and ensure sustainable operation.

The potential for accidental releases or uncontrolled reactions presents another environmental risk. Thermite is highly reactive and can ignite spontaneously under certain conditions. Stringent safety measures and containment protocols would be necessary to prevent environmental contamination and ecological damage in the event of accidents or spills.

On a positive note, thermite reactions produce minimal greenhouse gas emissions compared to traditional fossil fuel combustion. This aspect could potentially contribute to reducing overall carbon footprint if thermite-based energy systems were to replace more carbon-intensive energy sources. However, a comprehensive life cycle assessment would be required to fully quantify the net environmental impact of thermite as an alternative energy source.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!